Ball cage cage, precision automatic quick inspection system and detection method of ball cage cage

A cage and ball cage technology, applied in the field of precision automatic quick inspection system, can solve the problems of easy wear of steel balls, short service life of ball cage cages, affecting the service life of steel balls and ball cage cages, etc., so as to prolong the service life. , not easy to wear, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

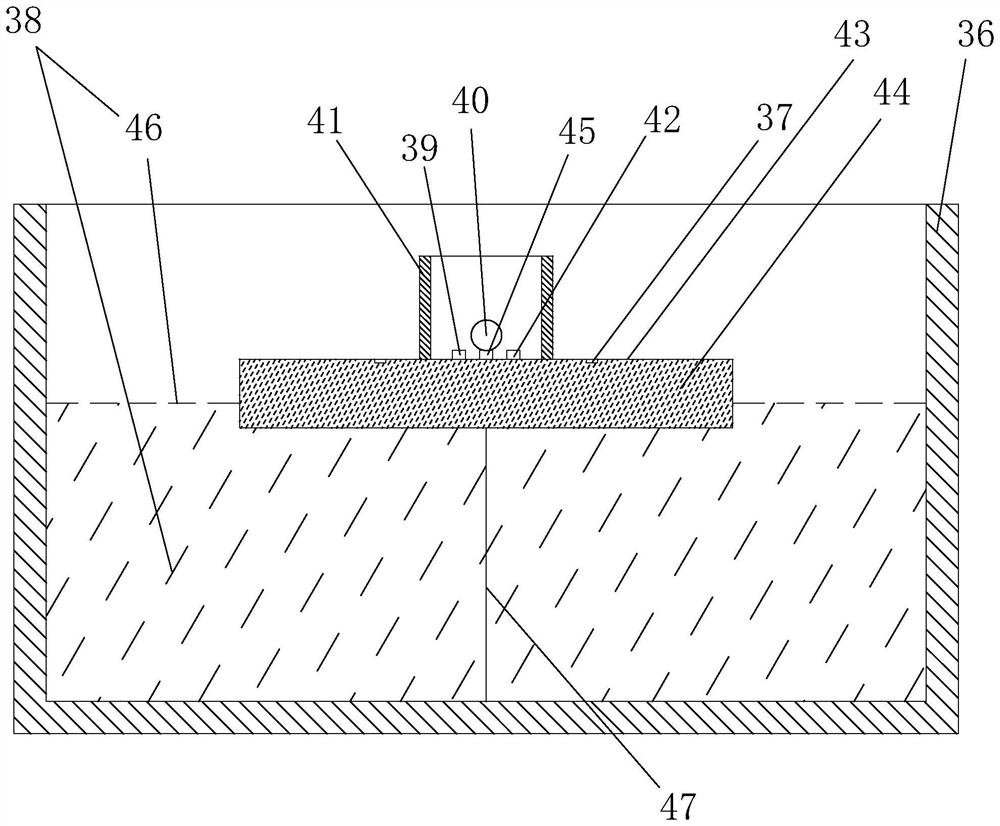

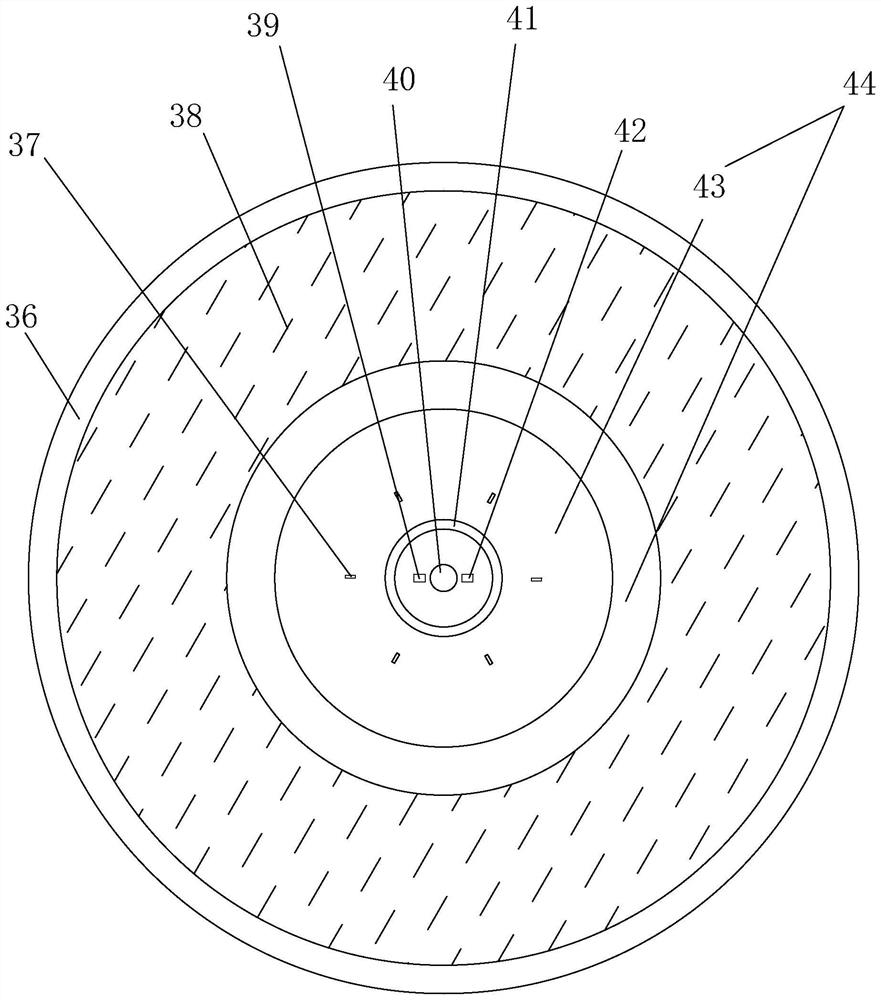

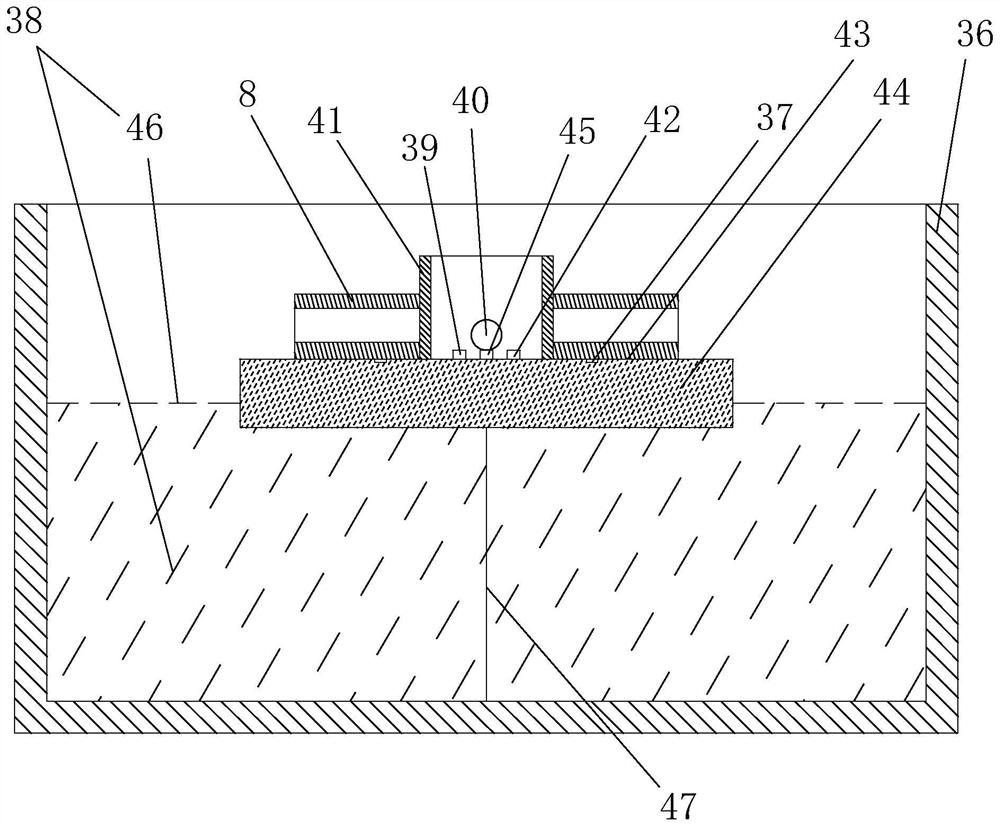

[0061] Embodiment 1, the accuracy automatic quick inspection system of the ball cage cage, see Figure 1-Figure 5 Shown, comprise controller 45, memory 39, voice prompter 42, pool 36 that water 38 is housed and can float on the circular horizontal floating plate 44 on water surface 46 in the pool;

[0062] A backguy 47 is fixedly installed on the bottom surface of the pool, and the upper end of the backguy is fixedly connected to the center of the lower surface of the circular horizontal floating plate;

[0063] A circular tube 41 is fixed vertically upward at the center of the circular horizontal floating plate, and the diameter of the outer tube of the circular tube is equal to the diameter of the inner hole of the cage body;

[0064] When the ball cage cage body to be tested is not placed on the upper surface of the circular horizontal floating plate, the upper surface of the circular horizontal floating plate is parallel to the horizontal plane;

[0065] A level detection...

Embodiment 2

[0071] Embodiment 2, ball cage cage, refer to Figure 6-Figure 15 As shown, it includes a bell housing 7, a ball cage body 8 and a star sleeve 9; several longitudinal chute 27 are evenly spaced on the outer peripheral wall of the star sleeve, and on the inner circumference of the bell housing There are also several longitudinal chute 28 evenly distributed on the wall, and the number of the longitudinal chute on the star sleeve is equal to the number of the longitudinal chute on the bell; There are steel ball holes 4 with the same number of longitudinal chute on the shape sleeve, the center line of the steel ball hole falls on the center line of the peripheral surface of the ball cage cage body, the ball cage cage body is movably arranged in the bell housing, and the star-shaped sleeve The activity is set in the cage body of the ball cage; a steel ball 1 is set in each steel ball hole; the inner and outer ends of each steel ball are respectively rolled and set in the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com