Preparation method of polyamide solvent-resistant nanofiltration membrane containing fluorinated organic nanoparticles

A nanoparticle and polyamide technology, applied in the field of membrane separation, can solve problems such as unstable membrane structure and affecting membrane separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

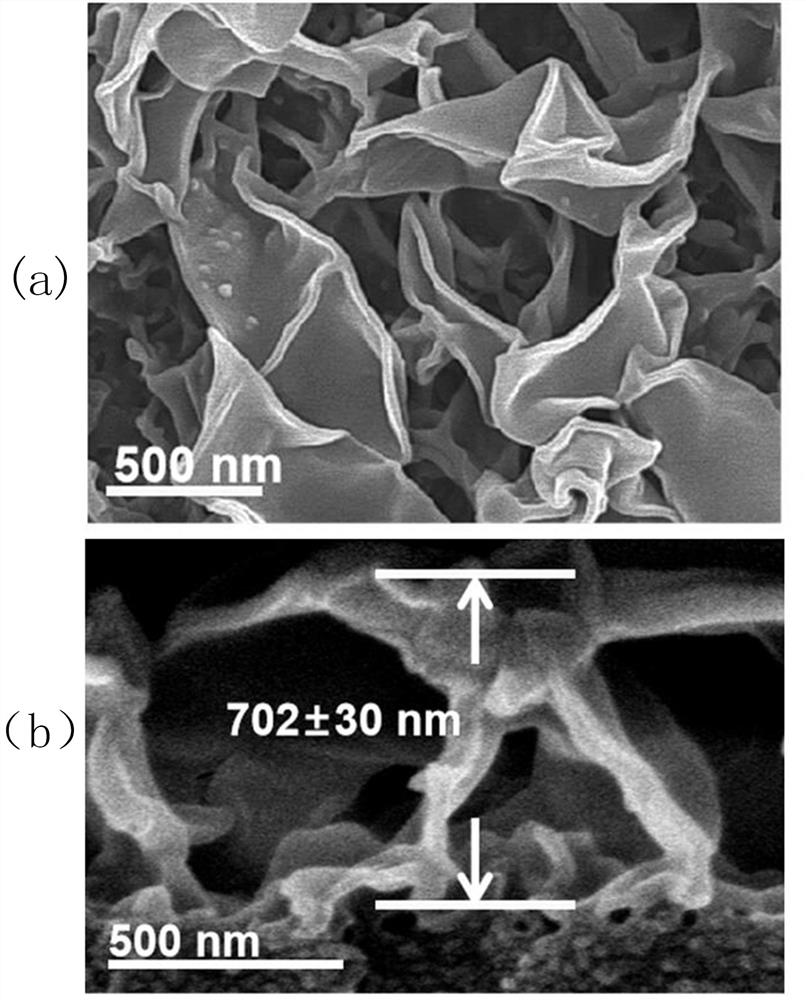

Image

Examples

preparation example Construction

[0016] A preparation method for a polyamide solvent-resistant nanofiltration membrane containing fluorinated organic nanoparticles, comprising the following steps:

[0017] 1) Dissolving 0.2 to 5 parts by mass of polyamine monomer molecules and 0.01 to 0.2 parts by mass of dopamine biomimetic adhesive in 100 parts by mass of an aqueous solution, and then dissolving 30 to 50 parts by mass of fluoroalkylthiol-containing compounds Add the ethanol solution of the above-mentioned aqueous solution into the above-mentioned aqueous solution, feed oxygen, and react at 15-35° C. for 1-6 hours to obtain an aqueous phase solution containing fluorinated organic nanoparticles;

[0018] 2) Immerse the porous support membrane in the above-mentioned aqueous phase solution containing fluorinated organic nanoparticles for 1 to 30 minutes, take out and remove the excess aqueous phase solution on the surface of the membrane; then immerse it into the organic phase containing polyacyl chloride monome...

Embodiment 1

[0021] Get 0.2g m-phenylenediamine and 0.01g dopamine and dissolve in 100g aqueous solution, then add 30g containing 0.01% 1H,1H,2H,2H-perfluorodecanethiol ethanol solution (concentration of ethanol mass percentage is 90%), pass Inject oxygen, polymerize at 15°C for 6 hours to obtain an aqueous phase solution containing fluorinated organic nanoparticles, immerse the polyethersulfone ultrafiltration membrane in the above aqueous phase solution for 1 minute, take out and remove the excess aqueous phase solution on the surface; Then immerse in the n-hexane solution of trimesoyl chloride with a concentration of 0.05%, carry out the interfacial polymerization reaction for 0.5 minutes, take out and remove the residual organic phase solution on the surface of the film; heat treat at 30°C for 30 minutes, and obtain the polymer containing fluorinated organic nanoparticles. Amide solvent resistant nanofiltration membrane.

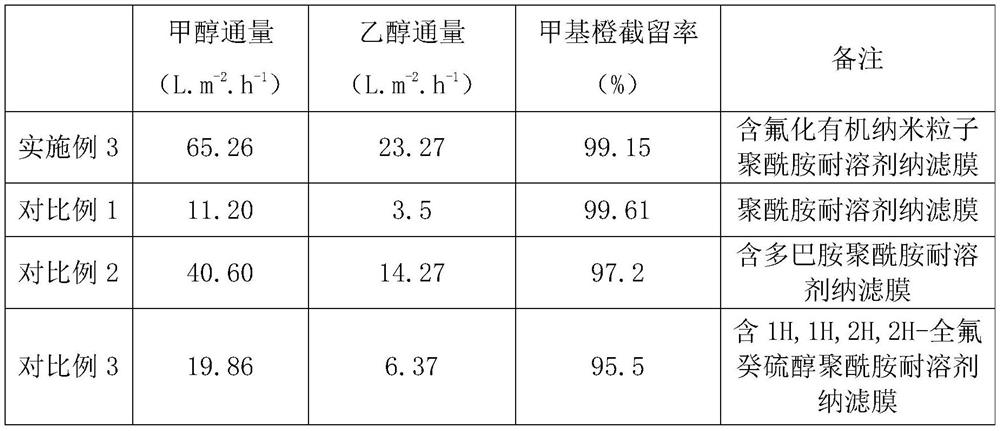

[0022]Fluorinated organic nanoparticles polyamide solvent-resis...

Embodiment 2

[0024] Get 5g m-phenylenediamine and 0.2g dopamine and dissolve in 100g aqueous solution, then add 50g containing 0.1% 1H, 1H, 2H, 2H-perfluorodecanethiol ethanol solution (the ethanol mass percentage concentration is 98%), pass into Oxygen, polymerized at 35°C for 1 hour to obtain a water phase solution containing fluorinated organic nanoparticles, soaking the polyethersulfone ultrafiltration membrane in the above water phase solution for 10 minutes, taking out and removing the excess water phase solution on the surface; then Immerse in a 0.5% trimesoyl chloride n-hexane solution, interfacially polymerize for 5 minutes, take out and remove the residual organic phase solution on the surface of the membrane; heat treat at 80°C for 5 minutes to obtain polyamide containing fluorinated organic nanoparticles Solvent resistant nanofiltration membrane.

[0025] Fluorinated organic nanoparticles polyamide solvent-resistant nanofiltration membrane at 25 ℃, 1.5MPa pressure, for differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com