Patents

Literature

65results about How to "Less prone to wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

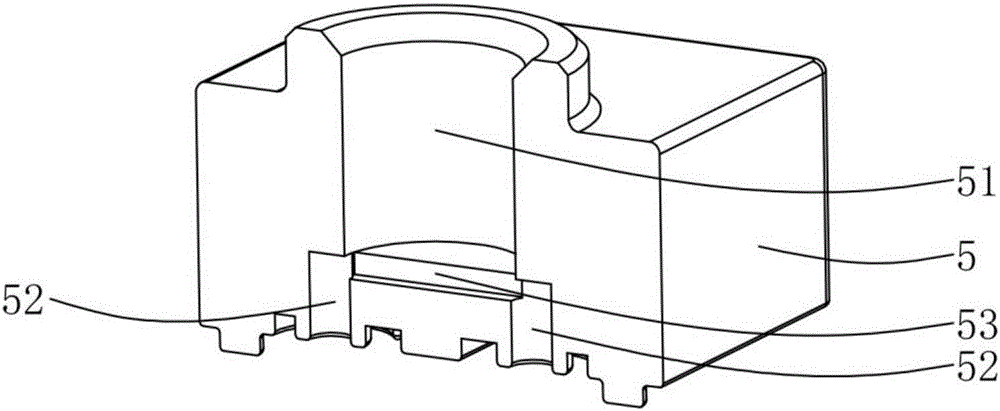

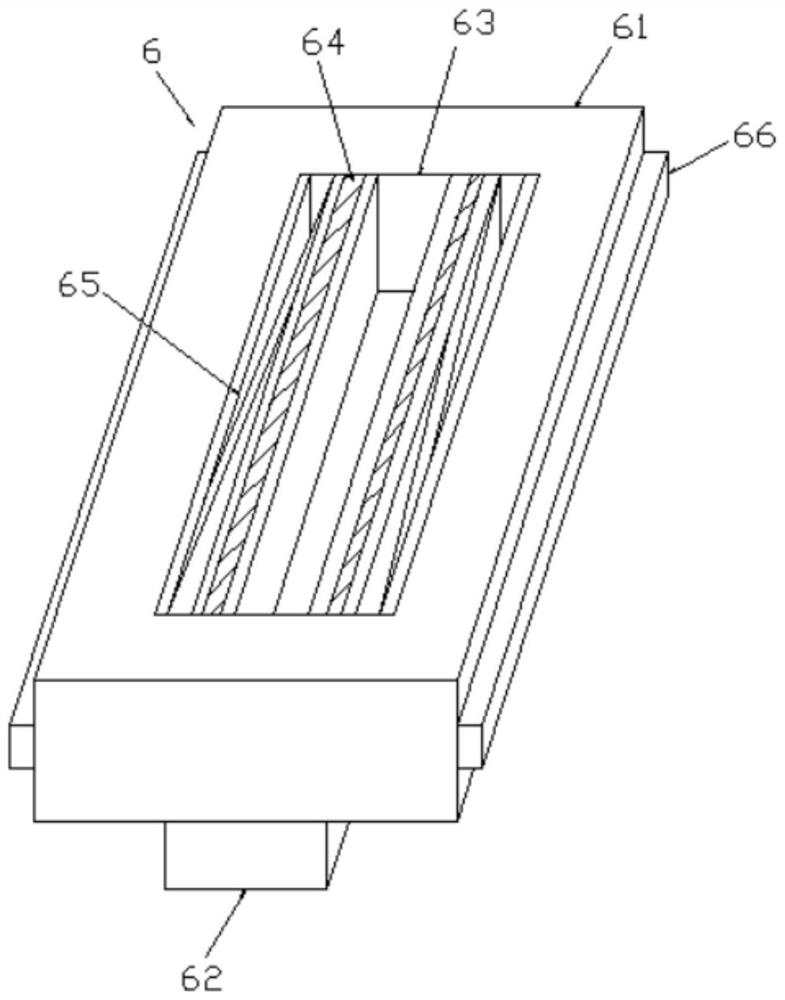

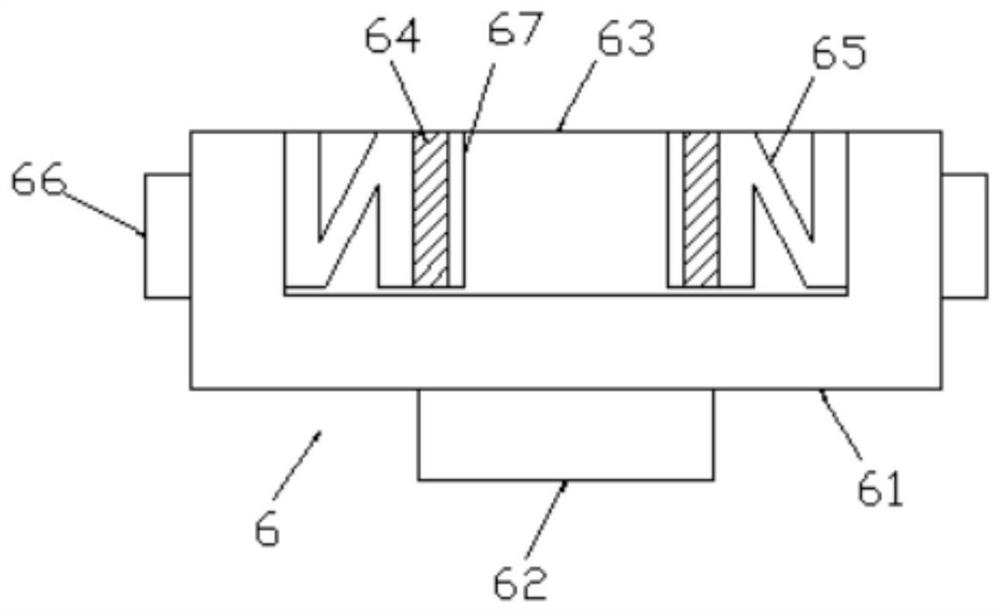

Magnetic refrigerating portable refrigerator and refrigeration method

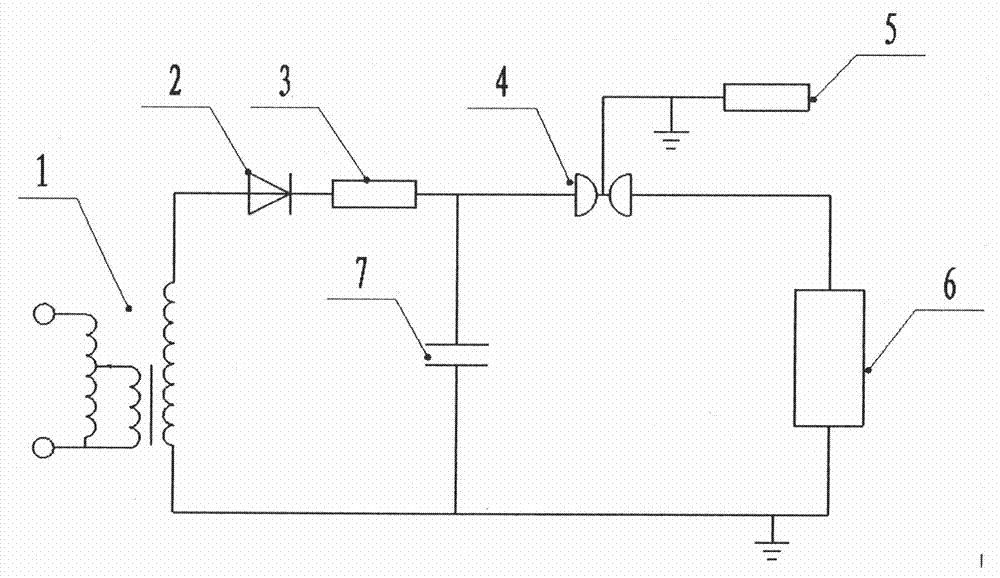

InactiveCN103062973ATo achieve the purpose of coolingSimple and fast operationEnergy efficient heating/coolingDomestic refrigeratorsWaste processingFilling materials

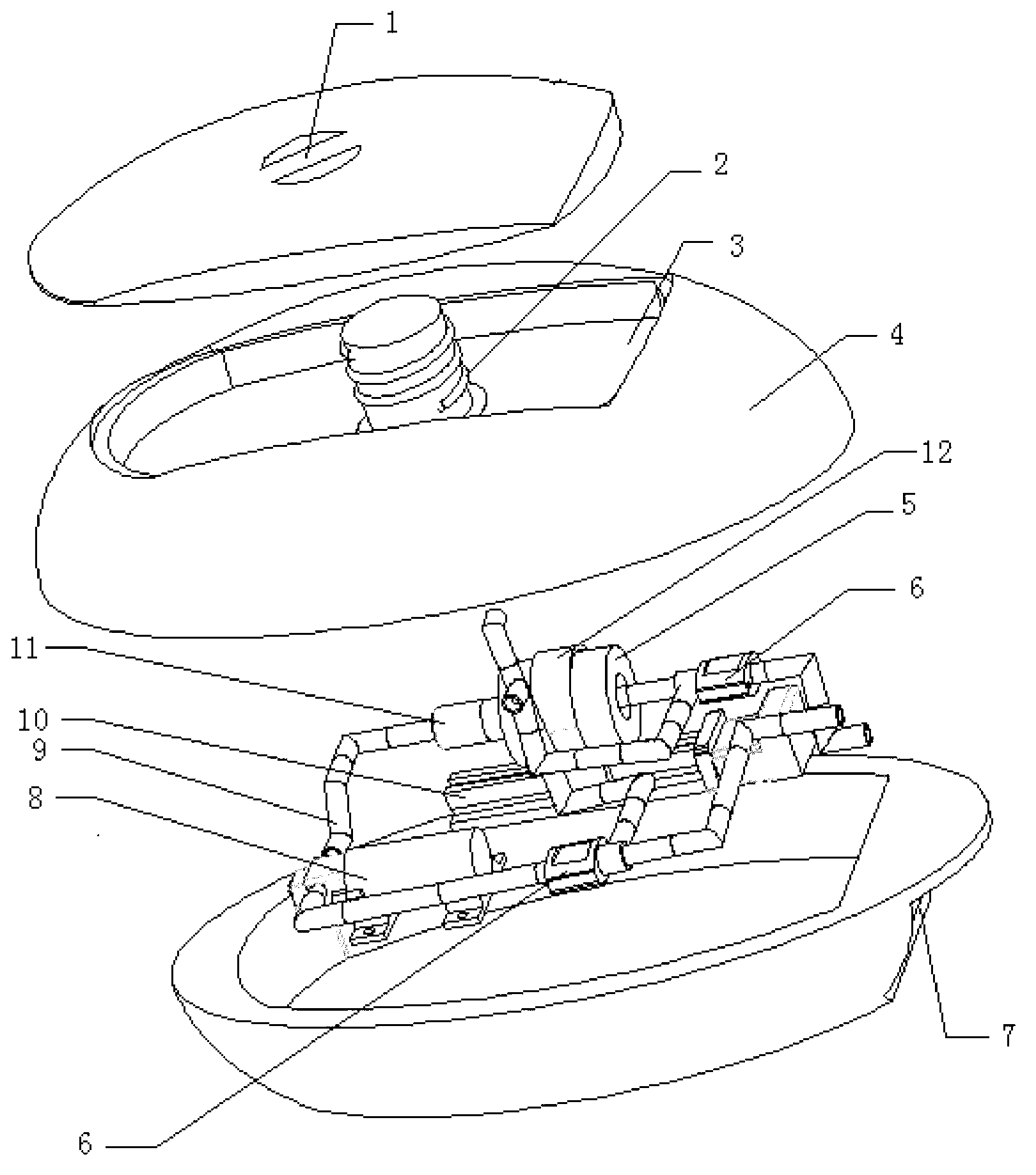

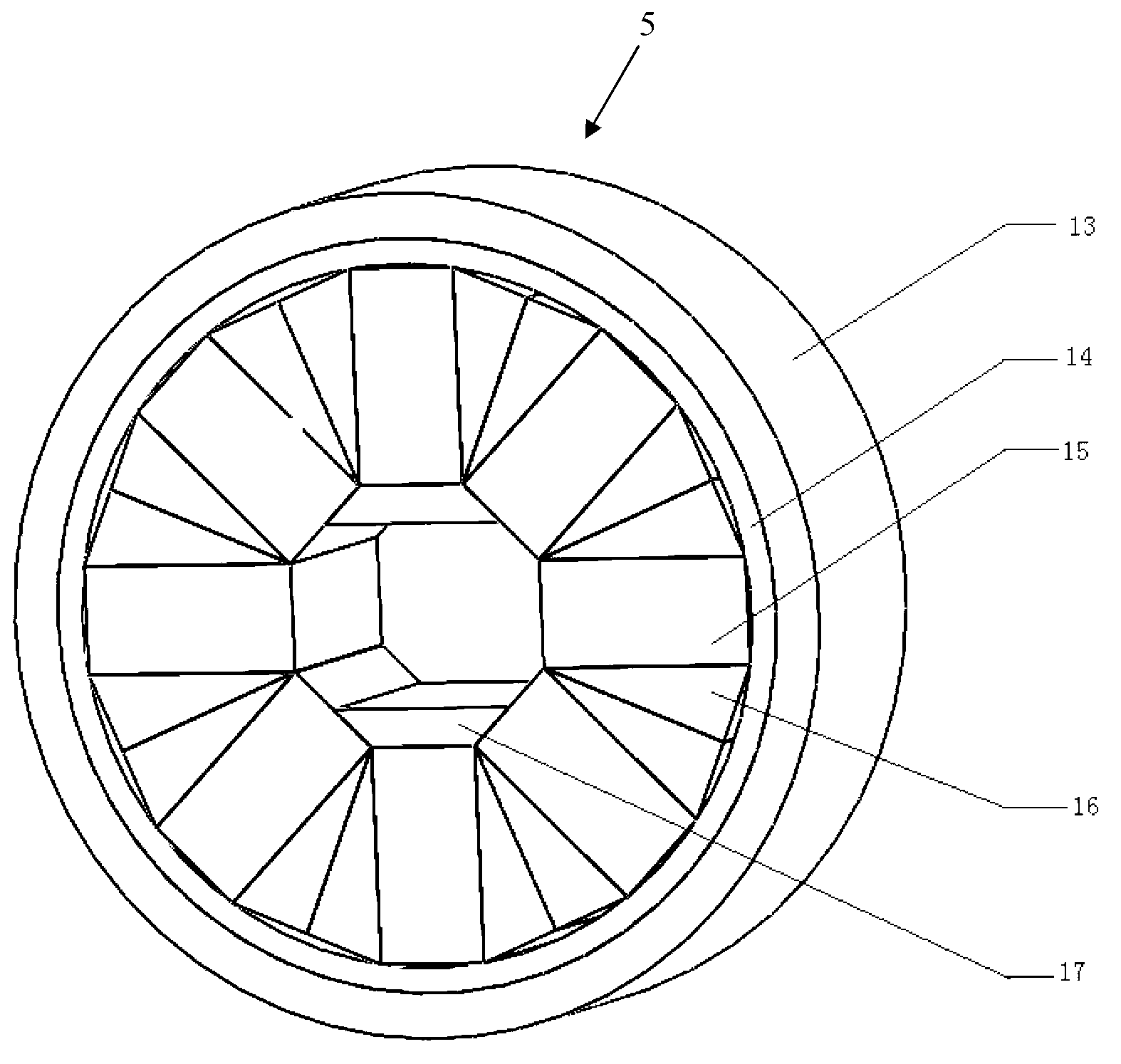

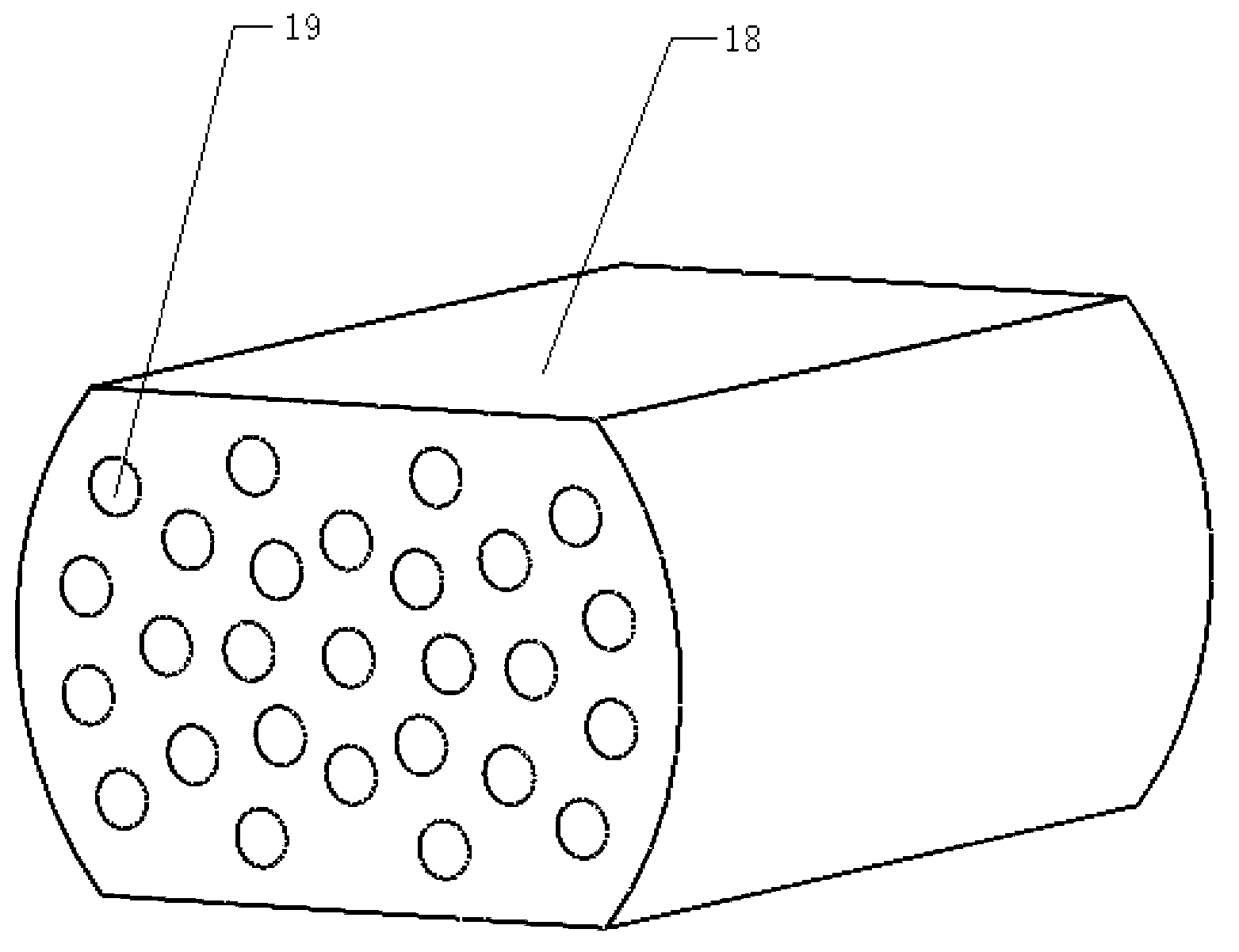

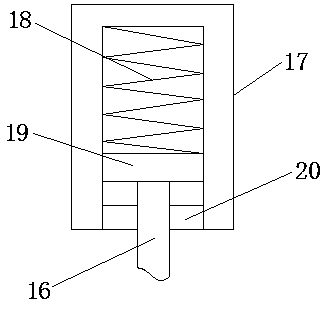

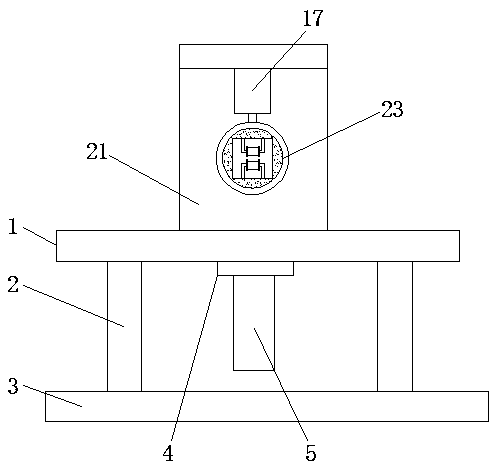

The invention discloses a magnetic refrigerating portable refrigerator and a refrigeration method. The magnetic refrigerating portable refrigerator belongs to the field of domestic electrical appliances and comprises a shell, a storage box arranged in the shell, a permanent magnet group, a magnetic working medium and the like, wherein the permanent magnet group is a tube-shaped body the centre of which is provided with a through hole; and the magnetic working medium is provided with multiple through holes and is closely sleeved in a magnetic working medium shell with a concave slideway. The function of the magnetic refrigeration portable refrigerator is realized by that the magnetic working medium is fixed, straight guide rails drive the permanent magnet to do a reciprocating straight motion relatively to the magnetic working medium, and the magnetic working medium realizes an excitation and demagnetizing process, so that the refrigeration of the refrigerator is realized; the relative movement method of the magnetic working medium and the permanent magnet is simple to operate, relatively stable in motion, and easy to control in the realizing manner; the structure of the magnetic working medium solves the problems that the filling materials is difficult to process and manufacture, and gaps among the filling materials are difficult to guarantee and the like; and a permanent magnet is simple in structure and convenient to process, so that the non-waste processing is realized, and the processing and manufacturing cost is greatly saved.

Owner:NORTHEASTERN UNIV

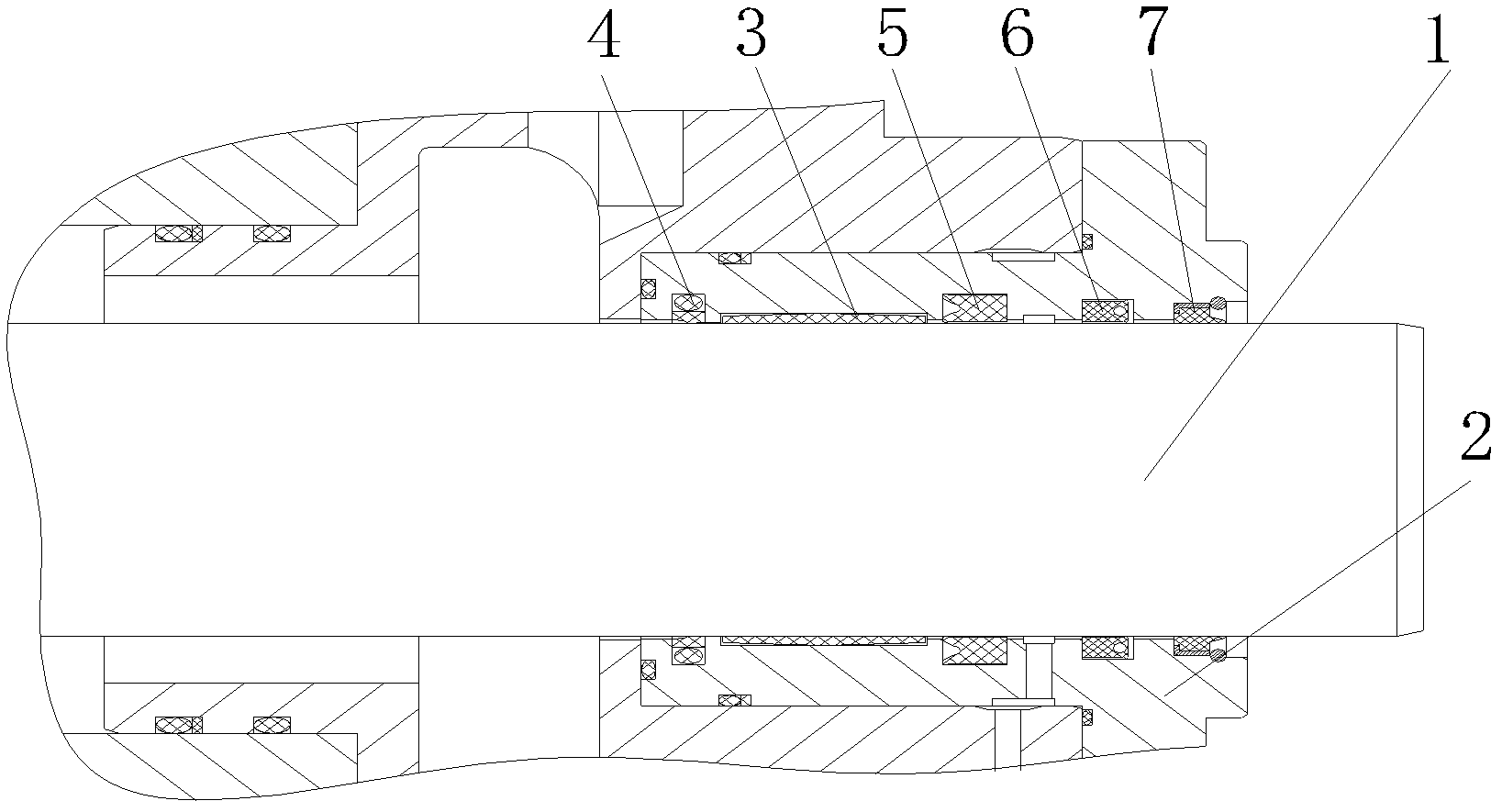

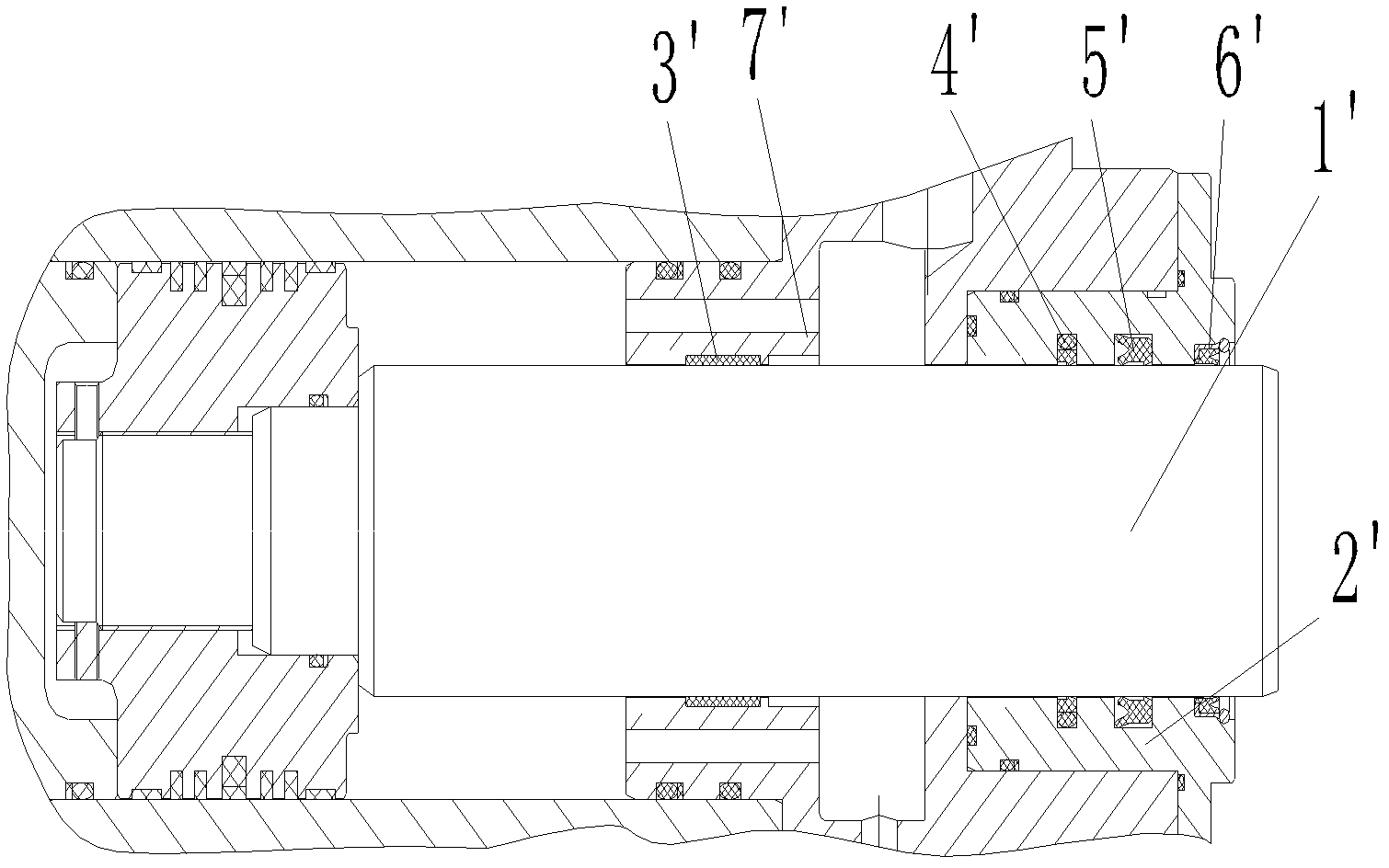

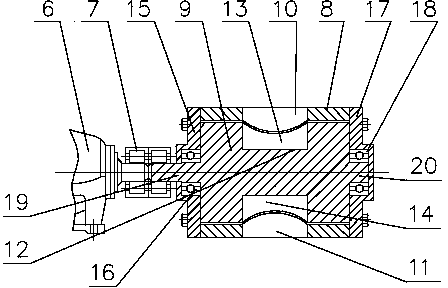

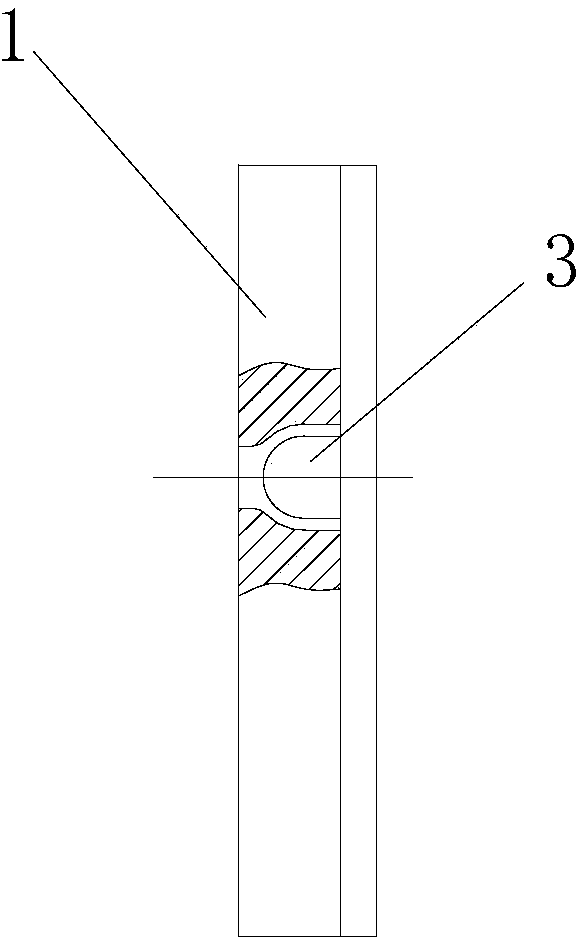

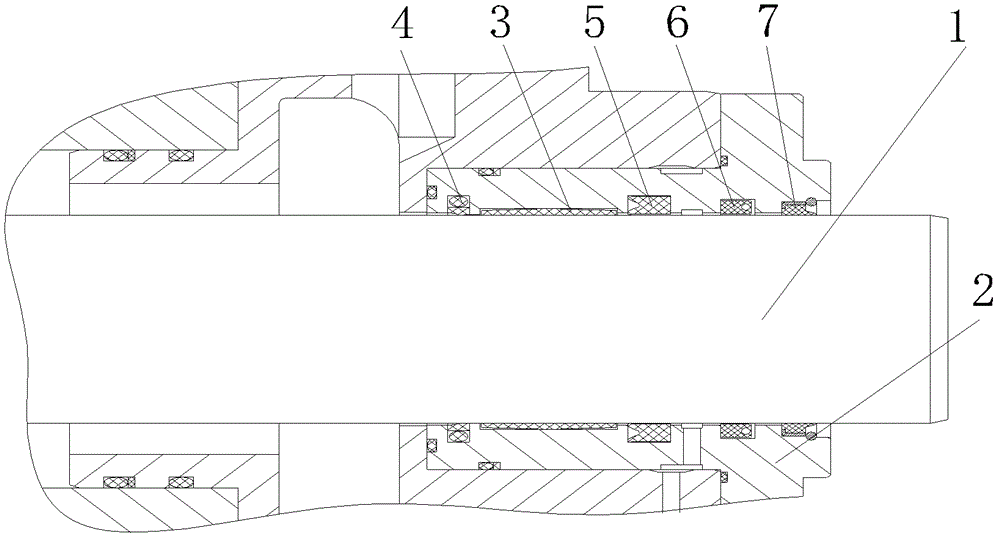

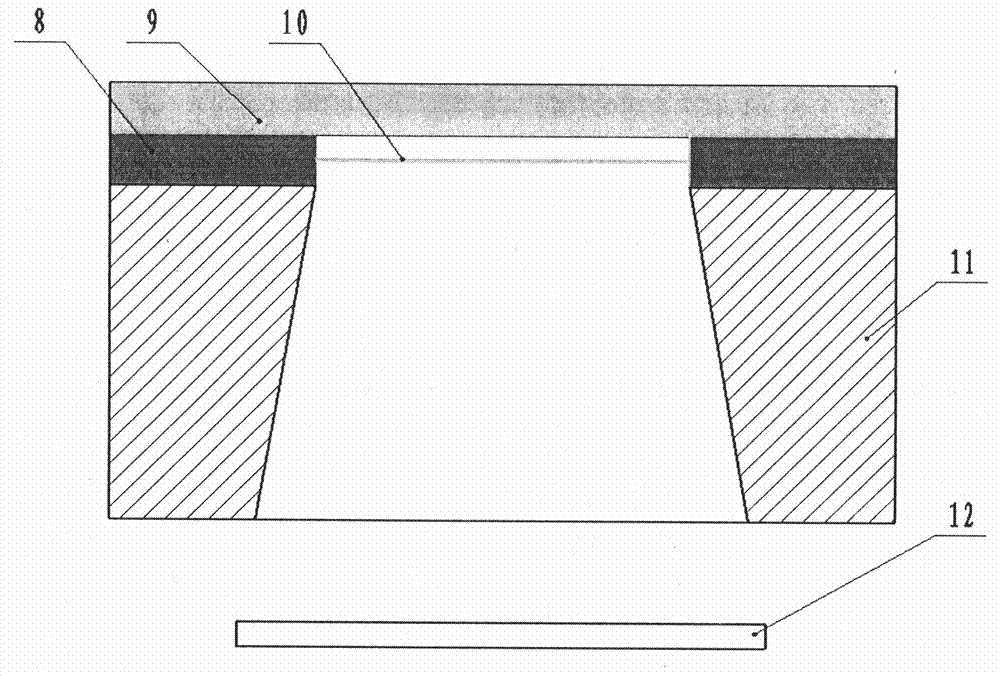

Hydraulic cylinder sealing structure

ActiveCN102434672AIncrease the effective support lengthEasy to install and replaceEngine sealsHydraulic cylinderEngineering

The invention provides a hydraulic cylinder sealing structure, which comprises a guide ring (3) and a guide part (2) disposed close to the end of a hydraulic cylinder. A groove (8) is formed on the inner wall of the guide part (2), the guide ring (3) is arranged in the groove (8), and the internal surface of the guide ring (3) is attached to a piston rod (1). The position of the guide ring is moved backwards from the middle of the hydraulic cylinder to the end of the hydraulic cylinder so that effective support length of the guide ring toward the piston rod is prolonged and the guide ring is led to be easier to demount, replace and install.

Owner:HUNAN TELI HYDRAULIC

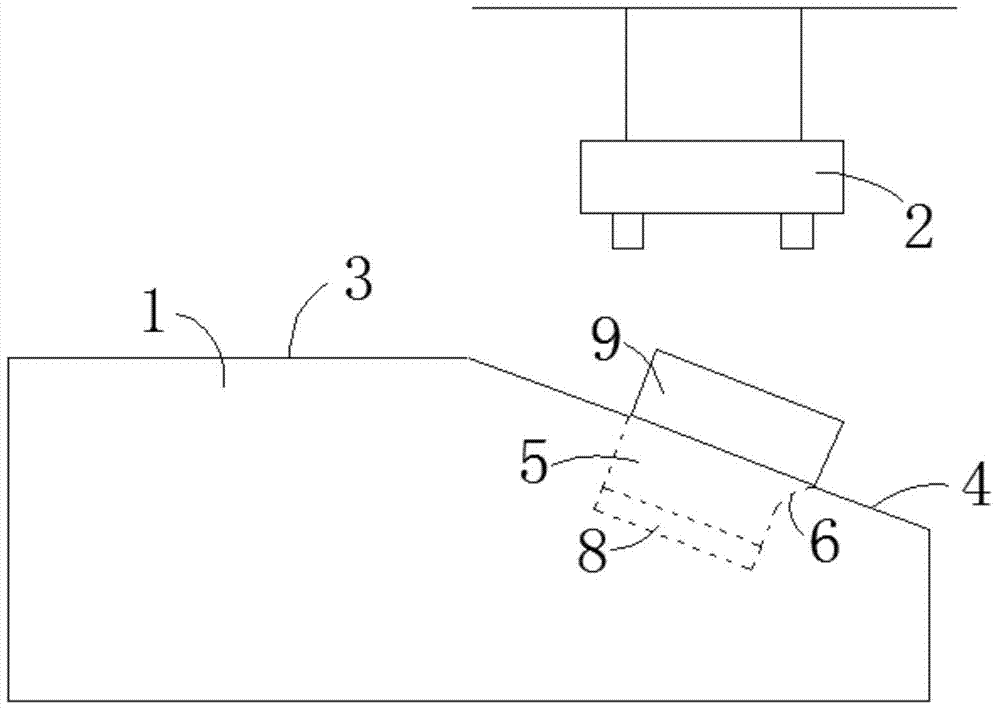

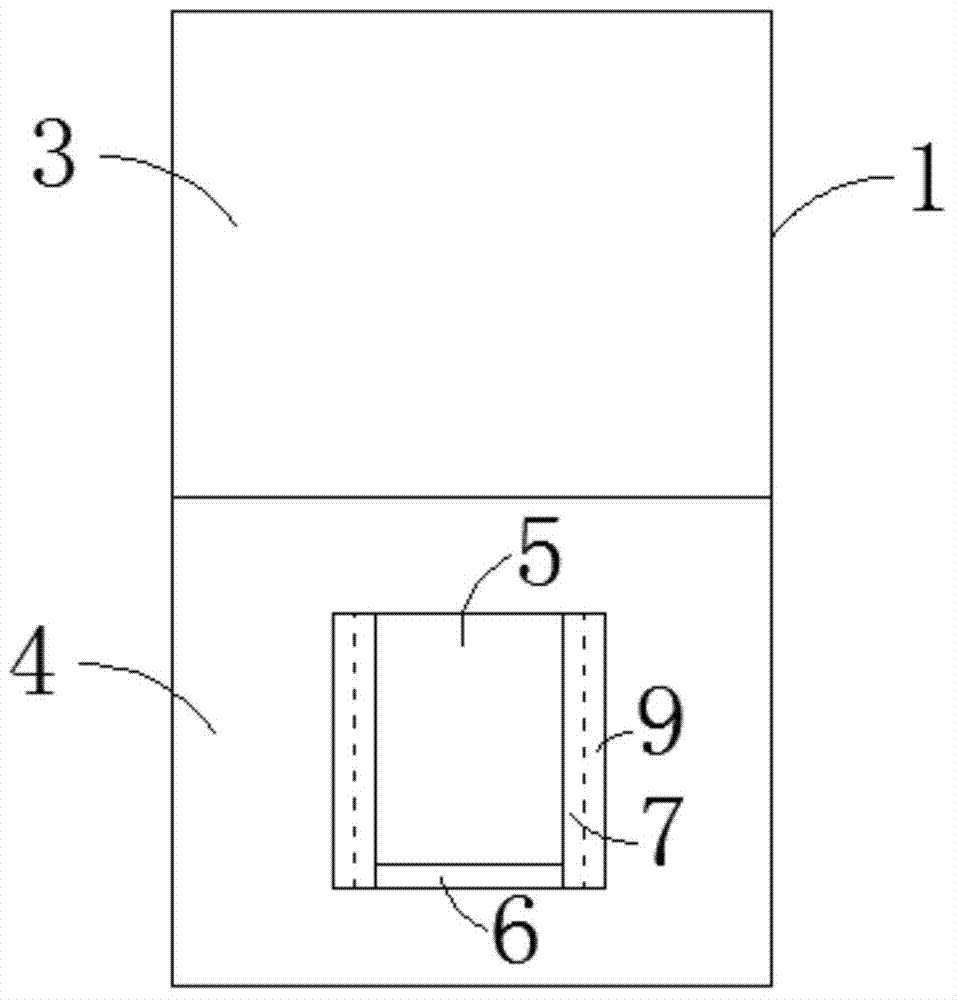

Bending device for automobile component

The invention relates to a bending device for an automobile component. The bending device comprises a base, a pressing device bending the component, and fixing blocks. The pressing device is arranged above the base. The base comprises a horizontal plane and a downwards-inclined plane. The downwards-inclined plane is arranged under the pressing device. The horizontal plane is arranged on one side of the downwards-inclined plane. The downwards-inclined plane is connected with the horizontal plane. A positioning groove is formed in the vertical coaxial line, opposite to the pressing device, of the lower inclined plane, a circular arc transition plane is arranged on the relatively low side of the positioning groove in the horizontal direction, and the two fixing blocks are fixedly arranged on the two sides of the positioning groove respectively and located on the two sides of the circular arc transition plane. Heating devices are embedded in the faces, close to the positioning groove, of the two fixing blocks. Compared with the prior art, the bending device is simple in structure, deflection bending can be reduced, the product yield and the product quality can be improved, and energy consumption can be reduced.

Owner:重庆市大足区万鑫卷闸门配件厂

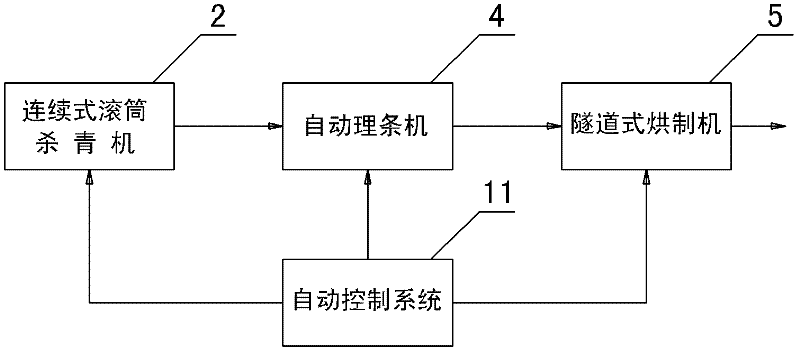

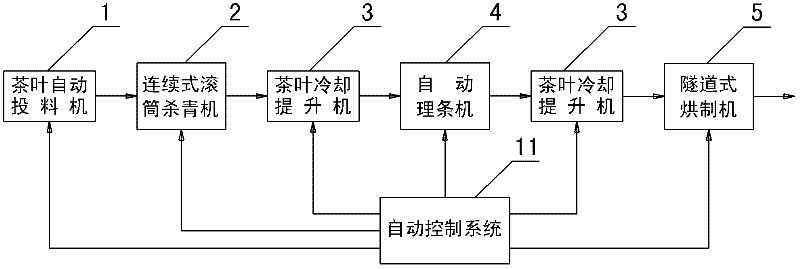

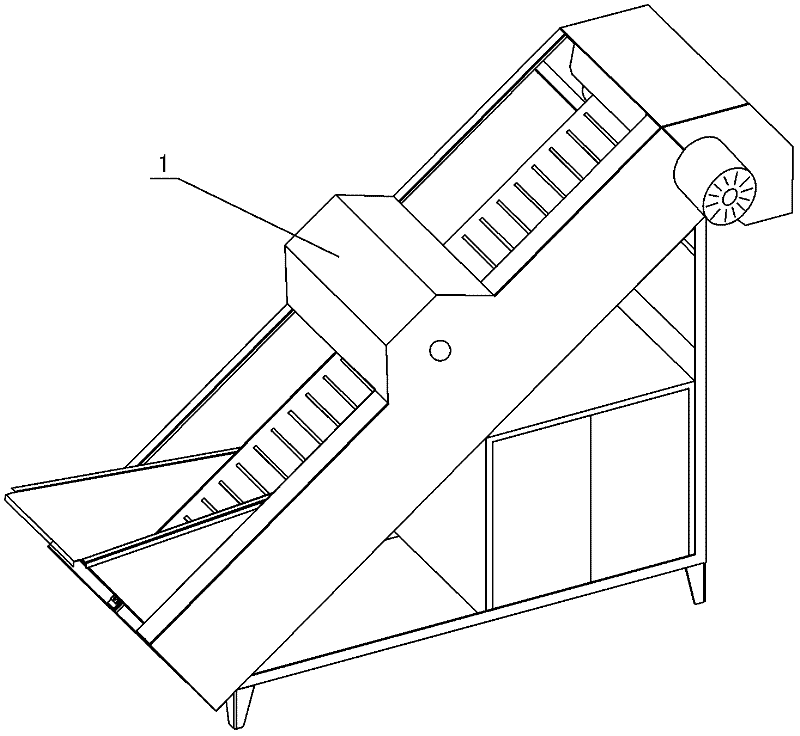

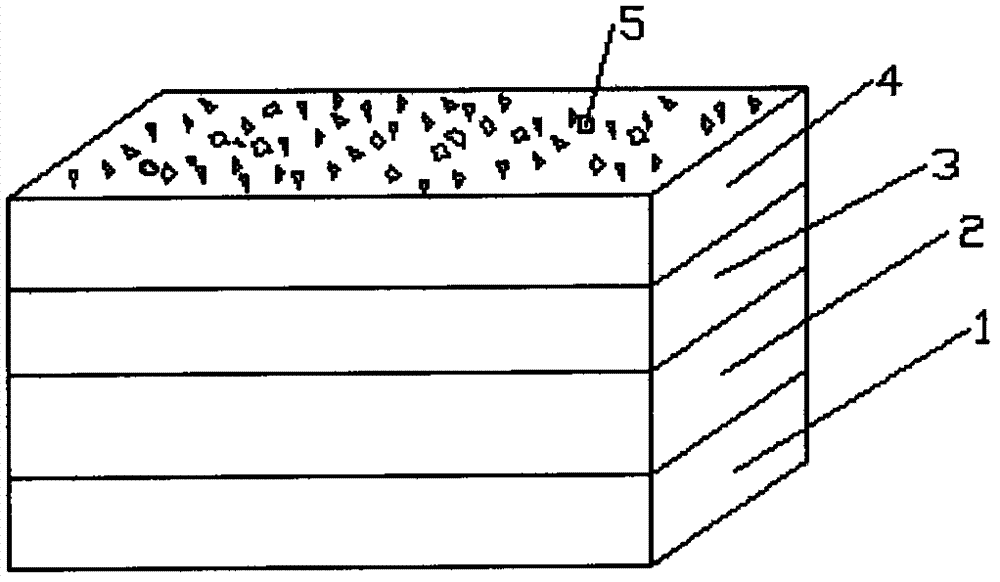

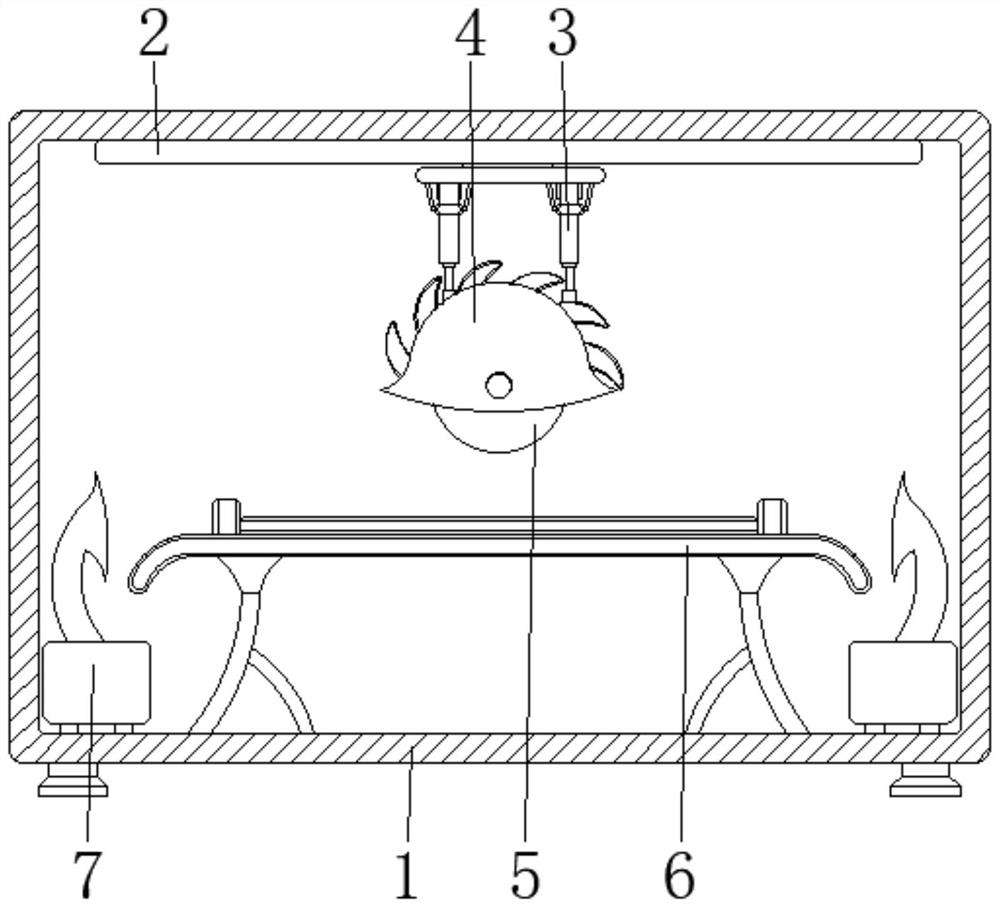

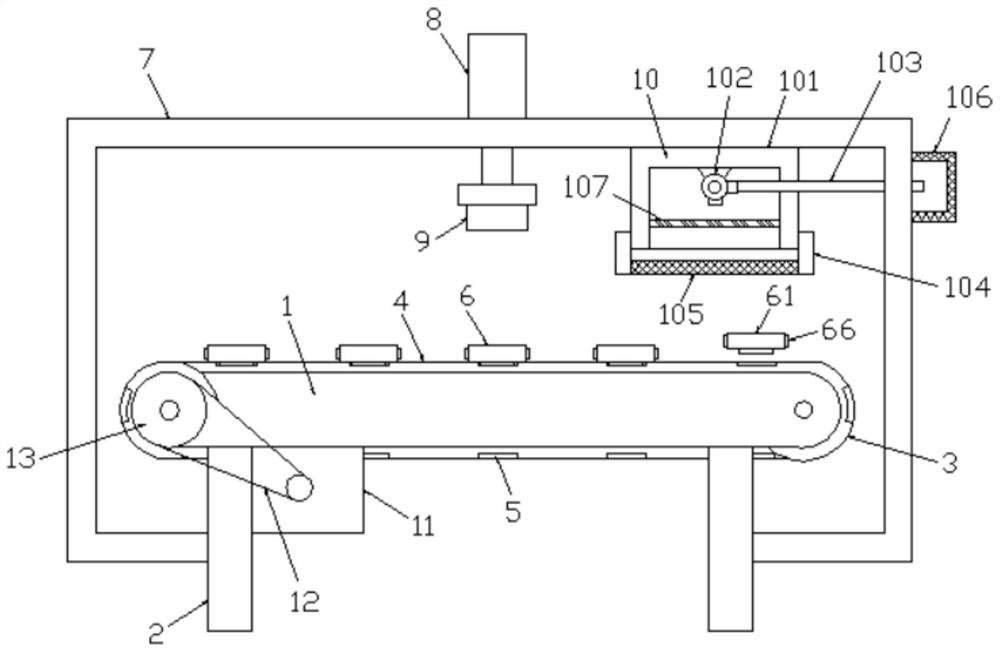

Automatic production complete plant for Maofeng tea

ActiveCN102630767AAchieve continuous flowFully automatedPre-extraction tea treatmentFlavorAutomatic control

The invention discloses an automatic production complete plant for Maofeng tea. The automatic production complete plant comprises a continuous rotary-drum type de-enzyming machine, an automatic tea management machine and a tunnel drier, all of which are mutually connected, wherein the tunnel drier comprises a stand and a drying tunnel, the drying tunnel is arranged on the stand, two sides of the drying tunnel are of sealing structures, the top of the drying tunnel is provided with a heater, and the bottom of the drying tunnel is provided with a tea conveyer belt. The automatic production complete plant for the Maofeng tea further comprises an automatic control system which is connected with and controls all machining devices on the automatic production complete plant. The automatic production complete plant disclosed by the invention effectively solves problems that the machining of the Maofeng tea is dispersive, the quality of the Maofeng tea is irregularly and labor and device resources are waste during present Maofeng tea production. The automatic production complete plant for the Maofeng tea, disclosed by the invention, has the advantages of high automation degree, stability and safety in operation, small dust pollution, no damage on the Maofeng tea, and Maofeng tea finished products have fragrant flavor and high quality grade, thus being high in promotion value.

Owner:浙江丰凯机械股份有限公司

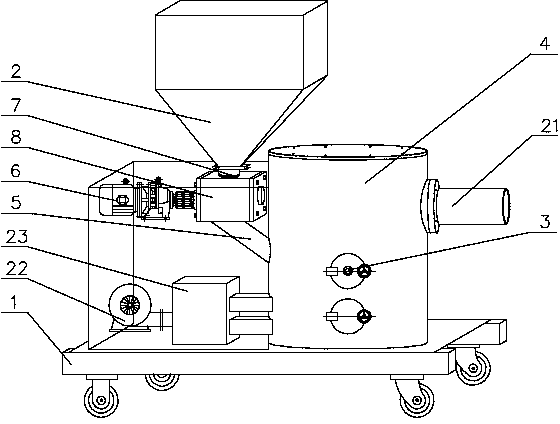

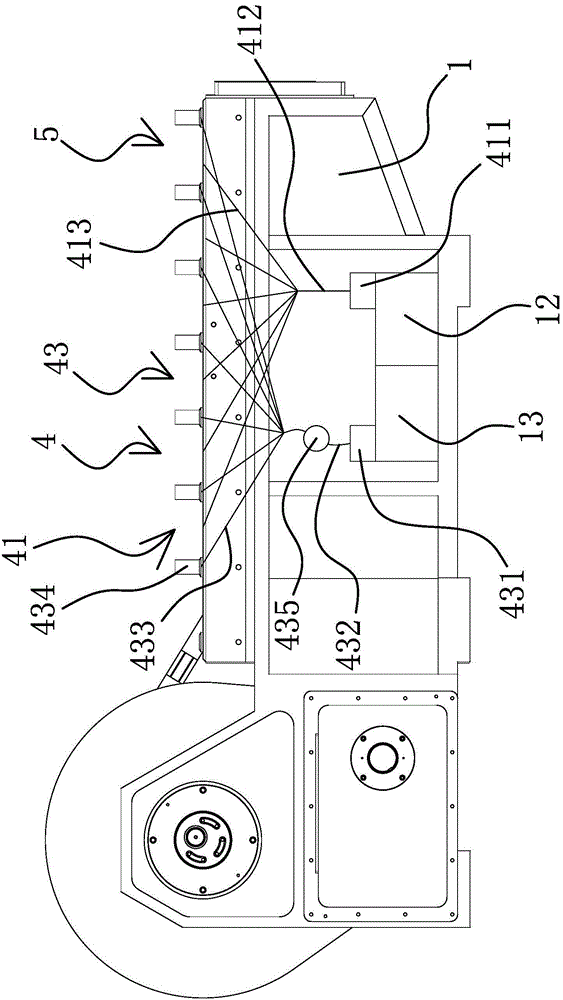

Biomass particle burner of cylinder-type feeding system

ActiveCN103438433APrevent flashbackImprove securitySolid fuel combustionLump/pulverulent fuel feeder/distributionMotor driveCombustion chamber

The invention relates to a biomass particle burner of a cylinder-type feeding system. The problem that an existing biomass particle burner is low in feeding efficiency during using, material blocking can easily happen, and service life is short is mainly solved. The burner comprises a machine frame, a hopper, a feeding mechanism, a burning chamber and a feeding pipe. The feeding mechanism comprises a motor, a feeder and a transmission piece. The feeder comprises an outer shell and a conveying body. The outer shell is fixed on the feeding pipe. The conveying body is placed in the outer shell. The motor drives the conveying body to rotate in the periphery direction. A material inlet and a material outlet which are separated are formed in the outer shell. The material inlet is communicated with the hopper. A material storage groove is formed in the outer periphery of the conveying body. The conveying body rotates in the periphery direction to form the material storage groove which is communicated with the material inlet or the material outlet. Due to the fact that the burner achieves feeding through a cylinder-type rotating disc, tempering is effectively avoided during burning, the biomass particle burner has the advantages of being good in safety and high in feeding efficiency, material blocking cannot happen easily during using, abrasion cannot happen easily, service life is long, and fault rate is low.

Owner:温州市龙湾永兴良正中频电炉厂

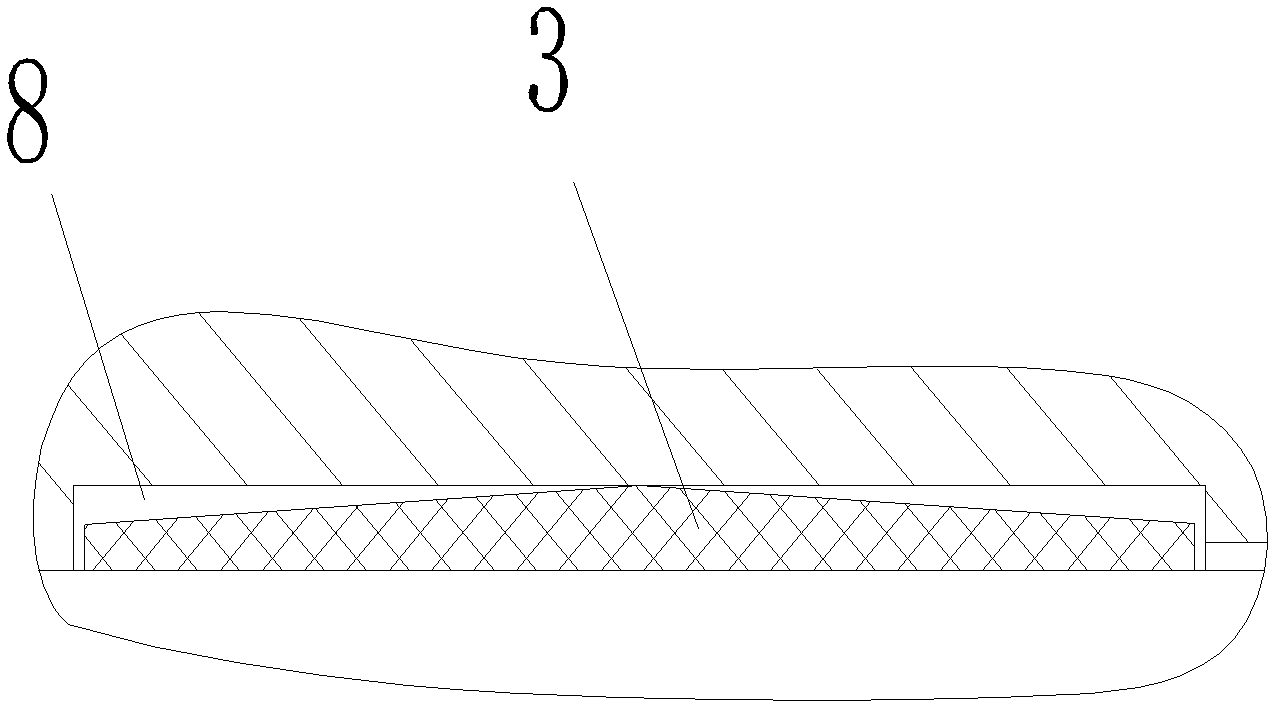

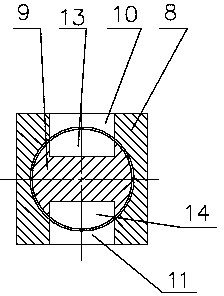

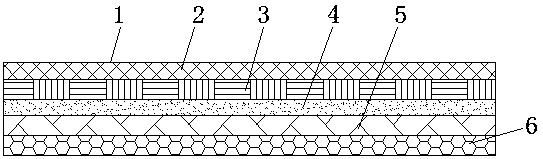

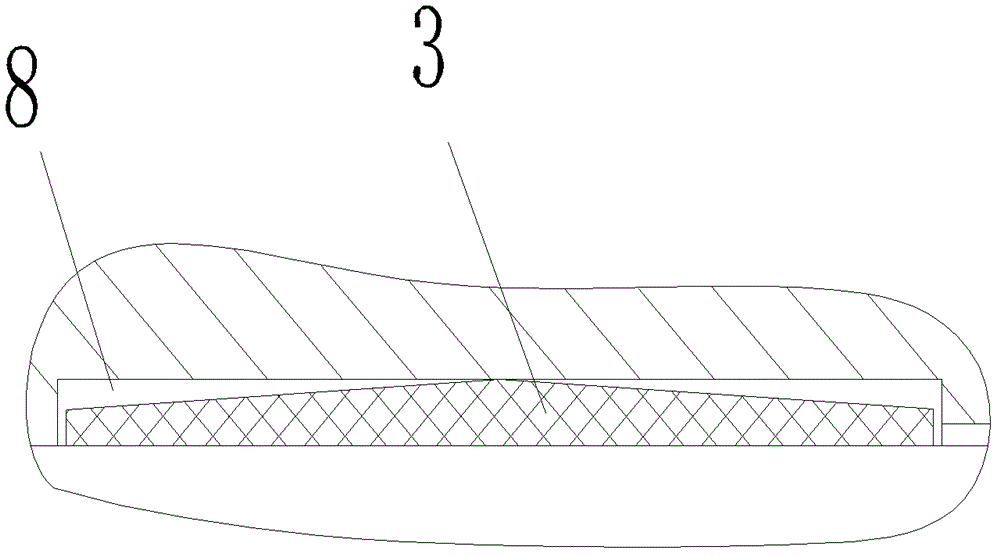

Full-size PVC (polyvinyl chloride) floor for coach and method for manufacturing full-size PVC floor

ActiveCN103921801AEasy to prepareBeautiful edges and cornersAxle-box lubricationFlat articlesPolyvinyl chlorideEngineering

The invention belongs to the field of floors, particularly relates to the field of PVC (polyvinyl chloride) floors for coaches, and discloses a full-size PVC floor for a coach. The full-size PVC floor comprises a base bottom plate and a PVC abrasion-resistant layer. The base bottom plate comprises a lower dense layer, a middle foaming layer and an upper dense layer, and the PVC abrasion-resistant layer is arranged on the upper dense layer; the abrasion-resistant layer comprises a homogenous body decorated by various colorful rubble-shaped PVC particles. The full-size PVC floor for the coach and the method for manufacturing the full-size PVC floor have the advantages that the integral full-size PVC floor with the width of 3.2m does not need to be spliced when used and is free of splicing weld joints, accordingly, easy cracking and damage to weld joints of an existing floor with a narrow width due to tailor welding can be prevented, and the full-size PVC floor is long in service life, attractive in appearance and applicable to places where the passenger flow and personnel passing treading frequencies are high as compared with the existing floor with the narrow width.

Owner:ANHUI MEIXIANG IND

Novel thread rolling machine

InactiveCN104785685AImprove stabilityLess prone to wear and tearMetal-working feeding devicesLubrication elementsFuel tankEngineering

The invention relates to a novel thread rolling machine. The novel thread rolling machine solves the technical problem that oil of an existing thread rolling machine cannot be recovered or used. The novel thread rolling machine comprises a thread rolling machine body, a main machine sliding groove, a main sliding block, a movable thread rolling plate, a fixed thread rolling plate, a thread rolling gap, a first oil tank and a second oil tank. A first conveying and recovering device is arranged on the first oil tank, a second conveying and recovering device is arranged on the second oil tank, adjustable thread rolling machine guide rails are arranged on the thread rolling machine body, and a blank one-by-one feeding device is arranged between the adjustable thread rolling machine guide rails and the thread rolling gap. The novel thread rolling machine has the advantages that lubricating oil and cooling oil can be separated and recovered at the same time, the production cost is saved, the blanks can be fed one by one, the noise in the feeding process is low, parts are not prone to abrasion, the positions of the guide rails are convenient to adjust and can be adjusted vertically as needed, only a bolt needs to be rotated during adjustment, the guide rails are firmly installed, stability is good, and the synchronism of vertical adjustment of the left guide rail and the right guide rail is good.

Owner:惠州东惠达精密五金制品有限公司

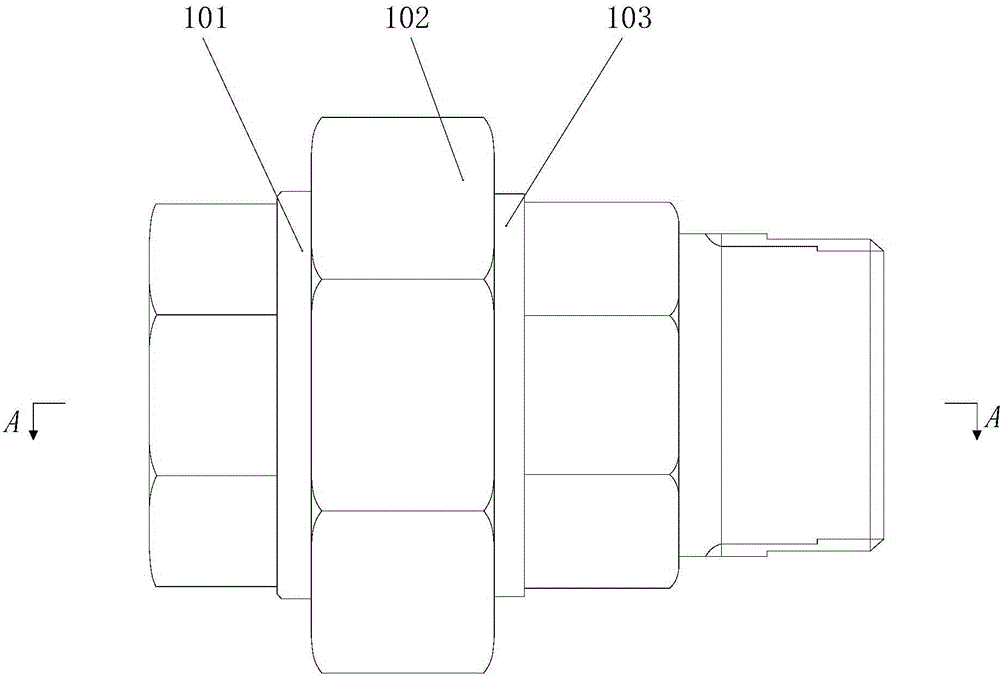

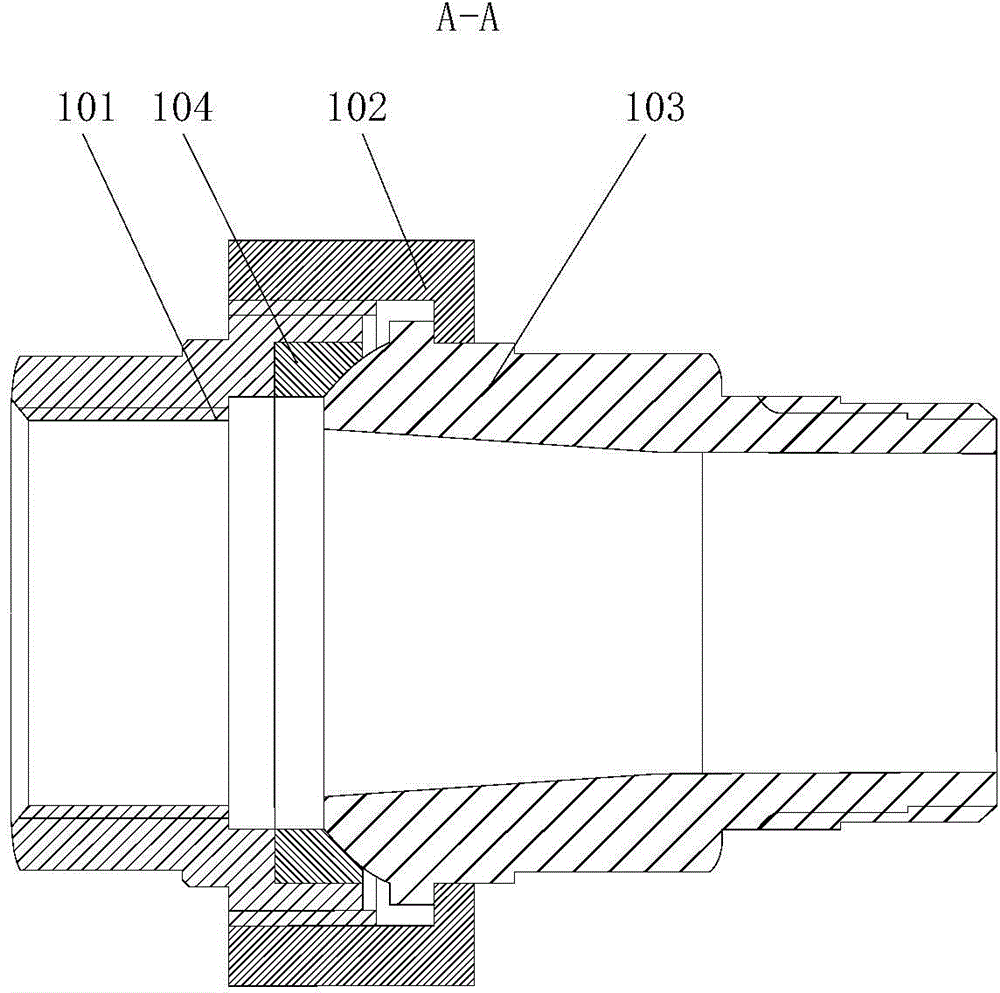

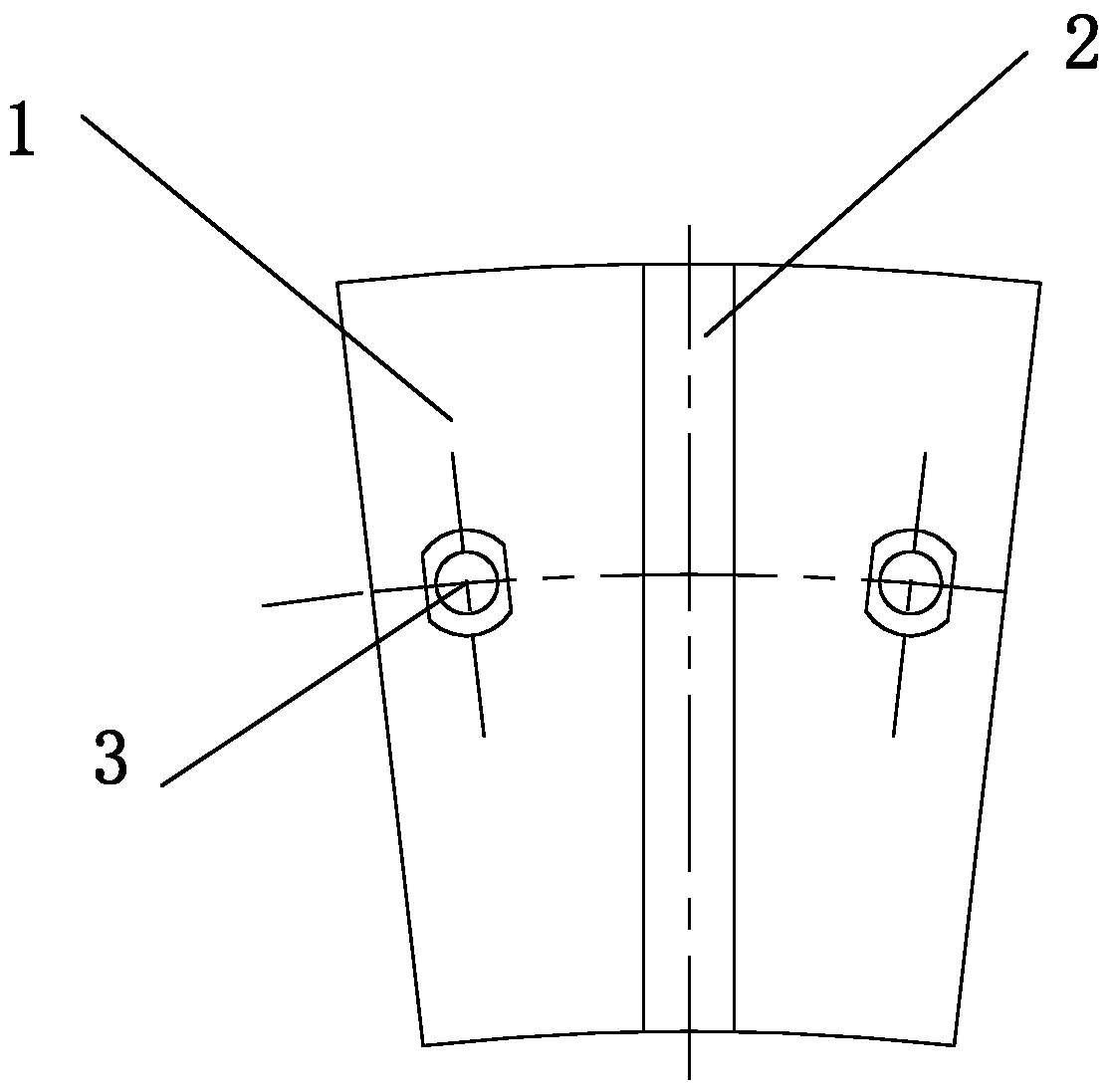

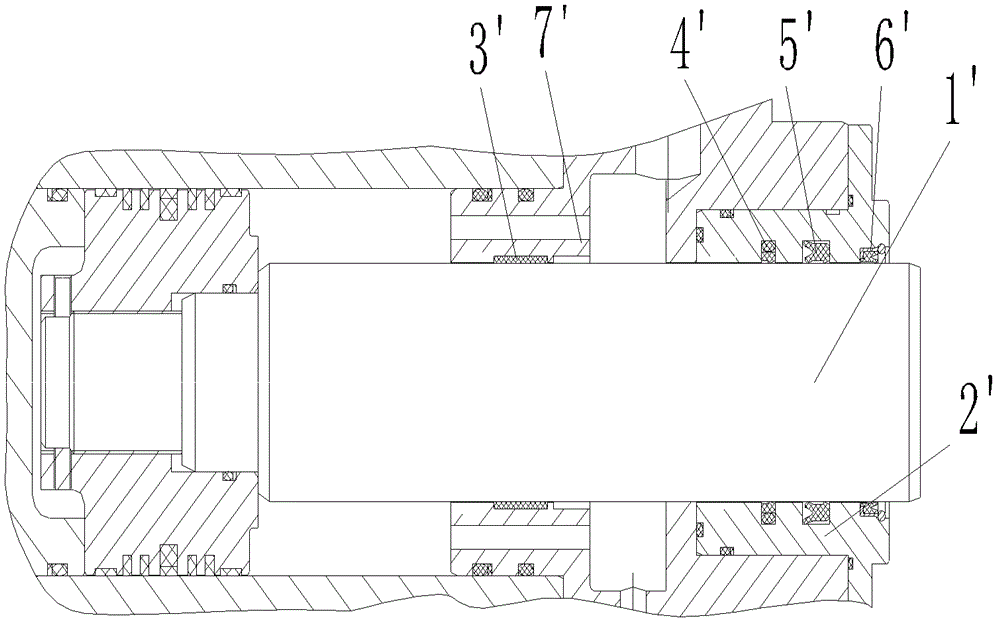

Novel pure-metal seal joint structure

InactiveCN104141840AFirmly connectedLess prone to wear and tearJoints with sealing surfacesEngineeringPure metals

The invention discloses a novel pure-metal seal joint structure which comprises a joint A and a joint B. A sealing base sleeve is connected to the inner wall of the joint A in a clamped mode. The novel pure-metal seal joint structure further comprises a fastening nut. Threads matched with the fastening nut are arranged on outer walls of the joint A and the joint B, a spherical surface corresponding to the sealing base sleeve is arranged at one end close to the sealing base sleeve, of the joint B, the joint A, all of the joint B and the sealing base sleeve are made of metal, and the hardness of the sealing base sleeve is smaller than that of the joint B. The joint A and the joint B are oppositely screwed through the fastening nut to enable the spherical surface arranged on the joint B to be pressed and arranged on the sealing base sleeve in the joint A, the spherical surface arranged on the joint B extrudes the sealing base sleeve through axial fastening force of the fastening nut, and accordingly the sealing base sleeve deforms elastically. Sealing is achieved through tight and reliable connection of the spherical surface and the sealing base sleeve, the structure is not easily abraded and does not age, and deformation influencing the sealing effect does not occur.

Owner:李志勇

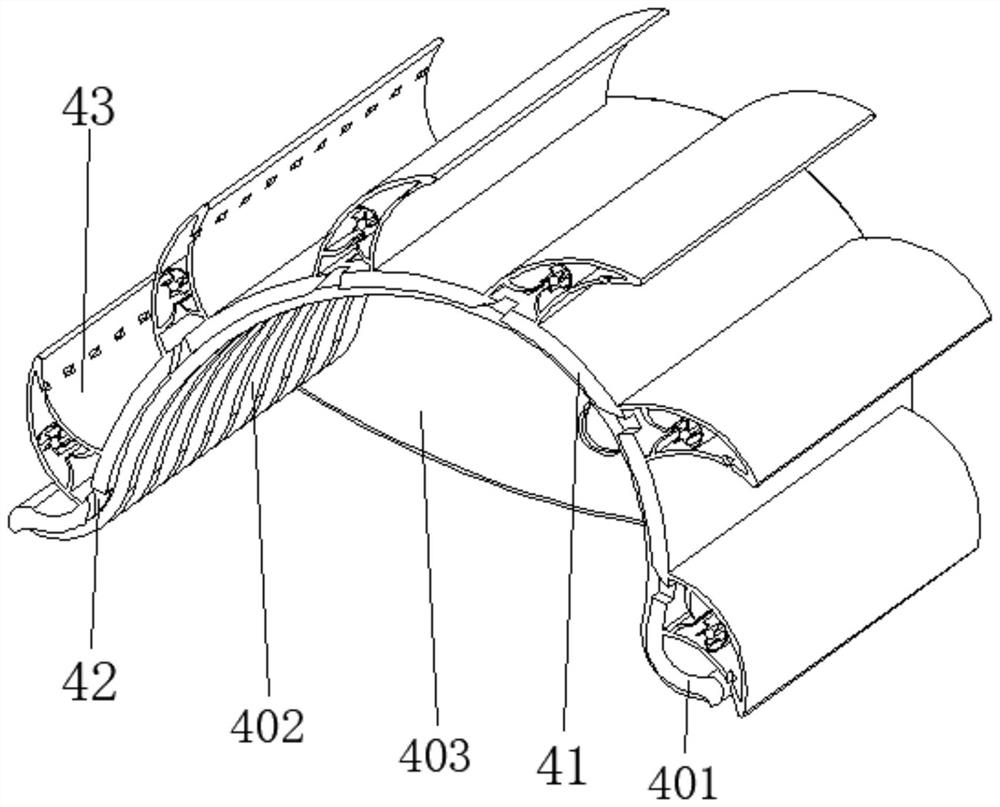

Surface treatment equipment and treatment method for chip capacitor

ActiveCN114400154ATimely processingLess likely to depositGrinding drivesMetal surface removal provisionDust controlStructural engineering

The surface treatment equipment comprises a machine body, a linear driving mechanism, a lifting mechanism, a housing device and a polishing device, the housing device is arranged at the bottom of the lifting mechanism, and the polishing device is arranged in the housing device and is close to the bottom. The dust removal device is arranged at the top of the arc-shaped housing body and is close to the conical opening, the cambered surface flow guide assembly is fixed to the inner wall of the ox horn shell and is close to the conical opening, the filter screen is fixed to the inner wall of the ox horn shell, and the cleaning device is arranged in the ox horn shell and is close to the filter screen. The invention relates to the technical field of capacitor processing equipment. According to the surface treatment equipment for the chip capacitor, the effect of removing impurities is achieved, the impurities can be removed in time, impurity deposition, polishing scratches and abrasion are not prone to occurring, the polishing quality is high, meanwhile, dust diffusion is reduced, human health is facilitated, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:淮安永捷电子科技有限公司

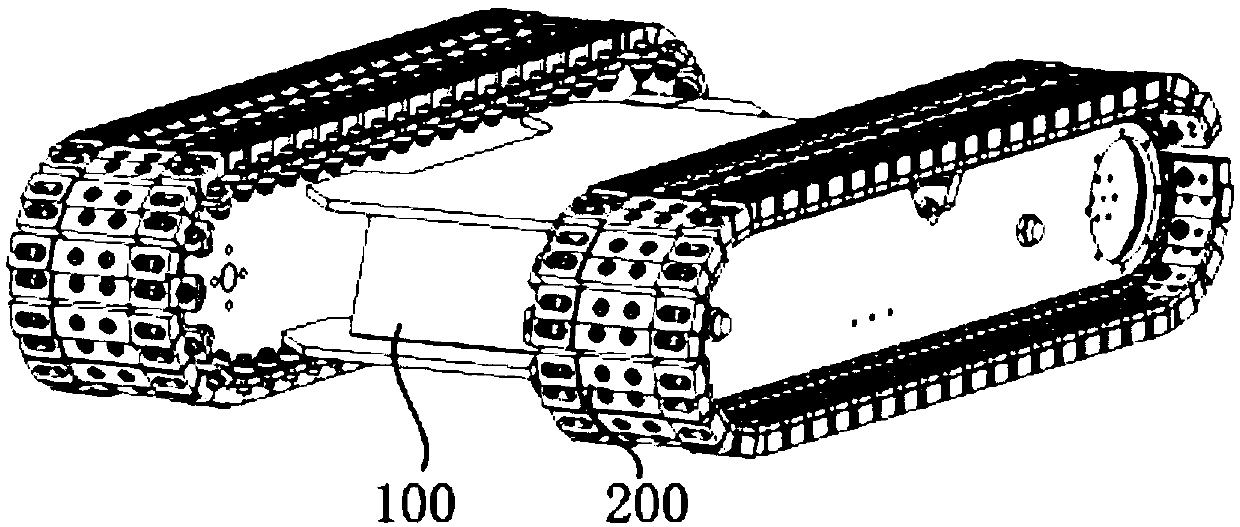

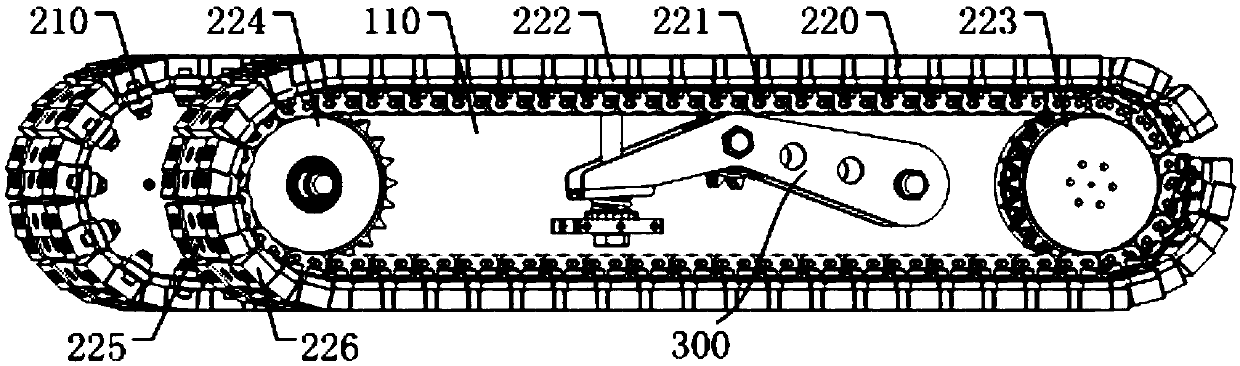

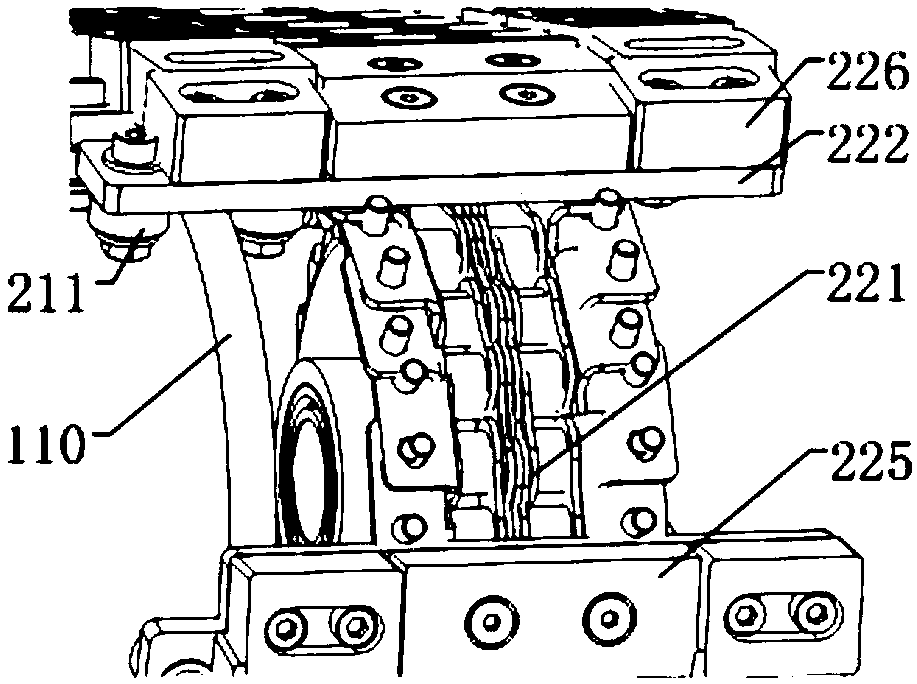

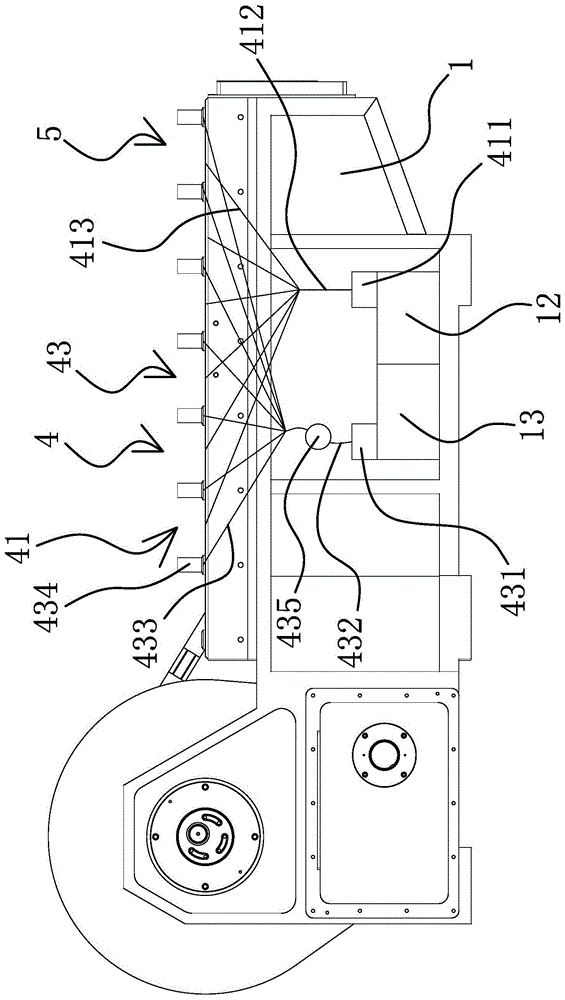

Magnetic adsorption running device and magnetic adsorption wall climbing robot

ActiveCN109533054APromotes relative motionEasy to replaceEndless track vehiclesClimbing robotsElectrical and Electronics engineering

The invention provides a magnetic adsorption running device and a magnetic adsorption wall climbing robot, and relates to the technical field of crawler-type magnetic adsorption robots. The magnetic adsorption running device comprises a device body and crawler belt running mechanisms arranged on the left and right sides of the device body; the device body comprises guiding plates respectively arranged on the inner sides of the two crawler belt running mechanisms; the crawler belt running mechanisms comprise a plurality of guiding assemblies arranged around the edges of the guiding plates, andthe guiding assemblies are in respective rolling connection with the two side surfaces of the guiding plates; when the crawler belt running mechanisms move relative to the device body, the guiding assemblies can move along the guiding plates. The magnetic adsorption wall climbing robot comprises the magnetic adsorption running device. The purpose is to provide the magnetic adsorption running device and the magnetic adsorption wall climbing robot, so that the problem that due to quick abrasion and poor stability of a guiding structure and other factors, normal operation of the wall climbing robot is influenced is alleviated.

Owner:杭州白泽方舟科技有限公司

New thread rolling machine

InactiveCN104785685BImprove stabilityLess prone to wear and tearMetal-working feeding devicesScrew-threads articlesFuel tankEngineering

The invention relates to a novel thread rolling machine. The novel thread rolling machine solves the technical problem that oil of an existing thread rolling machine cannot be recovered or used. The novel thread rolling machine comprises a thread rolling machine body, a main machine sliding groove, a main sliding block, a movable thread rolling plate, a fixed thread rolling plate, a thread rolling gap, a first oil tank and a second oil tank. A first conveying and recovering device is arranged on the first oil tank, a second conveying and recovering device is arranged on the second oil tank, adjustable thread rolling machine guide rails are arranged on the thread rolling machine body, and a blank one-by-one feeding device is arranged between the adjustable thread rolling machine guide rails and the thread rolling gap. The novel thread rolling machine has the advantages that lubricating oil and cooling oil can be separated and recovered at the same time, the production cost is saved, the blanks can be fed one by one, the noise in the feeding process is low, parts are not prone to abrasion, the positions of the guide rails are convenient to adjust and can be adjusted vertically as needed, only a bolt needs to be rotated during adjustment, the guide rails are firmly installed, stability is good, and the synchronism of vertical adjustment of the left guide rail and the right guide rail is good.

Owner:惠州东惠达精密五金制品有限公司

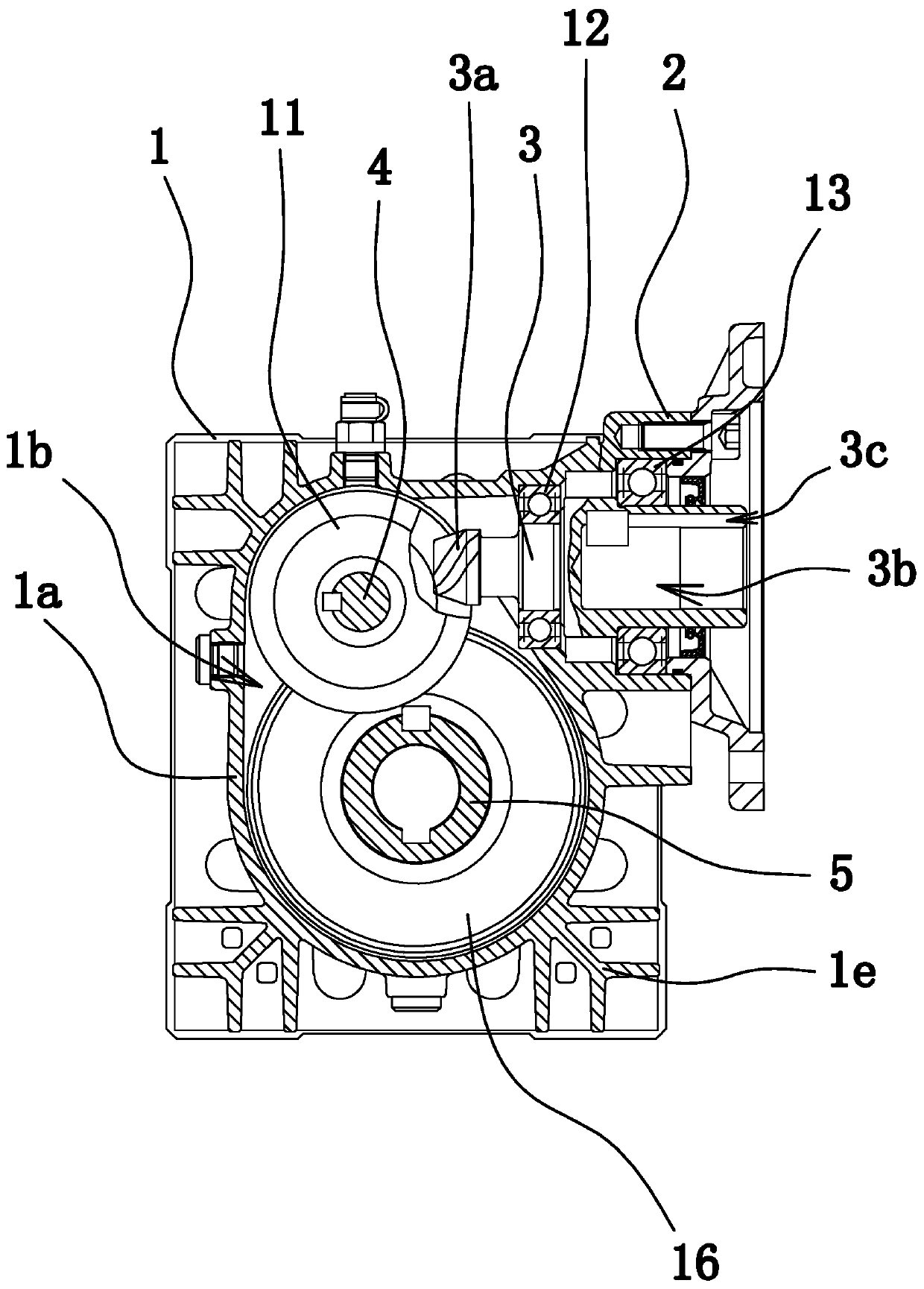

Speed reducer structure

PendingCN111075908AHigh transmission precisionExtended service lifeGearboxesGearing detailsReduction driveDrive shaft

The invention provides a speed reducer structure, which belongs to the technical field of machinery, and solves the problems that an existing speed reducer is poor in transmission precision and is short in service life. The speed reducer structure comprises a housing, a flange, an input shaft, a transmission shaft and an output shaft, wherein the two ends of the transmission shaft are separately connected in the housing through a bearing I and a bearing II; the two ends of the output shaft are separately connected in the housing through a bearing III and a bearing IV; a coaming is arranged inthe housing, and a mounting cavity is enclosed in the housing; an opening is formed in the end surface of the housing, and the edge of the opening is detachably connected with an end cover; both the bearing I and the bearing III are arranged on the end cover; both the transmission shaft and the output shaft are positioned in the mounting cavity; a hypoid gear is arranged on the input shaft; a bevel gear which is engaged with the hypoid gear is arranged on the transmission shaft; and the dimension of the bearing II is greater than that of the bearing I. The bearing II can bear greater axial bearing force relative to the bearing I, so that stable and consistent transmission efficiency can be kept, and therefore, the speed reducer structure has relatively high transmission precision, and theservice life of the speed reducer structure is prolonged.

Owner:浙江通宇变速机械股份有限公司

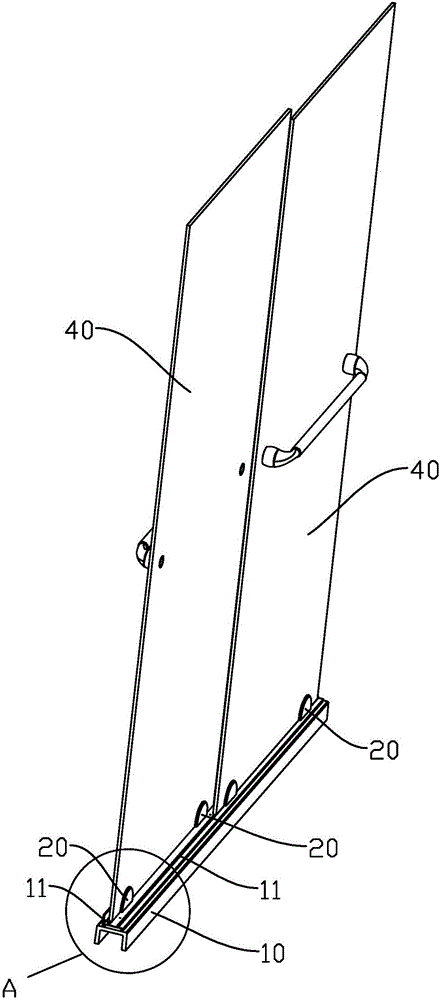

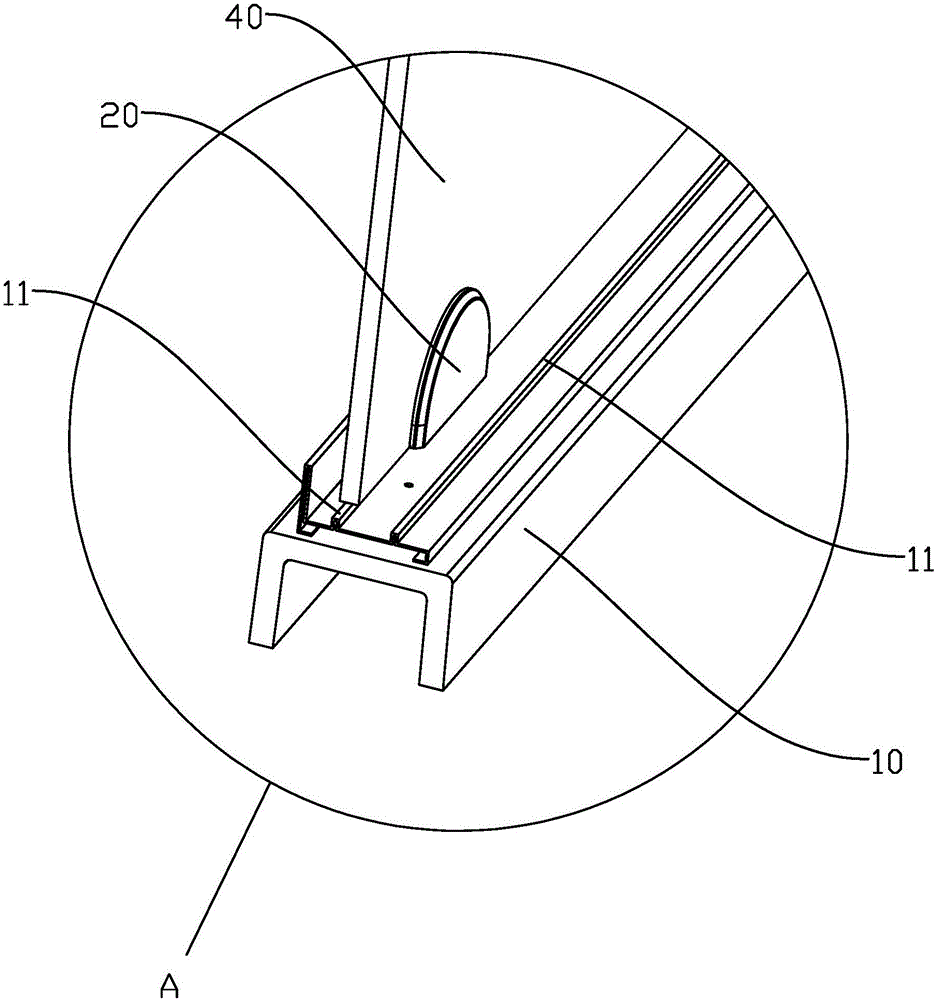

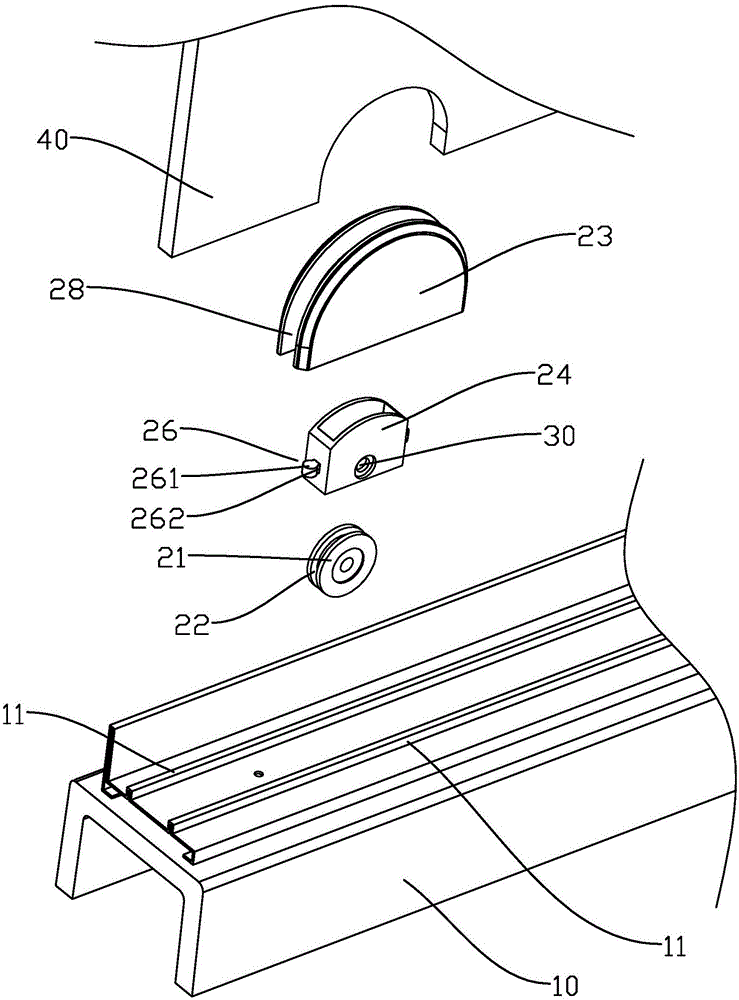

Sliding guide mechanism for bathroom

InactiveCN106150249AReduce resistanceReduce sideways swingWing suspension devicesEngineeringIdler-wheel

The invention discloses a sliding guide mechanism for a bathroom. The sliding guide mechanism comprises a base and at least one mounting base mounted on a door, wherein an idler wheel is pivoted on the mounting base through a horizontal pivot shaft; a first limiting part is arranged on the base; a second limiting part is arranged on the idler wheel around the pivot shaft; one of the first limiting part and the second limiting part is arranged as a longitudinal limiting groove and the other is arranged as a longitudinal limiting bulge matched with the groove; the limiting bulge is longitudinally inserted into the limiting groove; two outer side walls of the limiting bulge are respectively clung to or close to the two inner side walls of the limiting groove. The sliding guide mechanism for the bathroom can effectively reduce the resistance ensured by the door in a sliding process, so that the sliding smoothness of the door is effectively increased and the door is difficult to be worn. The outer side walls of the limiting bulge are respectively clung to or close to the two inner side walls of the limiting groove, so that the lateral swinging of the door relative to the base can be effectively reduced.

Owner:中山市雅润卫浴有限公司

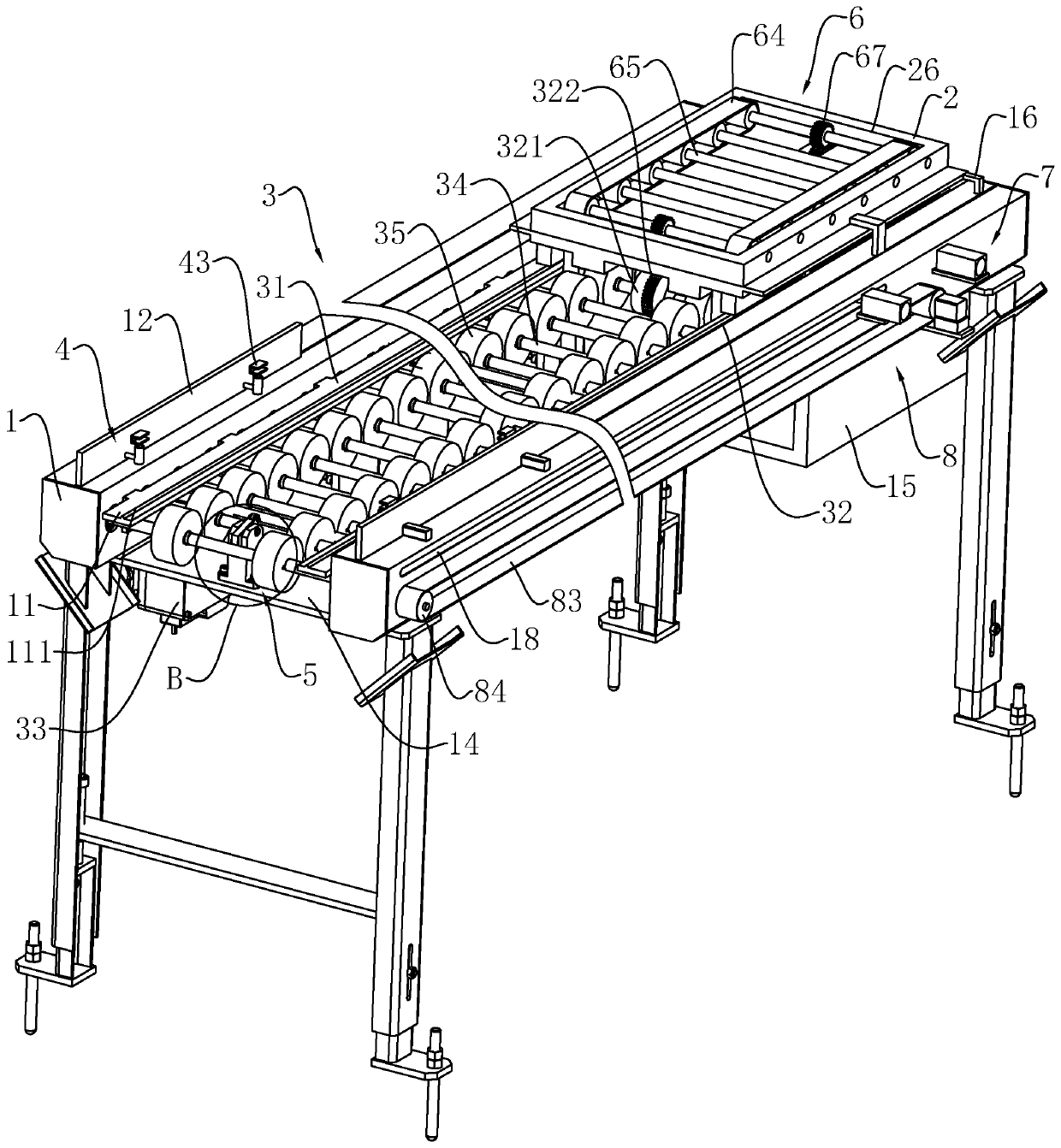

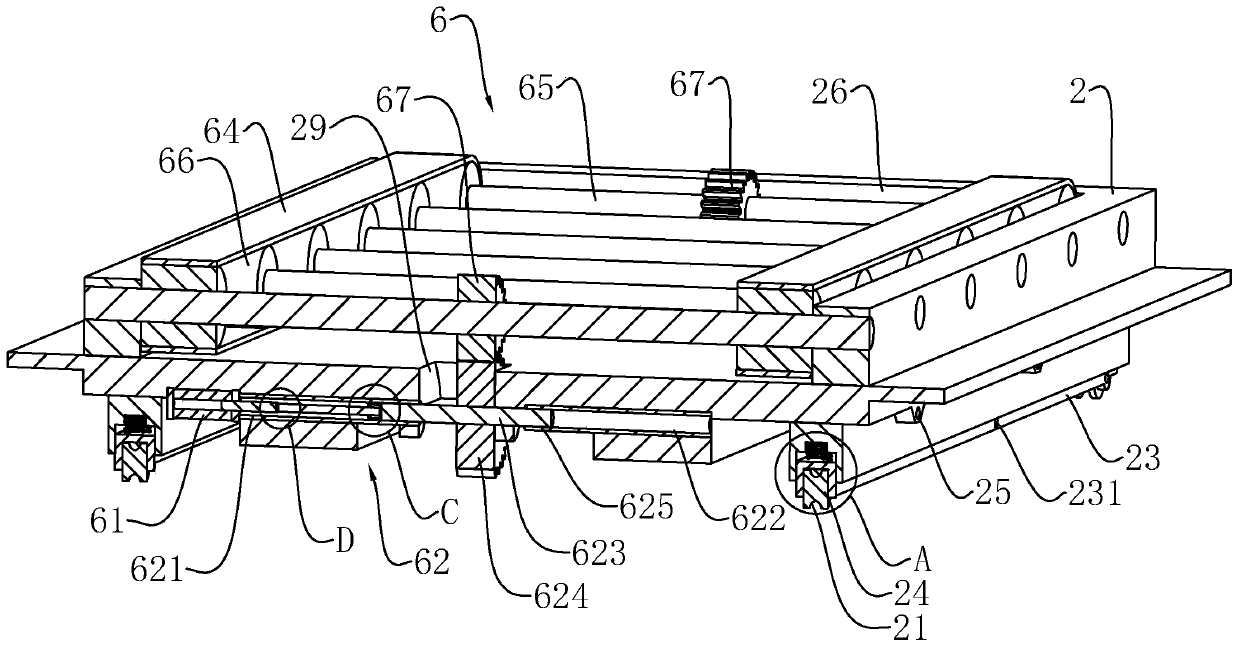

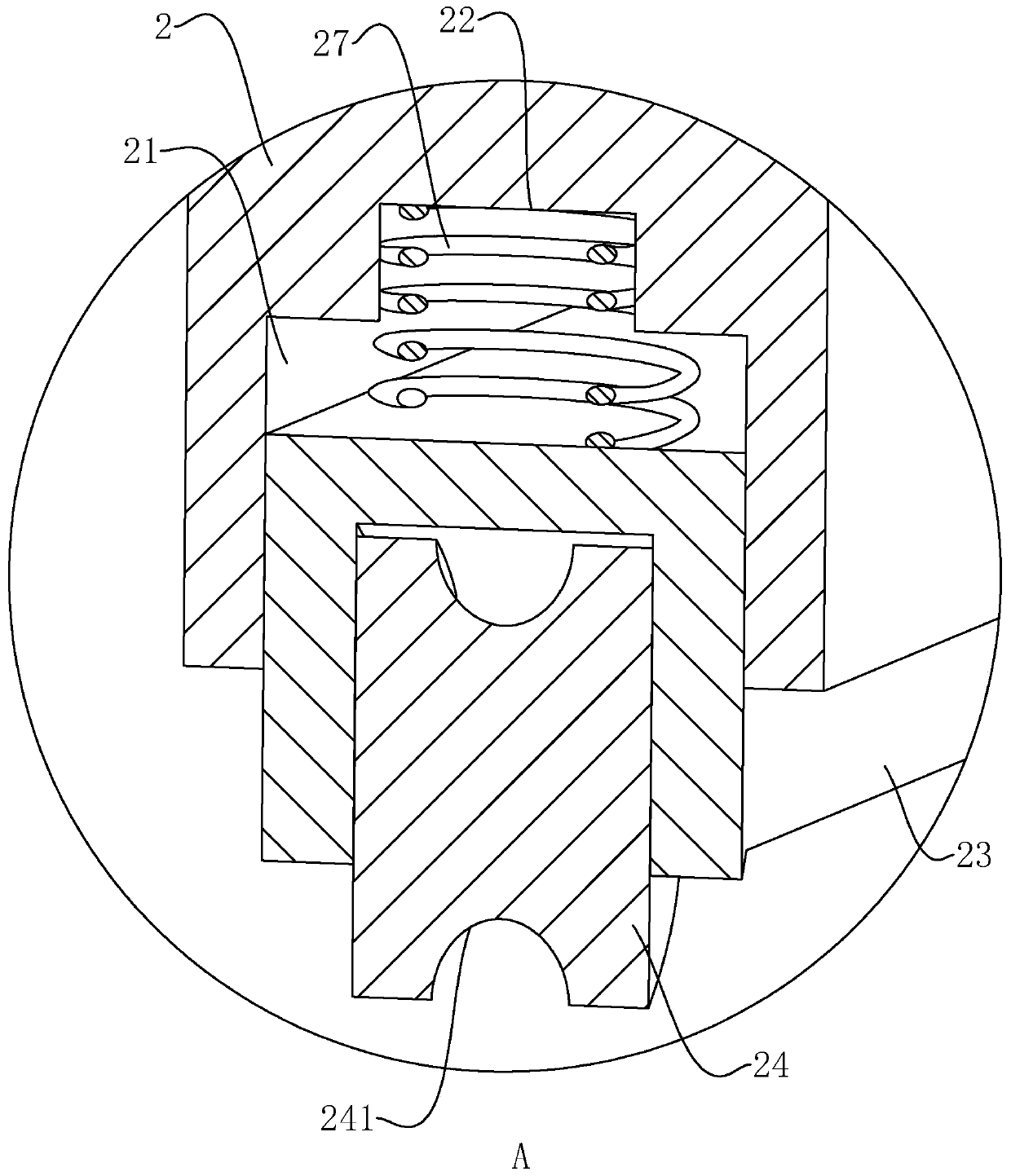

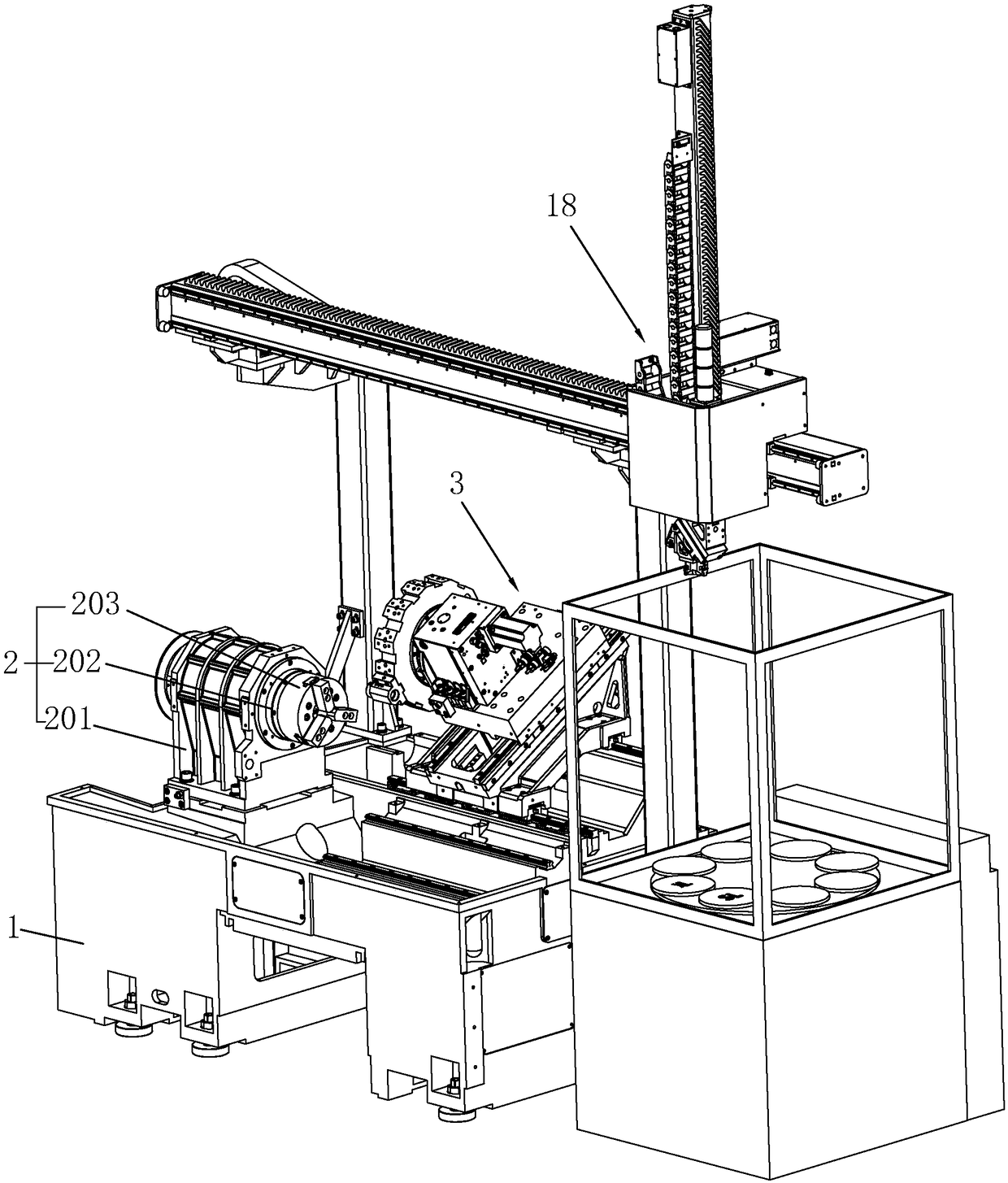

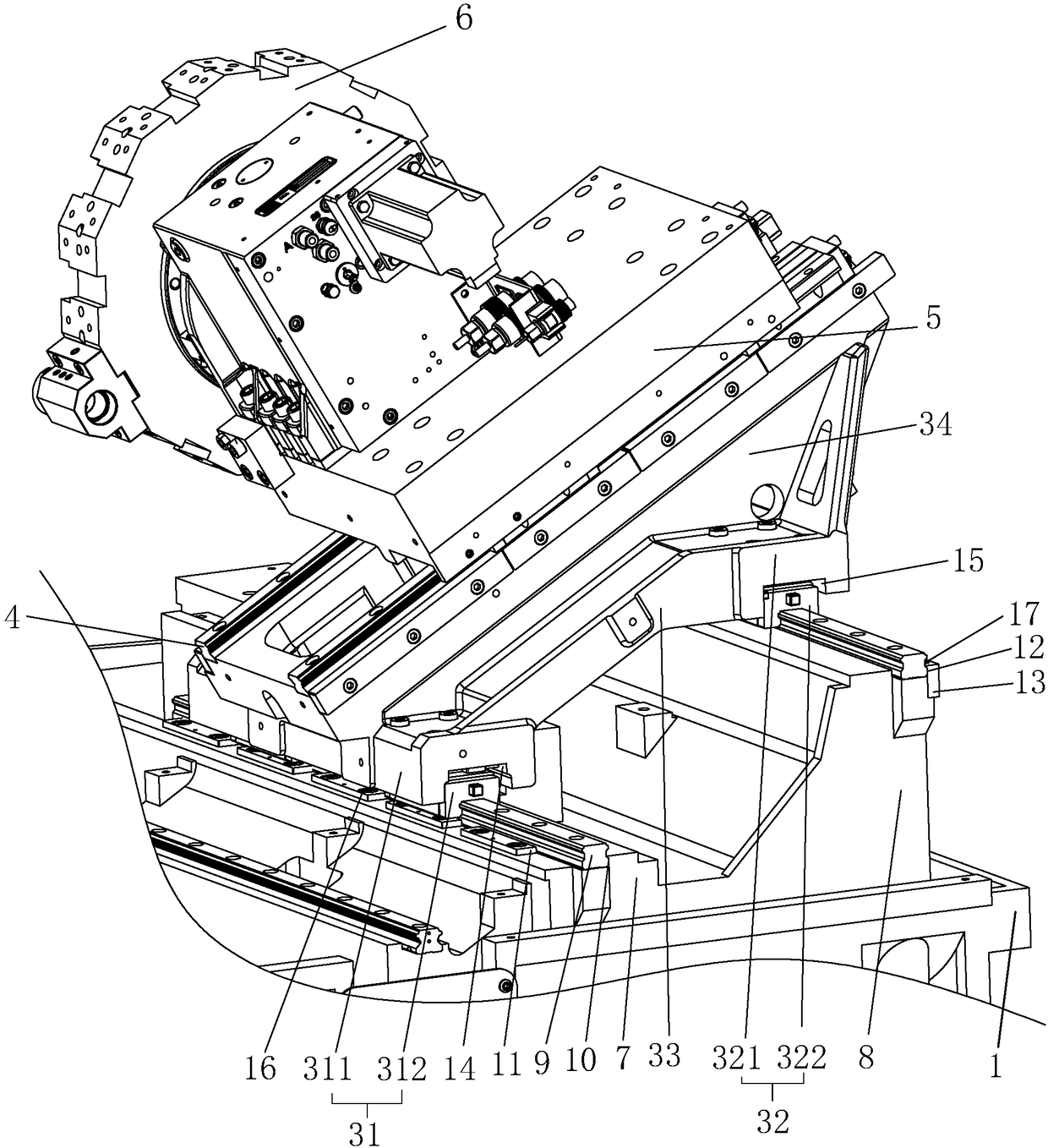

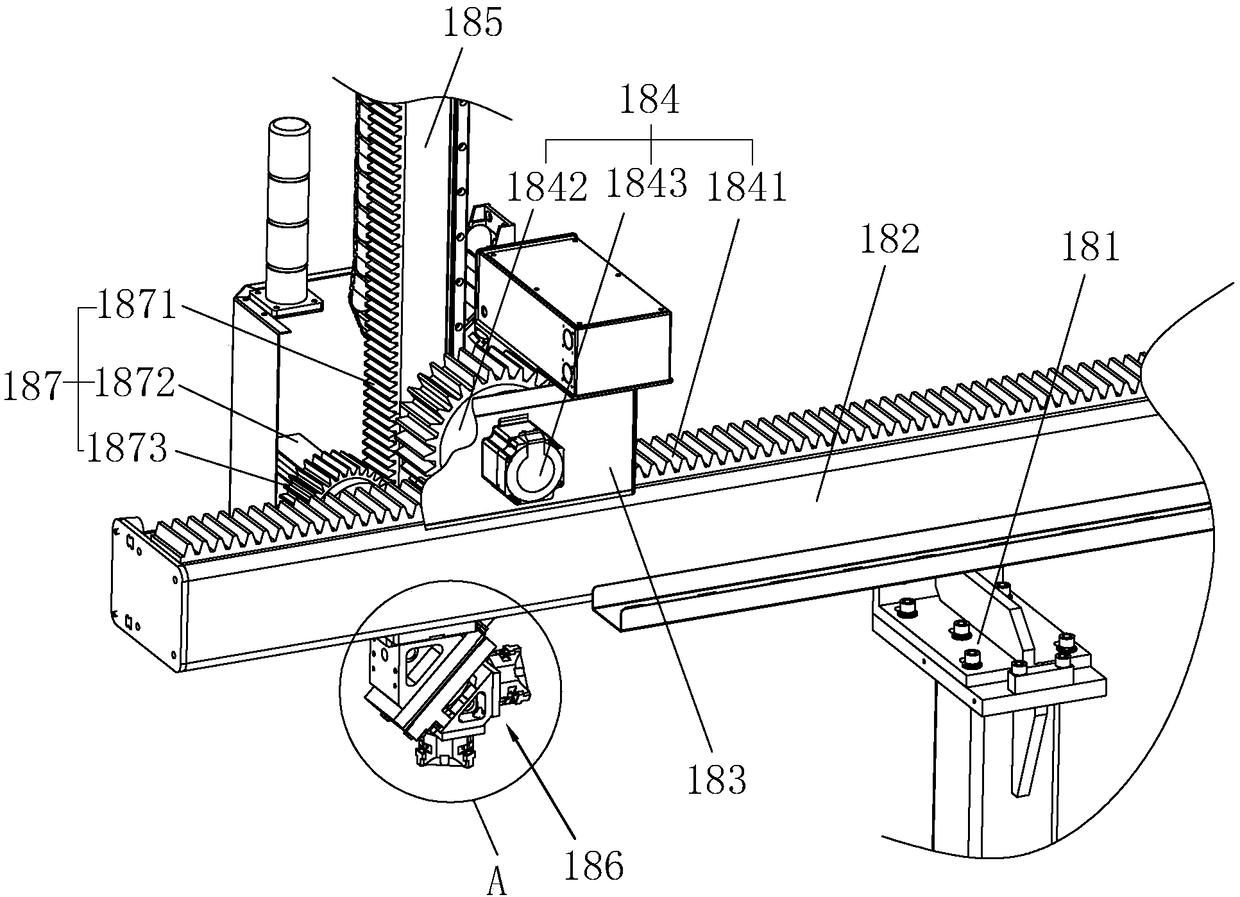

Conveying device suitable for stable conveying of cylinder block

ActiveCN111268355AConvenient and stable outputNot easy to wearControl devices for conveyorsMechanical conveyorsEngineeringCylinder block

The invention relates to a conveying device suitable for stable conveying of a cylinder block. The conveying device comprises a rack, wherein a conveying device for conveying the cylinder block is arranged on the rack in the length direction, a supporting plate used for supporting the cylinder block is arranged between the conveying device and the cylinder block, slide rails for guiding the supporting plate are symmetrically arranged in the rack, position control plates are arranged on two sides of the supporting plate in a penetrating manner, multiple pulleys inlaid in one side, away from thesupporting plate, of each position control plate, and a position control spring is connected between one side, away from the pulleys, of each position control plate and the supporting plate. The conveying device has effects as follows: the probability of mutual wearing between an engine cylinder block and a conveying roller in a transport process is low, and conveying stability of the engine cylinder block is improved.

Owner:南京文翔自动化设备有限公司

A kind of textile nylon guide wire device

The invention provides a spinning nylon wire guide device, and relates to the field of spinning. The spinning nylon wire guide device comprises a support plate; support legs are respectively arranged at four corners of the bottom of the support plate; the bottoms of the support legs are fixedly connected with the top of a base; a cylinder base is fixedly mounted in the center of the bottom of the support plate; and the bottom of the cylinder base is fixedly connected with the top of a hydraulic cylinder. The spinning nylon wire guide device transmits oil into the hydraulic cylinder through a first oil inlet and outlet pipe and returns the oil through a second oil inlet and outlet pipe; a piston drives a wire guide device body to stably descend under the effect of a vibration reducer; and through oil transmission of the second oil inlet and outlet pipe and oil return of the first oil inlet and outlet pipe, the piston drives a push rod to upwards move, so that the wire guide device body is stably ascended under the effect of the vibration reducer, the height of the wire guide device body can be changed as needed to achieve adjustment, the wire guide device is suitable for persons with various heights to perform the wire guide operation, and the practicability of the wire guide device is improved.

Owner:南通中丽锦纶科技有限公司

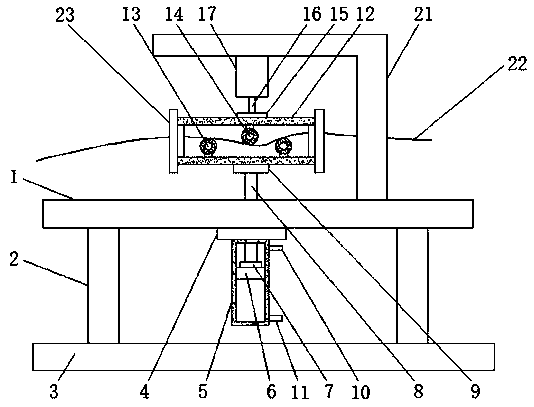

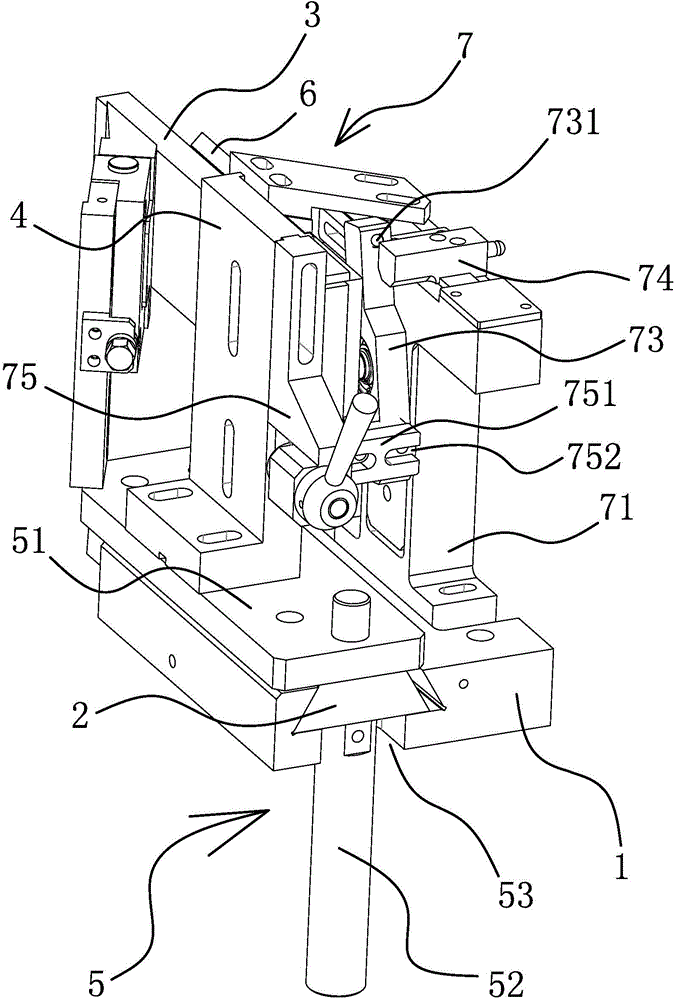

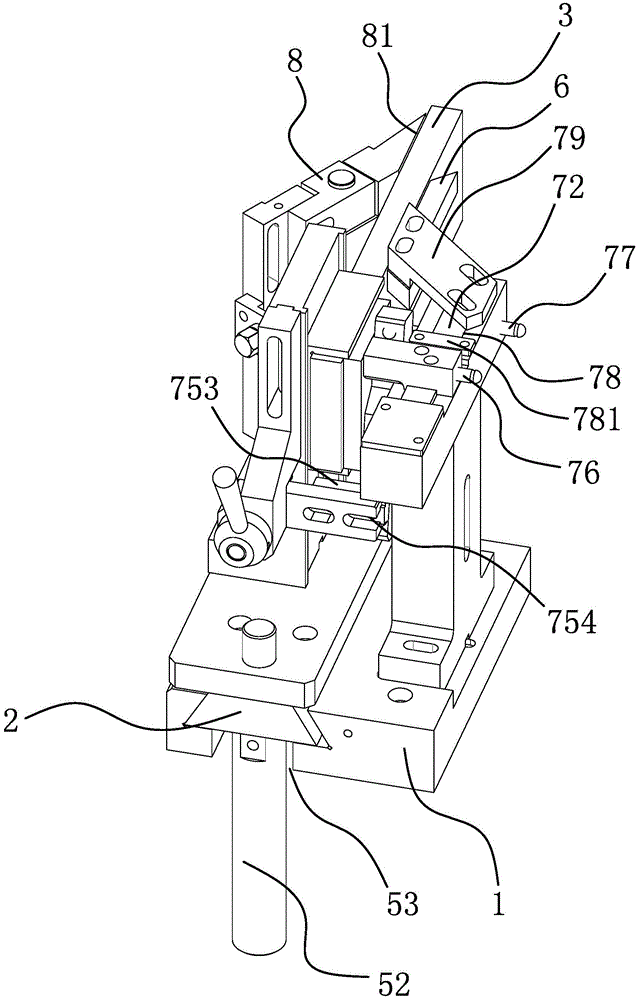

One-by-one feeding mechanism of blanks of thread rolling machine

InactiveCN104815933AReasonable designSimple structureMetal-working feeding devicesScrew-threads articlesEngineeringSlide plate

The invention relates to a one-by-one feeding mechanism of blanks of a thread rolling machine, and aims to solve the technical problems such as low feeding efficiency of the existing thread rolling machine. The mechanism comprises a horizontally arranged feeding slide plate seat, wherein the feeding slide plate seat is provided with a feeding slide plate in a sliding manner; the feeding slide plate is fixedly provided with a feeding knife switch rack which is vertically arranged and is provided with a feeding knife switch; the feeding slide plate is connected with a driving structure which can drive the feeding slide plate to slide so as to drive the feeding knife switch rack to reciprocally move along the axial direction of the feeding slide plate seat; a separation knife switch which is arranged parallel to the feeding knife switch is arranged on one side of the feeding knife switch, and a separation drive structure capable of driving the separation knife switch to synchronously and reversely move during movement of the feeding knife switch rack is arranged between the separation knife switch and the feeding knife switch rack. The one-by-one feeding mechanism of the blanks of the thread rolling machine has the advantages of rational design, simple structure, capability of realizing one-by-one feeding of the blanks, high feeding efficiency, no need of configuration of two drives, low cost, over-small feeding process and difficulty in wear of parts.

Owner:王景花

Numerical control machine tool

The invention discloses a numerical control machine tool. The Key points of the technical scheme of the numerical control machine tool are that the numerical control machine tool comprises a machine frame, a clamp, a sliding saddle, a longitudinal sliding rail, a sliding plate and a rotary knife rest; a first rail seat and a second rail seat are arranged on the machine frame in parallel, and the second rail seat is higher than the first rail seat; transverse sliding rails perpendicular to the longitudinal sliding rail are arranged on the first rail seat and the second rail seat respectively; and the sliding saddle is slidingly connected between the first rail seat and the second rail seat; the top surface of the transverse sliding rail on the first rail seat and the top surface of the transverse sliding rail on the second rail seat are both horizontal surfaces so as to enable the contact surfaces of the sliding saddle and the transverse sliding rails are also horizontal planes, so thatthe gravity of the sliding saddle directly acts on the top surfaces of the transverse sliding rails; the gravity direction of the sliding saddle is perpendicular to the top surfaces of the transversesliding rails, so that the sliding saddle is not prone to generating the trend of longitudinal movement and vertical movement in the moving process, and therefore the side walls of the transverse sliding rails are not prone to deformation and even damage, and machining precision of the numerical control machine tool is guaranteed to a certain degree.

Owner:台州新发自动化设备有限公司

Air control stable starting valve

ActiveCN106439094ACompact installation structureSimple installation structureEqualizing valvesMultiple way valvesWork performanceColloid

The invention discloses an air control stable starting valve. The air control stable starting valve comprises a valve body, a valve cover, a valve base, a first valve element module, a second valve element module and an adjusting valve module; a first cavity and a second cavity are formed between the valve body and the valve cover; a third cavity is formed between the valve body and the valve base; the first valve element module is arranged in the first cavity; the second valve element module is arranged in the second cavity; an air control base is arranged on the valve cover, and is provided with an air control port; the adjusting valve module includes a base formed on the valve base; a valve inlet communicated with the third cavity is formed in the side wall of the base; a valve outlet communicated with the second cavity is formed in the top of the base; an adjusting valve needle is arranged in the base; a conical head part is arranged at the top of the adjusting valve needle; and a vulcanized colloid is arranged at the external of the conical head part. The air control stable starting valve is simple and reasonable in structure, convenient for installation, lower in manufacturing cost, wider in application range, higher in action sensitivity, higher in sealing performance, longer in service life and stable and reliable in working performance.

Owner:NINGBO HUAYI PNEUMATIC ENG CO LTD

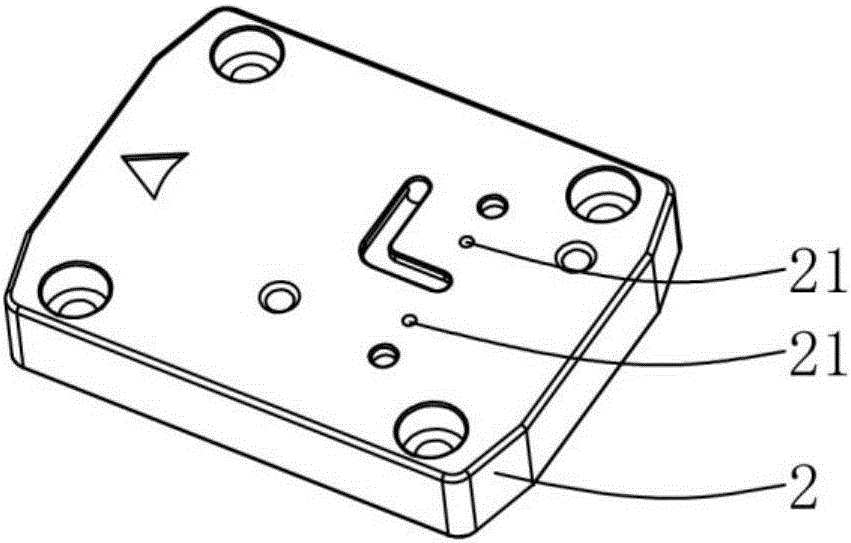

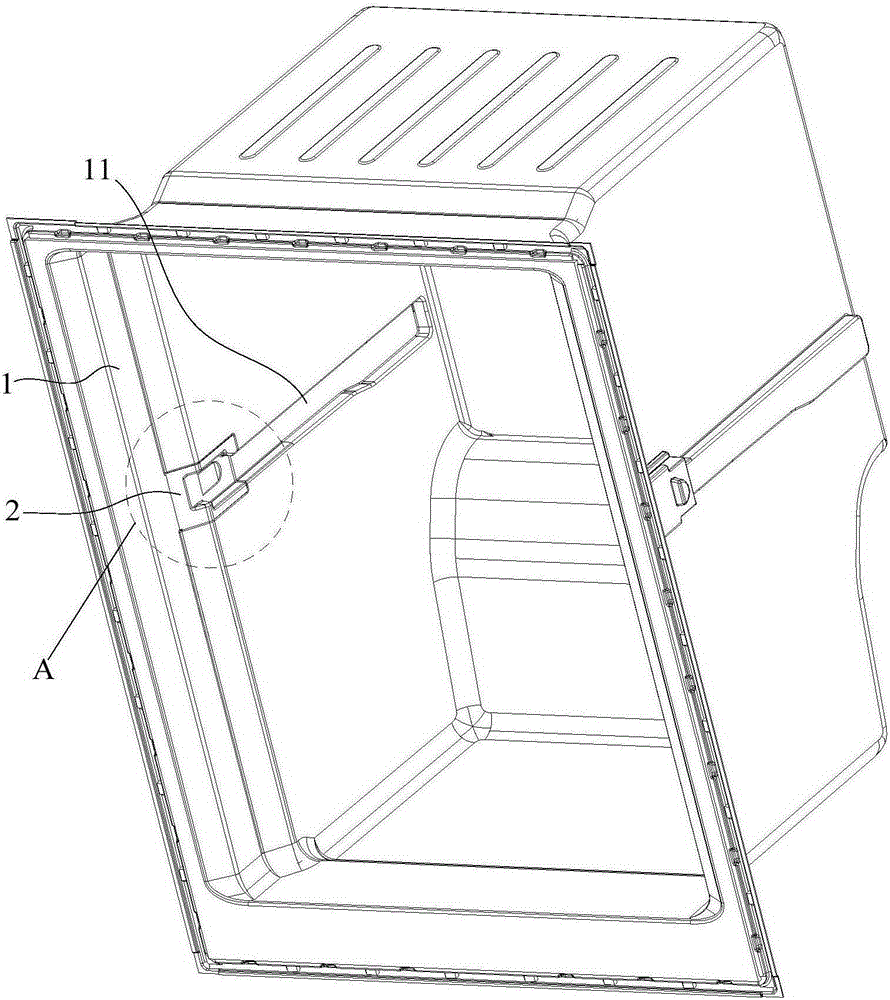

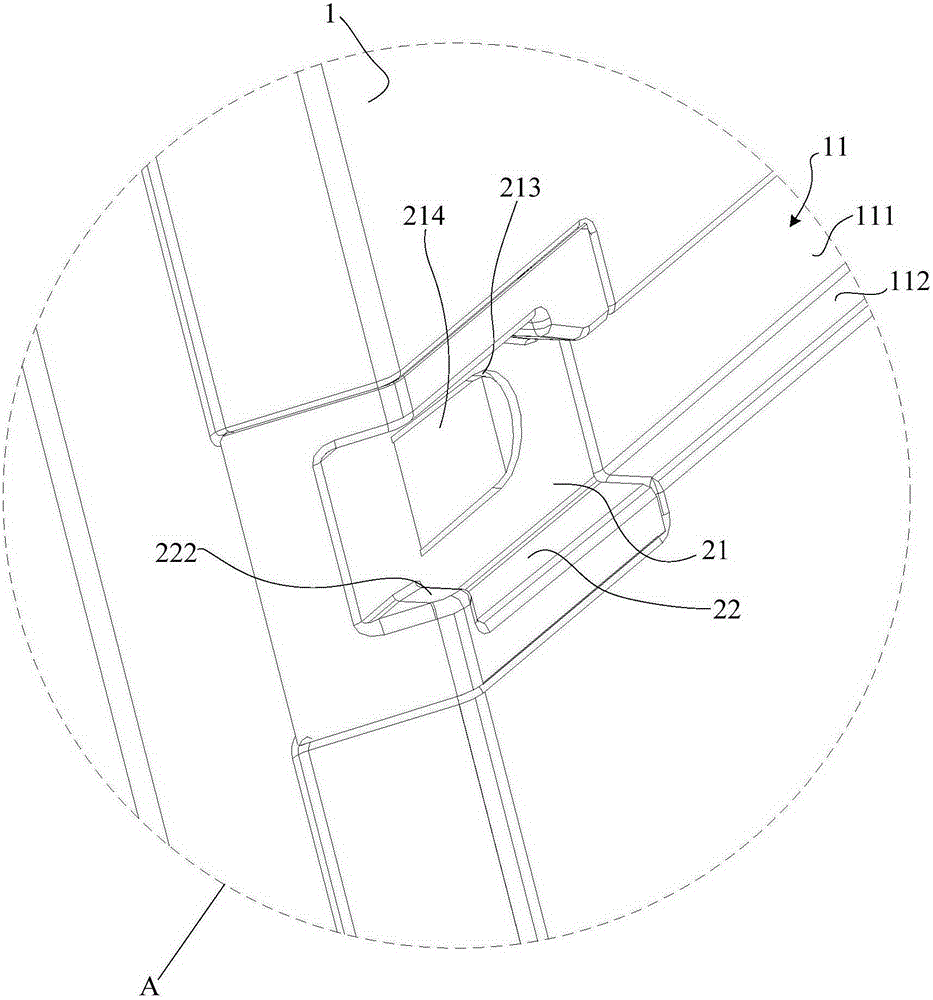

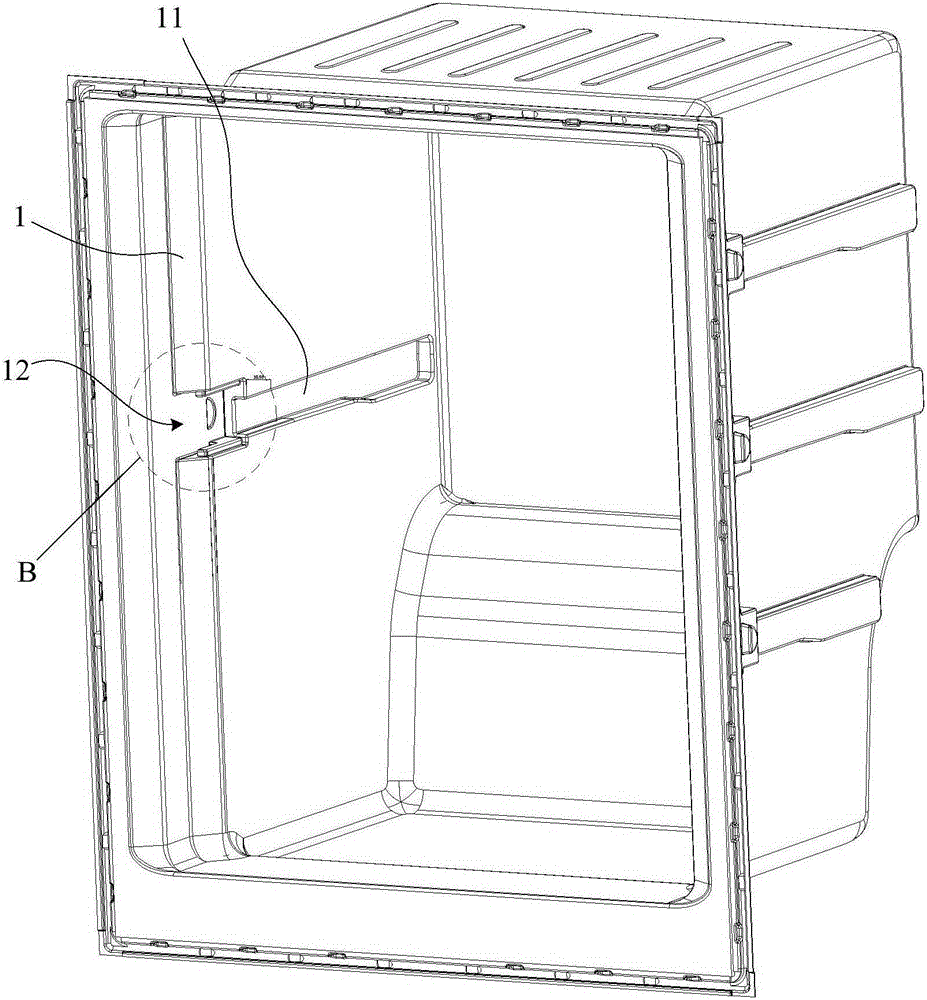

Sliding chute structure of drawer of refrigerator and refrigerator

ActiveCN105352259AEasy to assembleLess prone to wear and tearLighting and heating apparatusSupportEngineeringRefrigerated temperature

The invention discloses a sliding chute structure of a drawer of a refrigerator and the refrigerator. The sliding chute structure of the drawer of the refrigerator is used for being matched with a sliding rail of the drawer of the refrigerator. The sliding chute structure of the drawer of the refrigerator comprises a stop part and a sliding chute formed in an inner container of the refrigerator. The sliding chute is used for being in slidable fit with the sliding rail. The stop part is fixedly mounted on the inner wall surface of the inner container, arranged adjacent to an inlet of the sliding chute, and used for preventing the sliding rail from getting out of the sliding chute. According to the technical scheme, the sliding chute structure is not liable to fracture or abrasion, and the stop part is convenient to mount.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

Lipstick tube pattern printing device with drying function

InactiveCN112659743AImprove stabilityNot easy to moveCylinder pressesPlaten pressesPrinting inkConveyor belt

The invention belongs to the technical field of lipstick tube pattern printing, and particularly discloses a lipstick tube pattern printing device with a drying function. The lipstick tube pattern printing device comprises a rack, wherein support columns are arranged at the bottom of the rack; conveying wheels are rotationally connected to two ends of the rack; a conveyor belt coats the conveying wheels; a plurality of clamping grooves are arranged in the outer side of the conveyor belt; positioning mechanisms for fixing lipstick tubes are arranged in the clamping grooves; the rack is sleeved with a housing, and the bottom end of the housing is fixedly connected to the sides of the support columns; a lifting cylinder is arranged at the top of the housing, and the piston end of the lifting cylinder is inserted into the housing and fixedly provided with a printing head used for printing the lipstick tubes; and a drying mechanism is arranged at the bottom of an inner cavity of the housing and at the right side of the printing head. According to the lipstick tube pattern printing device, the lipstick tube is clamped between two clamping plates under the action of elastic sheets, the stability of the lipstick tube can be improved, and the lipstick tube is not prone to moving in the printing process; and through the arrangement of the drying mechanism, the printing ink can be rapidly air-dried, and the printing ink is not prone to being scratched.

Owner:安徽裕佳铝塑科技有限公司

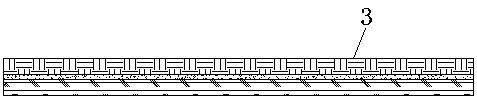

End lining plate for ball mill

The invention relates to an end lining plate for a ball mill. The end lining plate is provided with an end lining plate body, wherein a boss is arranged at the longitudinal center position of the end lining plate body; two 'Y'-shaped grooves are respectively formed in the two sides of the boss. The end lining plate for the ball mill is simple in structure and convenient to use, has good impact resistance and wear resistance, is unlikely to be broken, worn and deformed, and has small possibility of falling off; after the end lining plate is used, the production cost is lowered, the safety factor is increased, and the service life of the lining plate is prolonged.

Owner:顾开明

Moisture-absorbing and oil-resistant textile fabric

PendingCN110435247AImprove drynessImprove cleanlinessRubber layered productsEngineeringMoisture absorption

The invention discloses a moisture-absorbing and oil-resistant textile fabric. The fabric comprises a fabric body, an oil-stain-resistant layer is arranged on the inner surface of the fabric body, a moisture absorption layer is connected to the bottom of the oil-stain-resistant layer in an interwoven mode, an antibacterial layer is connected to the bottom of the moisture absorption layer in an interwoven mode, a breathable layer is arranged at the bottom of the antibacterial layer, and a protective layer is connected to the bottom of the breathable layer in an interwoven mode. The oil stain-resistant layer is arranged on the outer side of the moisture absorption layer, and thus oil stains can be blocked during use; meanwhile, moisture contained in the oil stains can be absorbed into the interior through the moisture absorption layer; and moisture in the moisture absorption layer can be quickly dissipated through the breathable layer, and thus the overall dryness of the fabric is improved, the cleanliness of the fabric can be guaranteed for a long time, the fabric has good applicability, the application range is widened, and meanwhile the problems that clothes, shoes, hats, gloves and the like made of fabrics are not attractive, cannot well remove oil stains after being contaminated by the oil stains and are poor in moisture absorption and breathability are solved.

Owner:苏州翰海纺织整理有限公司

Hydraulic cylinder sealing structure

ActiveCN102434672BIncrease the effective support lengthEasy to install and replaceEngine sealsHydraulic cylinderEngineering

The invention provides a hydraulic cylinder sealing structure, which comprises a guide ring (3) and a guide part (2) disposed close to the end of a hydraulic cylinder. A groove (8) is formed on the inner wall of the guide part (2), the guide ring (3) is arranged in the groove (8), and the internal surface of the guide ring (3) is attached to a piston rod (1). The position of the guide ring is moved backwards from the middle of the hydraulic cylinder to the end of the hydraulic cylinder so that effective support length of the guide ring toward the piston rod is prolonged and the guide ring is led to be easier to demount, replace and install.

Owner:HUNAN TELI HYDRAULIC

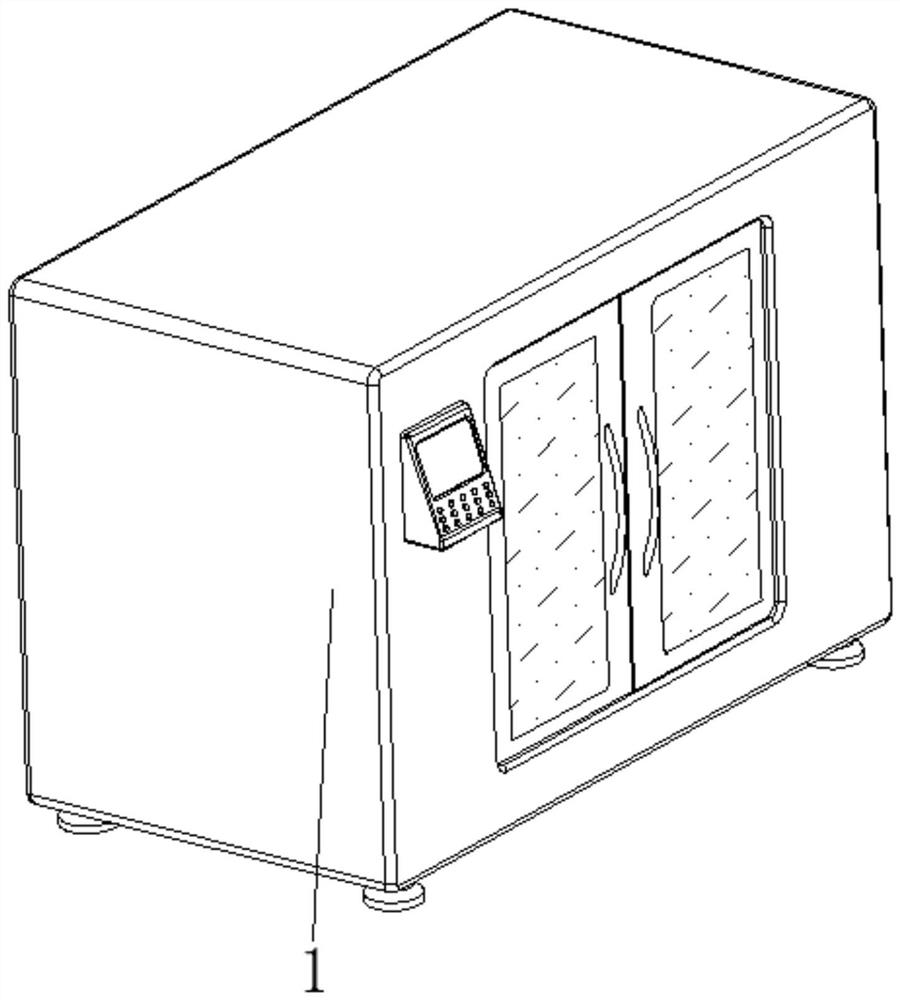

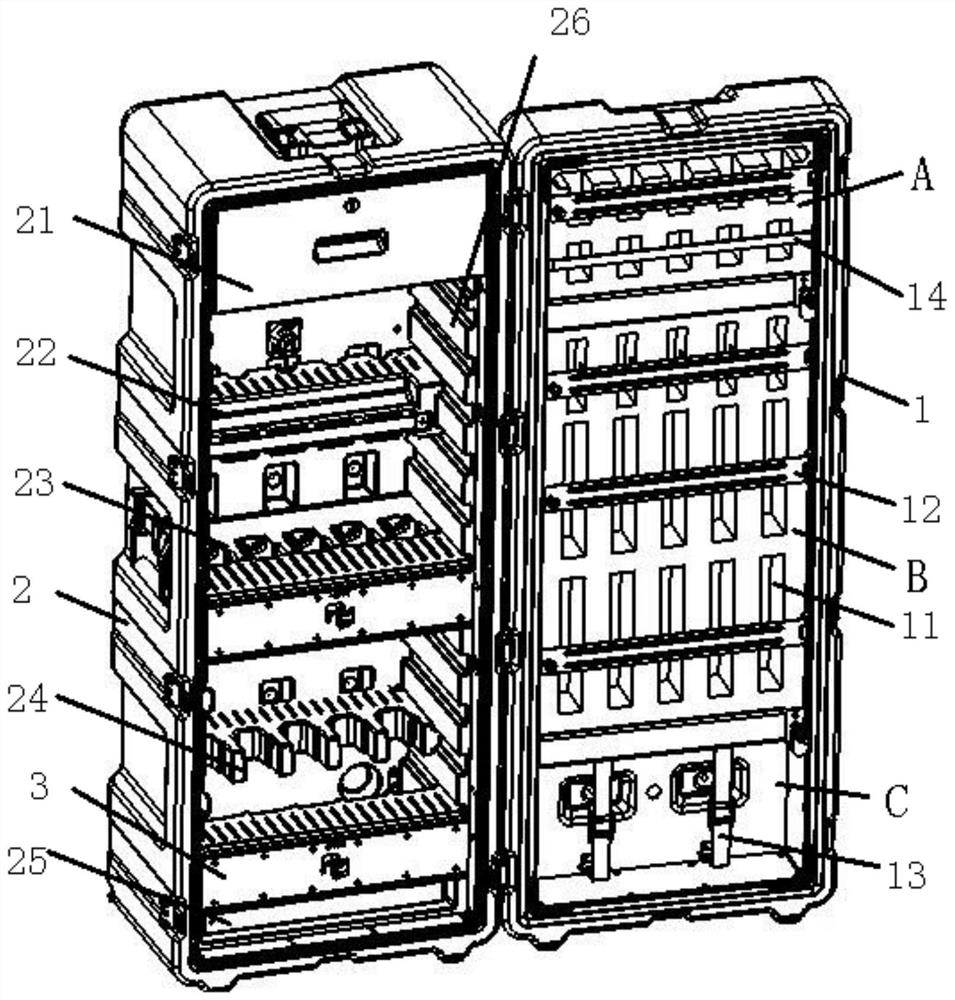

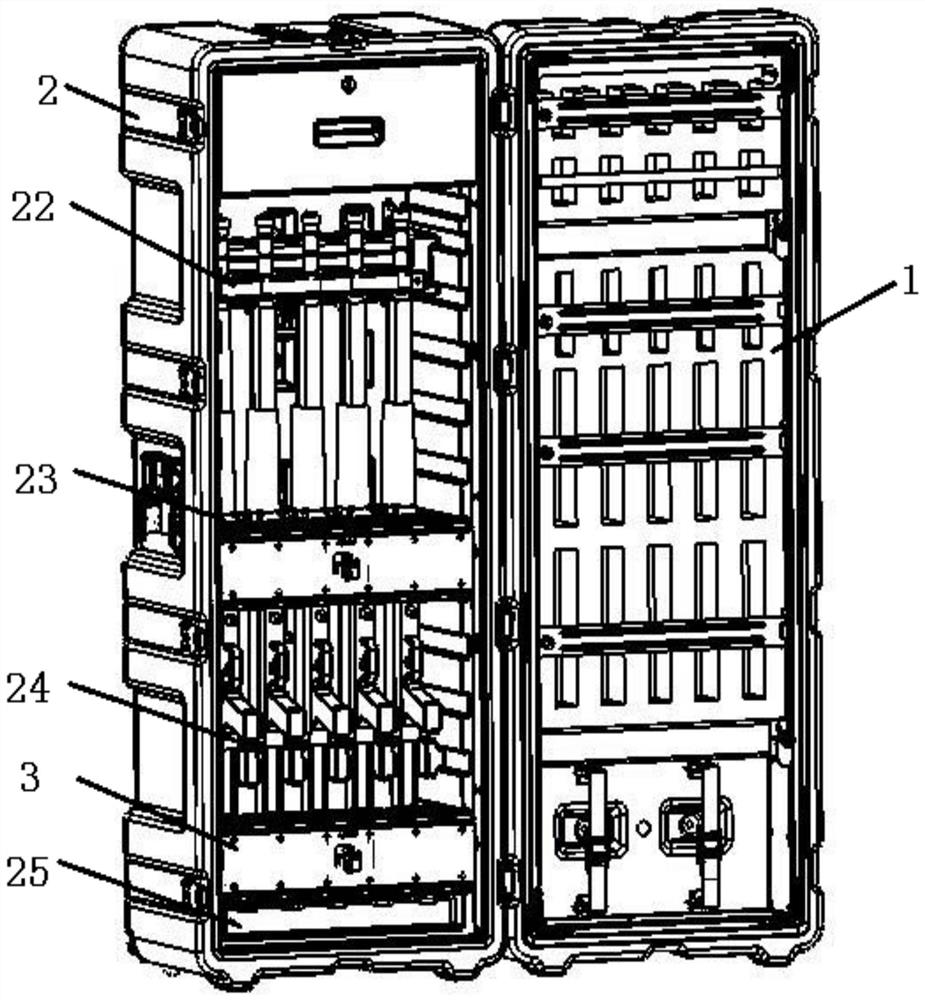

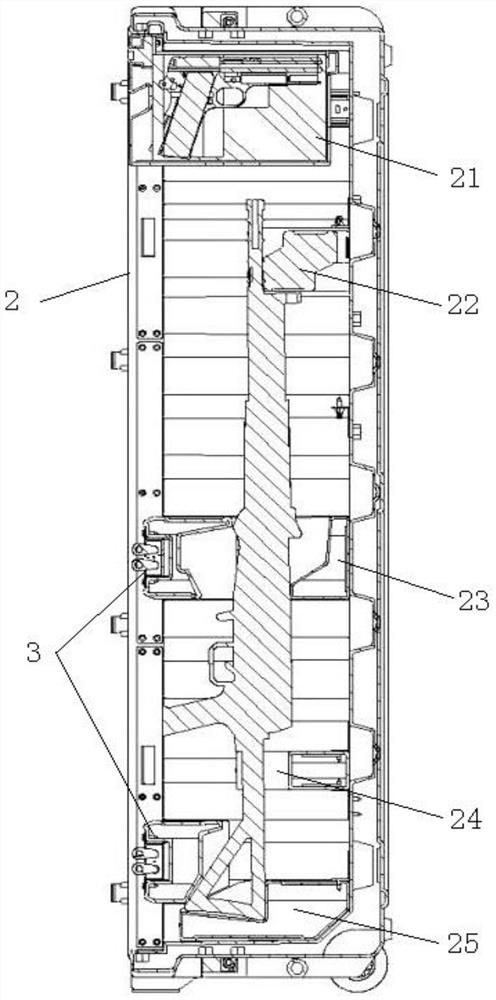

Ordnance packaging device

The invention relates to a packaging box, in particular to an ordnance packaging device, and aims to solve the problems that when an existing packaging box is used, the packaging stability effect is poor, and the function application range is small. According to the technical scheme, the ordnance packaging device comprises a box door and a box body, wherein the box door is arranged on the box body through a locking assembly and a connecting assembly; N storage areas and limiting assemblies are arranged on the inner side of the box door, N is larger than or equal to 2, and a plurality of storage grooves are formed in each storage area; the limiting assemblies are arranged on each storage area; a storage box, a gun barrel clamping piece, a gun body clamping piece, a gun stock clamping piece and a gun base clamping piece are sequentially arranged in the box body from top to bottom, and the gun barrel clamping piece, the gun body clamping piece, the gun stock clamping piece and the gun base clamping piece are used for clamping and fixing a gun barrel, a gun body, a gun stock and a gun base of a gun respectively; and mortise lock clamping pieces are arranged right in front of the gun body clamping piece and the gun stock clamping piece and used for limiting, clamping and fixing the gun.

Owner:XIAN KUNLUN IND EQUIP SUPPORTING CO LTD

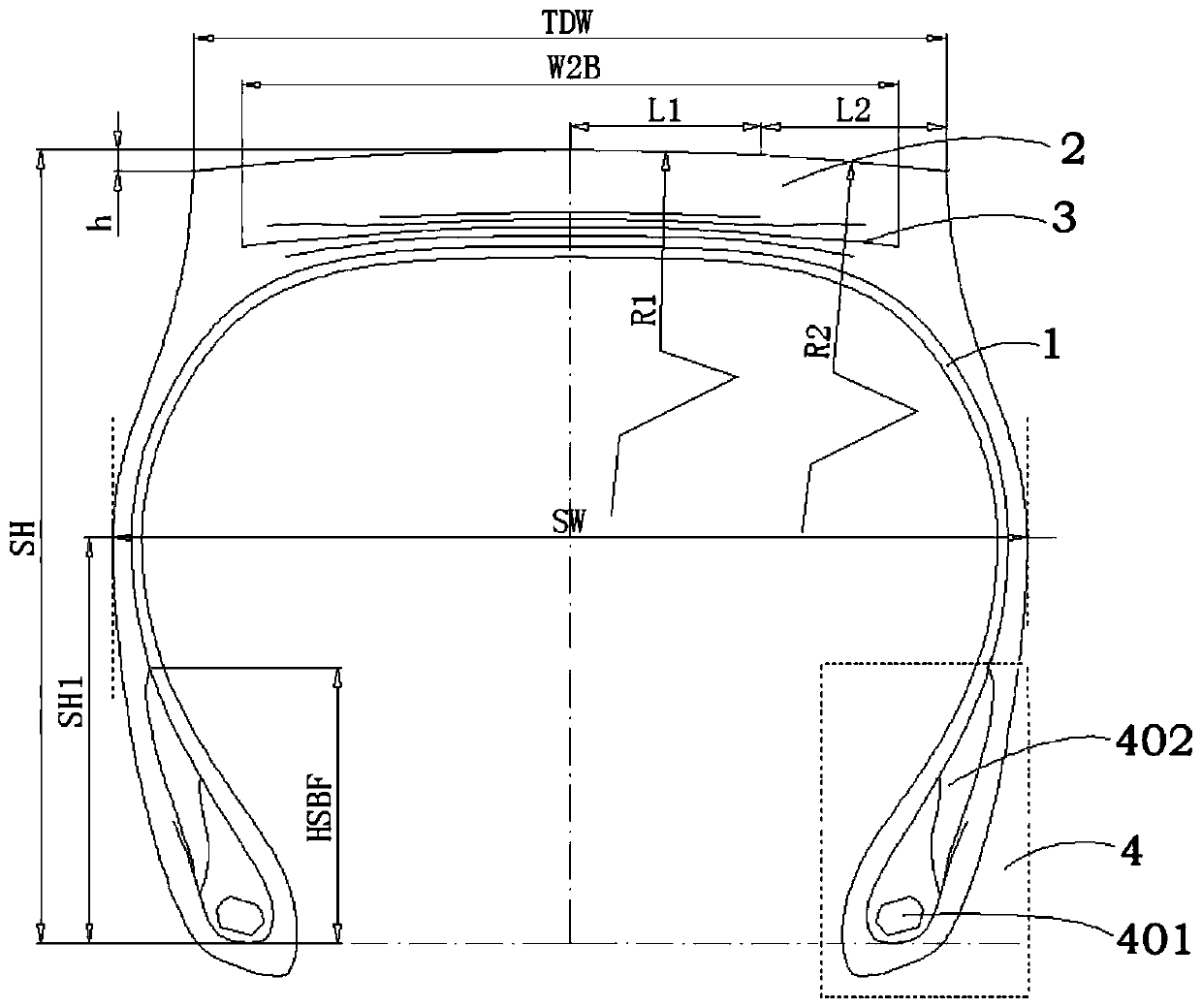

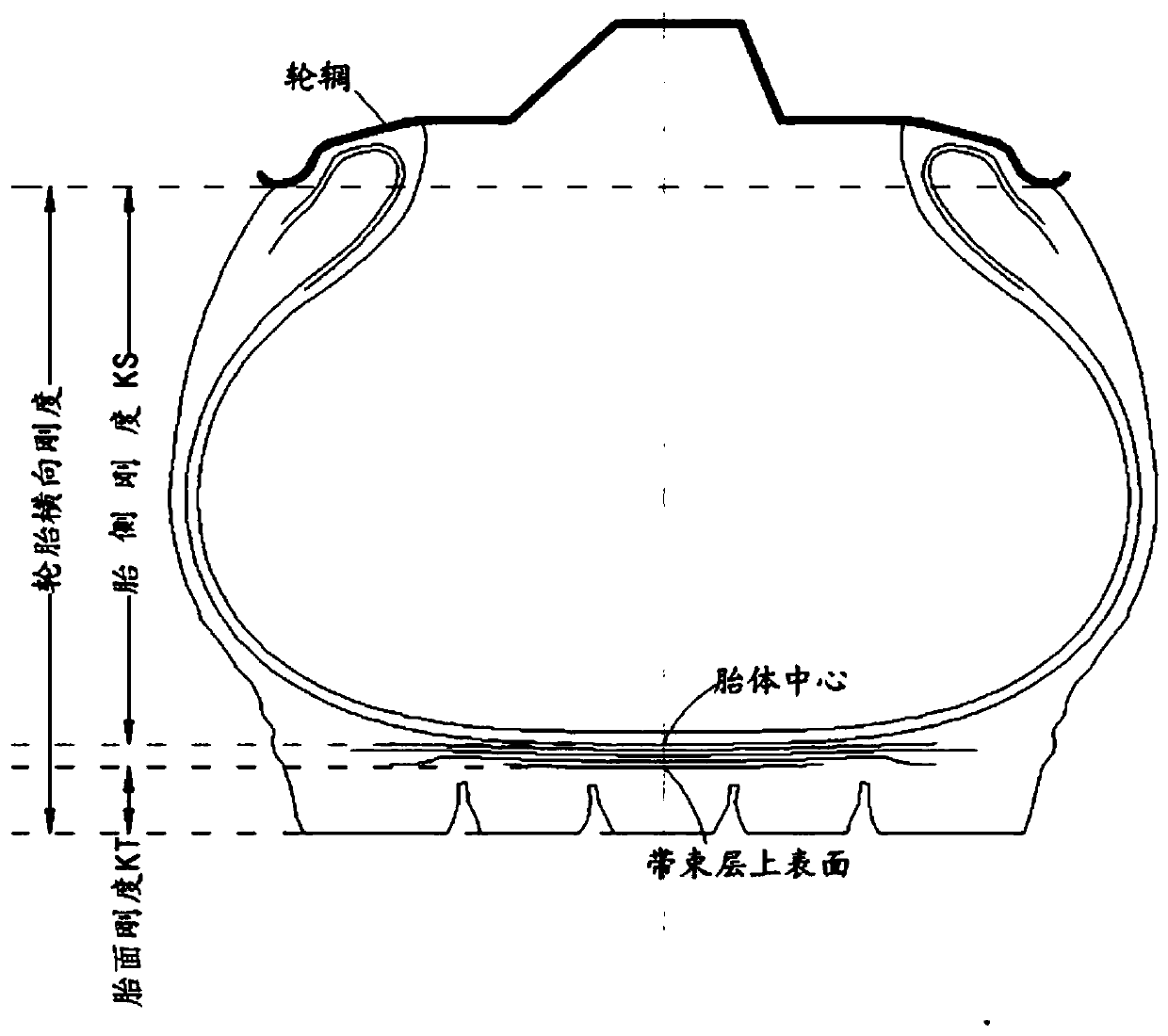

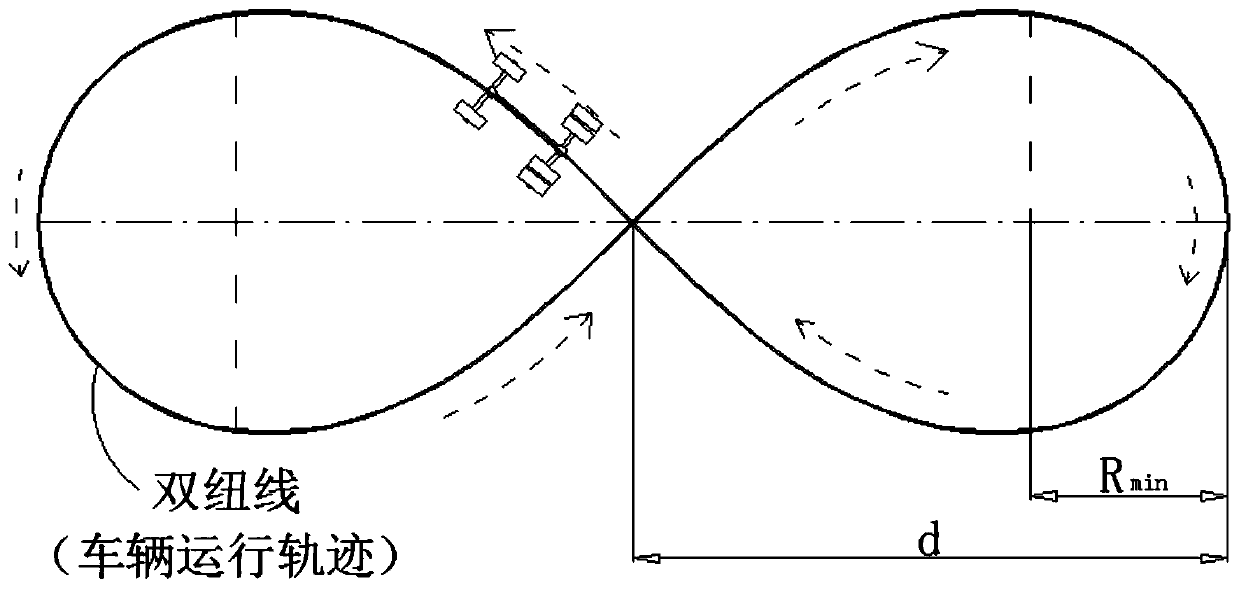

Radial tire capable of resisting transverse slip wear of tire

ActiveCN111016545ALess prone to early failureImprove wear lifeTyre tread bands/patternsRoad surfaceControl theory

The invention provides a radial tire capable of resisting transverse slip wear of a tire. The radial tire comprises a tire body and a tire tread coating the outermost periphery of the tire body in a radial direction. The tire tread comprises a tire crown and tire shoulders. The tire crown contour of the tread is sequentially divided into a first section of crown arc and a second section of crown arc on the section of the meridian of the tire from the intersection point of the equatorial plane of the tire and the contour of the tread to the starting part of the tire shoulder. The outer diameterR1 of the first section of crown arc and the outer diameter R2 of the second section of crown arc have a relationship: R1 / R2 is larger than or equal to 1.2 and is less than or equal to 1.6; the arc length L1 of the first section of crown arc and the arc length L2 of the first section of crown arc have a relationship: L1 / L2 is larger than or equal to 0.8 and is less than or equal to 1.8; and the fall h of the tire shoulder on the meridian section of the tire and the tread width TDW have a relationship: h / TDW is larger than or equal to 0.02 and is less than or equal to 0.035. According to the radial tire capable of resisting transverse sliding abrasion of the tire, the effective contact area between the tread and the road surface is increased, and the transverse rigidity of the tread is improved; and thus, the tread is not easy to transversely slide when being stressed by a transverse force, so that the transverse abrasion is reduced.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

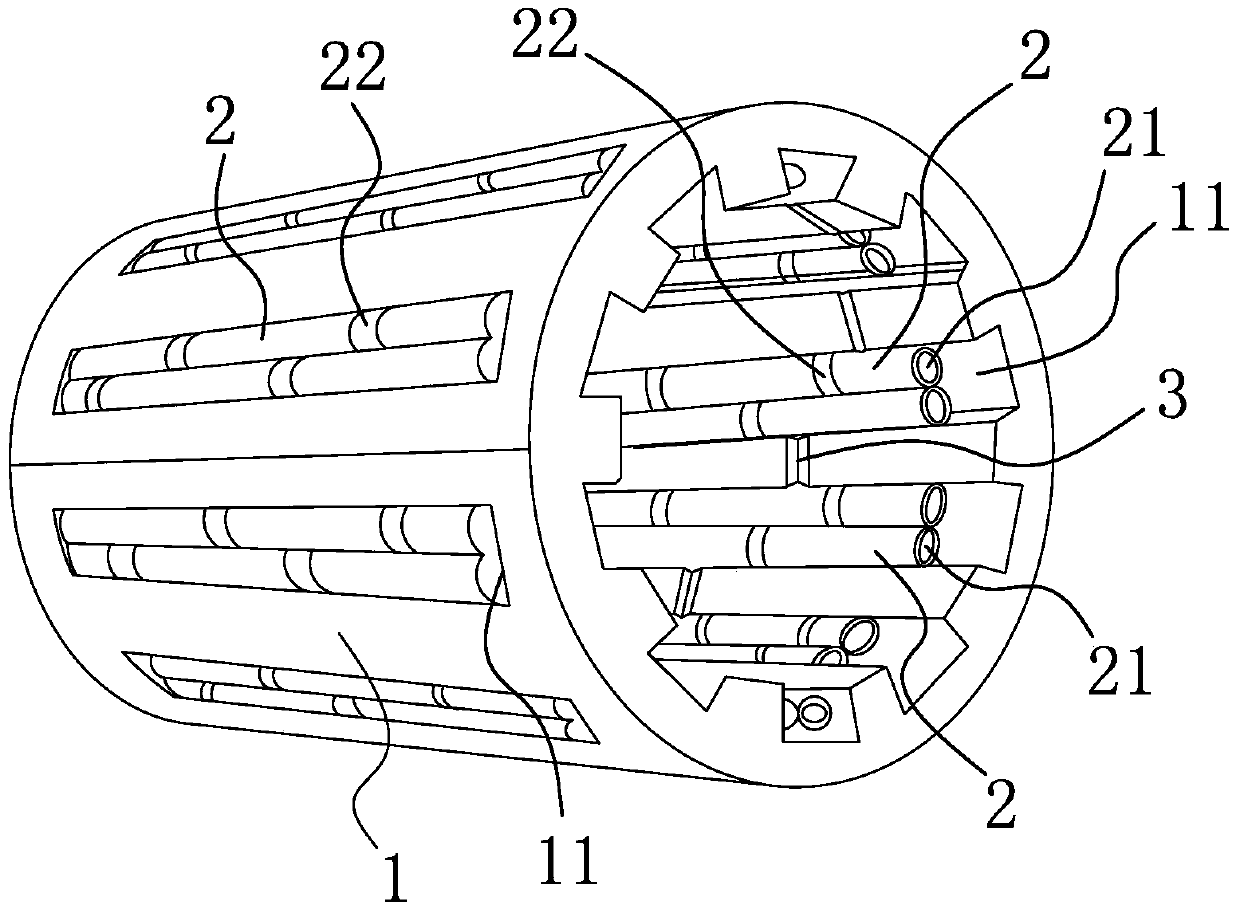

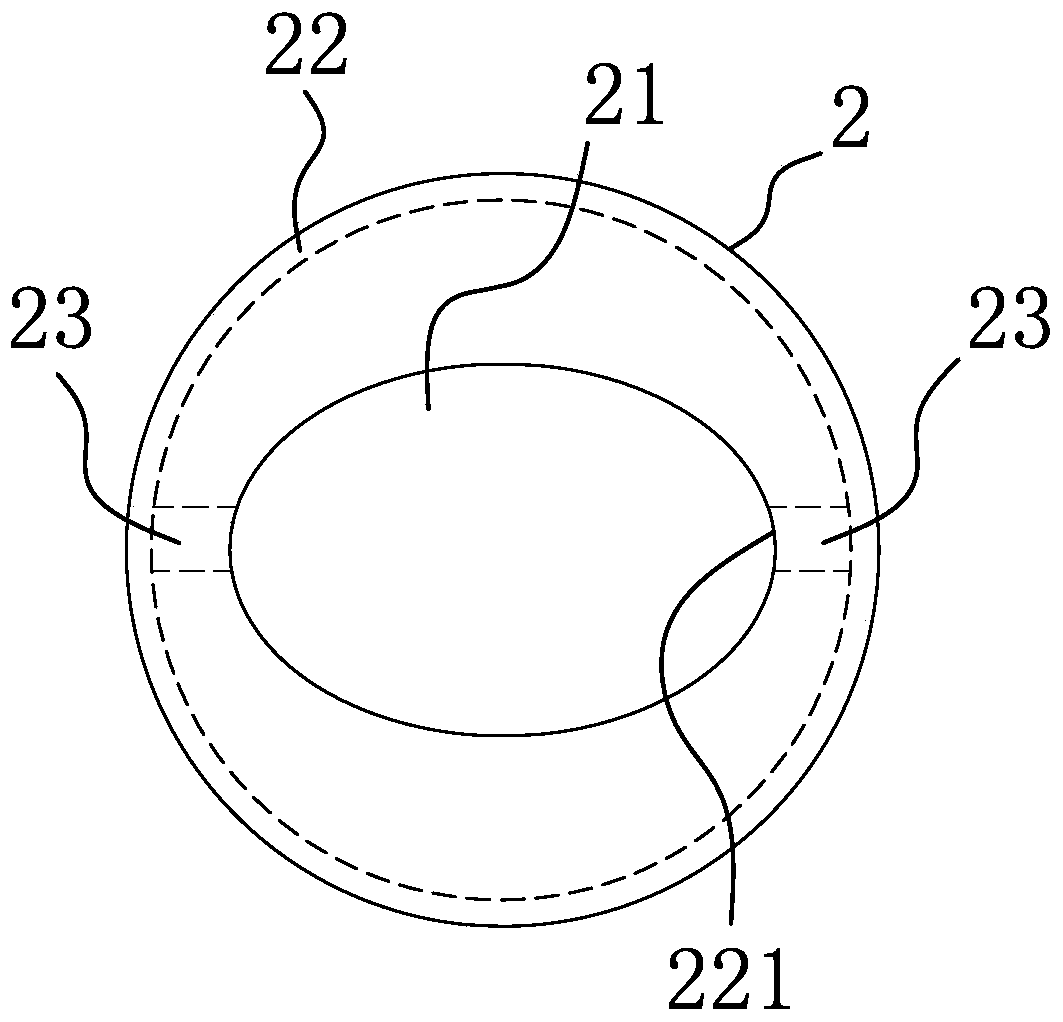

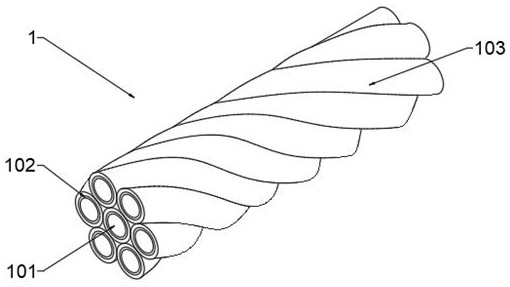

Needle Roller Mounting Structure for Needle Roller Bearings

ActiveCN104895937BSmooth rotationLess prone to wear and tearBearing componentsNeedle roller bearingLubrication

The invention relates to a needle roller installation structure of a needle roller bearing. It solves the technical problems such as the poor installation stability of the existing needle roller bearings and the like. It includes a needle roller cage body and a holding groove. There are at least two needle roller bodies in each holding groove. The body is cylindrical, and there is a non-circular through hole extending along the axial direction of the needle body in the needle body and having a cross-section with at least two protrusions, and several annular grooves are arranged on the circumferential outer side of the needle body , the annular grooves are distributed sequentially along the axial direction of the needle roller body and the annular grooves on two adjacent needle roller bodies are alternately arranged one by one. oil hole. The advantages are: more reasonable design, simple structure, good installation stability, less shaking, smooth needle rotation, less wear and tear, and good needle lubrication.

Owner:浙江昕兴科技有限公司

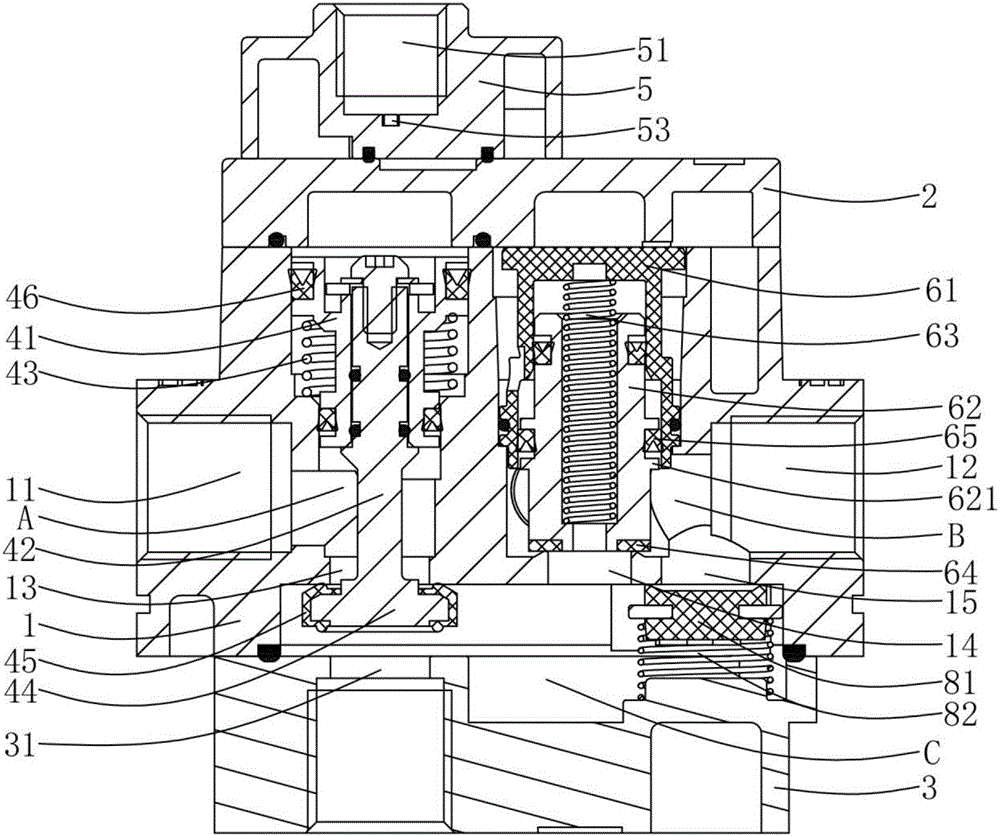

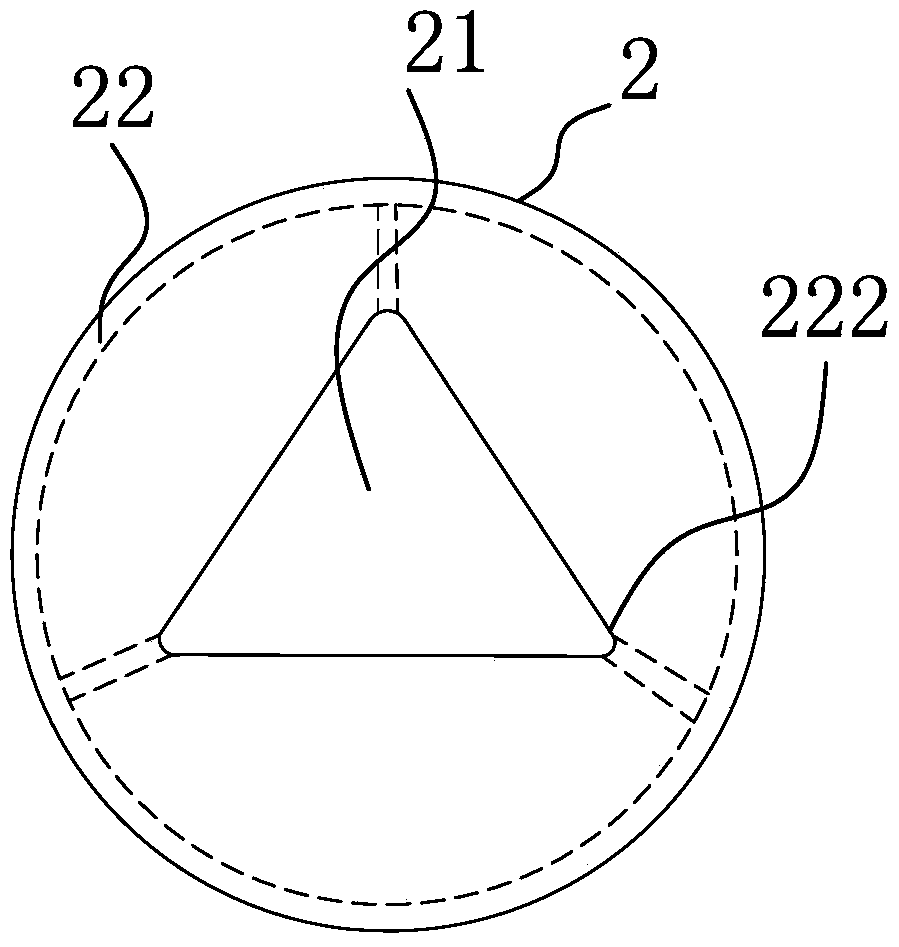

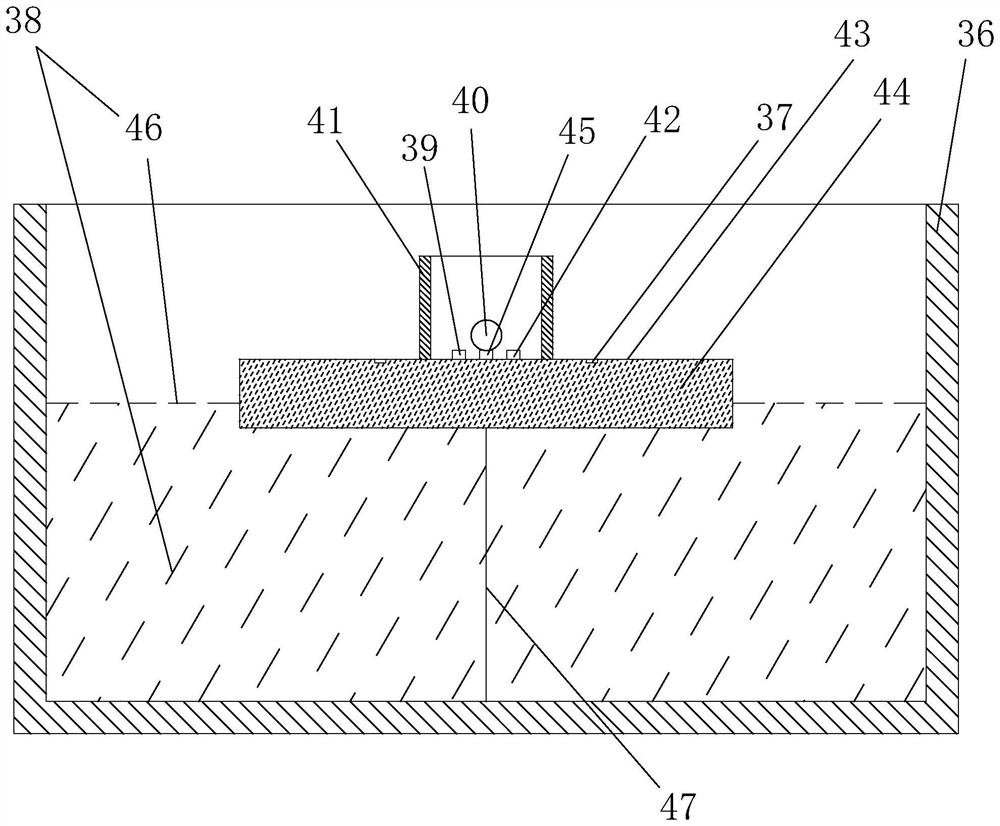

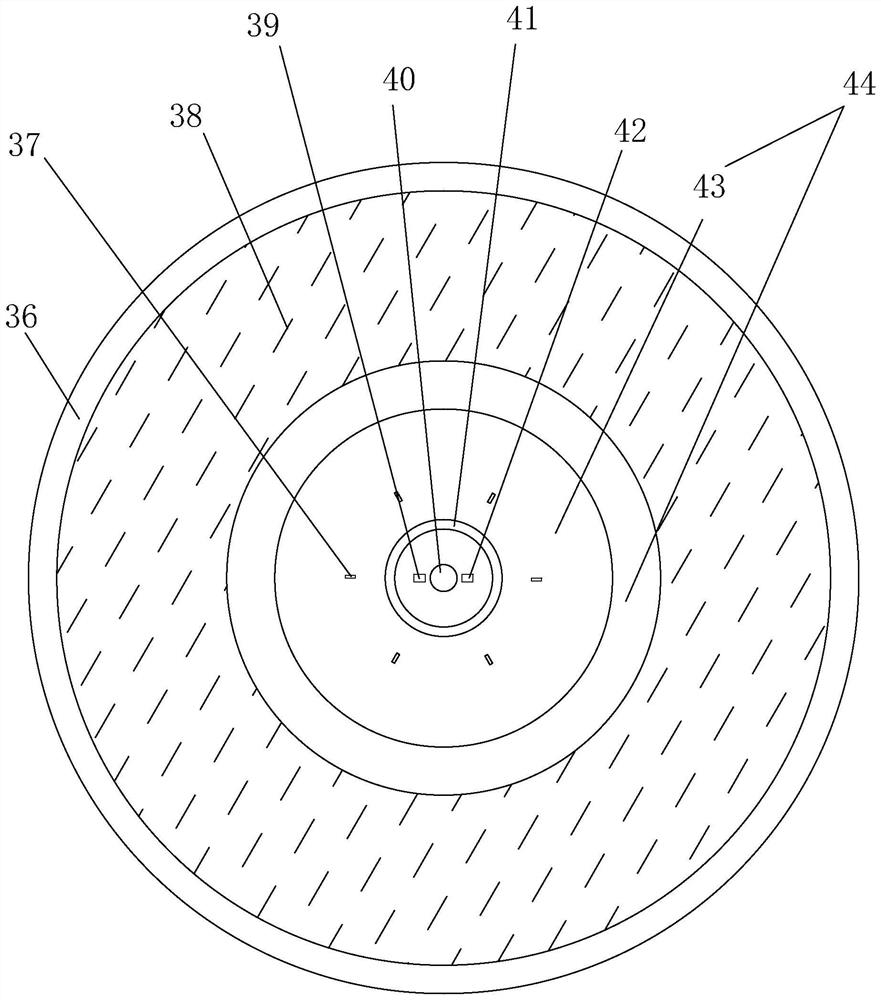

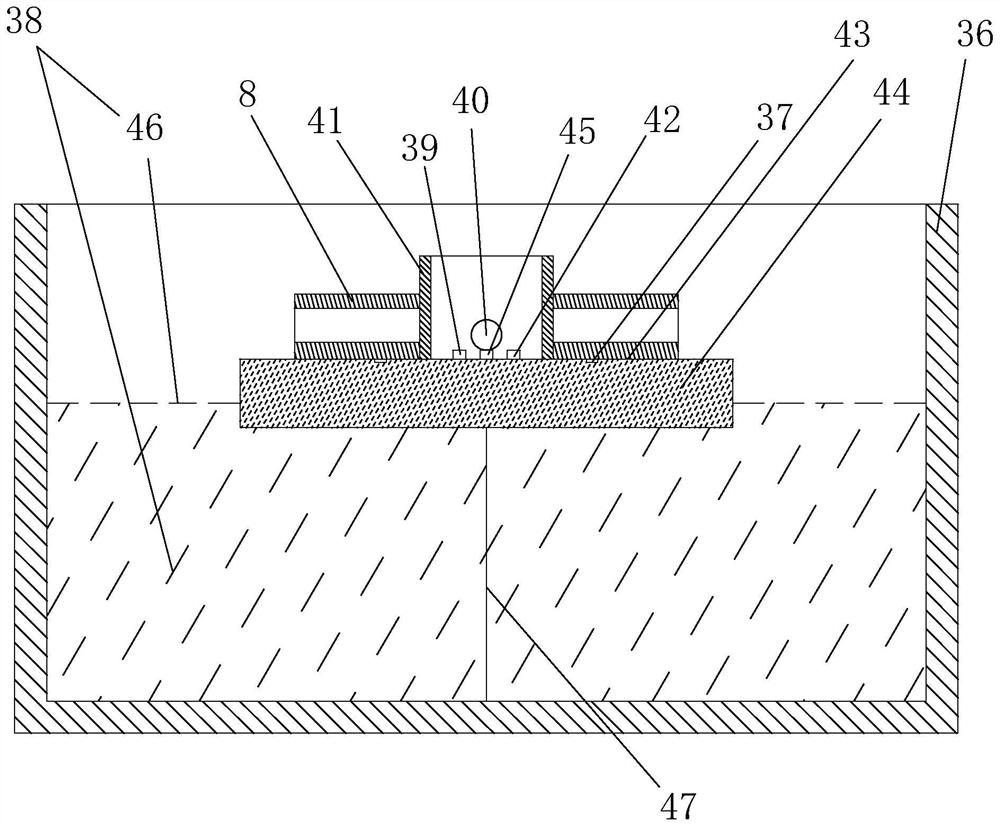

Ball cage cage, precision automatic quick inspection system and detection method of ball cage cage

ActiveCN111678495BExtended service lifeLess prone to wear and tearYielding couplingAlarmsProximity sensorStructural engineering

The invention discloses a ball cage cage, an automatic quick inspection system for the accuracy of the ball cage cage and a detection method thereof, and belongs to the technical field of ball cage cages. It is easy to detect whether the main body of the ball cage cage is qualified, including the controller, memory, voice prompter, pool filled with water, and a circular horizontal floating plate that can float on the water surface in the pool; fixed on the bottom surface of the pool Pull wire, the upper end of the pull wire is fixedly connected to the center of the lower surface of the circular horizontal floating plate; a circular tube is fixed vertically upward at the center of the circular horizontal floating plate, and a level detection sensor is fixedly installed in the circular tube; The tube center line of the tube is the center, and the annular area located outside the circular tube is the detection placement area, and several proximity sensors are evenly distributed on the upper surface of the circular horizontal floating plate in the detection placement area; each proximity sensor, horizontal detection The sensor, memory and voice prompter are respectively connected with the controller.

Owner:杭州杭海实业有限公司

Method of wire explosion spraying executed directly by powder material

The method of discharge-induced explosion directly by powder material designed in the invention comprises: attaching powder material to metal explosion material; causing high density electric energy to discharge to the conductive metal explosion material in heavy impacting current mode by a charging capacitor to cause the metal explosion material together with the powder material to melt, explode,form mixed particle jet flow, and jet to a base to form coating. The obtained metal-base composite material coating is composed by metal and powder materials with bonding effect, instead of the conventional layered structure composed by different materials; has the advantages of compact, fine particles, low voidage, high bonding strength, and almost no delaminate wear appearing in the wearing process. The powder material on the metal explosion material is generally hard particles which increases the coating wear resistance; and the metal base body coated by the metal explosion material is relatively soft, can bear a certain degree of plastic deformation, and achieves a better 'soft base + hard phase' characteristic combined with hard particles.

Owner:机械科学研究院浙江分院有限公司

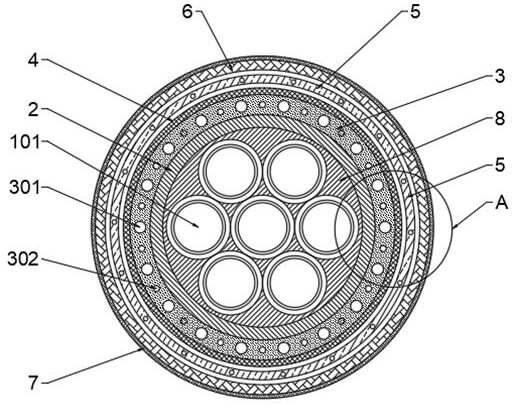

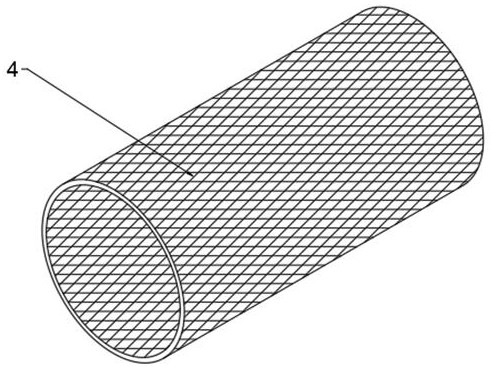

High-flame-retardant multi-layer cable

InactiveCN114068083AAvoid bitesImprove the protective effectInsulated cablesAnimal repellantsFiberEngineering

The invention discloses a high-flame-retardant multilayer cable. The cable comprises a cable core main body and an auxiliary mechanism, a first flame-retardant mechanism is arranged outside the cable core main body, a second flame-retardant mechanism is arranged outside the first flame-retardant mechanism, the auxiliary mechanism is composed of a metal net pipe, an inner sleeve, latex paint and mint fibers, the metal net pipe sleeves the cable core main body, the outer wall of the metal net pipe is sleeved with an inner sleeve, the outer wall of the inner sleeve is coated with the latex paint, and the latex paint is filled with the mint fibers. Through the arrangement of the metal net pipe, the inner sleeve, the latex paint and the mint fibers, a mouse can bite the inner sleeve coated with the latex paint when biting the cable, and the mouse cannot quickly damage the metal net pipe due to the fact that the toughness of the metal net pipe is high; at the moment, mint factors in the mint fibers can emit thick mint smell through the bite part of the cable, so that the mouse which bite the metal net pipe are repelled, and the protection performance of the cable is improved.

Owner:温桂华

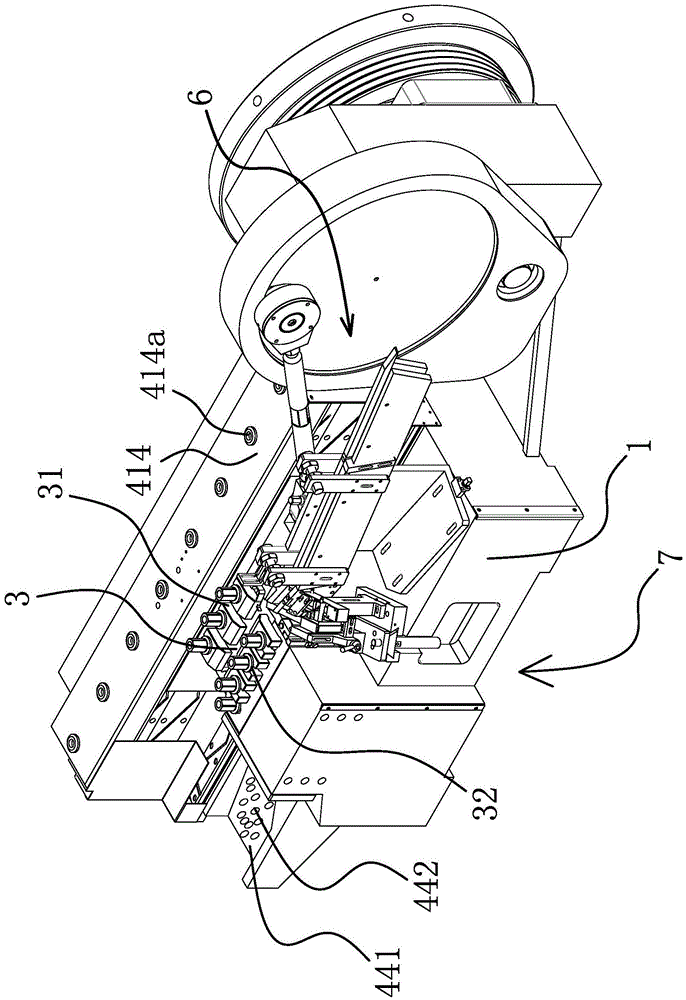

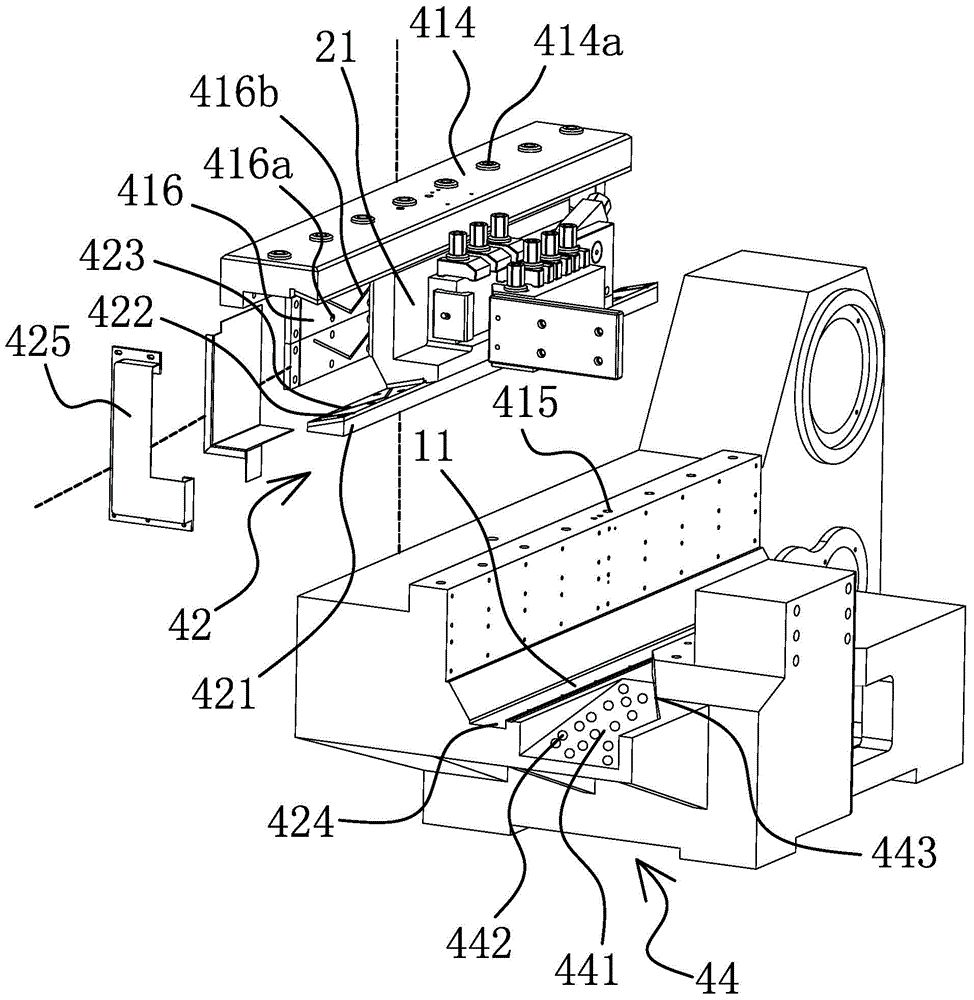

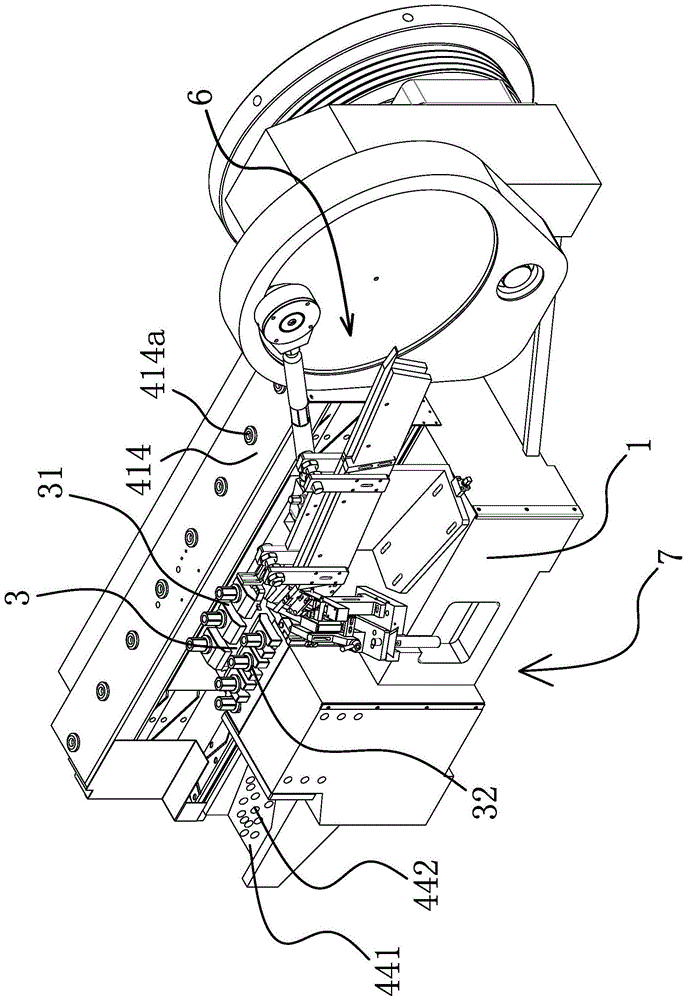

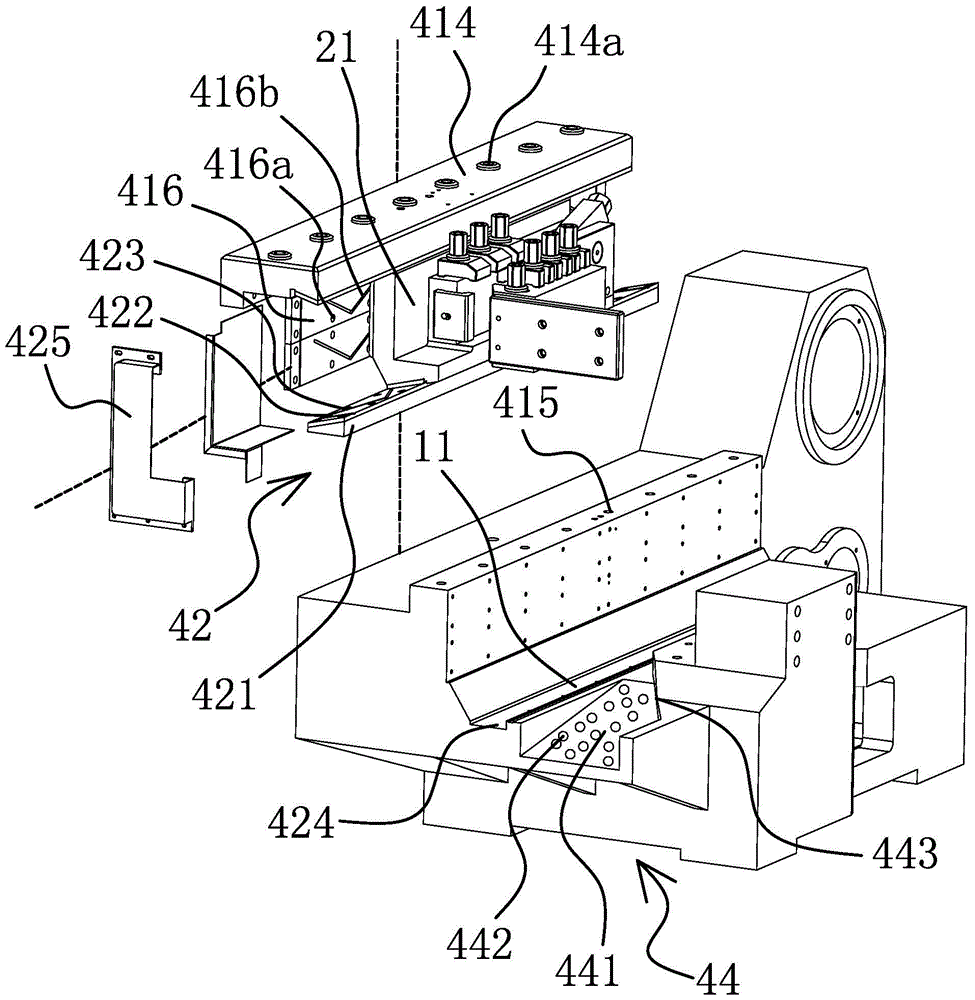

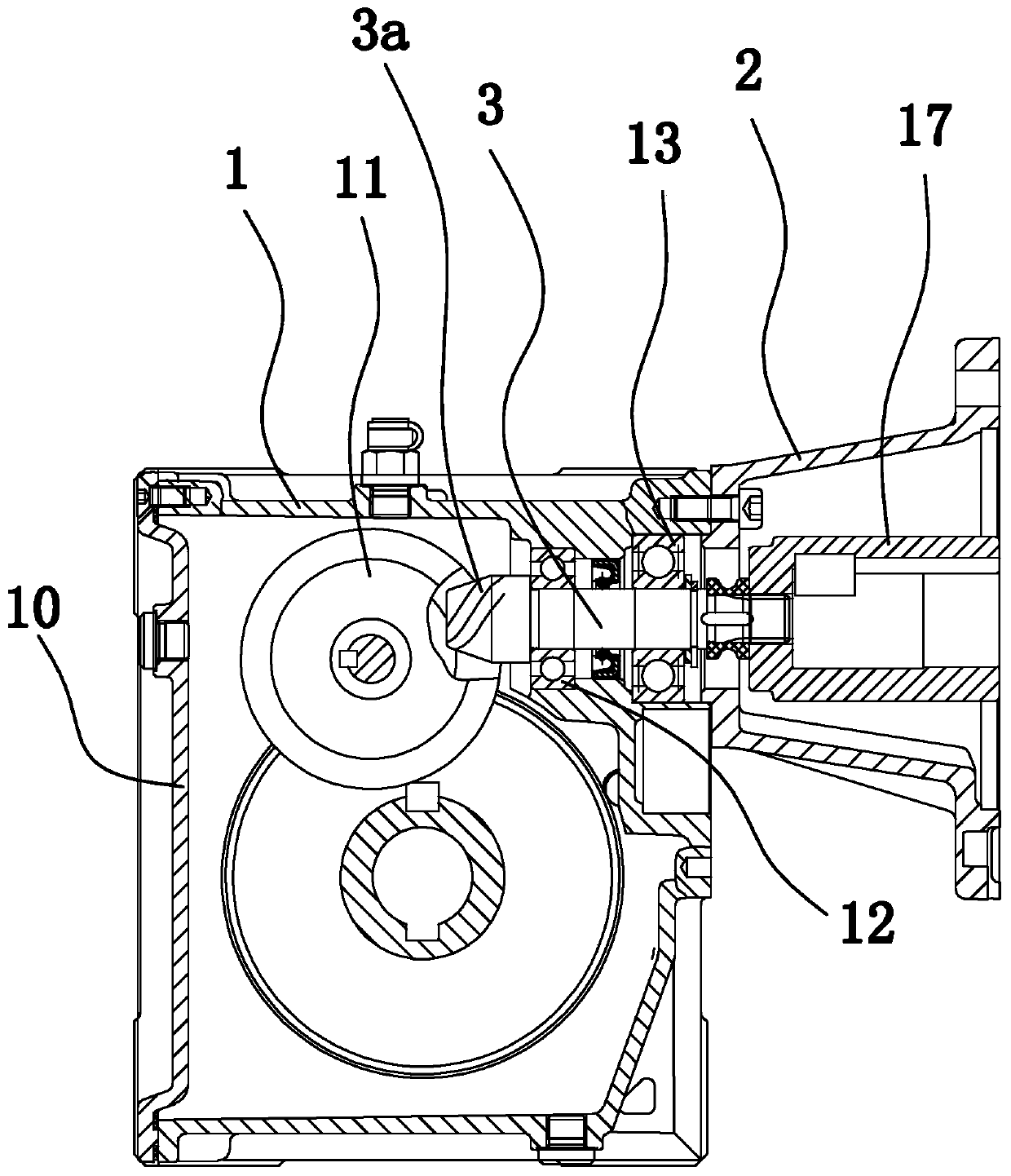

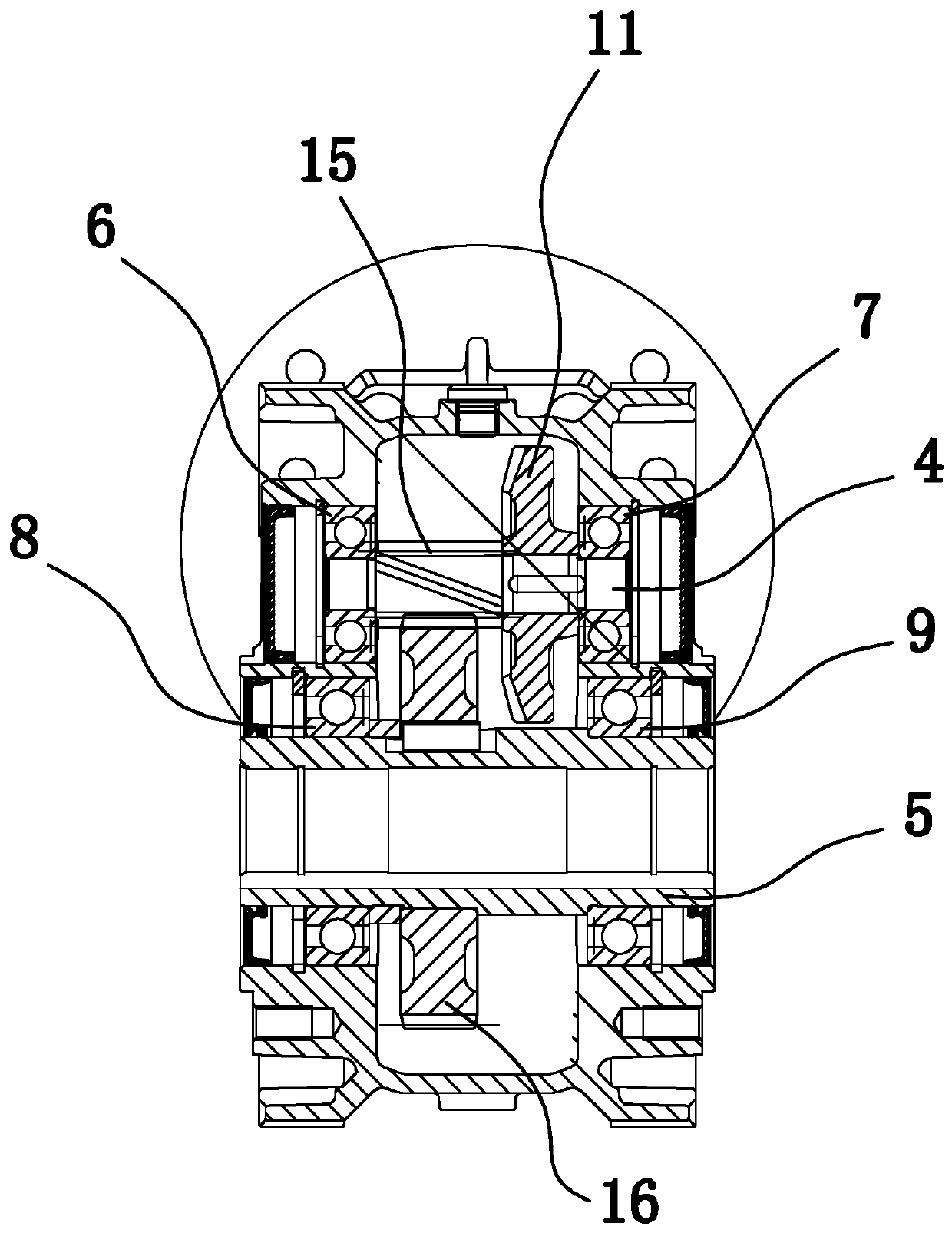

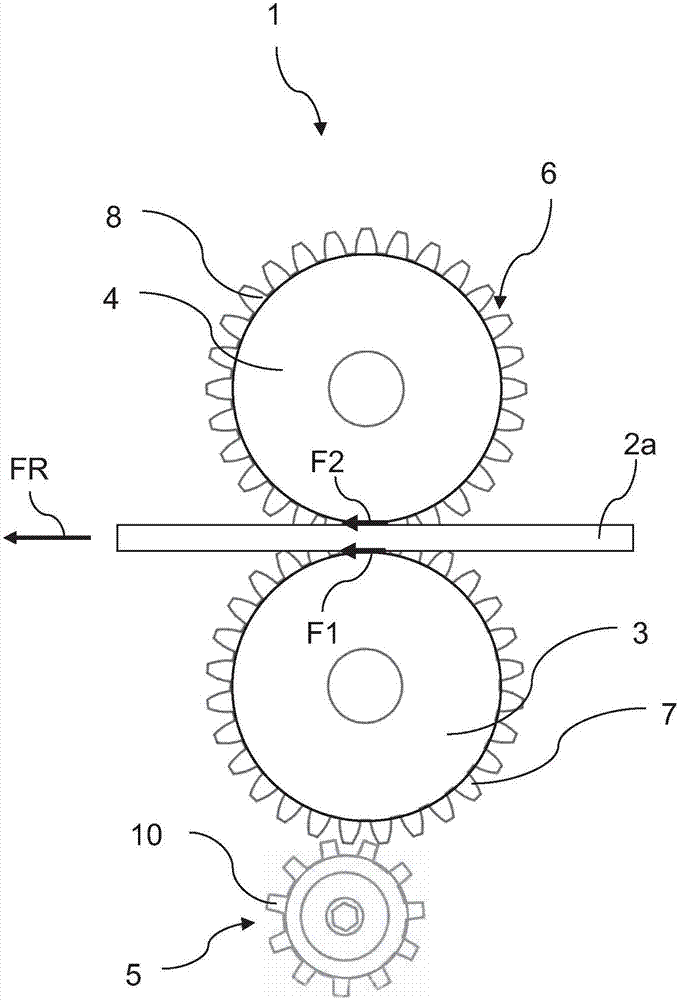

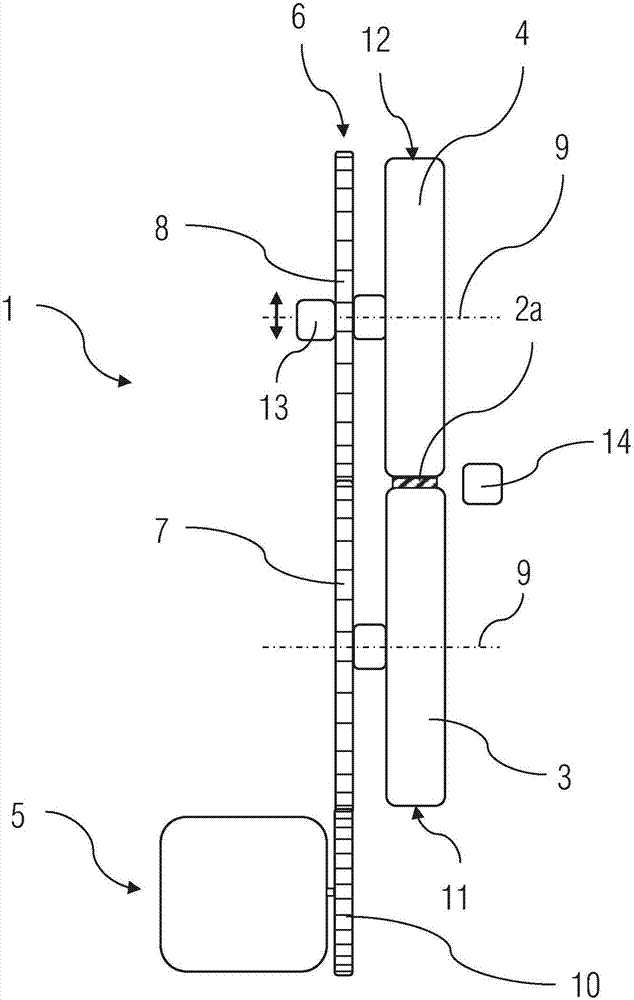

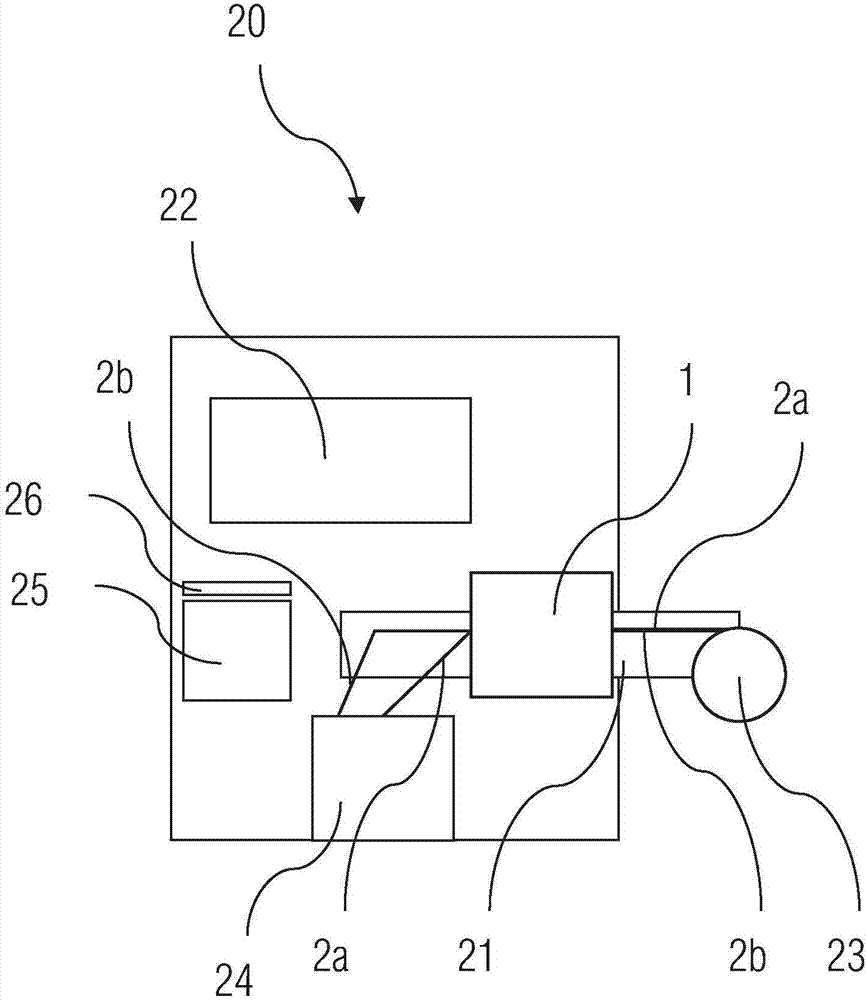

Filling device and automatic placement machine

InactiveCN107396544AReduce mechanical loadHigh transmission powerPrinted circuit assemblingElectrical componentsSurface mountingEngineering

The invention relates to a filling device (1) for removing a coating (2a) on a surface mount device conveyor belt (2b) from a surface mount device conveyor belt (2b), having a first filling gear (3) and a The relative mounting between the second filling gear (4), the first filling gear (3) and the second filling gear (4) enables the coating (2a) to be clamped between the first filling gear (3) and the second (4) and can be transported by the rotation of the first filling gear (3) and the second filling gear (4) while the filling device (1) also has a driving device (5) A filling gear (3) and a second filling gear (4) of the driving force. The first filling gear and the second filling gear are mechanically connected to the driving device such that the driven first filling gear and the driven second filling gear are mechanically connected to each other, A conveying force (F1, F2) of one transportable coating (2a) can be generated for the coating (2a). In addition, the invention also relates to an automatic placement machine (20) with a filling device (1) according to the invention for placement of a circuit board and an electronic component.

Owner:ASM ASSEMBLY SYST GMBH & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com