Filling device and automatic placement machine

An automatic placement machine and filling device technology, which is applied in transportation and packaging, assembly of printed circuits with electrical components, winding strips, etc., can solve the difficulty of increasing transportation and waste disposal, film deformation, tearing, etc. problems, to achieve the effect of improving program security, reducing mechanical load, and improving transmission force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

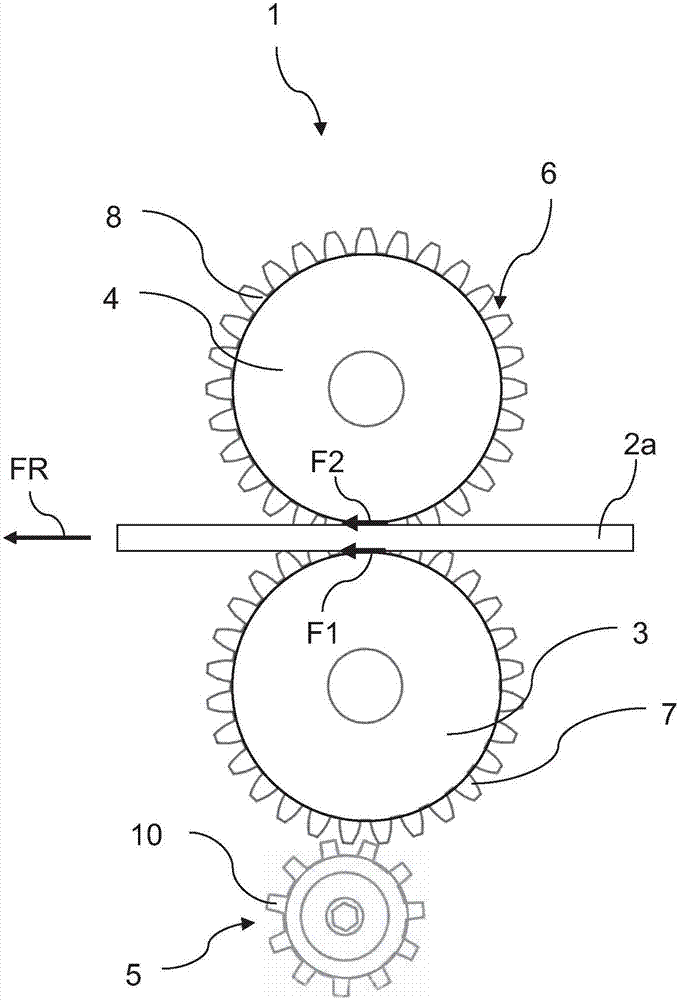

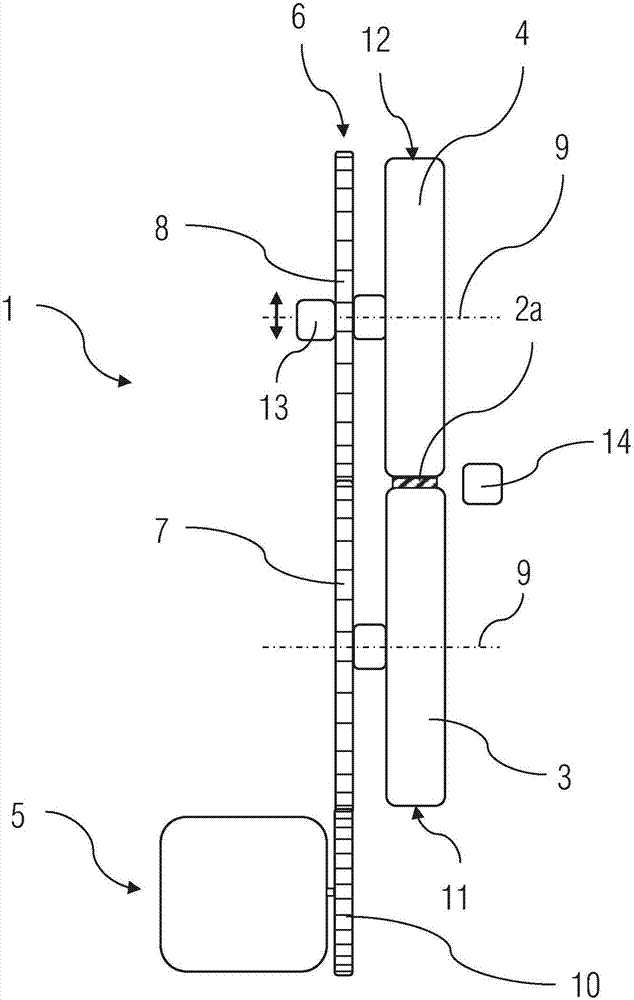

[0053] figure 1 and figure 2 A side section of a first realization of the filling device 1 according to the invention is shown diagrammatically. The filling device 1 has a first filling gear 3 and a second filling gear 4 , both gears having equal diameters in the present embodiment. Another possibility is that the first filling gear 3 and the second filling gear 4 have different diameters. The first filling gear 3 and the second filling gear 4 each have a rotational axis 9 parallel to each other. exist image 3 The covering film 2a of the surface mount device conveyor belt 2b shown in the middle is located between the first filling gear 3 and the second filling gear 4, and is clamped by a kind of pressure. In this way, the first filling gear and the second filling gear will apply a frictional force to the film 2a when they rotate, and thus convert it into a transmission force F1, F2 for the film 2a, so that the film 2a is pressed figure 1 The transmission direction mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com