Lipstick tube pattern printing device with drying function

A pattern printing, lipstick tube technology, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of ink scratching, poor stability of lipstick tube, dislocation of pattern and pattern, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

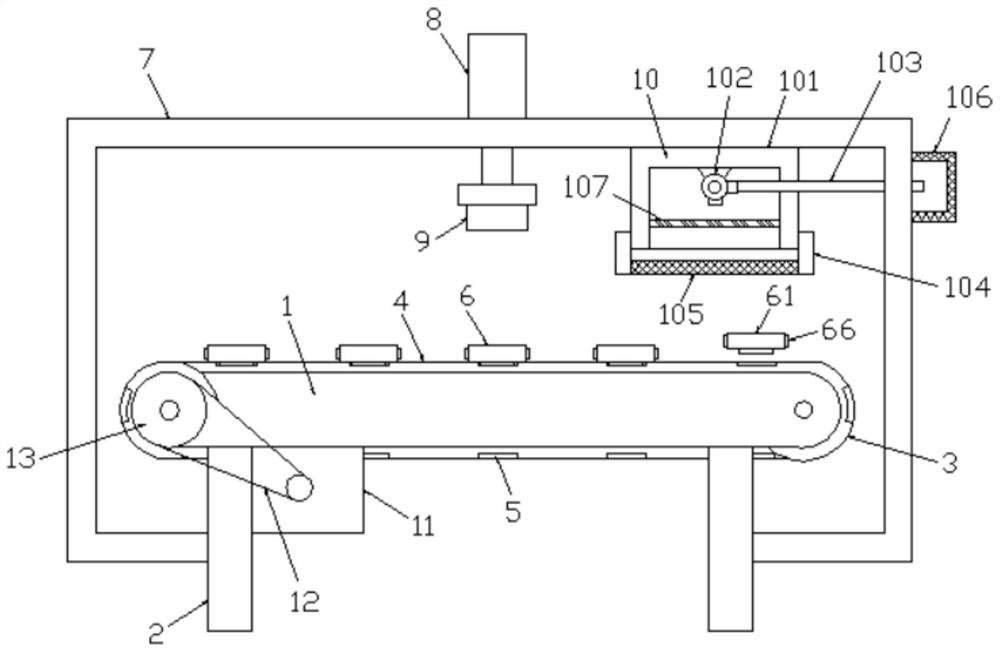

[0025]Example 1: SeeFigure 1-3The present invention provides a technical solution: a lipstur tube pattern printing apparatus with drying function, including a frame 1, and a support post 2 is provided for supporting the entire device, the rack 1 Both ends are rotated to be connected to the conveying wheel 3, and the outer portion of the conveying wheel 3 is covered with the conveyor belt 4, and the drive motor 11 is fixedly mounted, the drive motor 11 is connected to the belt wheel 13, the pulley 13 and the conveying wheel. 3 Connectation, when the drive motor 11 is operated, the pulley is rotated by the belt 12, and the pulley 13 is conveyed by the conveying wheel 3 to convey the conveyor of the conveyor with the conveyor, without manual delivery, it can improve the working efficiency;

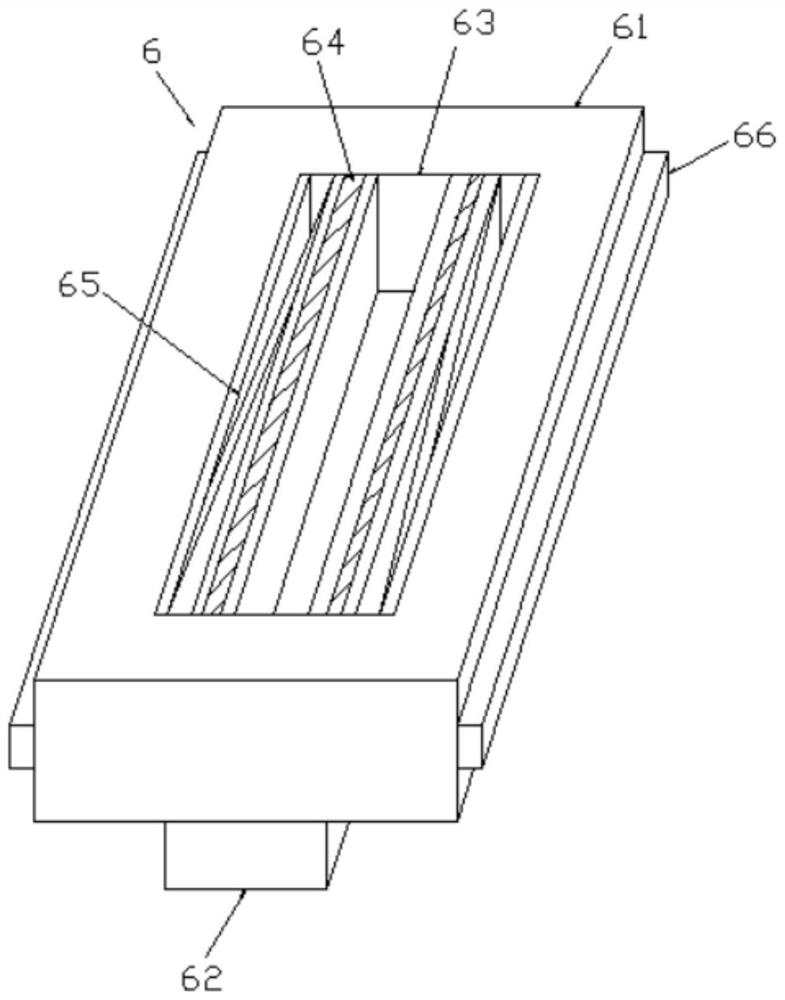

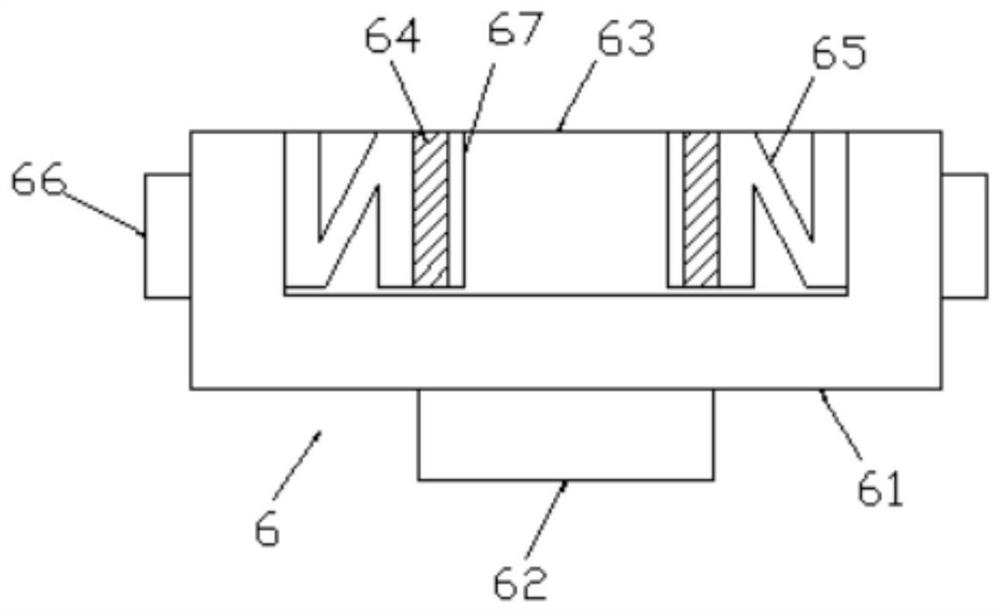

[0026]The outer side of the conveyor belt 4 is provided with a plurality of card slots 5, and the card slot 5 is provided with a positioning mechanism 6 for fixing the red tube, and the positioning me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com