Full-size PVC (polyvinyl chloride) floor for coach and method for manufacturing full-size PVC floor

A technology for floors and passenger cars, applied in applications, railway car bodies, flat products, etc., can solve the problems of easy wear and tear, low service life, overturning and warping, etc., to achieve beautiful appearance, long service life, and particle edges and corners many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

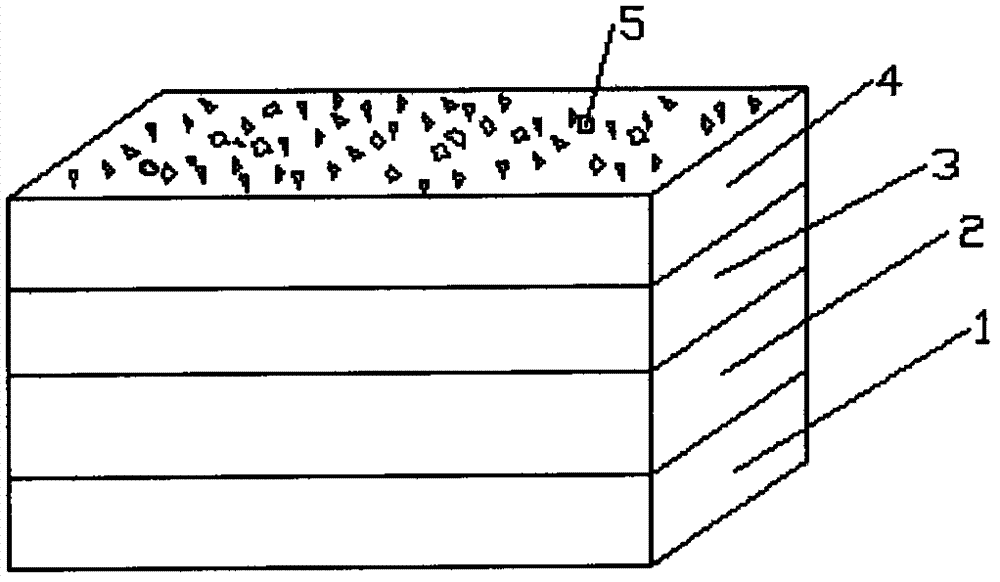

[0020] Such as figure 1 As shown, a whole width PVC floor for a passenger car includes a substrate base plate and a PVC wear-resistant layer, and the base material base plate includes a lower dense layer 1, a middle foam layer 2 and an upper dense layer 3, and the upper dense layer 3 The upper surface is provided with a PVC wear-resistant layer 4, the width of the substrate bottom plate is 3.2m, the width of the wear-resistant layer is 3.2m, and the width of the entire PVC floor is 3.2m.

[0021] The PVC wear-resistant layer 4 is dotted with a variety of PVC colored particles 5 that are different in basic color from the PVC wear-resistant layer 4 .

[0022] The invention discloses a method for preparing a whole PVC floor for a passenger car, comprising material preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com