Method of wire explosion spraying executed directly by powder material

A powder material, electric explosion technology, applied in the field of electric explosion spraying, can solve the problems of poor wear resistance and erosion resistance, and achieve the effect of dense coating, low porosity, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

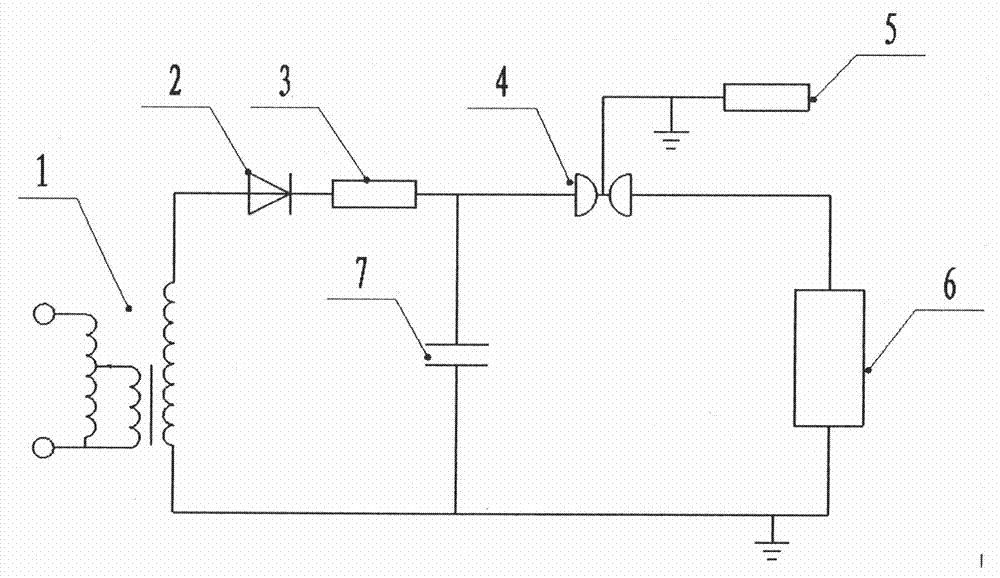

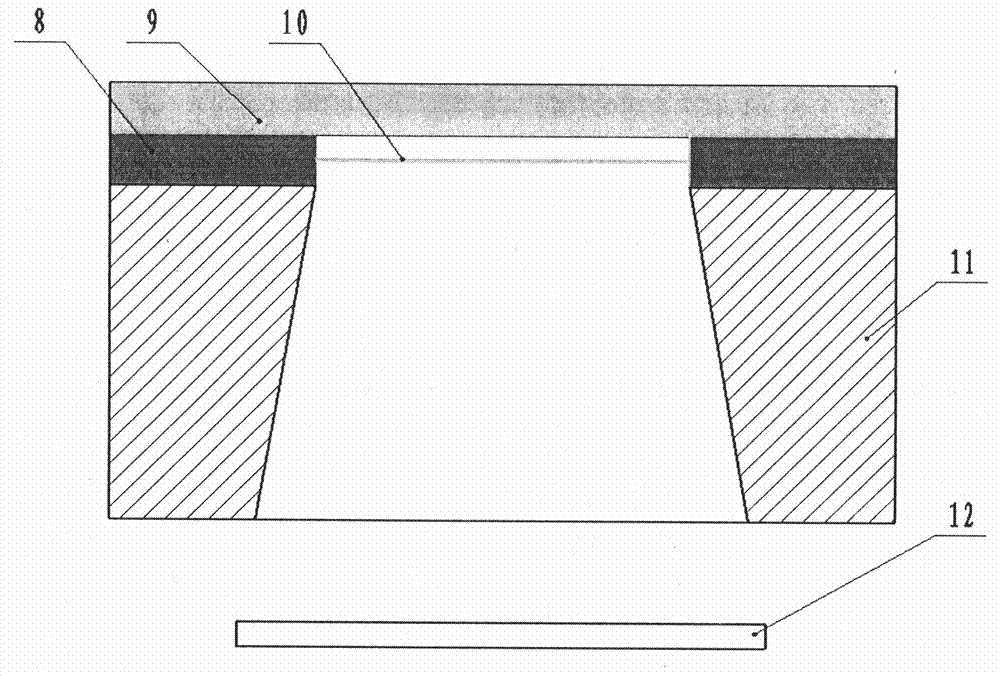

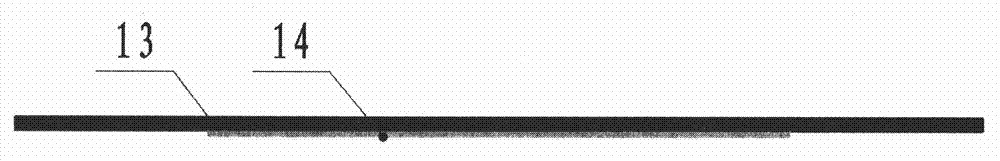

[0016] Such as figure 1 , figure 2 As shown, in the method of direct electric explosion spraying with powder materials described in this embodiment, the spraying equipment is mainly composed of a transformer 1, a three-electrode switch 4, a spray chamber 6, a pulse capacitor 7 and an explosive material 10 containing metal. At first on one side of the metal explosive material 10 of certain specification, paste powder material 14 with glue, this powder material 14 is cemented carbide powder, and fully dries, makes metal explosive material 10 such as image 3 Shown; then do sandblasting to the surface of substrate 12 that needs to be sprayed, and prepare substrate 12; then the metal explosive material 10 that is bonded with powder material 14 after drying is placed between two electrodes 8 of spray chamber 6, And let the side that is glued with powder material 14 face toward spout; Charge certain electric energy to pulse capacitor 7 then, conduction three motor switch 5, will p...

Embodiment 2

[0018] Such as Figure 5 As shown, the electric detonation spraying material described in this embodiment is used for the method of directly performing electric detonation spraying with powder materials, which mainly includes a metal substrate 13, on which a powder material 14 is adhered through glue. The metal substrate 13 is a filamentous structure. The powder material 14 is ceramic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com