Rain test system for aviation aircraft testing

A technology for rain test and aviation aircraft, which is used in aircraft component testing, machine/structural component testing, and liquid/vacuum measurement for liquid tightness. In order to achieve the effect of convenient handling and transportation, accurate coverage, and reduced area due to problems such as fixed value or small adjustment range, which cannot be fully applied to the rain test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

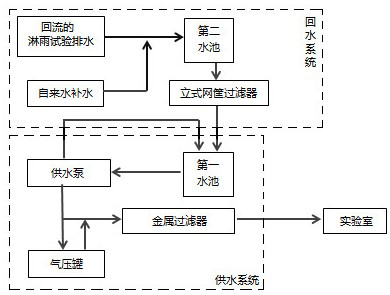

[0078] Such as figure 1 and 2 Shown is a rain test system for aircraft testing, including: a water supply system, a water distribution system, a sprinkler system, a rain collection system, and a water return system;

[0079] The water supply system includes the first pool for storing water in the rain test, the water supply pump and pressure tank for water supply, and the metal filter for filtering the water in the rain test; The water supply pump is combined with the small flow pressure tank for water supply; the filtration accuracy of the metal filter is 100 mesh / square inch;

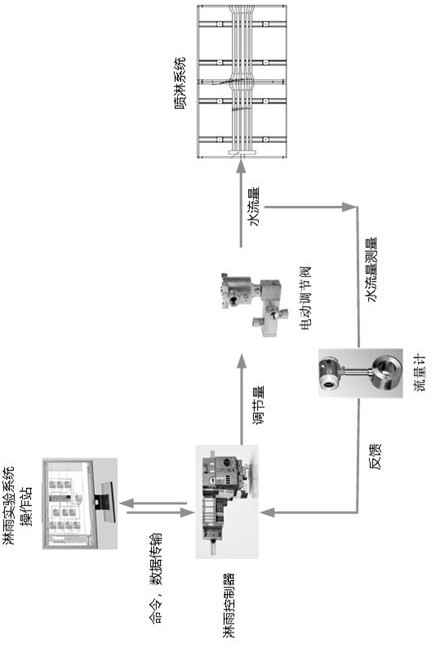

[0080] The water distribution system includes a first water divider for primary water division of the rain test water in the first pool, and multiple sets of second water dividers for secondary water division of each branch of the first water divider. The water outlet of each first water separator is equipped with an electric regulating valve for adjusting the water supply flow of the second water s...

Embodiment 2

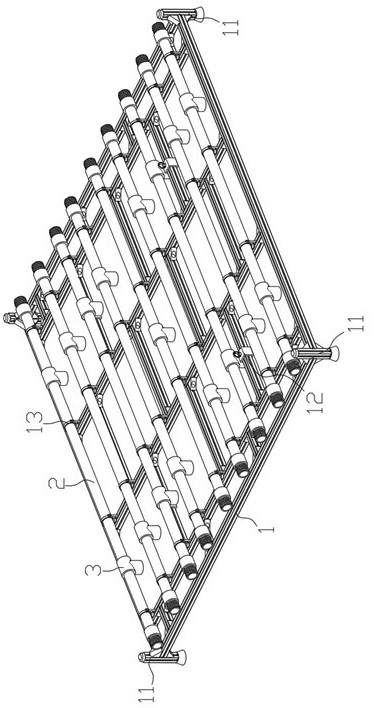

[0087] This embodiment is basically the same as Embodiment 1, the difference is that, as Figure 5-8 As shown, the spray rack of the spray system adopts the folding spray rack 4, the water supply pipeline adopts the second water supply pipe 5 and the third water supply pipe 6, and the nozzle adopts the rotating nozzle 7;

[0088] Such as Figure 5-8 As shown, the foldable shower frame 4 includes a first frame body 41 for carrying four sets of second water supply pipes 5, and a second frame body 42 for carrying four groups of third water supply pipes 6. The first frame body 41 1. The second frame body 42 is an aluminum alloy frame composed of aluminum alloy rods arranged horizontally and vertically. Each aluminum alloy rod at the junction of the first frame body 41 and the second frame body 42 is provided with a bar magnet 44 for docking and positioning by means of magnetic attraction; through the setting of the bar magnet 44, the first frame can be optimized The operation ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com