Novel pure-metal seal joint structure

A sealing joint, pure metal technology, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of deformation, easy deformation of rubber parts, leakage, etc., and achieve broad application prospects and the effect of not being easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

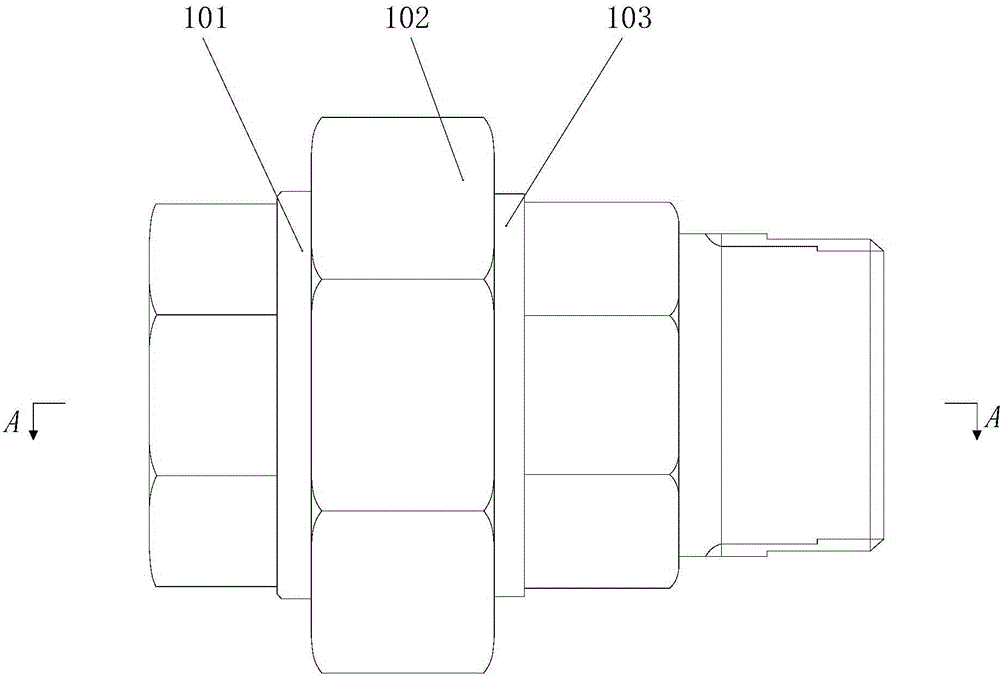

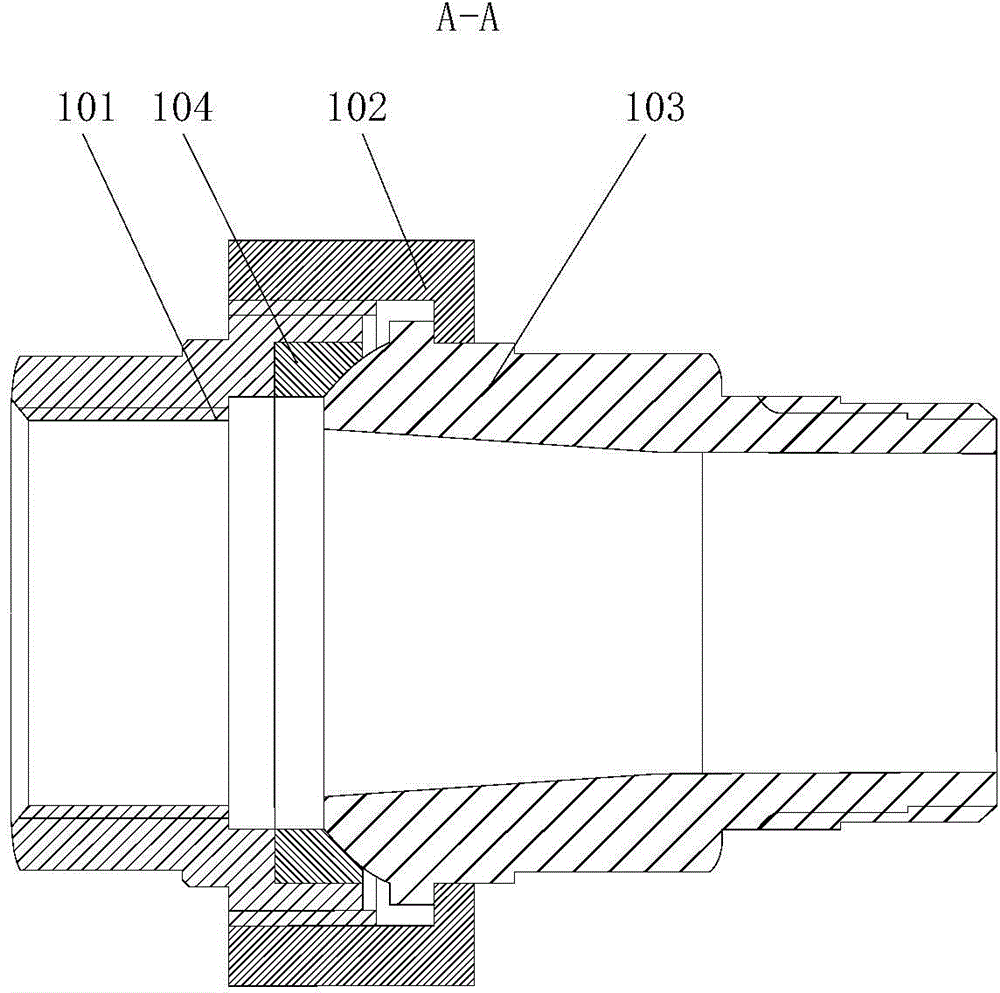

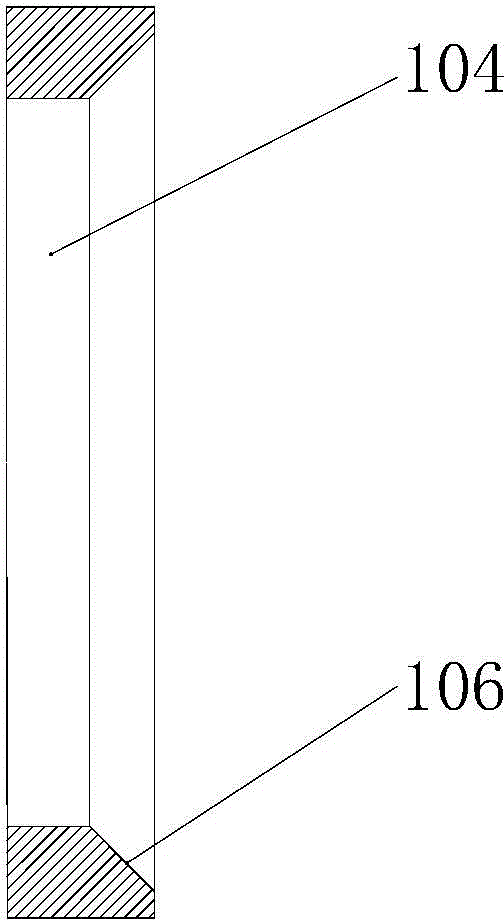

[0022] Such as Figure 1-4 As shown, a new type of pure metal sealing joint structure includes a joint A101 and a joint B103. A sealing base sleeve 104 is clamped on the inner wall of the joint A101, and a fastening nut 102 is also included for connecting the joint A101 and the joint B103. The outer walls of the joint A101 and the joint B103 are provided with threads matching the fastening nut 102, and the end of the joint B103 close to the sealing base sleeve 104 is provided with a spherical surface 105 corresponding to the sealing base sleeve 104. The joint A101, joint B103 and the sealing base sleeve 104 are both made of metal, and the hardness of the sealing base sleeve 104 is less than that of the joint B103; the joint B103 is screwed into the fastening nut 102, the sealing base sleeve 104 is installed in the joint A101, and the joint A101 is screwed into the fastening nut 102, and the fastening nut 102 is tightened so that the spherical surface 105 squeezes the sealing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com