Numerical control machine tool

A technology of CNC machine tools and racks, which is applied in the field of CNC machine tools, and can solve problems such as easy deformation, longitudinal deviation, and fracture of the side walls of slide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

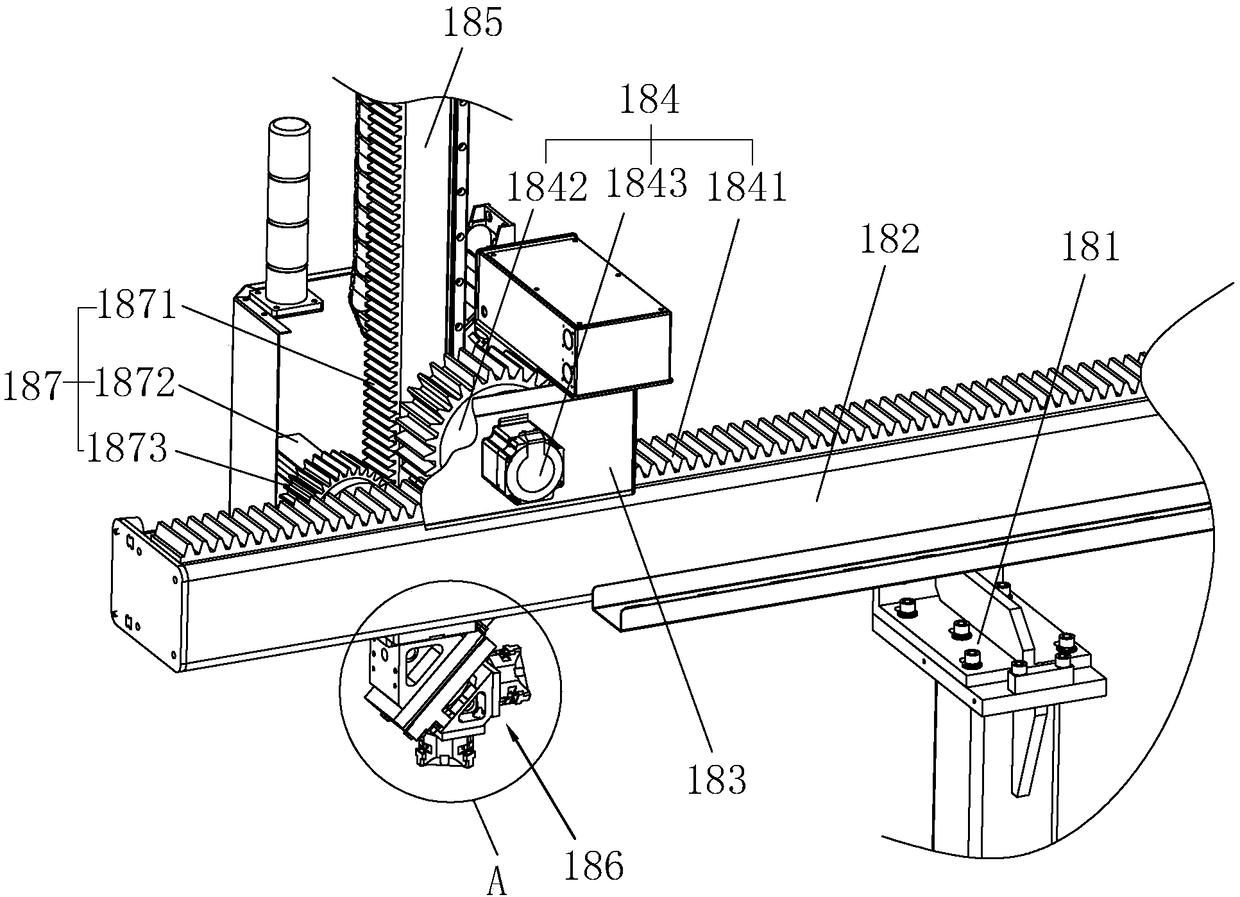

[0046] Such as Figure 5 , Figure 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that a receiving groove 21 is provided on the top surfaces of the first track seat 7 and the second track seat 8, and the length direction of the receiving groove 21 is parallel to the first track seat 7 and the first track seat 8. The second track seat 8. A plurality of grooves 22 are arranged on the inner groove wall of the receiving groove 21 , and the grooves 22 vertically penetrate the top surface of the first track seat 7 or the second track seat 8 . The grooves 22 are evenly divided into two groups and symmetrically distributed on the inner groove walls on both sides of the storage groove 21 , and the grooves 22 are evenly distributed along the length direction of the storage groove 21 .

[0047] A hinge plate 23 is hinged inside the groove 22 , and the rotation axis of the hinge plate 23 is parallel to the receiving groove 21 . A supporting plate 24 and a resisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com