Patents

Literature

71results about How to "Convenient punching operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

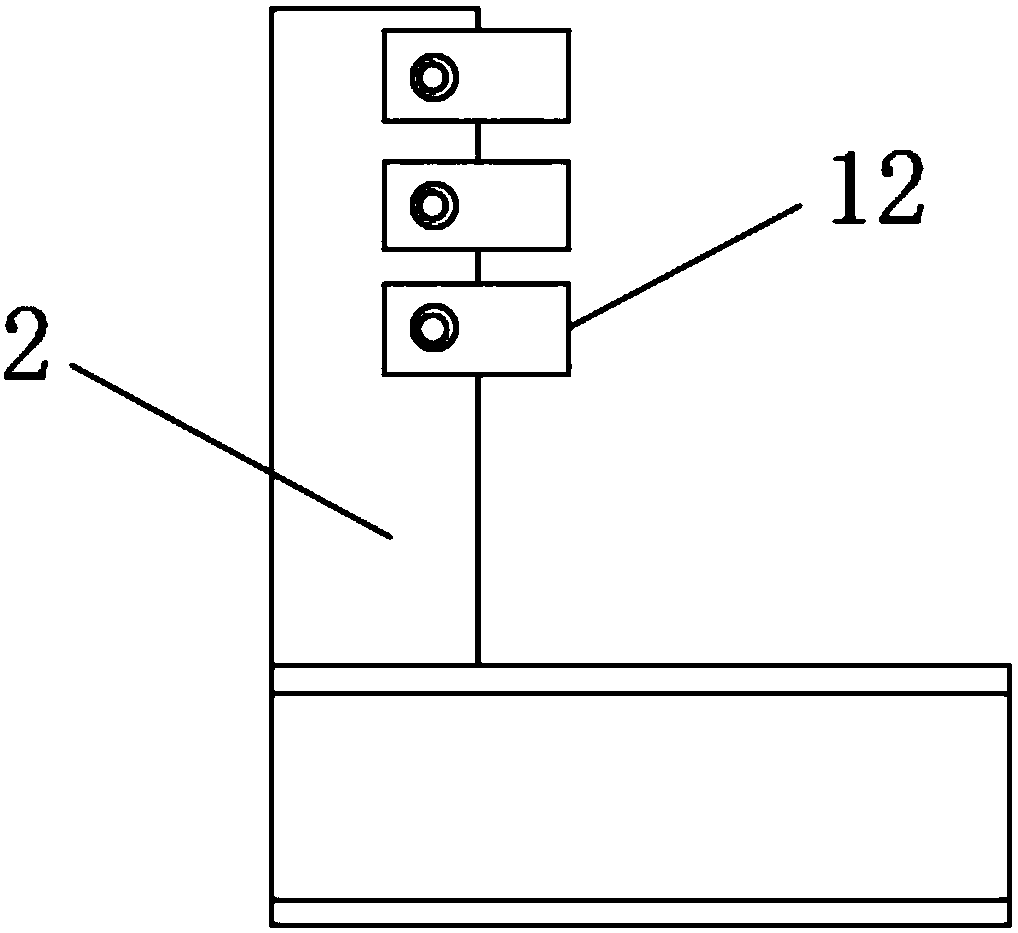

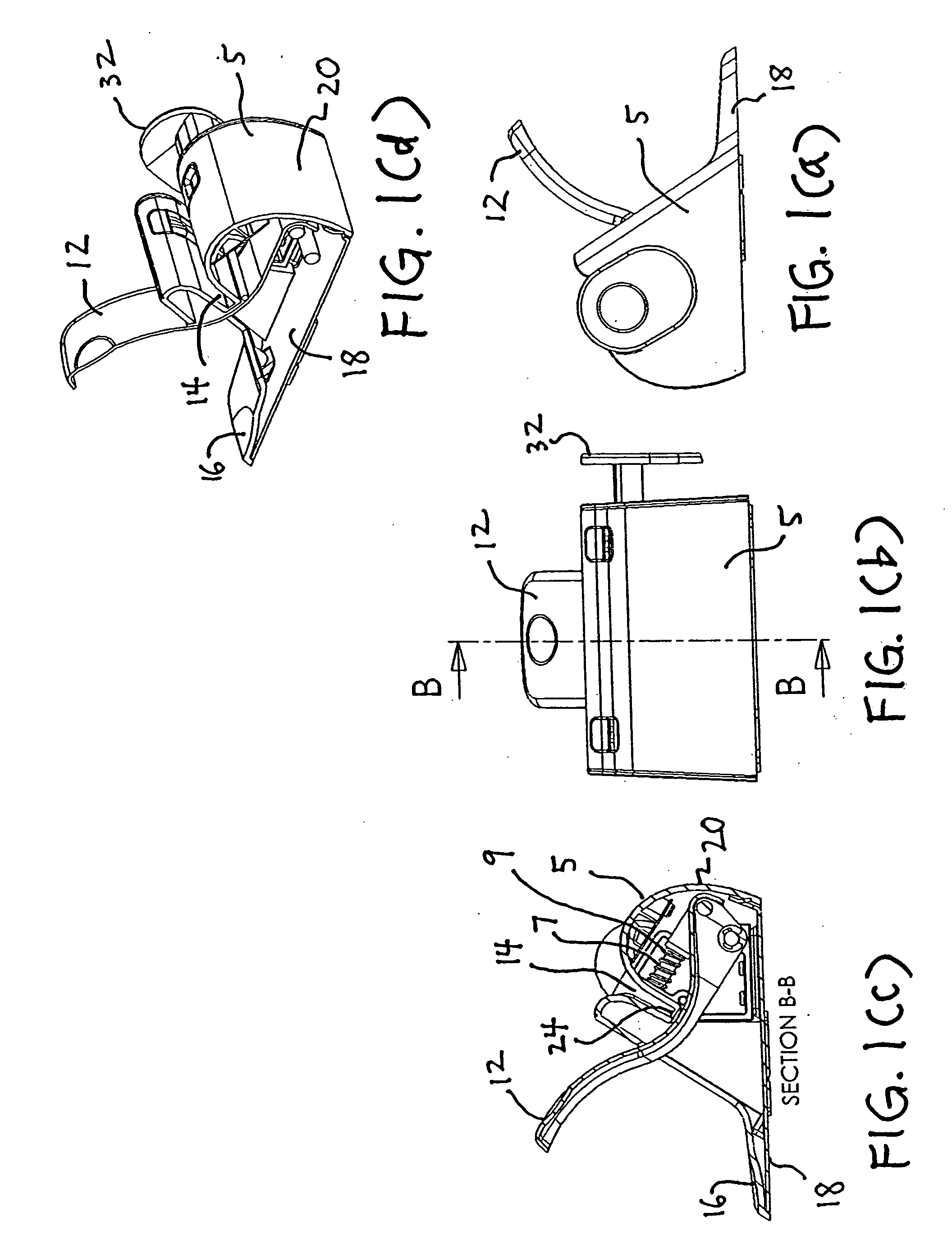

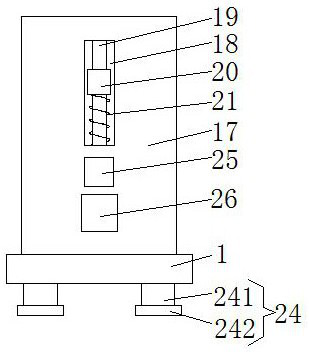

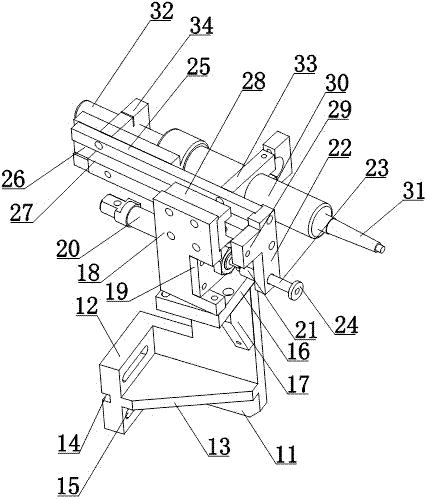

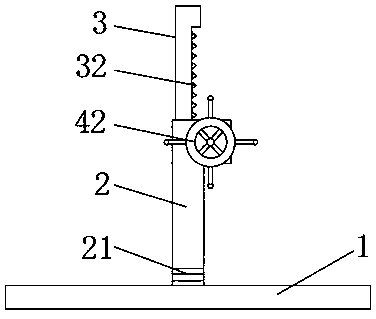

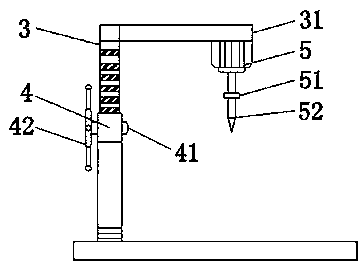

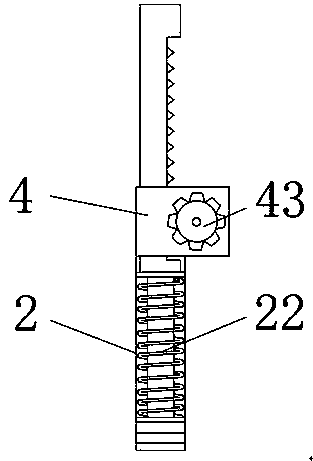

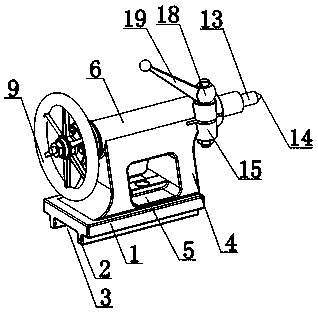

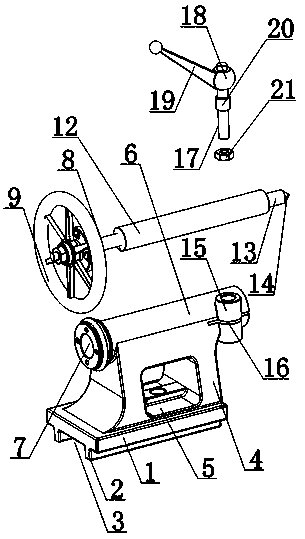

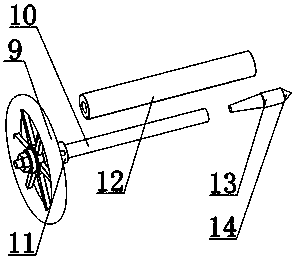

Leaning-preventing electric portable drill facilitating drilling depth control

ActiveCN108465842AAvoid breakingAvoid skewPortable power-driven toolsWork benchesEngineeringSlide plate

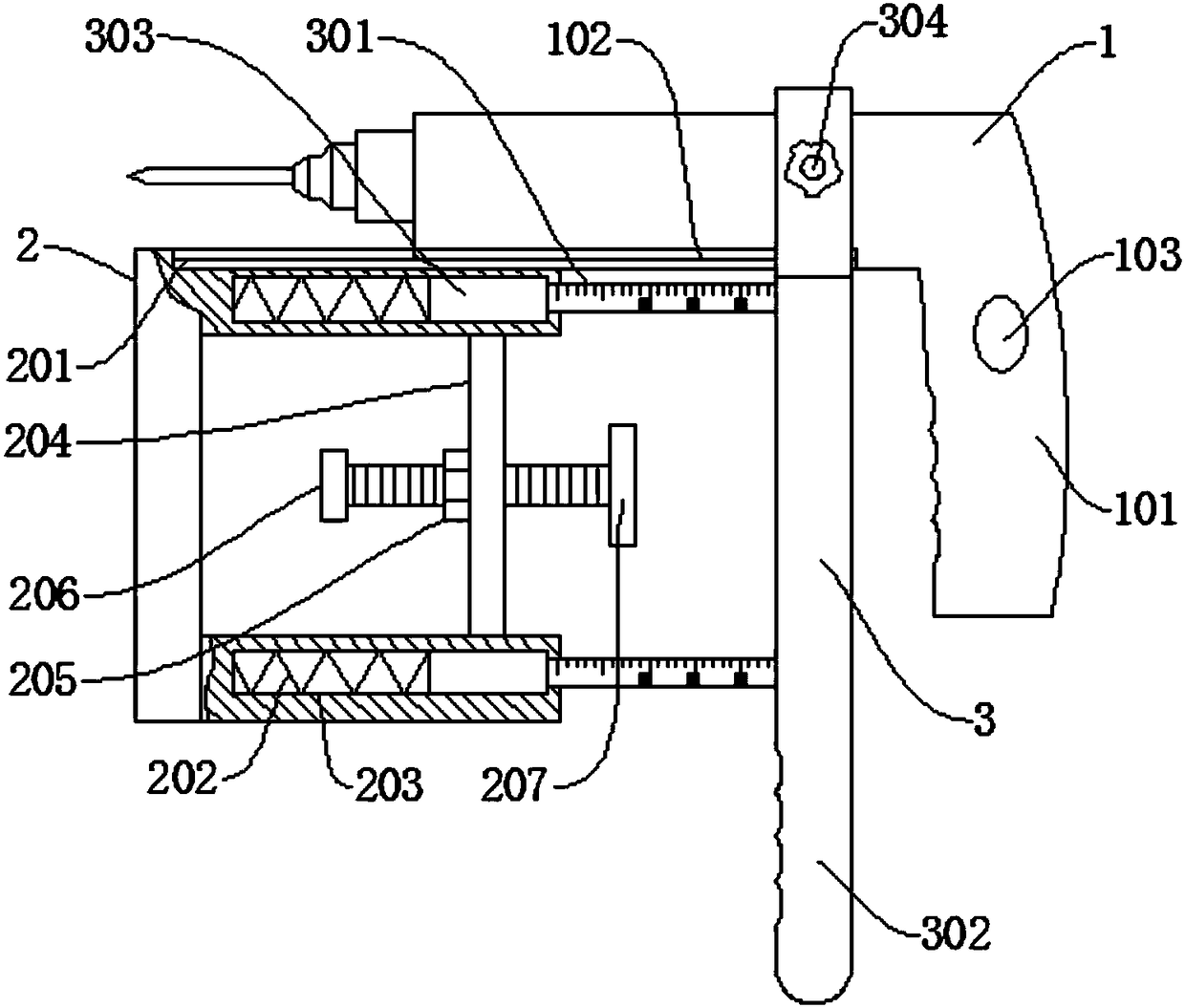

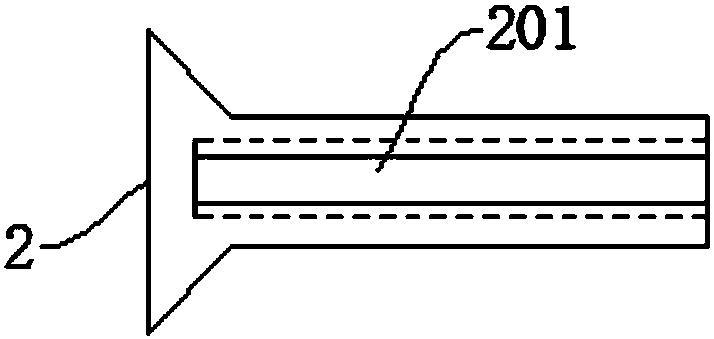

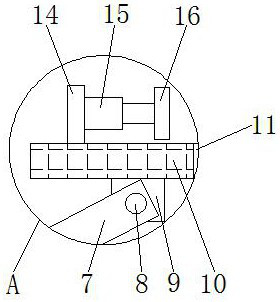

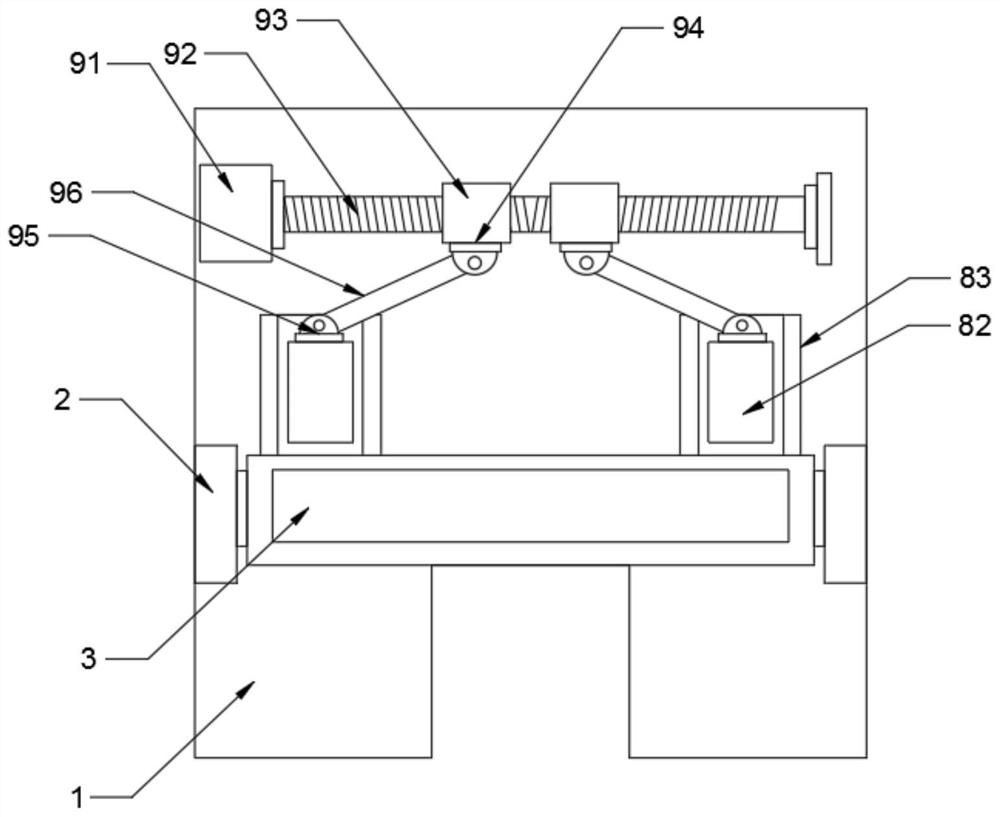

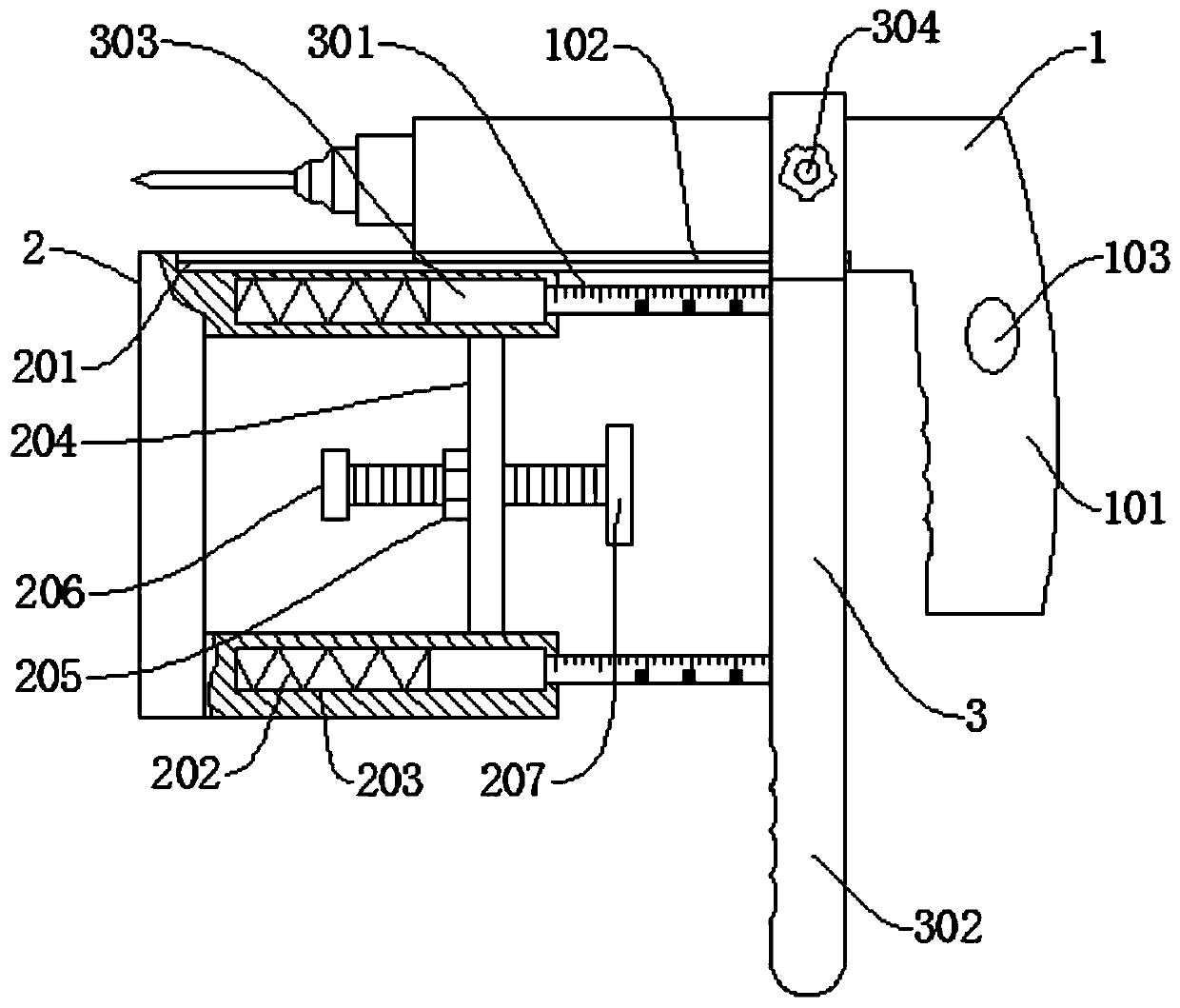

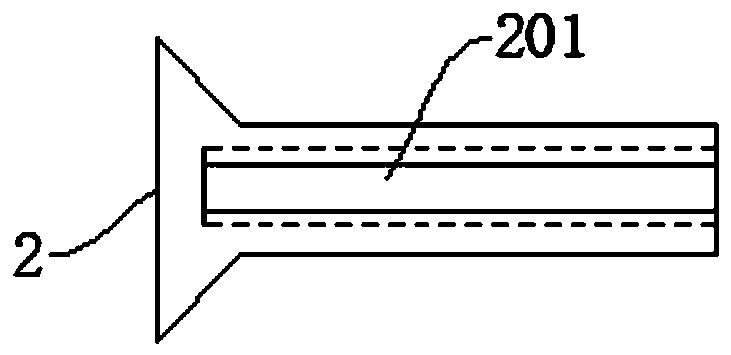

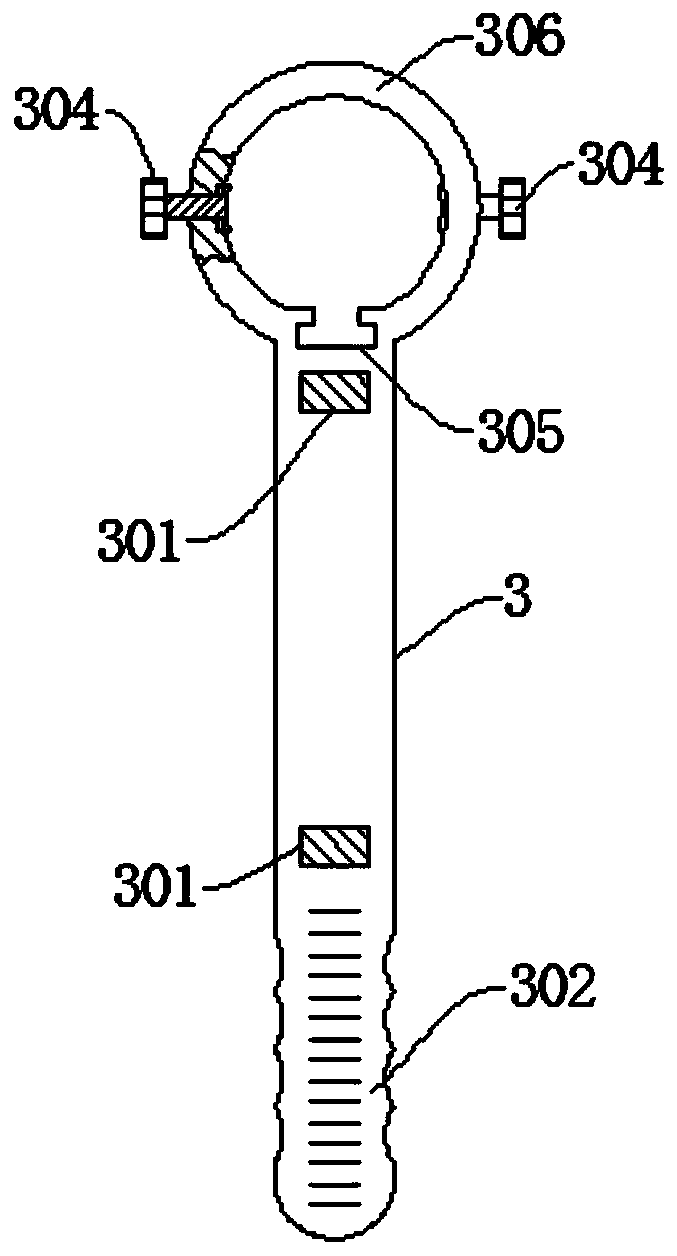

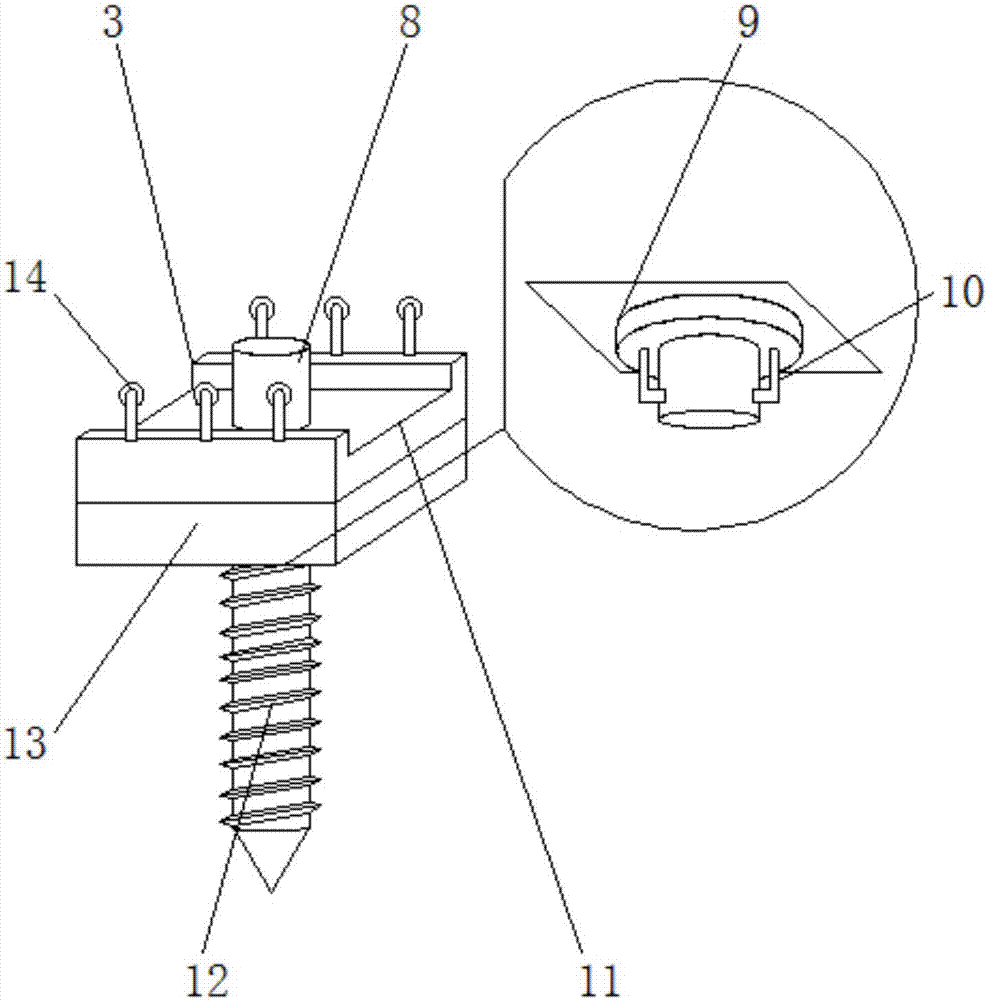

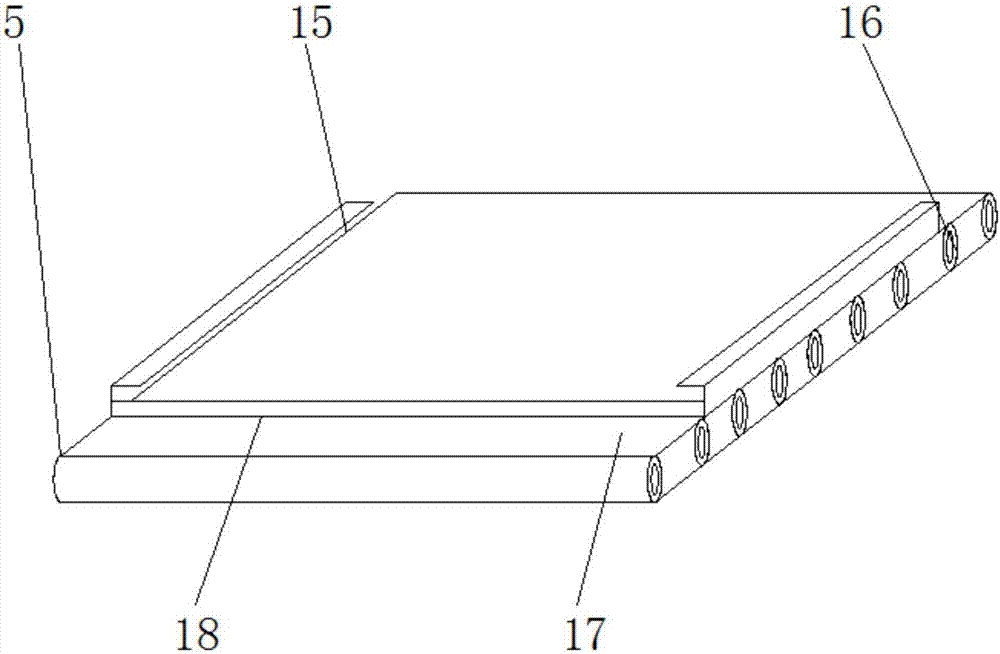

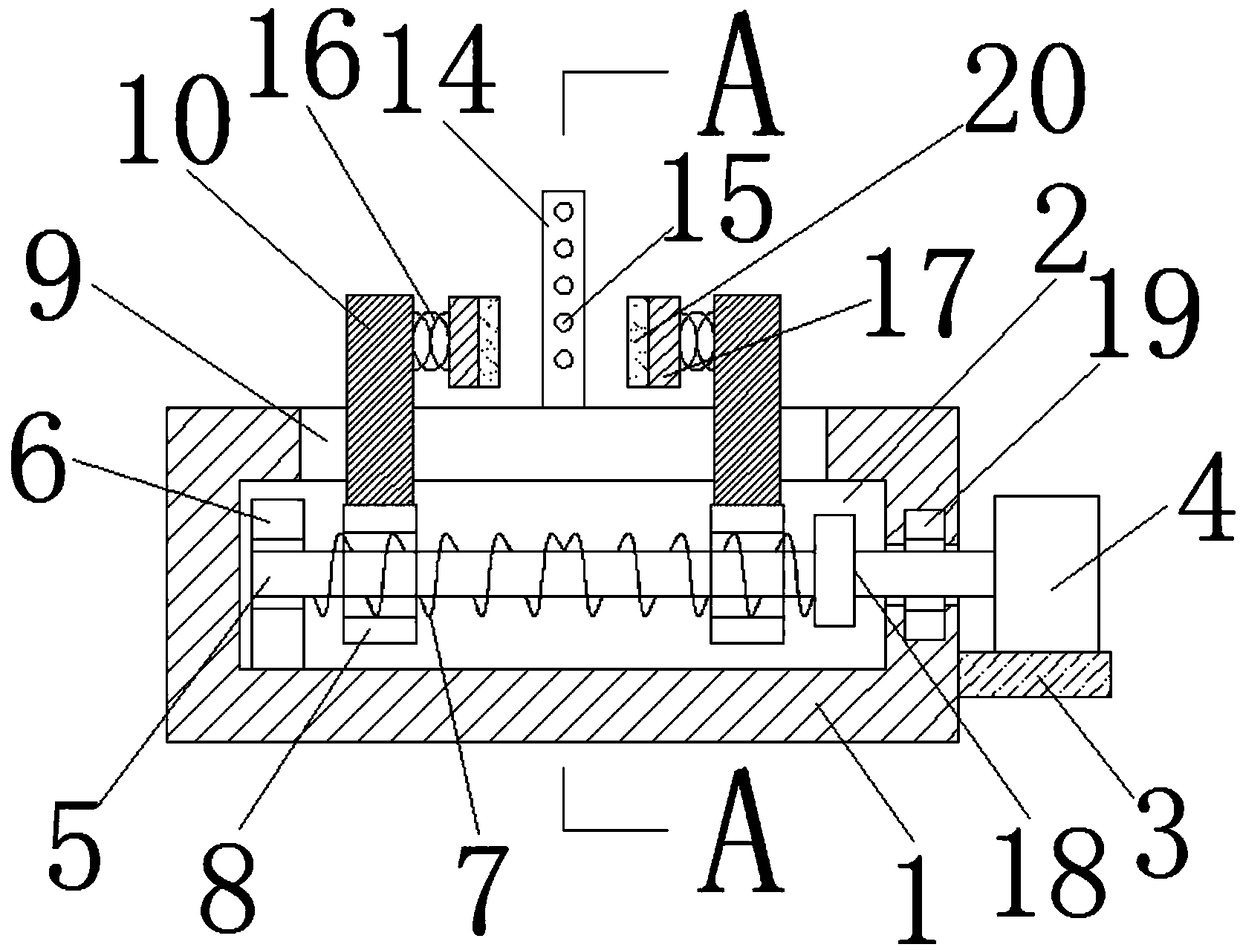

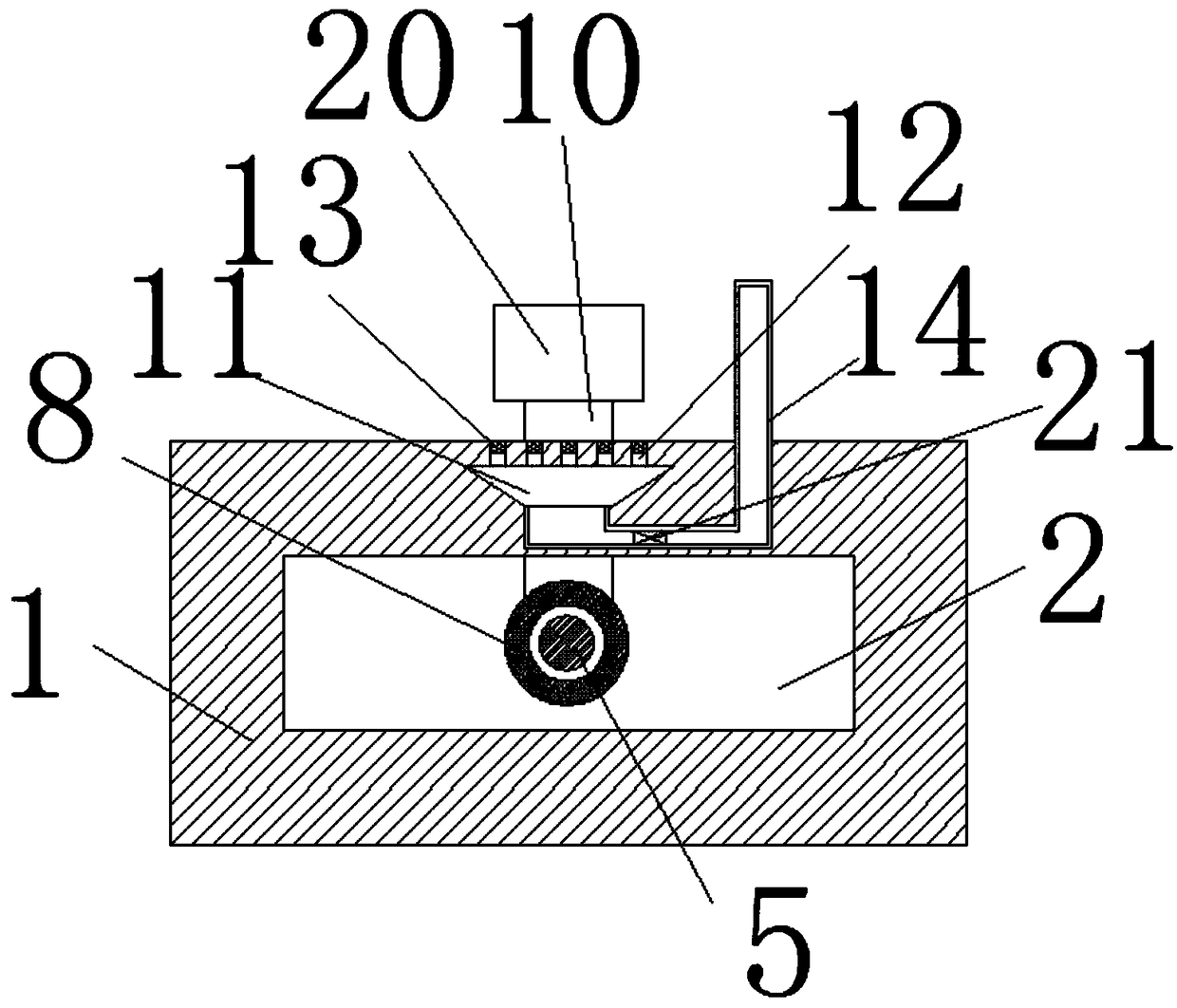

The invention discloses a leaning-preventing electric portable drill facilitating drilling depth control. The leaning-preventing electric portable drill comprises an electric portable drill body, a handle is arranged below the side of the electric portable drill body, a switch key is arranged on the side face of the handle, a horizontal rail groove is formed in the bottom of the electric portabledrill body, a U-shaped top plate standing on the side is arranged at the bottom of the electric portable drill body, a second sliding way is arranged on a top horizontal face of the U-shaped top plate, the rail groove is in sliding fit with the second sliding way, and therefore the electric portable drill body can horizontally slide on the U-shaped top plate, and a supporting plate is arranged atan opening of the side face of the U-shaped top plate. The leaning-preventing electric portable drill has the beneficial effects that the U-shaped top plate is attached to the surface of an object, and therefore a drill bit is perpendicular to the object all the time when the electric portable drill body drills a hole, and drill bit breaking or hole leaning is avoided; and the position of a positioning plate is adjusted, a sliding plate is limited, and the hole drilling depth is accurately controlled.

Owner:浙江富翼科技有限公司

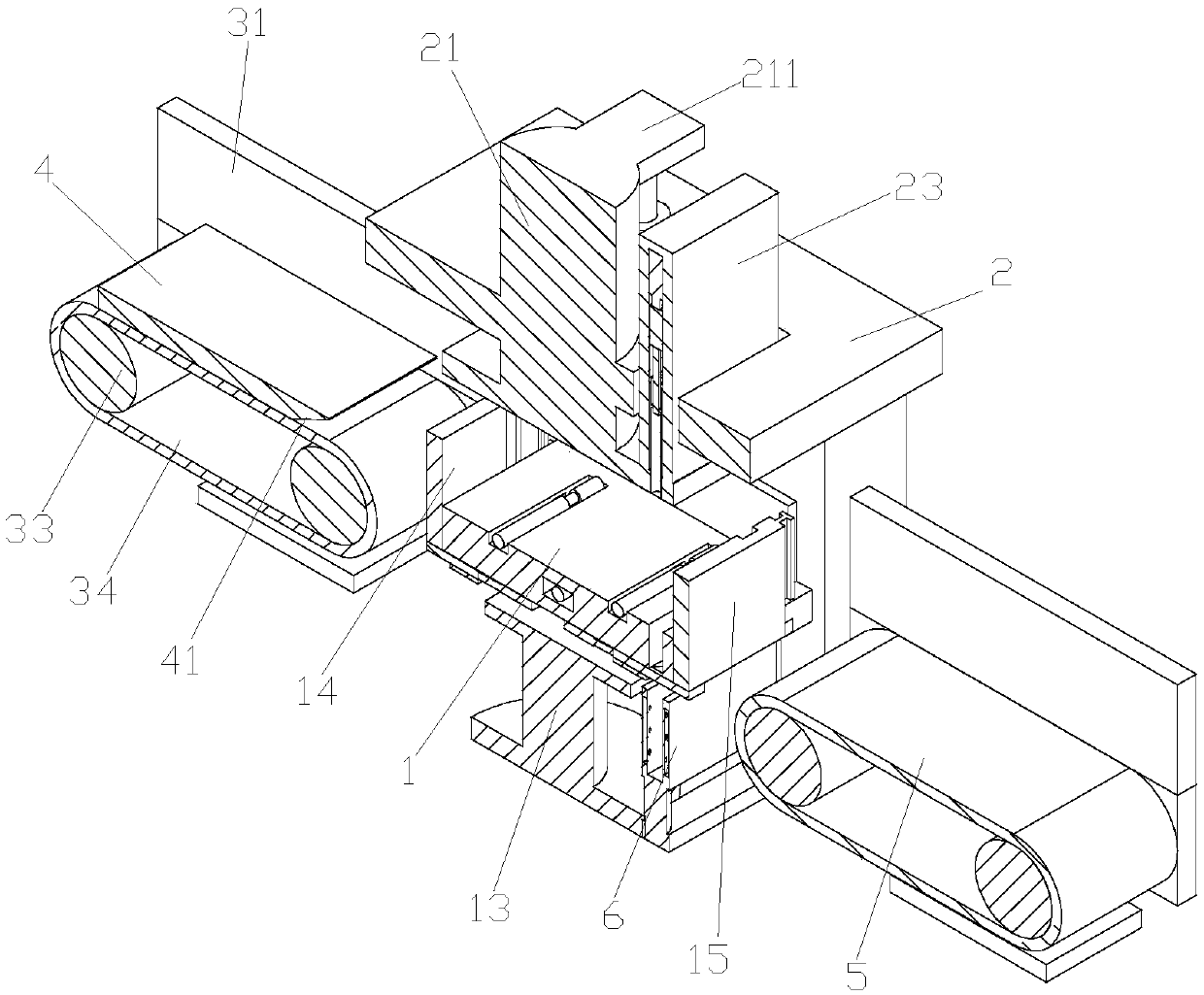

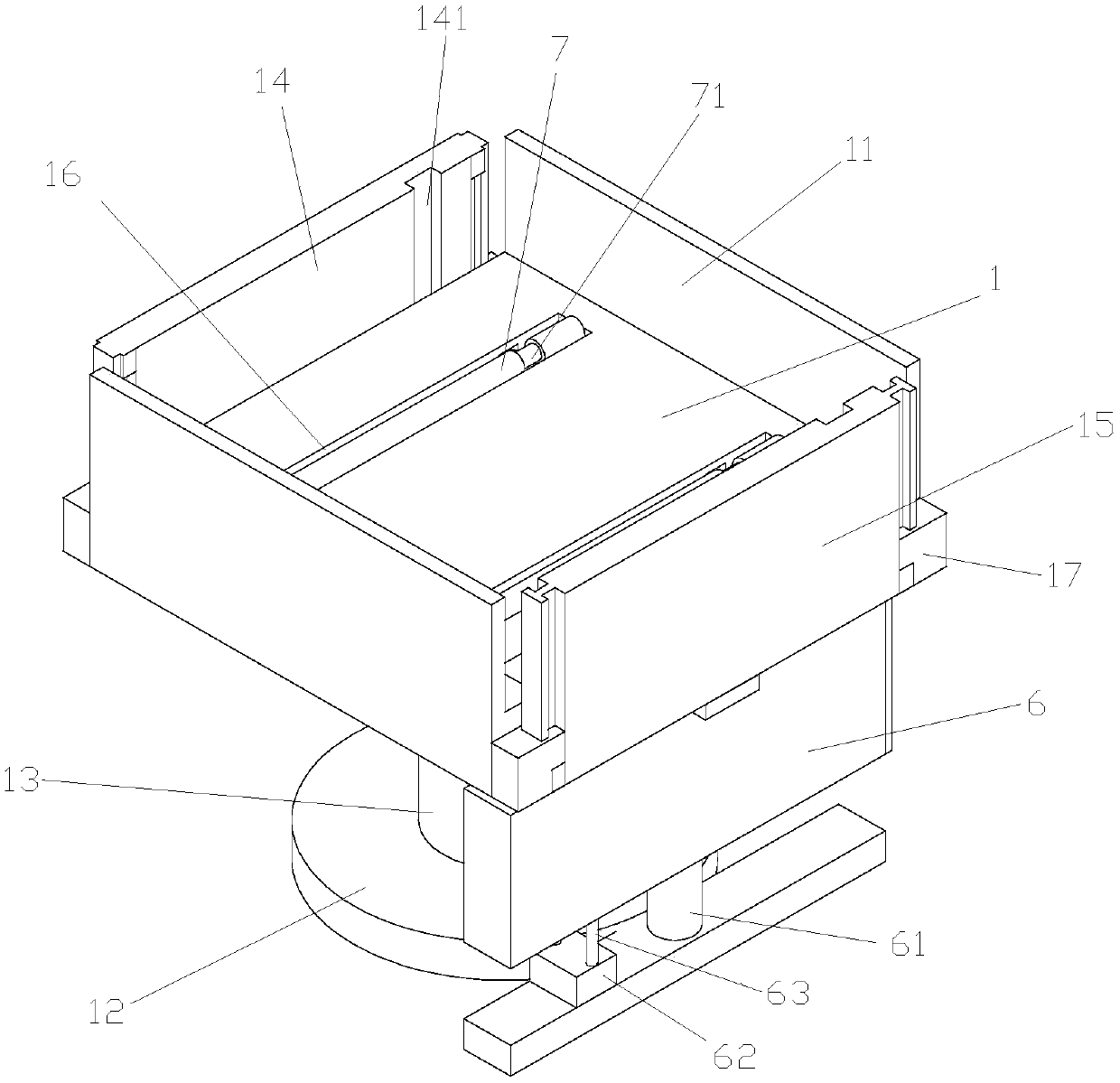

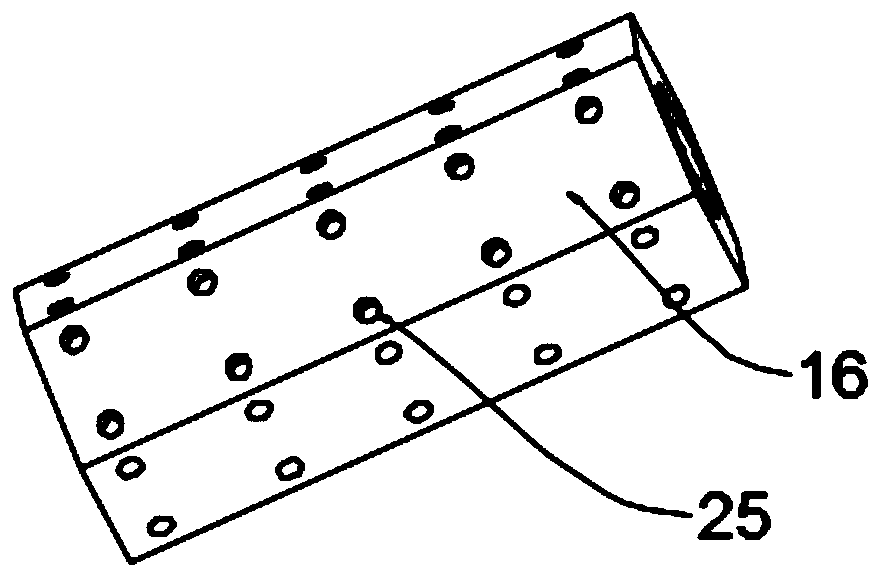

Paper processing and punching device

The invention discloses a paper processing and punching device comprising a first conveyor device, a carrying table arranged on one side of the first conveyor device, a punching device arranged abovethe carrying table, and a second conveyor device arranged on the other side of the carrying table; the first conveyor device comprises a connecting frame, a first roller arranged on the connecting frame, and a conveyor belt arranged on the first roller in a sleeved manner; the conveyor belt is provided with a tray used for placing paper; the paper processing and punching device is characterized inthat the carrying table is provided with two first baffles, and the two first baffles are arranged on the both sides of the carrying table separately; and the carrying table is further provided witha second baffle and a third baffle which can do lifting motion along the side wall of the carrying table.

Owner:SHAOXING UNIVERSITY

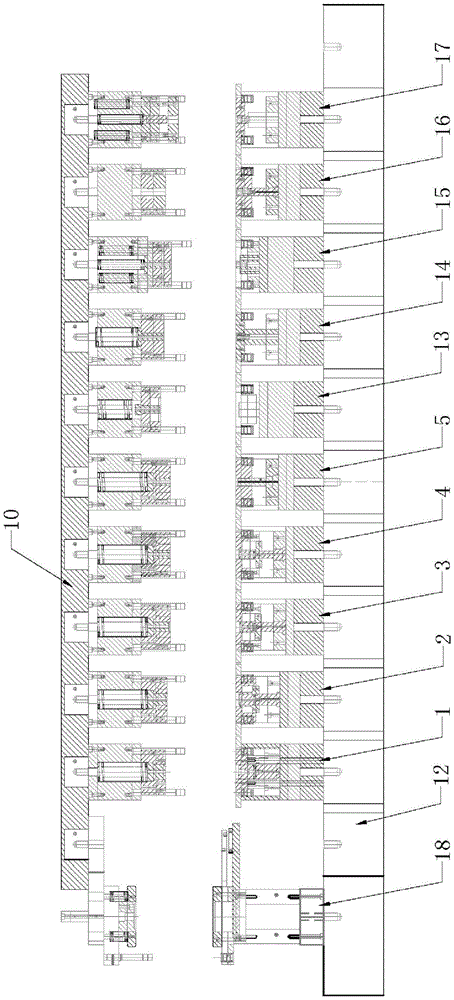

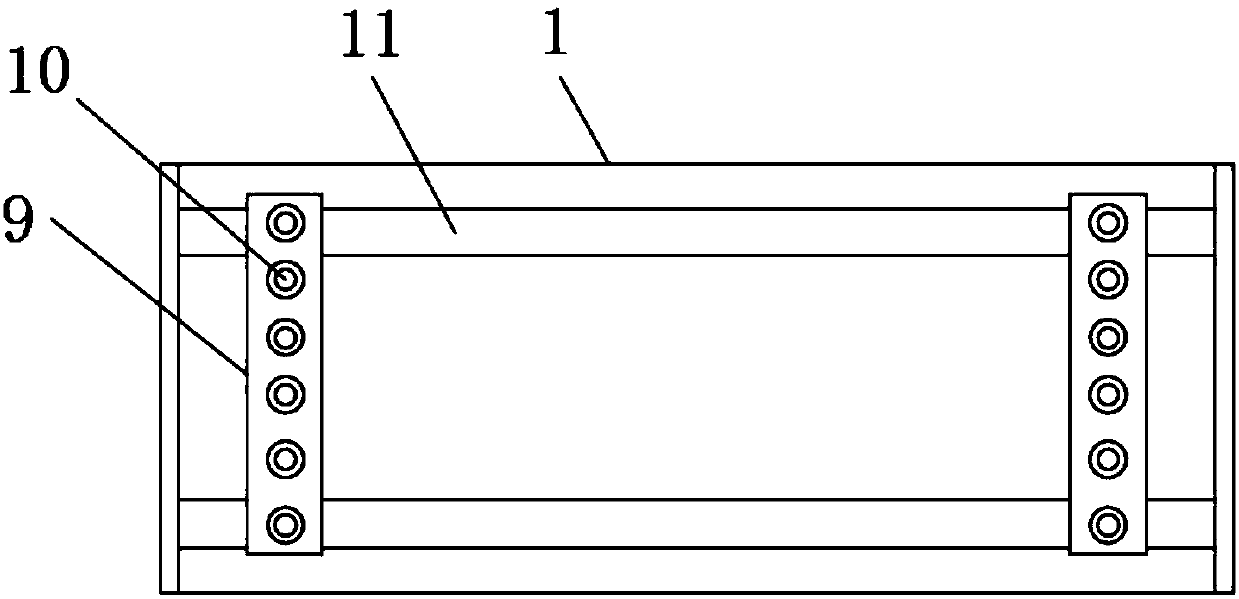

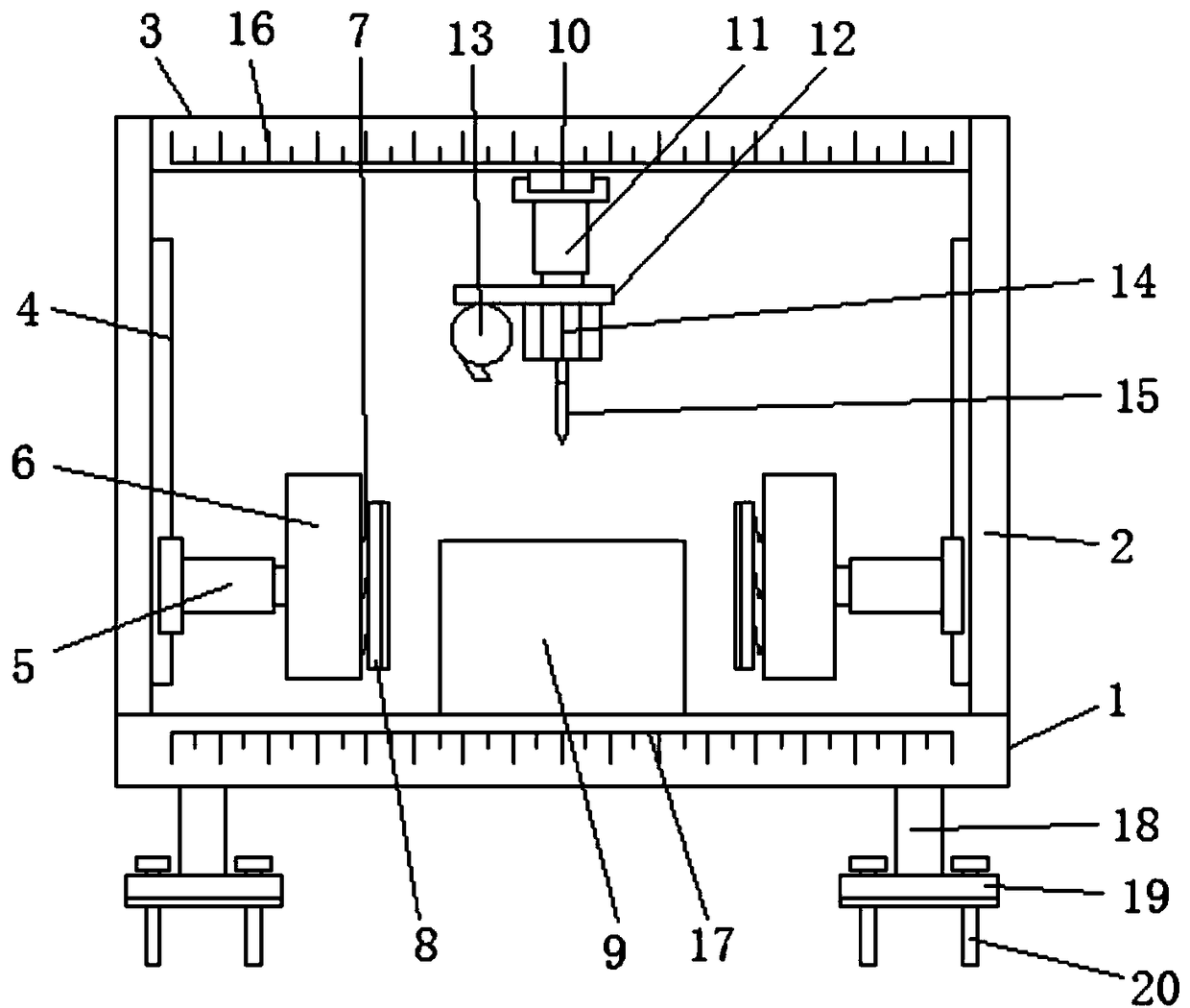

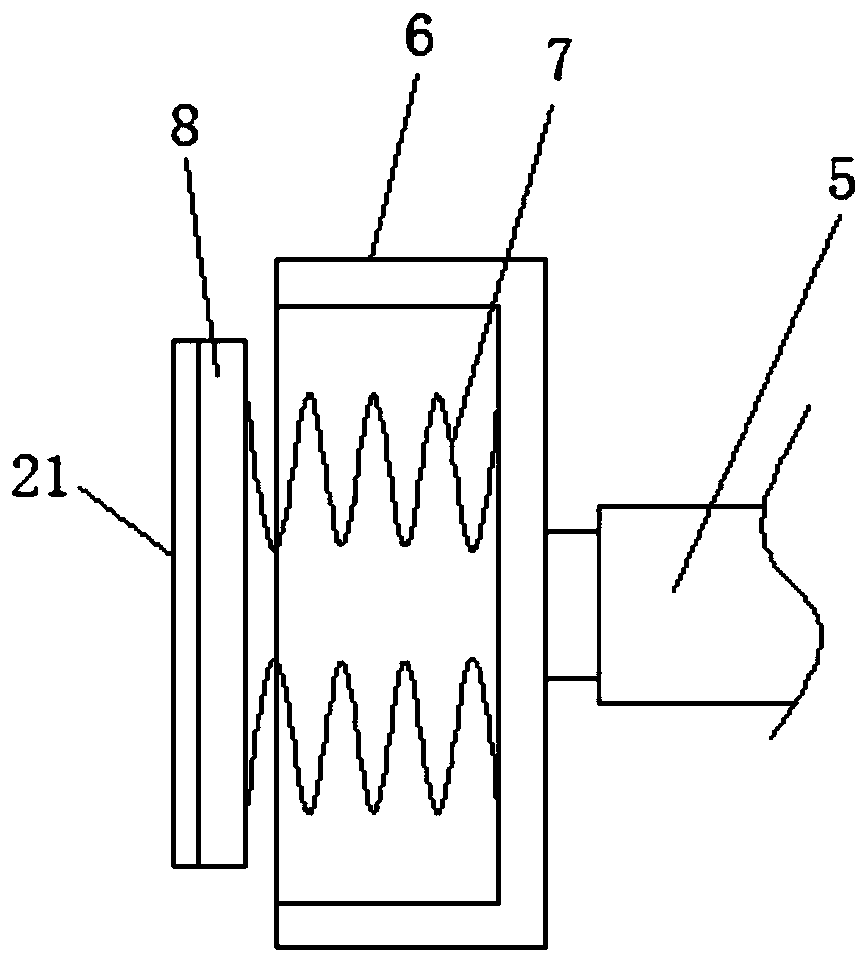

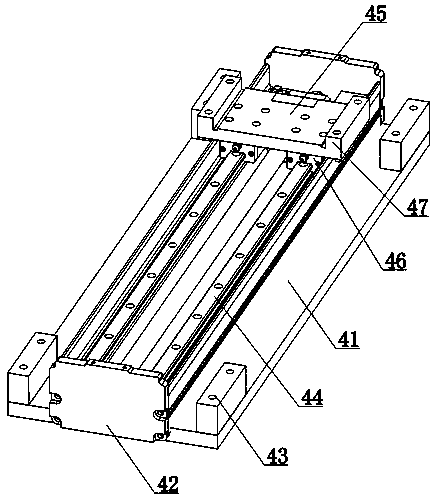

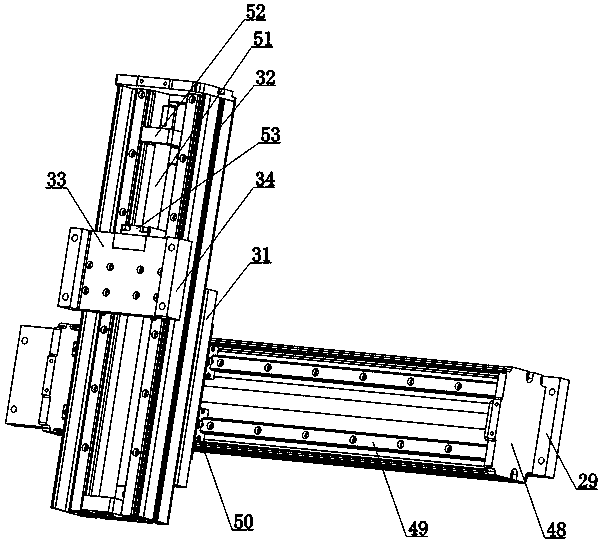

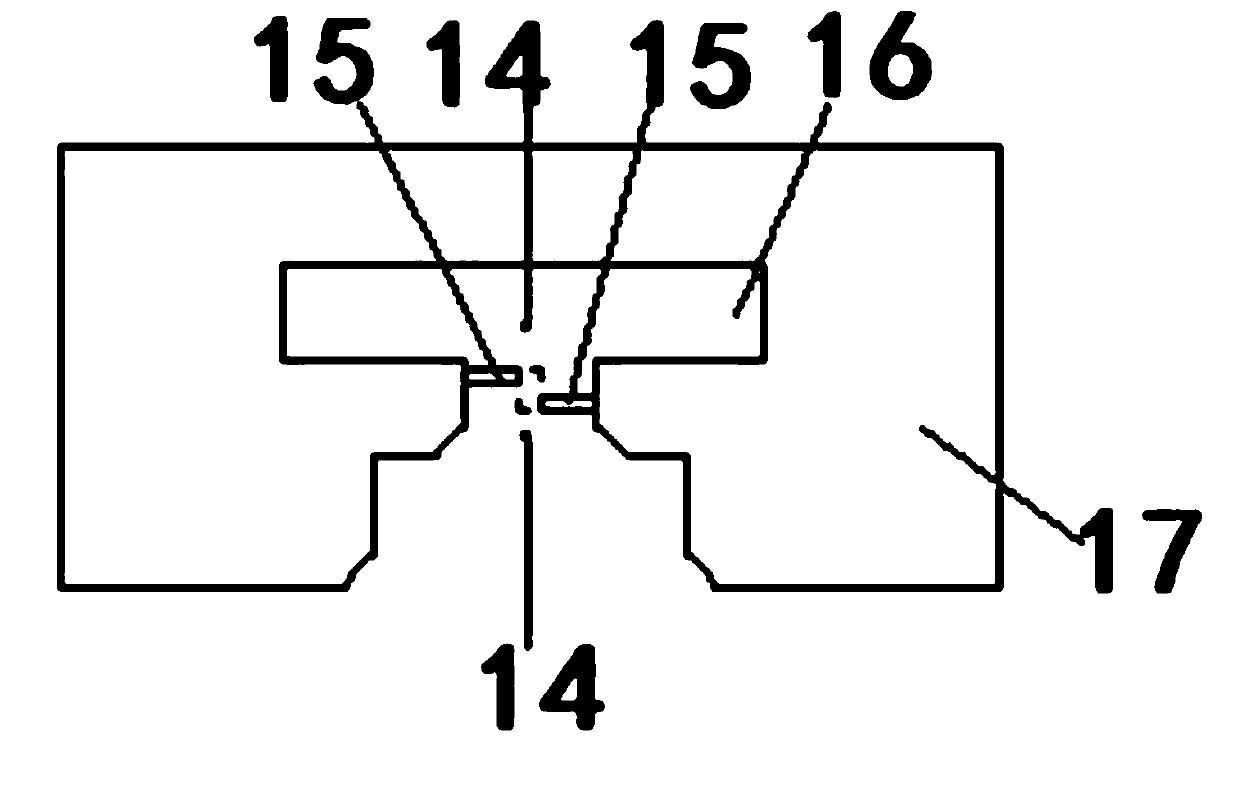

Cylindrical drawn part production and machining equipment

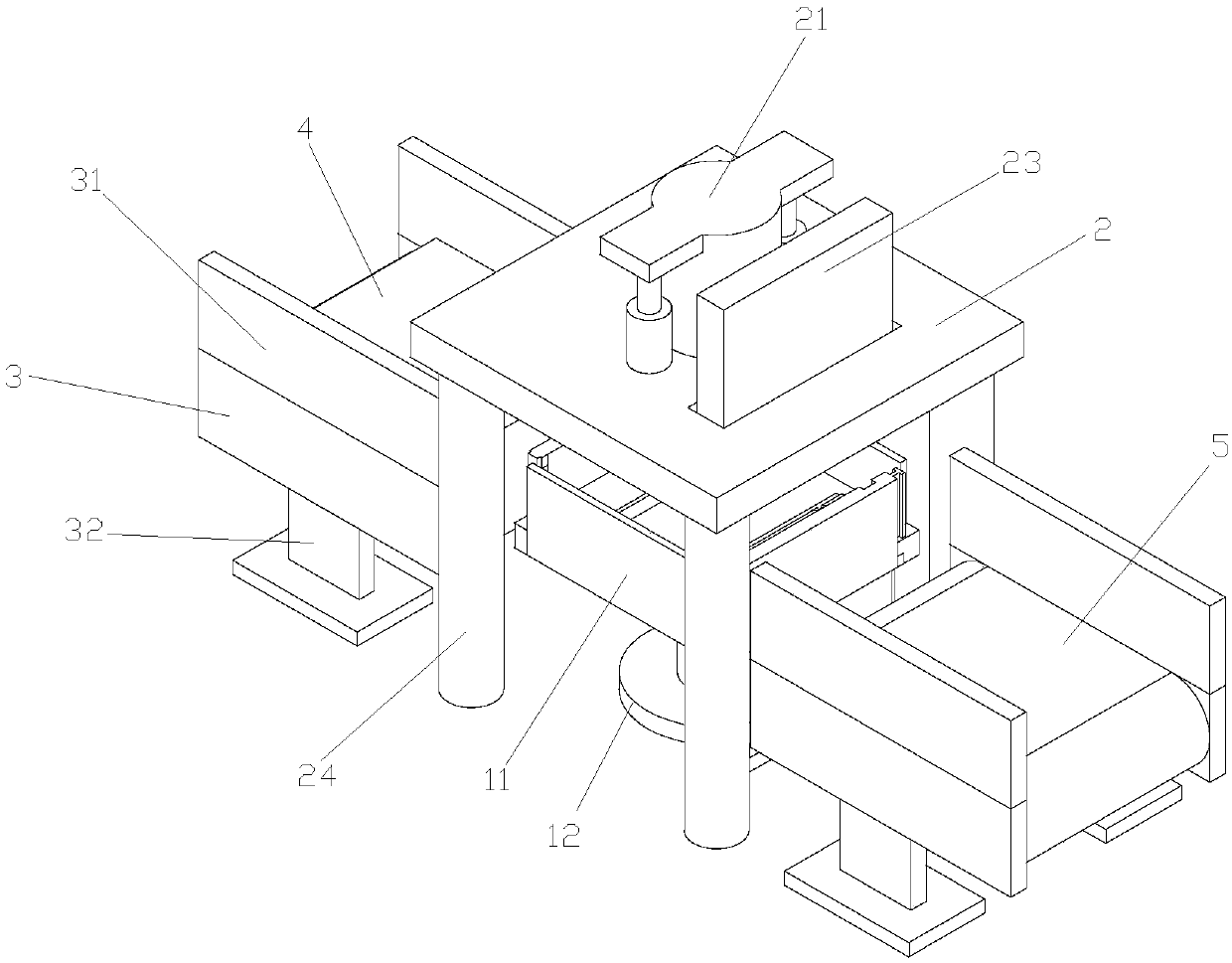

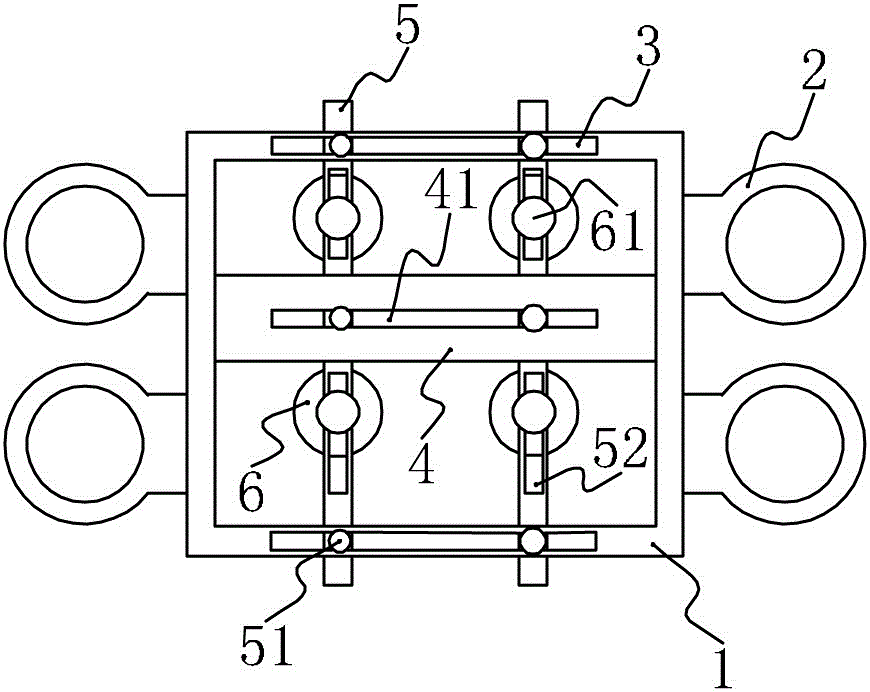

ActiveCN105414349AConvenient punching operationIncrease productivityShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses cylindrical drawn part production and machining equipment. The equipment comprises an upper die base and a die mold base, wherein a plurality of drawing molds, a side-shearing punching mold, a bump blanking mold, a top hole punching mold and a claw blanking mold are arranged on the upper die base and the lower die base; the side-shearing punching mold, the bump blanking mold, the top hole punching mold and the claw blanking mold are sequentially arranged behind the drawing molds; a material falling mold is also arranged in front of the drawing molds; an upper die of each mold is fixedly mounted on the upper die base; a lower die of each mold is fixedly mounted on the lower die base; mechanical arms are mounted at one side of the upper die base and one side of the lower die base. By adopting the structure, various different procedures of synchronous machining can be implemented on the same equipment, so that the production efficiency is greatly improved and the labor cost is lowered; by arranging the top hole punching mold, a cylindrical drawn part can be conveniently blanked; a material can be blanked quite conveniently and rapidly and can also be drained quite conveniently; by arranging a locating plate, product deflection caused in a clamping process or a transportation process can be corrected by a V-shaped groove which is formed in the locating plate, so it is ensured that a product does not rotate.

Owner:镇江泛美汽车零部件有限公司

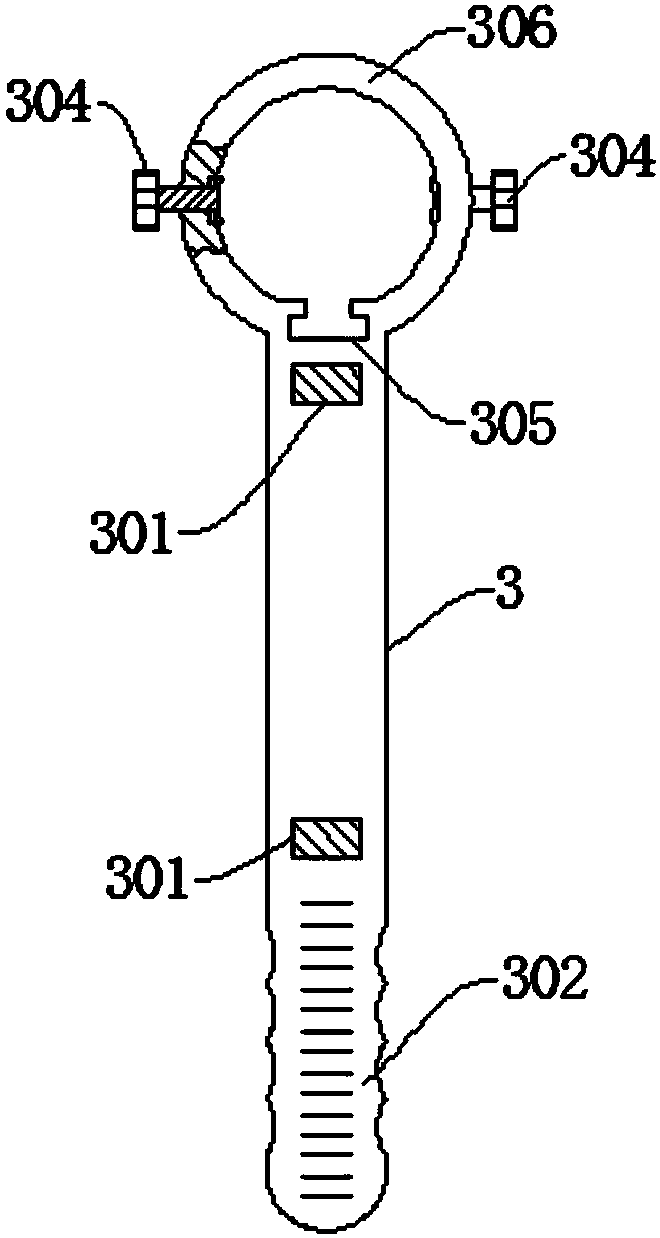

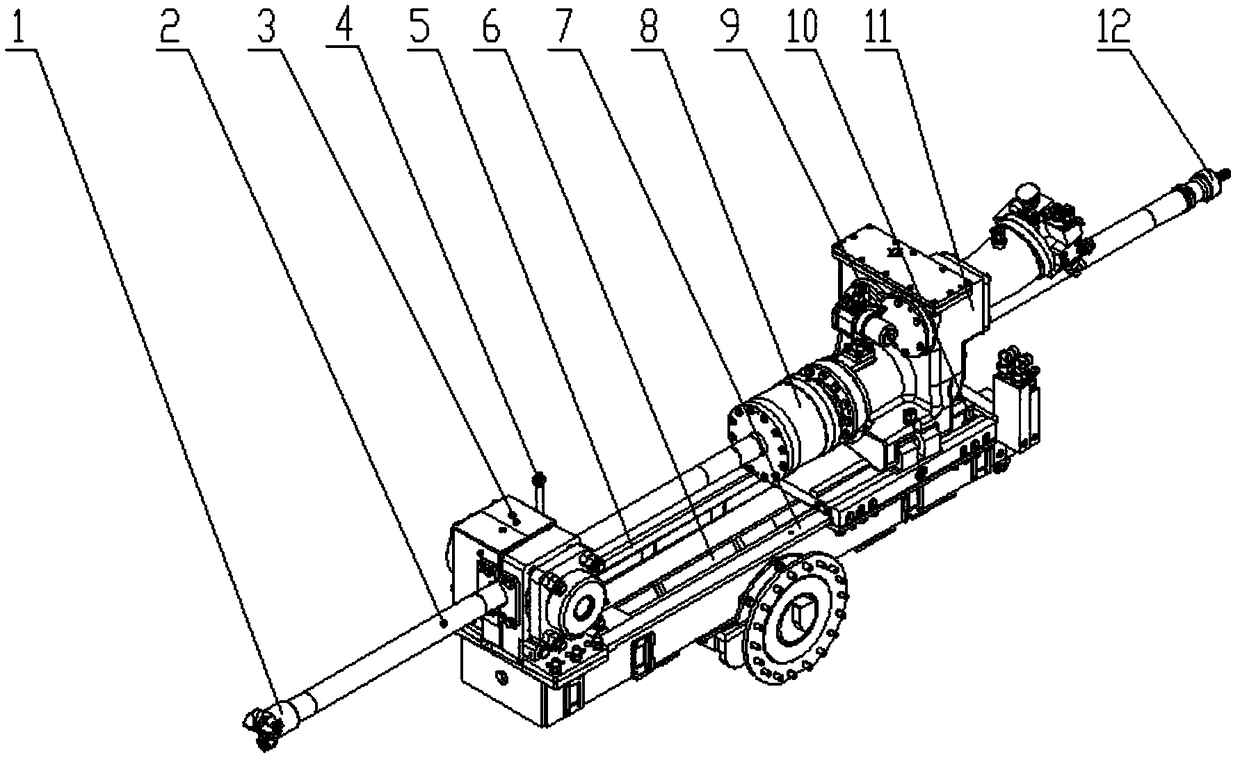

Device and method capable of measuring drilling depth of hydraulic drill carriage

PendingCN108343375AGuaranteed accuracyConvenient punching operationSurveyConstructionsPunchingRare-earth magnet

The invention discloses a device and method capable of measuring the drilling depth of a hydraulic drill carriage. The device comprises a drill bit, a drill pipe, a gripper, a gripper opening cylinderoil inlet pipe, a guide rail, a propulsion cylinder, rare earth magnets, a hydraulic chuck, a hydraulic chuck oil inlet pipe, a proximity switch, a gyrator reduction gearbox and a small water adaptersubstitute. The device and method capable of measuring the drilling depth of the hydraulic drill carriage have the beneficial effects that a drilling rig can accurately record the drilling depth in real time in the drilling process of the drill bit, and personnel does not need to record the number of drill pipes and supervise; the advance and retreat of the drill pipe are judged by the oil inletpipeline pressure of the hydraulic chuck, the pipeline pressure of the open side of the gripper, the pipeline pressure of the feeding side of an oil cylinder and the pipeline pressure of the retracting side of the oil cylinder, and the record of the positive and negative values of the stroke is convenient; the proximity switch is composed of an inductive element and a single-chip microcomputer, and can sense a plurality of rare earth magnets for collecting signals so that the proximity switch can record the stroke when continuously sensing two rare earth magnets; and the small water adapter substitute is used for ventilation and drainage in the drilling process, and the punching operation is facilitated for workers.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

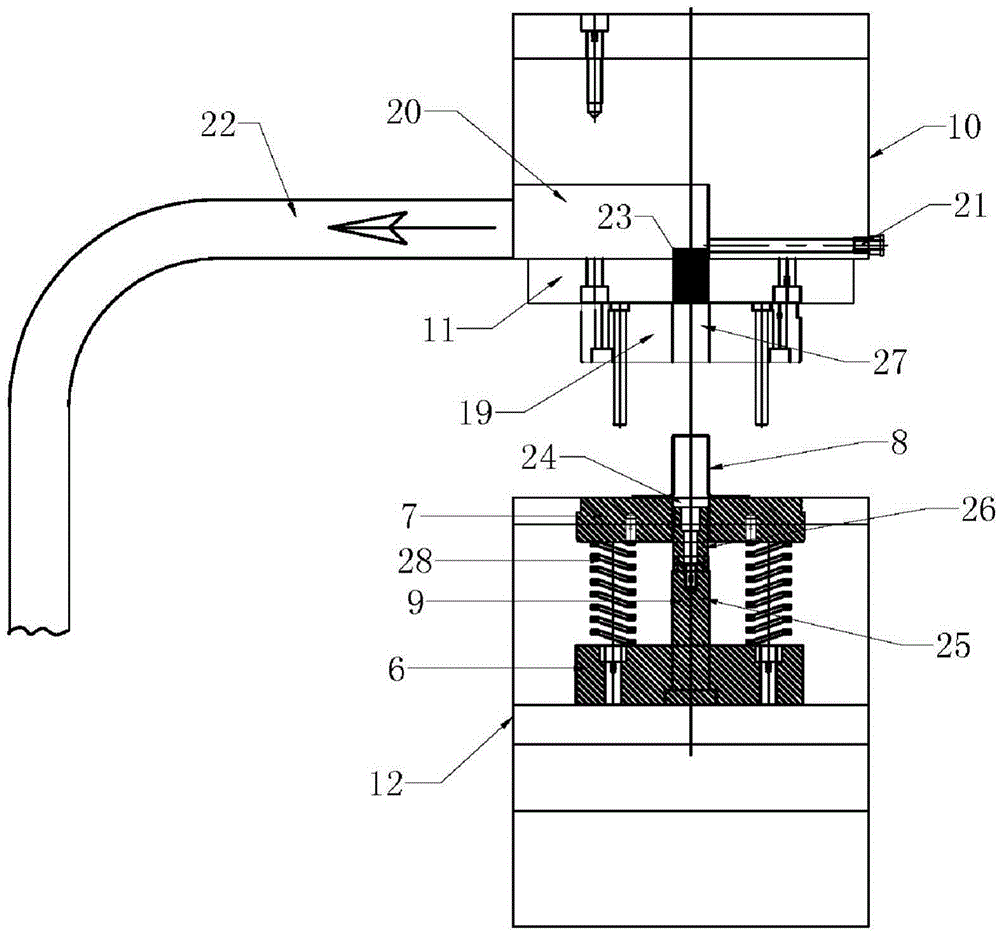

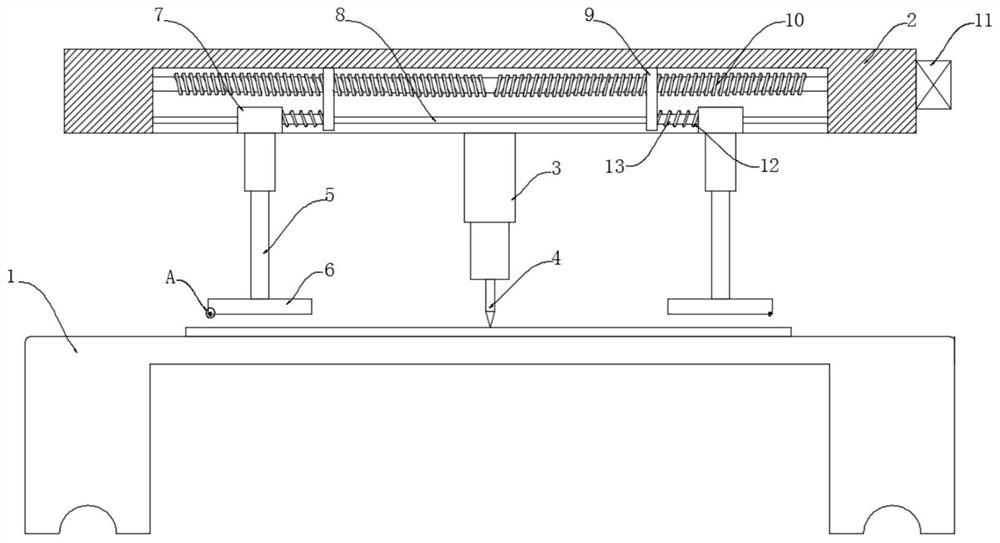

Punching device

InactiveCN107627393AThere will be no deviationConvenient punching operationMetal working apparatusPunchingPulp and paper industry

The invention discloses a punching device which comprises an operating platform. A pressing plate is slidably arranged above the operating platform through two supporting plates, cross rods are symmetrically fixed between the upper ends and the lower ends of the two supporting plates, and punching strips are slidably embedded in the inner sides of sliding grooves; and punching needles are fixed tothe bottoms of the punching strips at equal intervals. According to the punching device, firstly, clamping pins are slidably embedded in the two sides of the top of the operating platform, when labelpaper is placed on the operating platform, limiting buckles on the clamping pins can be rotated to fix the label paper, and thus when the label paper is punched, the off-tracking phenomenon can be avoided; and secondly, since the pressing plate is connected with the cross rod between the upper ends of the two supporting plates through springs, when the label paper is punched, the pressing plate can be sprung back to the original position after punching is completed, and the punching is easier and more convenient accordingly.

Owner:TIANJIN GRAND PAPER IND

Adjustable punching device for plastic die production and machining

InactiveCN109317722AConvenient punching operationEasy to adjustLarge fixed membersPositioning apparatusPunchingEngineering

The invention relates to the technical field of plastic die production and machining, in particular to an adjustable punching device for plastic die production and machining. The adjustable punching device comprises a base. Supporting plates are perpendicularly and fixedly arranged at the two ends of the side face of the base, and the two supporting plates are parallel to each other. A fixing device is fixed to the side face, away from the supporting plates, of the base. A plastic die is arranged at the position, between the two supporting plates, of the base. By means of the adjustable punching device, the plastic die can be firmly fixed through two clamping and fastening devices, in addition, under the effect of a first electric telescopic rod, the position of the plastic die on the basecan be conveniently adjusted, under the common effect of a second electric telescopic rod and a second linear motor, the position of a motor is also conveniently adjusted, and therefore punching operation with better effects can be more conveniently conducted on the plastic die.

Owner:HUANGSHAN MINGSHENG DIE MATERIAL CO LTD

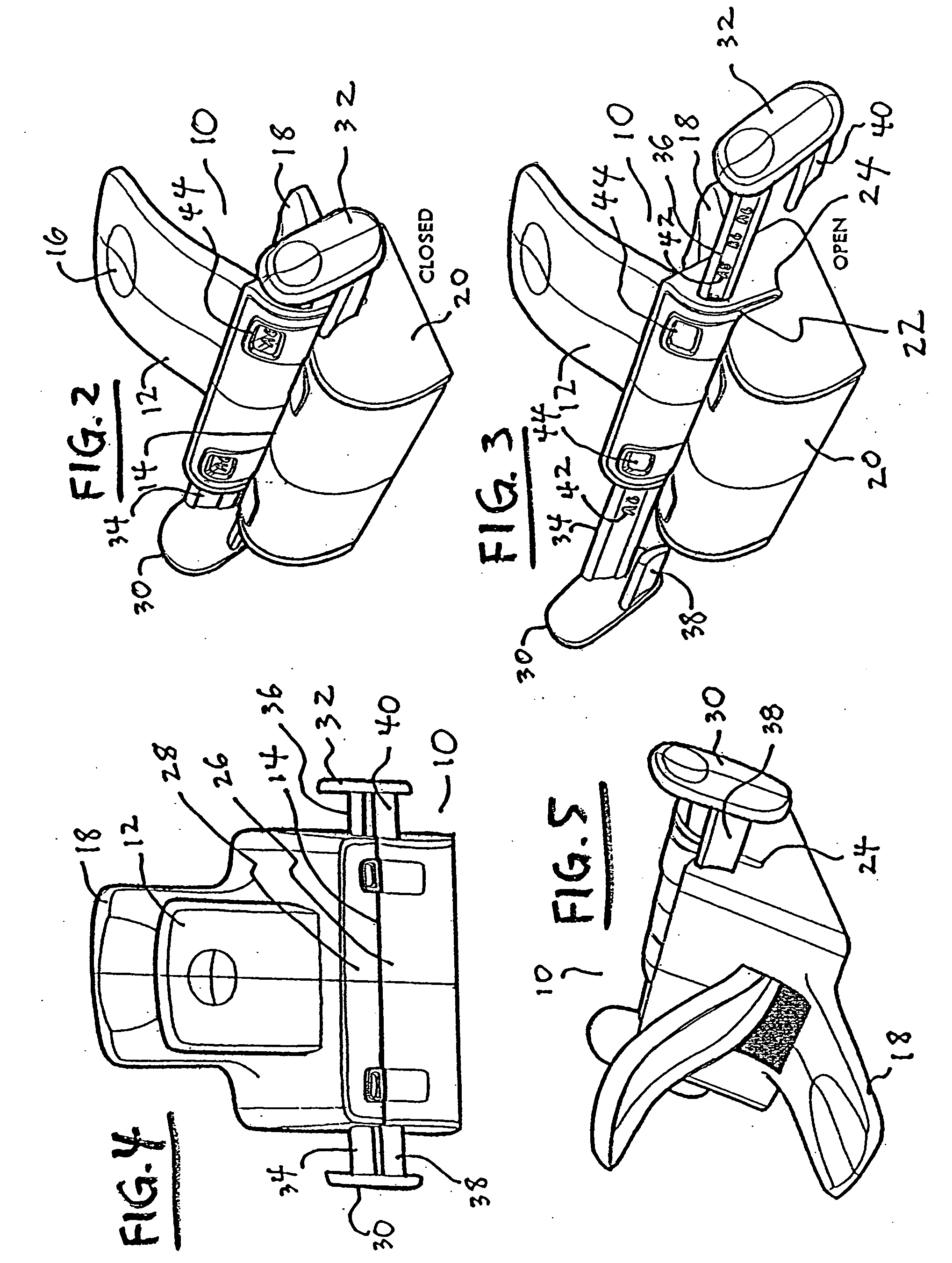

Paper guide for hole punch

InactiveUS20070251367A1Convenient punching operationSmall sizeMetal working apparatusEngineeringVia device

A desktop hole punch device for punching holes in stacked sheet media such as paper is disclosed. The hole punch device includes at least one adjustable, laterally extending arm having markings thereon indicating standard office paper sizes. The markings are visible to the user through a window in the device. An edge guide at the distal end of the arm aligns the stack of sheet media and a curved page lifter extending from the edge guide reverses the natural curl in the paper stack for better and more precise hole punching.

Owner:ACCENTRA

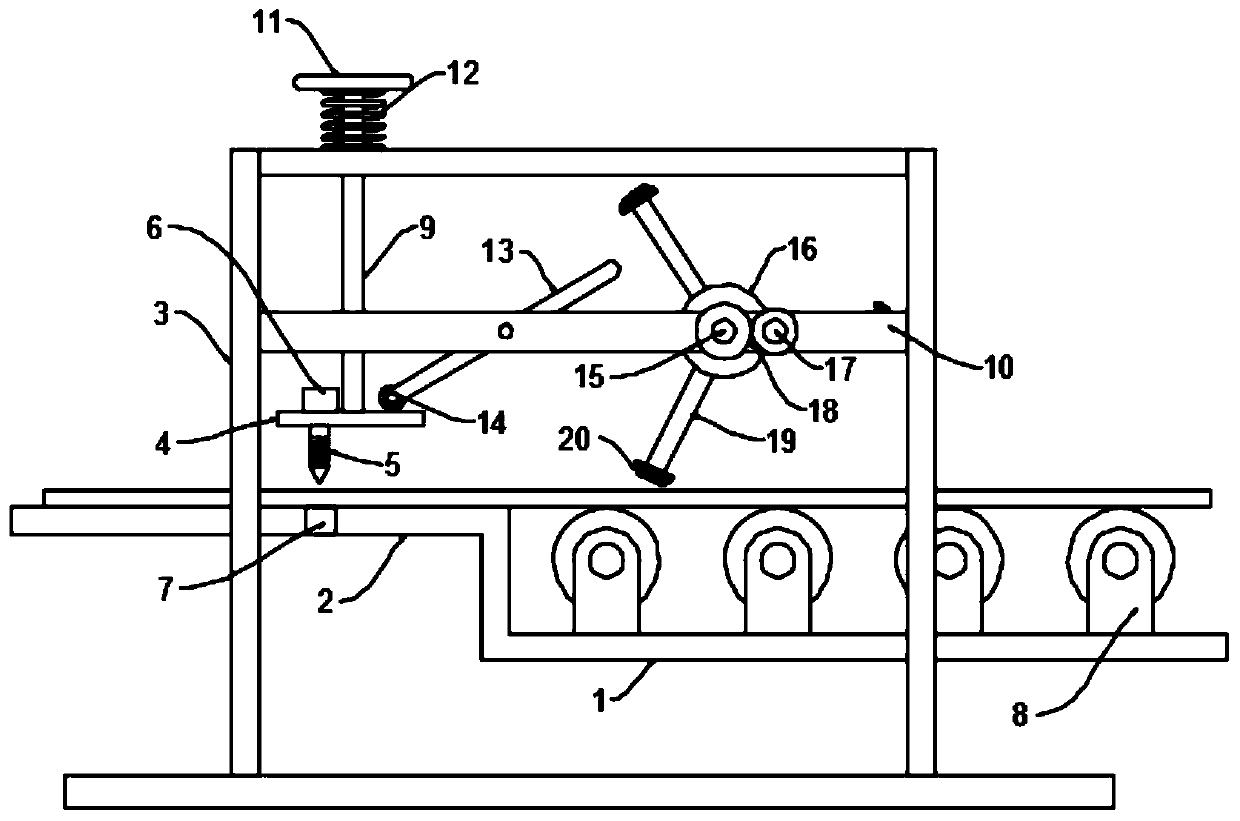

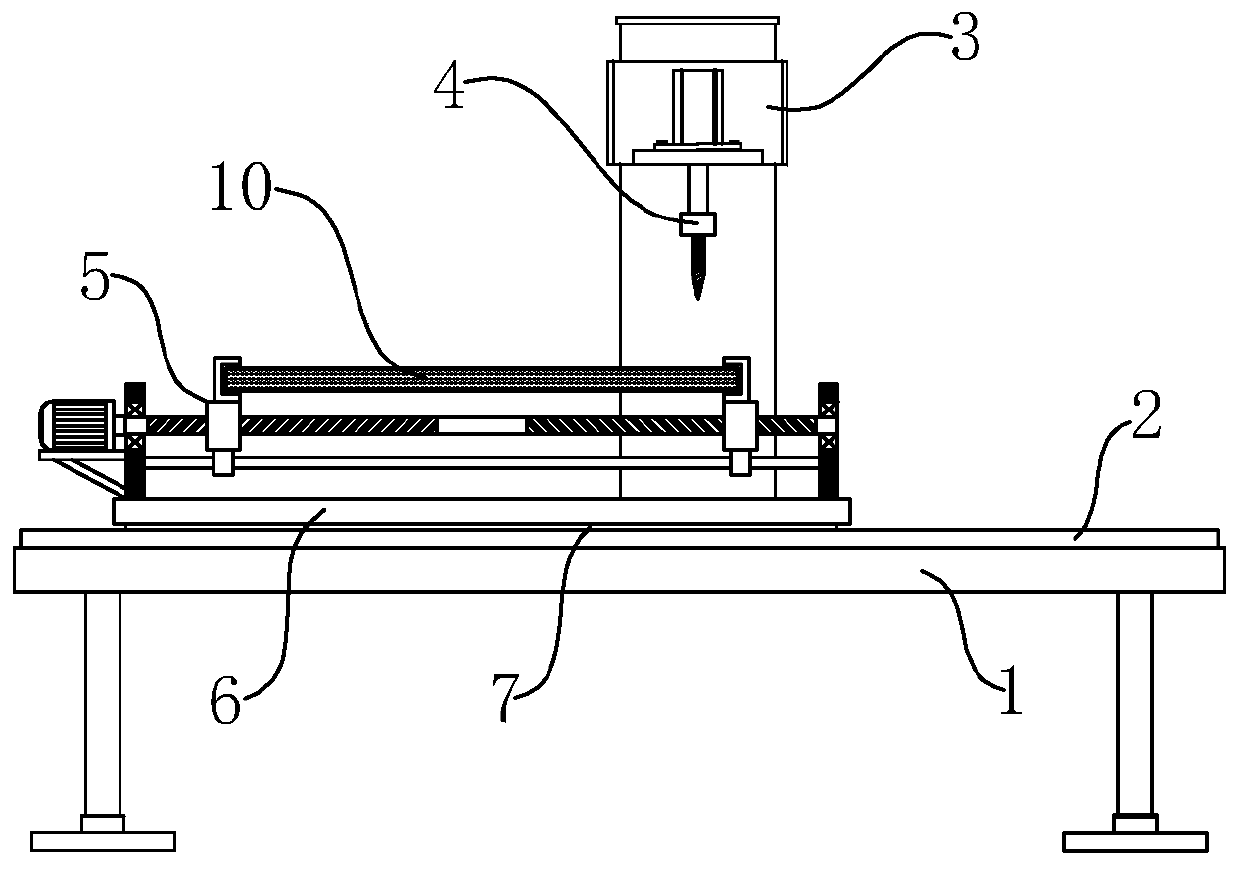

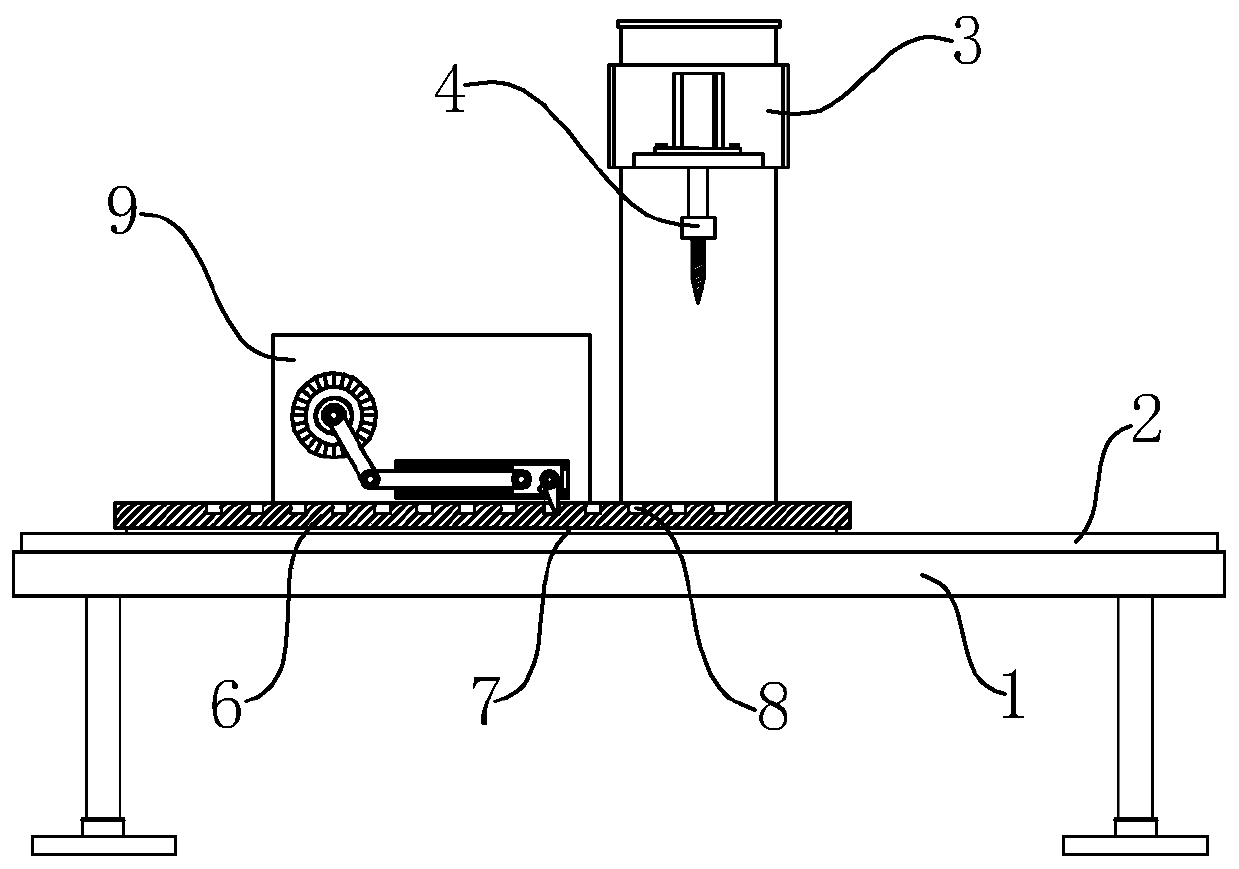

Pushing perforating device used for furniture wood board machining

InactiveCN110900723AConvenient punching operationEasy to useStationary drilling machinesWood plankMachining

The invention discloses a pushing perforating device used for furniture wood board machining, and relates to the technical field of wood board machining. The pushing perforating device mainly aims atsolving the problem that wood board perforating conveying needs manual pushing. The perforating device comprises a base basal plate, an installation outer frame arranged on the base basal plate and aconveying table used for wood board conveying. The conveying table comprises a first supporting plate and a second supporting plate which are both in a horizontal state. Multiple carrier rollers distributed at equal intervals are arranged on the first supporting plate. A transverse frame is arranged on the middle portion of the installation outer frame, and a drilling assembly and a pushing assembly are installed on the transverse frame. A rotating pushing and pressing rod is further arranged on the transverse frame, the middle portion of the rotating pushing and pressing rod is hinged to thetransverse frame through a hinge pin, and one end of the rotating pushing and pressing rod is located on the upper side of an installation plate. The device does not need manual control and operationand can continuously conduct perforating, and the perforating efficiency can be effectively improved; and meanwhile, due to the fact that the distance by which a wood board is pushed by push rod pieces to move each time is the same, the perforating gaps are equal, and use is facilitated.

Owner:李可娟

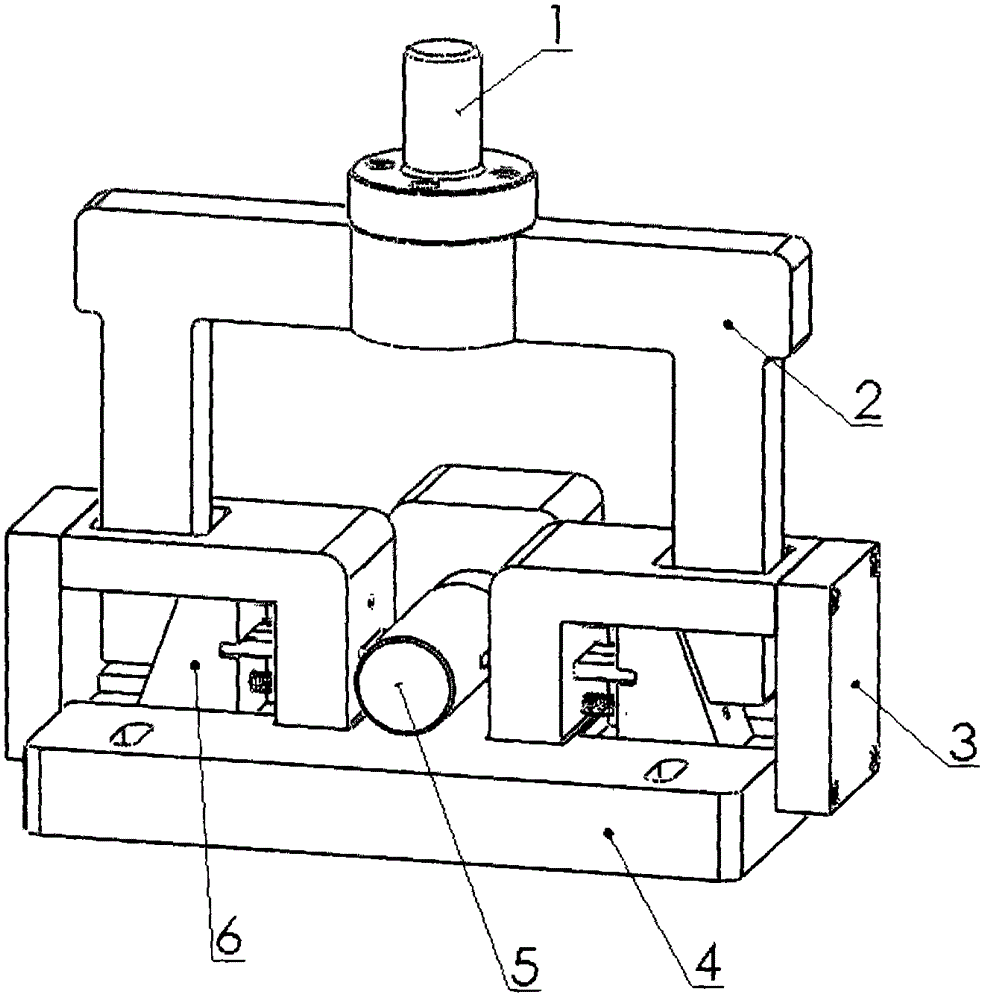

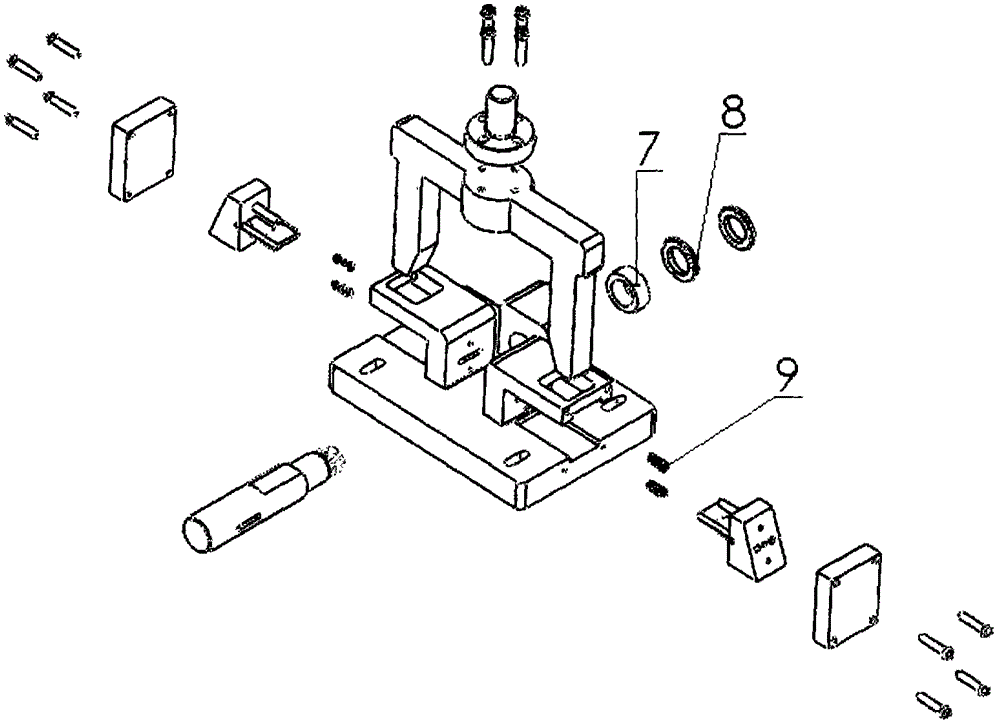

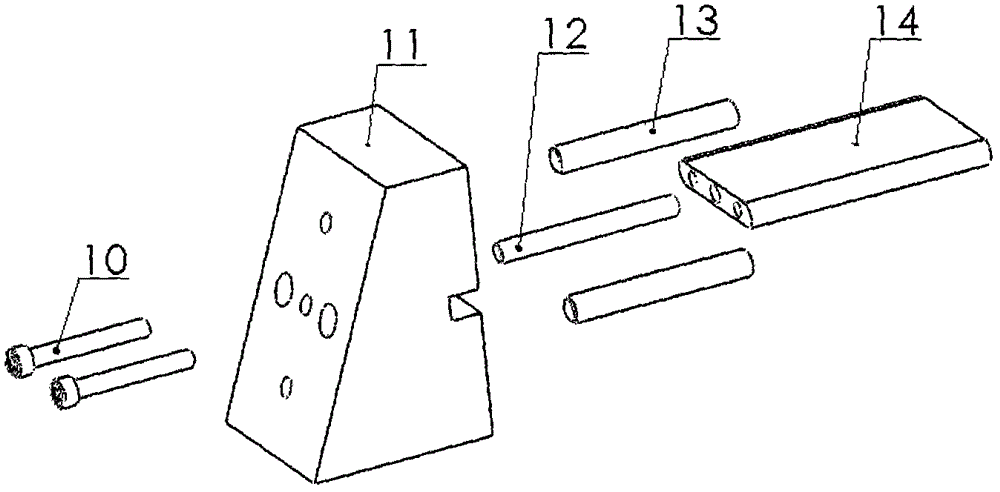

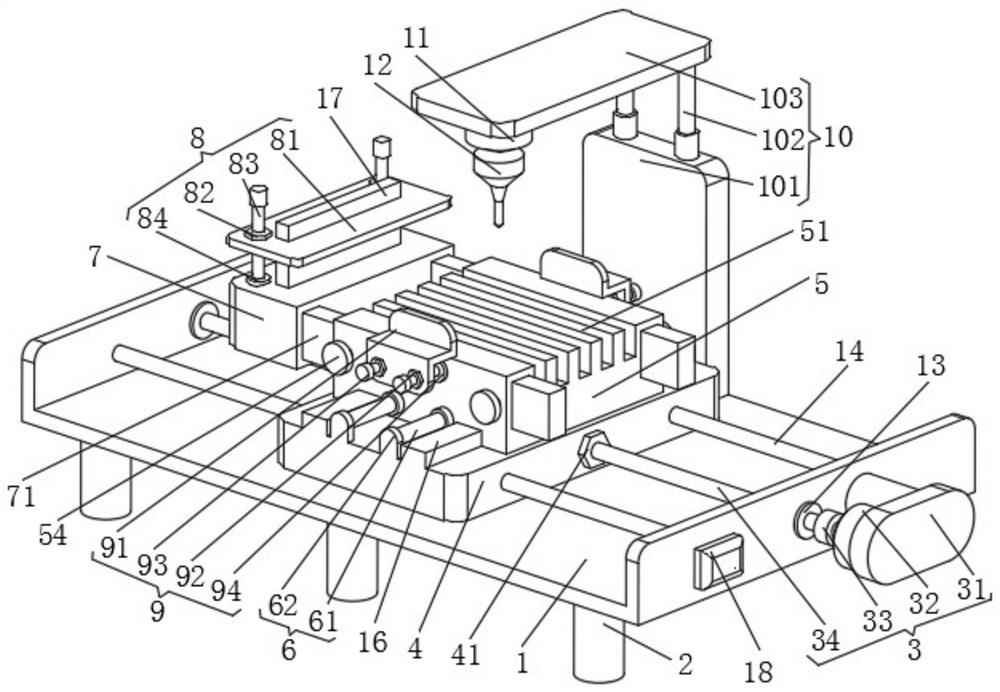

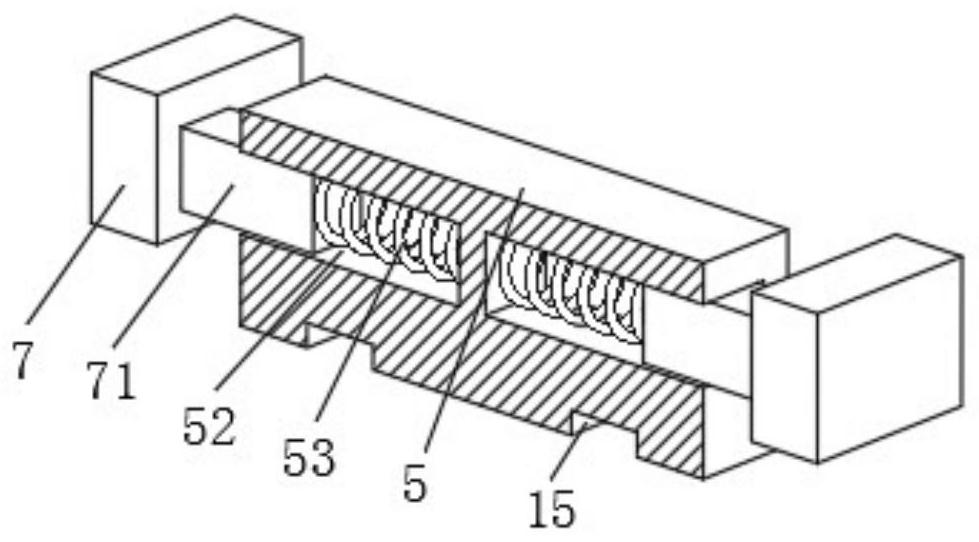

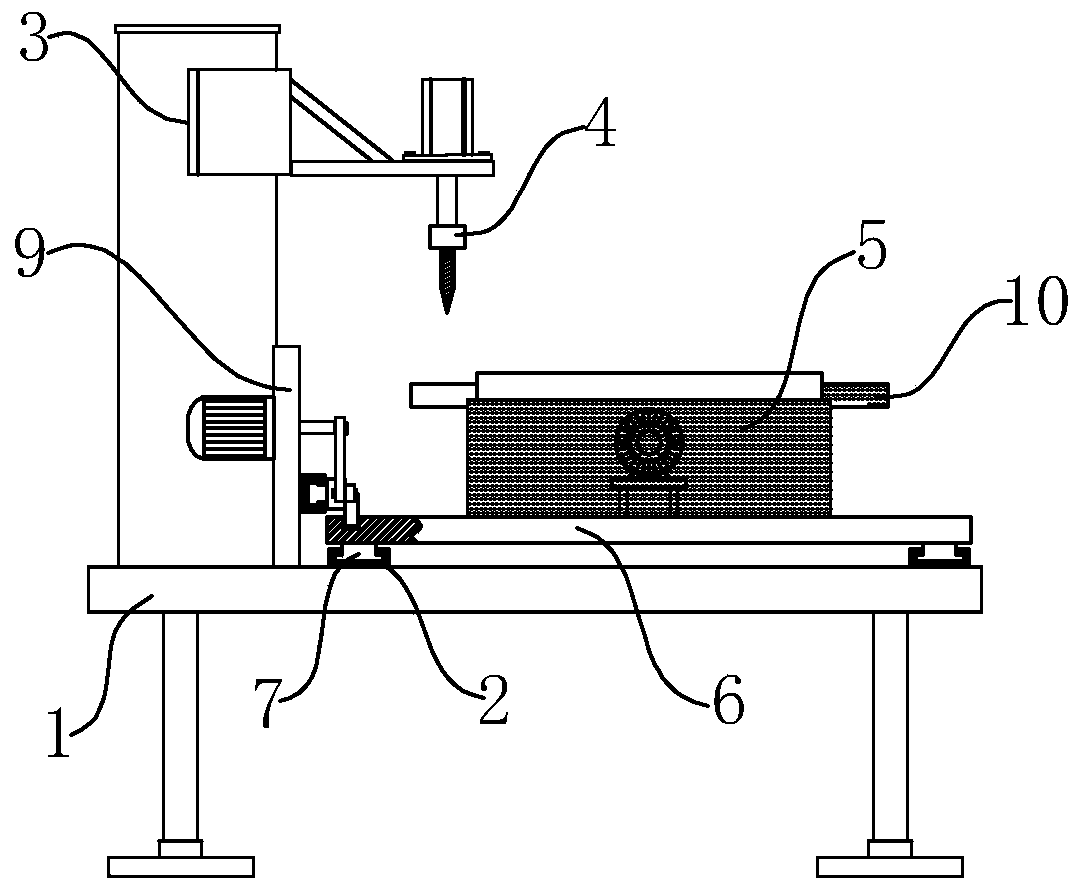

Thin-wall steel pipe symmetrical hole machining method

ActiveCN104525704AReasonable structureEasy to install and adjustPerforating toolsMachiningSteel tube

The invention relates to the technology of press machine machining, in particular to a method for machining a pair of holes which are symmetrical relative to a plane which passing a central axis on a thin-wall steel pipe through a stamping die. The stamping die mainly comprises a die shank, an upper die plate, a lateral plate, a base, a cavity die, a core die mechanism, a round washer, a round nut and a spring I; the core die mechanism is mainly formed by a screw I, a mobile seat, a cylinder pin, a guide pillar and a core die. The stamping die is reasonable in structure and convenient to install and adjust. The hole punching operation is convenient, the machining efficiency is high, and the hole punching symmetry accuracy is good.

Owner:平湖市华杨旅游制品有限责任公司

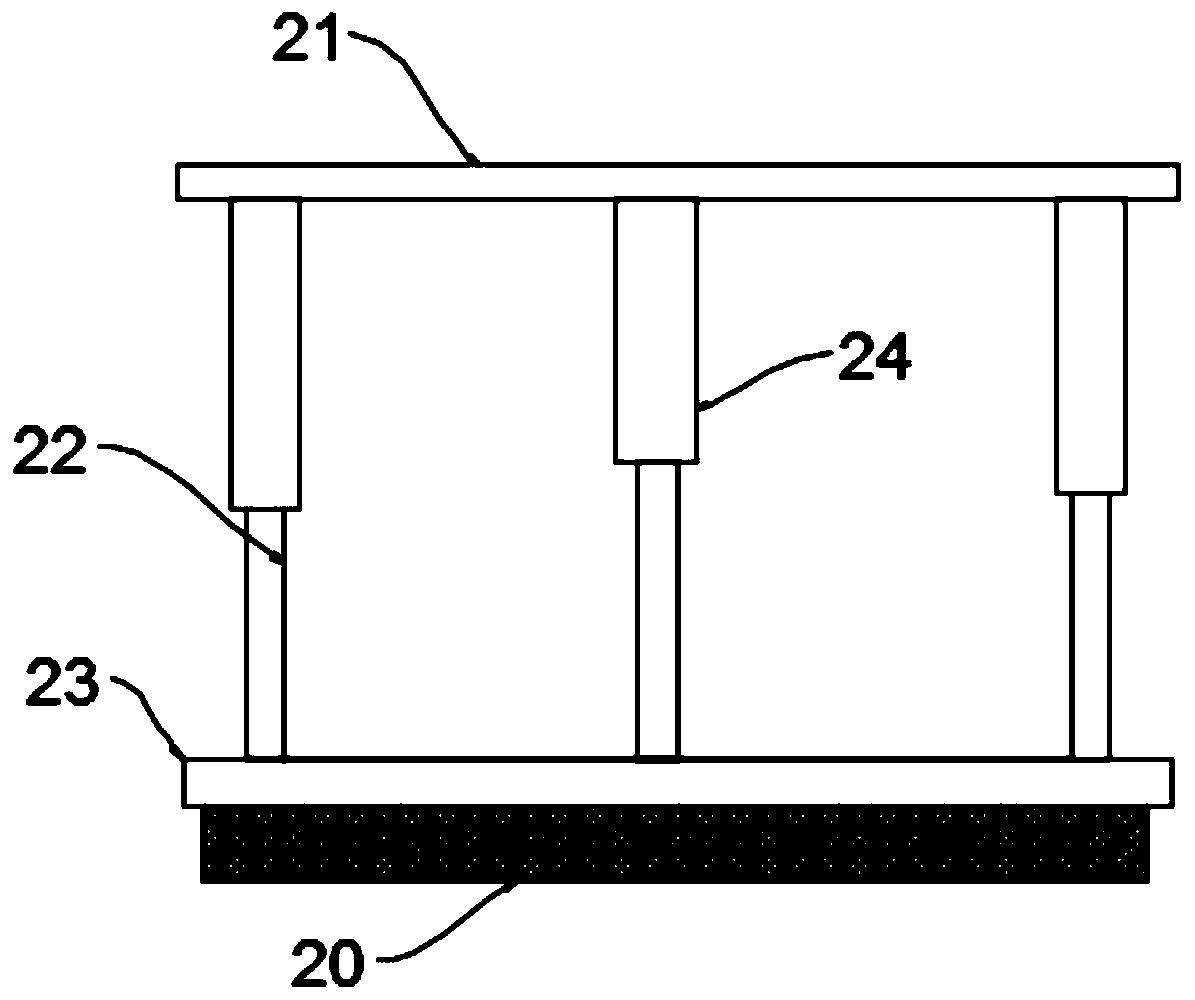

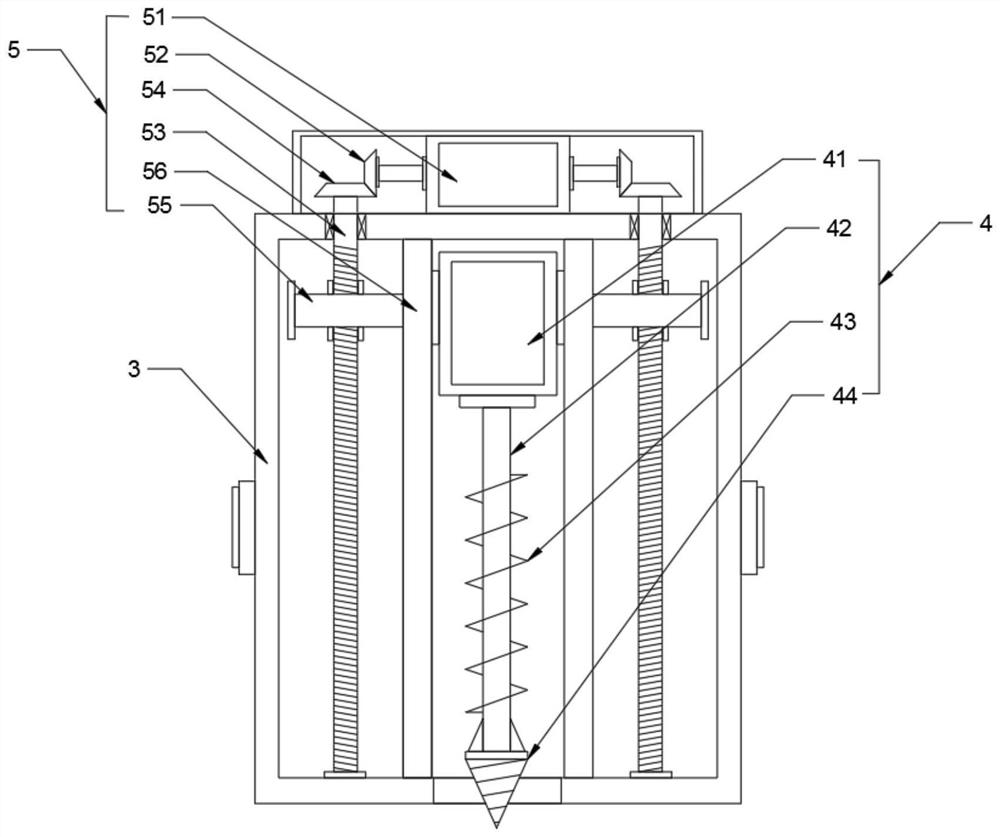

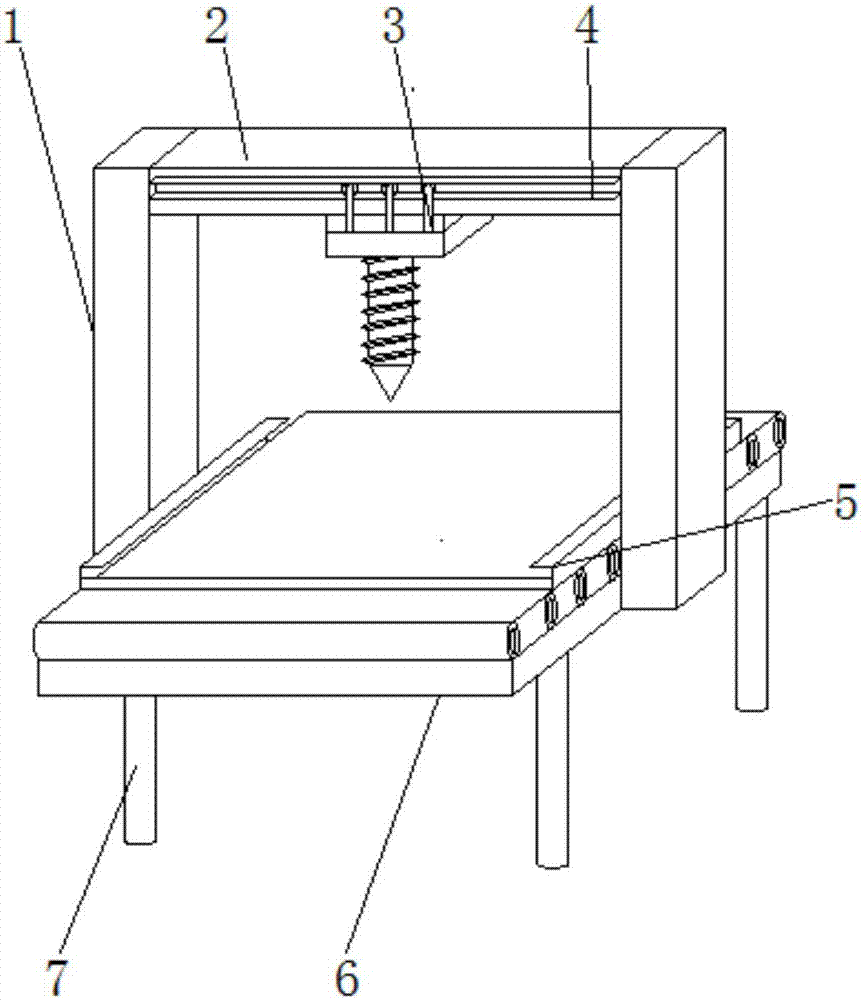

Collection and analysis device for different-height samples of solid waste heap

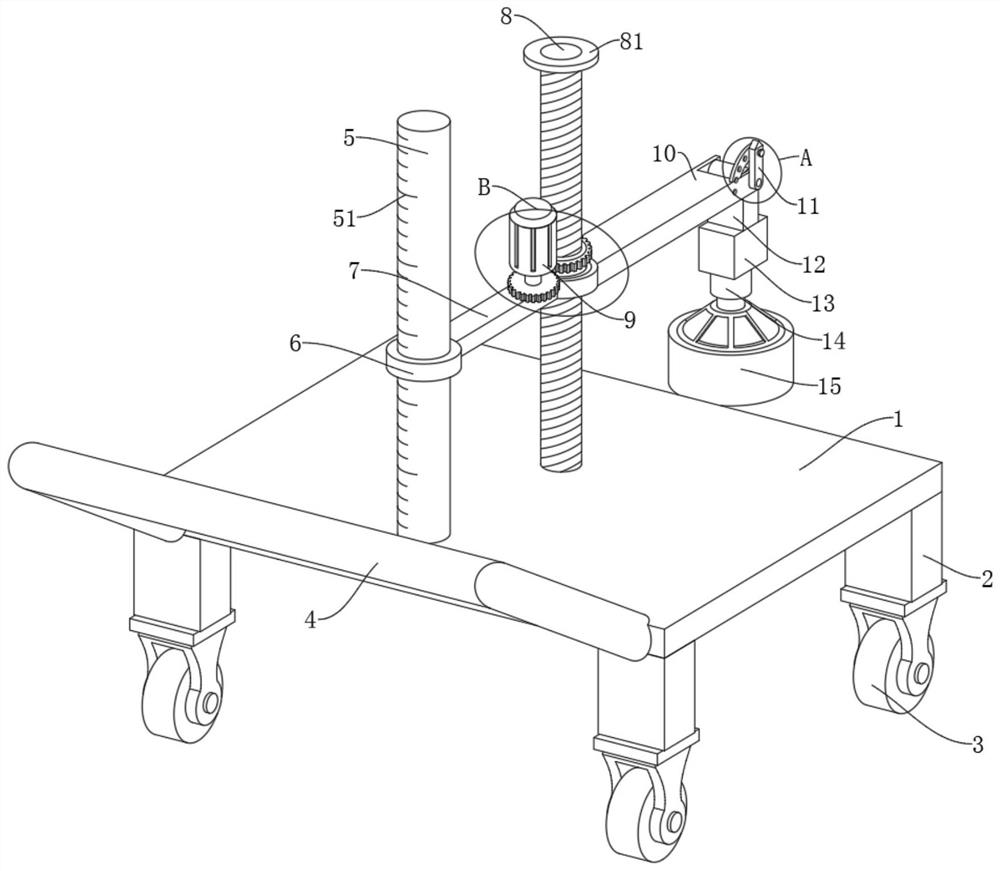

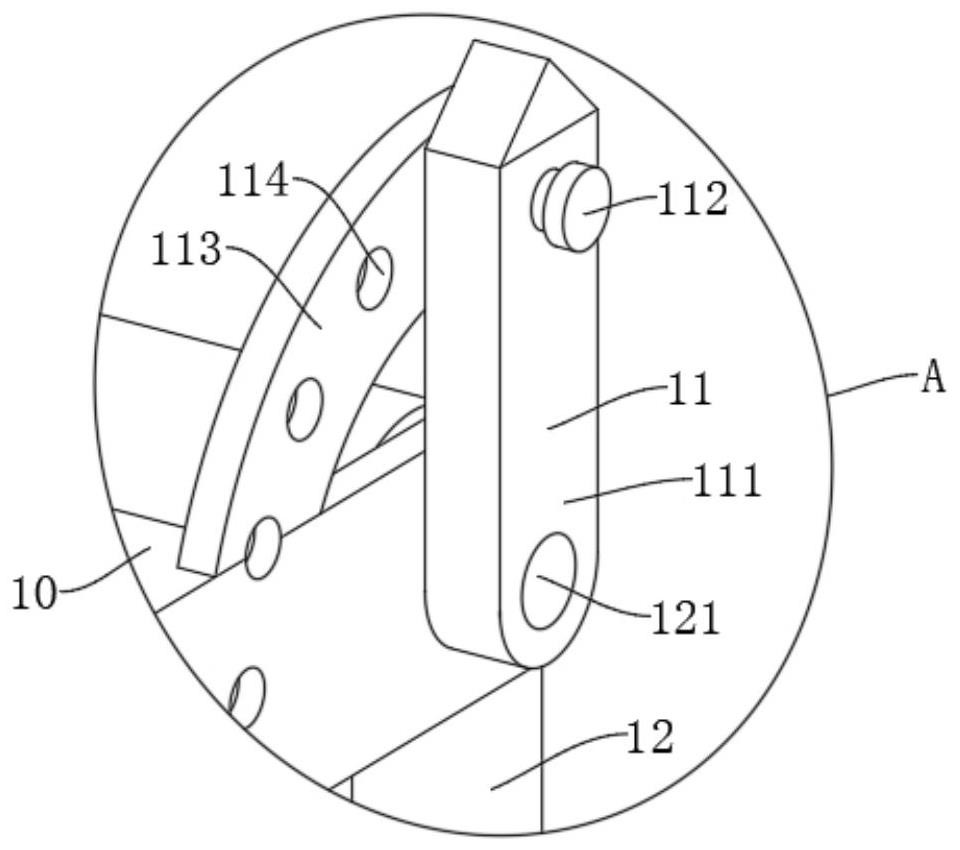

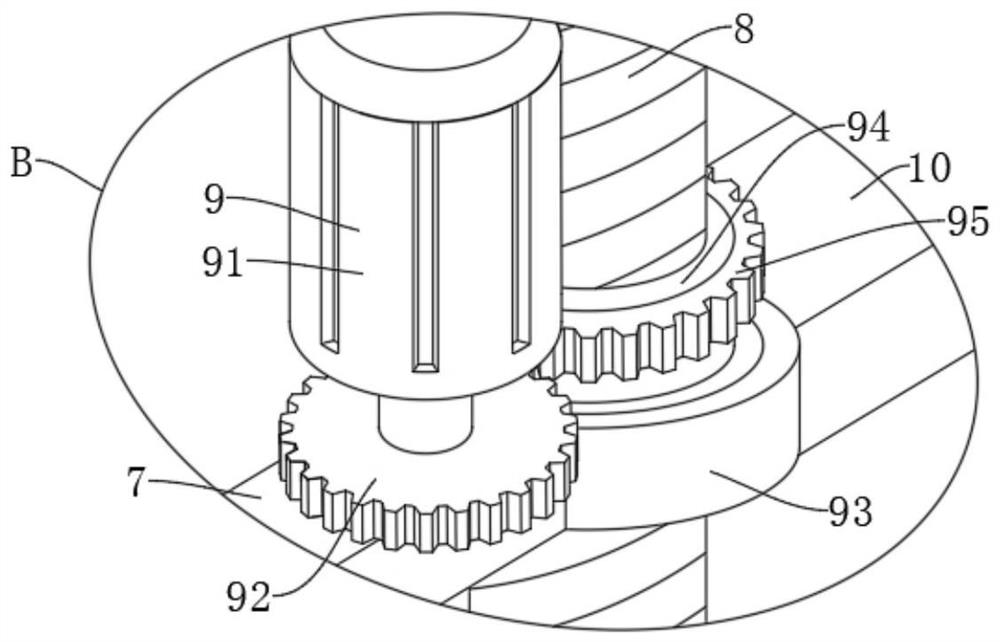

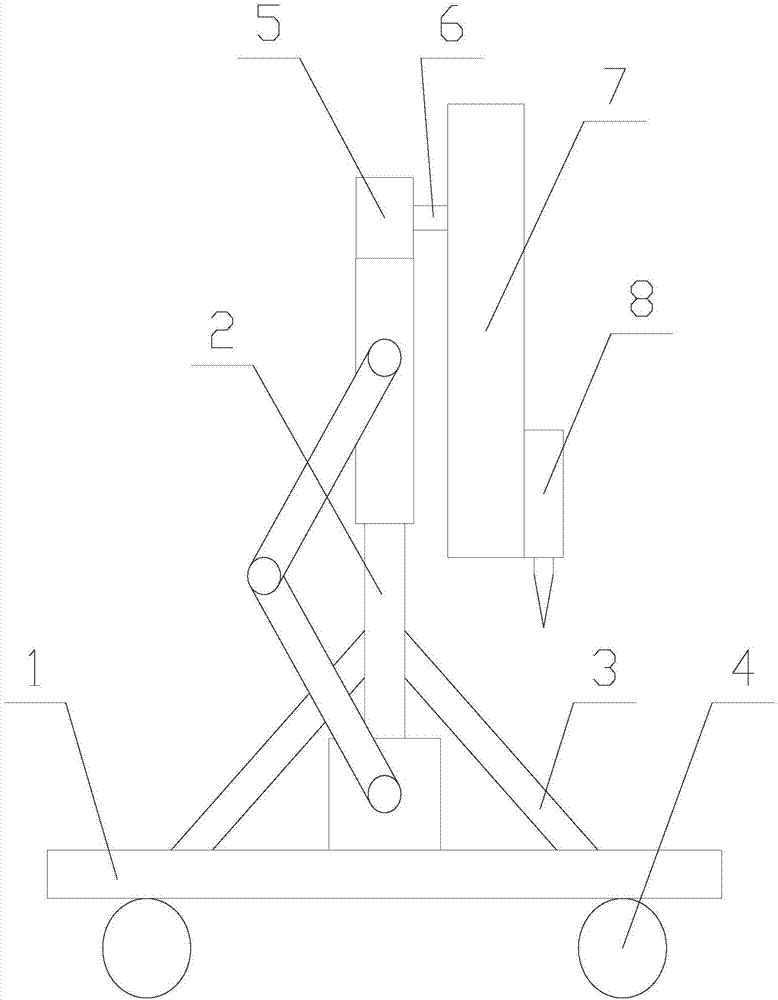

InactiveCN114279745AEasy to disassembleEasy to collectWithdrawing sample devicesScrew threadThreaded rod

The invention discloses a device for collecting and analyzing samples at different heights for solid waste heap, which comprises a workbench, one side of the top of the workbench is fixedly connected with a scale rod, the scale rod is slidably sleeved with a sliding cylinder, one end of the sliding cylinder is fixedly connected with a connecting rod, and one end, away from the sliding cylinder, of the connecting rod is fixedly connected with a transmission mechanism. A threaded rod is rotationally sleeved with the transmission mechanism, and the bottom end of the threaded rod is fixedly connected to the other side of the top of the workbench. A supporting rod is fixedly connected to the end, away from the connecting rod, of the transmission mechanism, a rotating rod is rotationally connected to one end of the supporting rod, switching assemblies are fixedly connected to the two sides of one end of the rotating rod, a servo motor is fixedly connected to the other end of the rotating rod, and a threaded cylinder is fixedly connected to an output shaft of the servo motor; the end of the threaded cylinder is sleeved with a drilling piece through a threaded structure.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

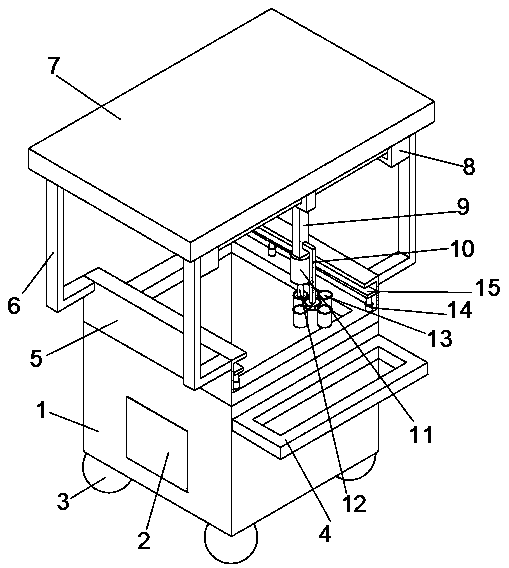

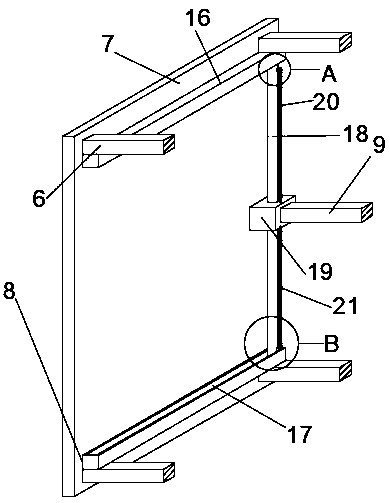

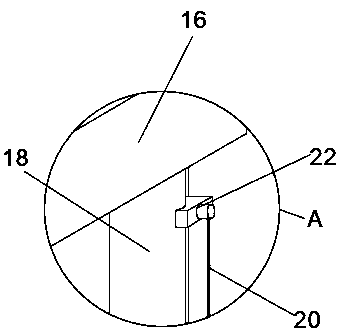

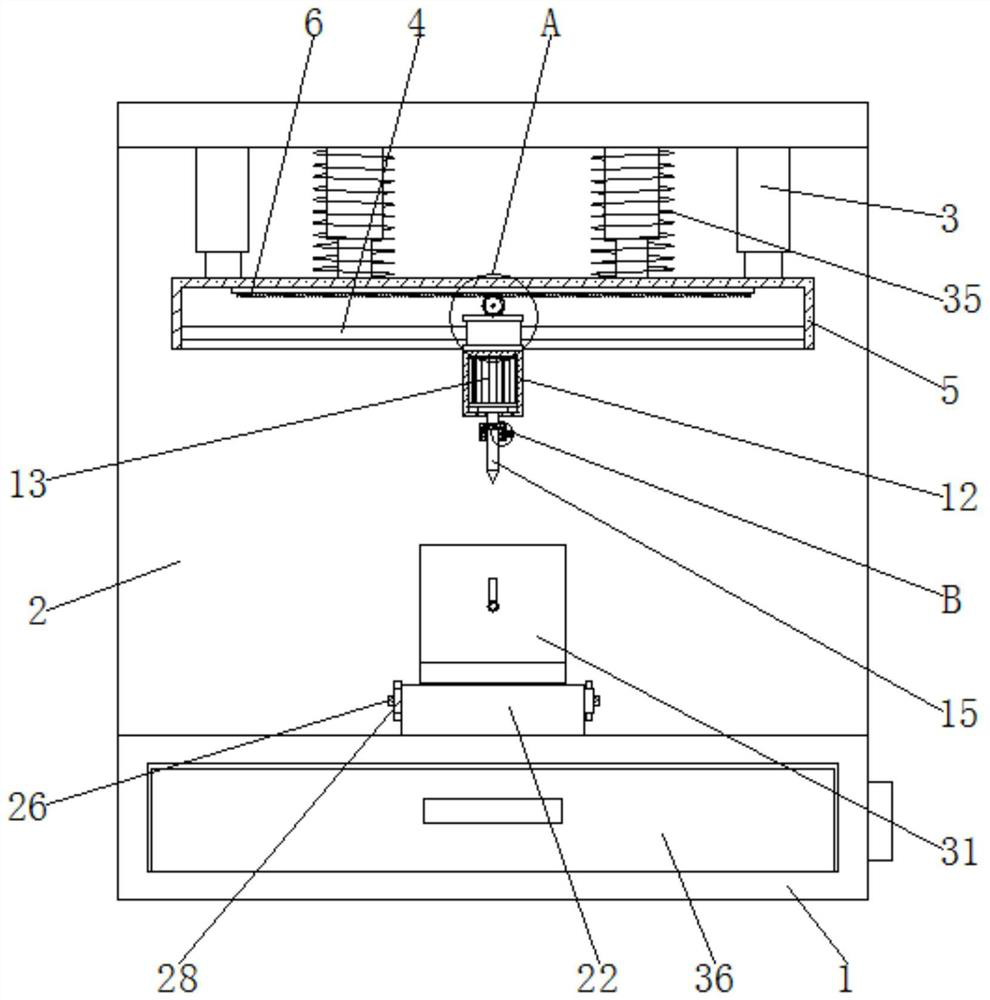

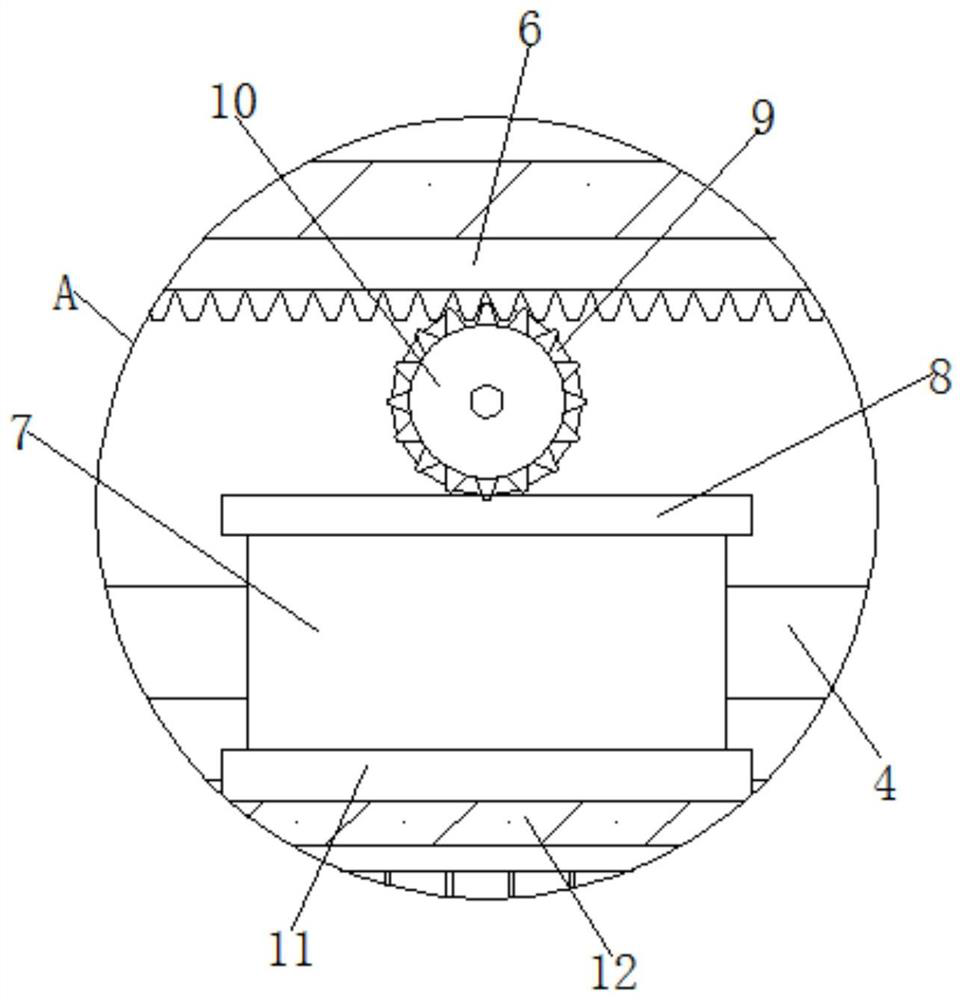

Drilling device capable of multi-angle operating based on internet of things

InactiveCN107363639AIncrease heightConvenient punching operationAutomatic control devicesMeasurement/indication equipmentsDistance sensorsPower circuits

The invention relates to a multi-angle drilling device based on the Internet of Things, including a chassis, a lifting device arranged above the chassis, a driving mechanism, an angle adjustment mechanism and a drilling assembly, and the driving mechanism is arranged above the lifting device , the drive mechanism is connected to the angle adjustment mechanism, and the drilling assembly is arranged on the angle adjustment mechanism. The multi-angle drilling device based on the Internet of Things drives the rotation ring to rotate through the first motor, and adjusts the rotation ring on the rotation ring. The angle and position of the drilling assembly, and use the distance sensor and infrared transmitter to monitor the distance to the target, so as to achieve precise drilling. Not only that, the lifting device drives the driving mechanism to move upwards, increasing the height of the drilling assembly, which is convenient For the punching operation of the target object at a high place, in the working power circuit, the model of the integrated circuit is M5230L, which has two DC voltage outputs, which improves the scope of application of the working power circuit and improves the practicability of the system.

Owner:时枫娇

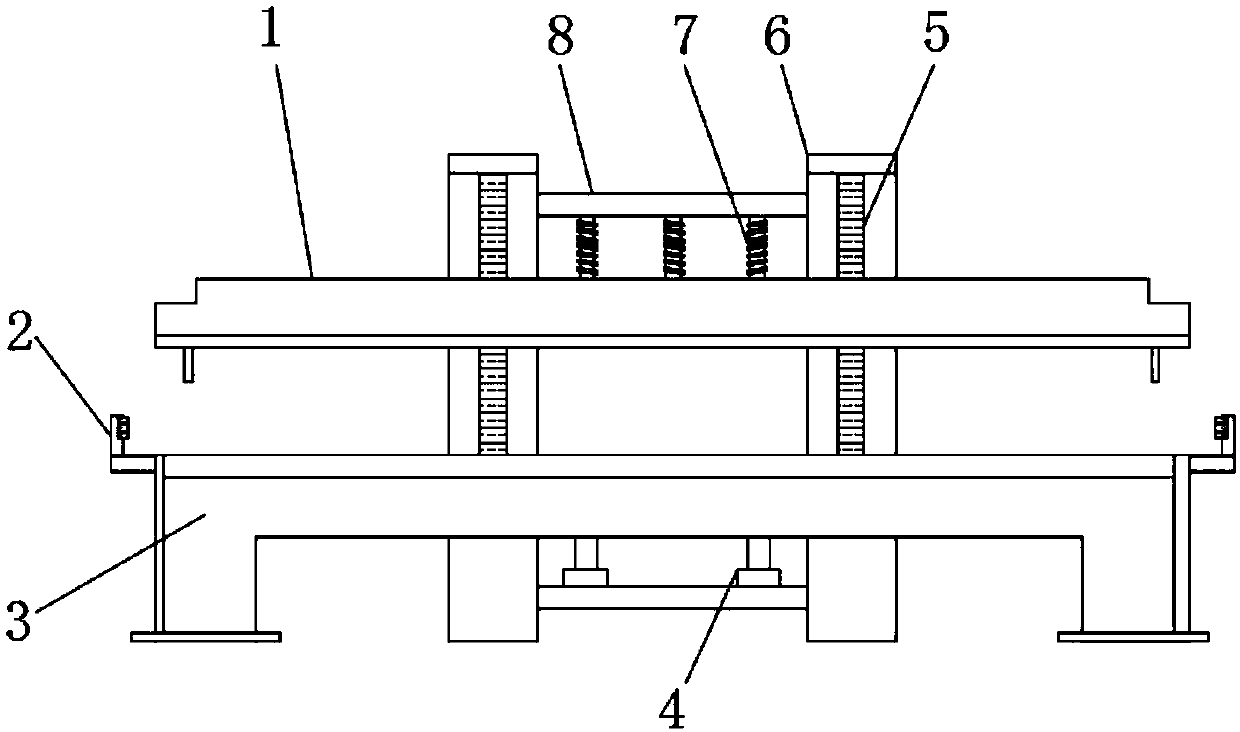

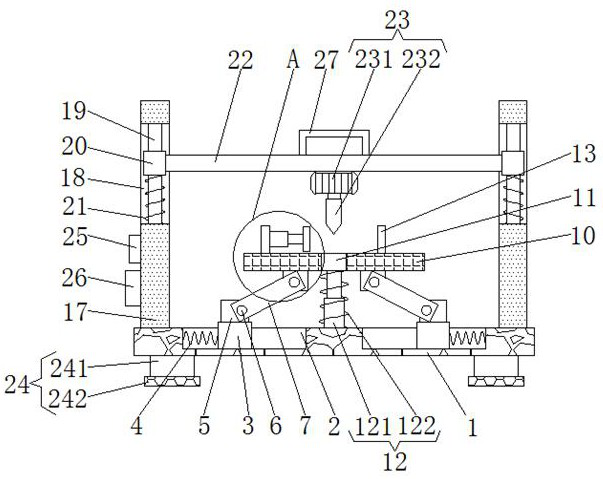

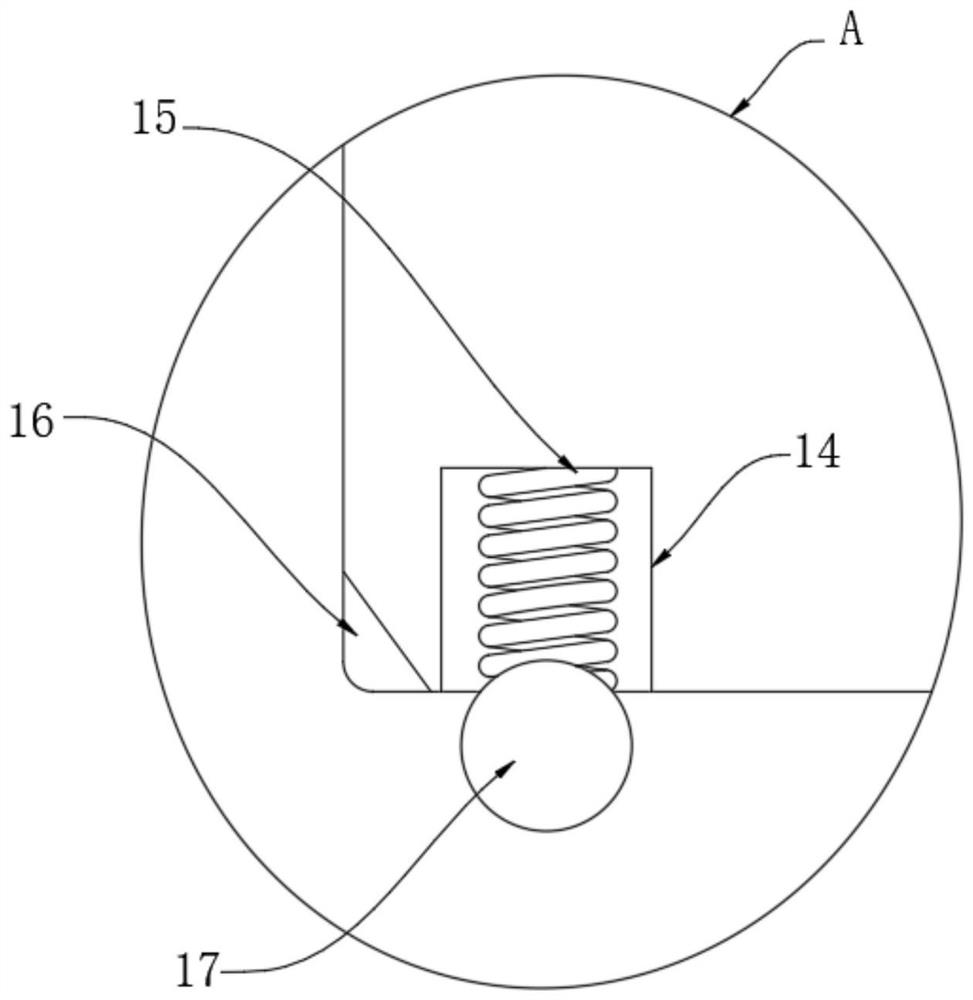

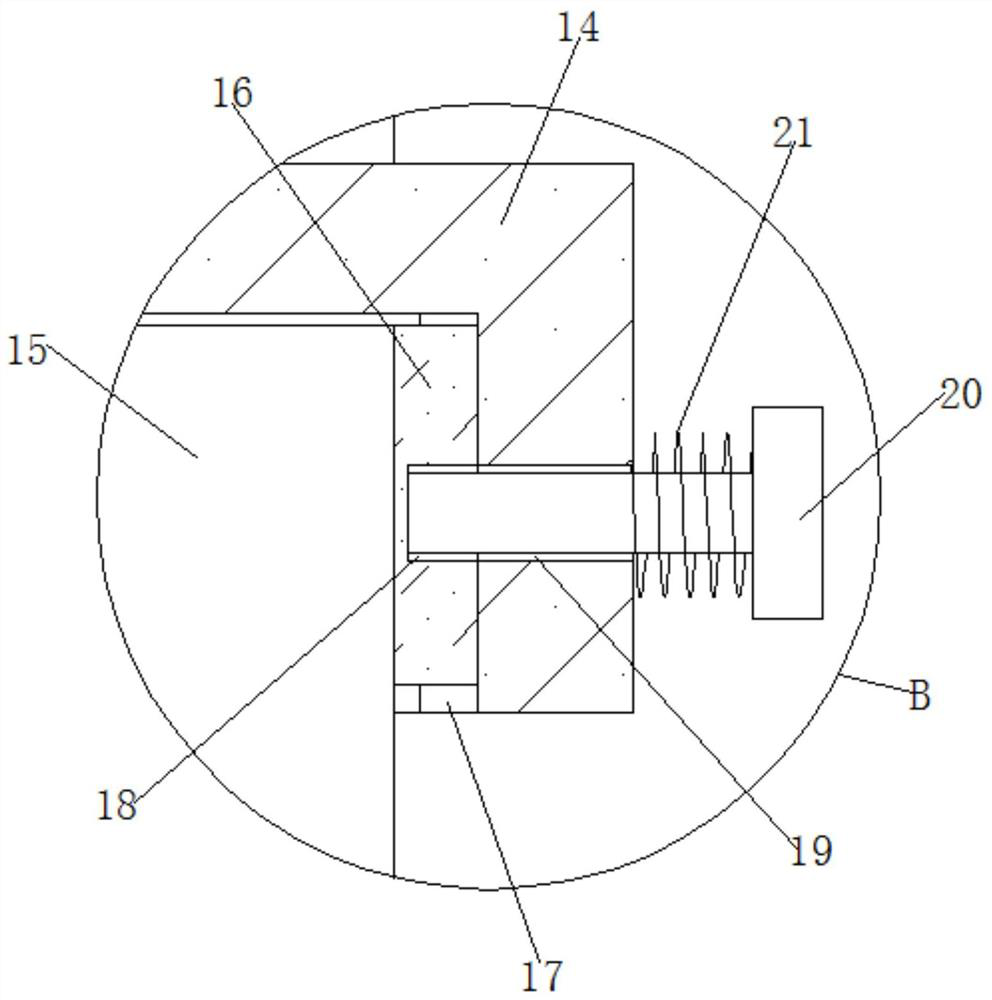

Metal punching device with damping function

InactiveCN111842990AWith shock absorption functionReduce vibrationPositioning apparatusBoring/drilling componentsPunchingDamping function

The invention discloses a metal punching device with a damping function. The metal punching device comprises a bottom plate, wherein sliding grooves are formed in the left side and the right side of the upper surface of the bottom plate, and sliding blocks are slidably connected into the sliding grooves; and first springs are fixedly connected to the left side faces of the inner walls of the sliding grooves, the right ends of the first springs are fixedly connected to the left side faces of the sliding blocks, and the upper surfaces of the sliding blocks are fixedly connected with first connecting blocks. According to the metal punching device with the damping function, through mutual cooperation among the first springs, second connecting blocks, second hinge pins, connecting plates, firsthinge pins, the first connecting blocks and the sliding blocks, when a workbench vibrates up and down, the workbench can be driven to move downwards, the workbench drives the two second connecting blocks to move downwards, then the two sliding blocks are enabled to move away from each other, the two sliding blocks drive the two first springs to retract correspondingly, and vibration generated when a drill bit carries out punching on metal can be reduced, so that the punching accuracy is improved, and then convenience is brought to people during punching.

Owner:刘闪闪

Hand-held mulching film puncher

InactiveCN105123033AAdjust hole spacingConvenient punching operationManure treatmentPunchingHand held

The invention provides a hand-held mulching film puncher which includes a tapered punching head and a frame. A handle is arranged on the frame. The frame is provided with a slide trough to which a sliding board is connected slidingly. A locking bolt passing through the slide trough is arranged on the sliding board. A sliding trough is formed on the sliding board. A bottom surface of the punching head is provided with a fixing bolt passing through the sliding trough. The tapered punching head can punch a mulching film and is partially stretched into soil, thereby punching the film and breaking soil. Because that the bottom surface of the punching head is provided with the fixing bolt, through which the tapered punching head can be fixed on the sliding board and the position of the tapered punching head on the sliding board can be adjusted according to practical demand, thereby obtaining a proper film breaking position. In addition, the position of the sliding board can be adjusted according to practical demand, thereby indirectly adjusting the position of the punching head, so that an operator can hold the frame and the punching head fixed thereon by hands, thereby conveniently punching the film.

Owner:CHONGQING SHUANGEN AGRI MACHINERY MFG

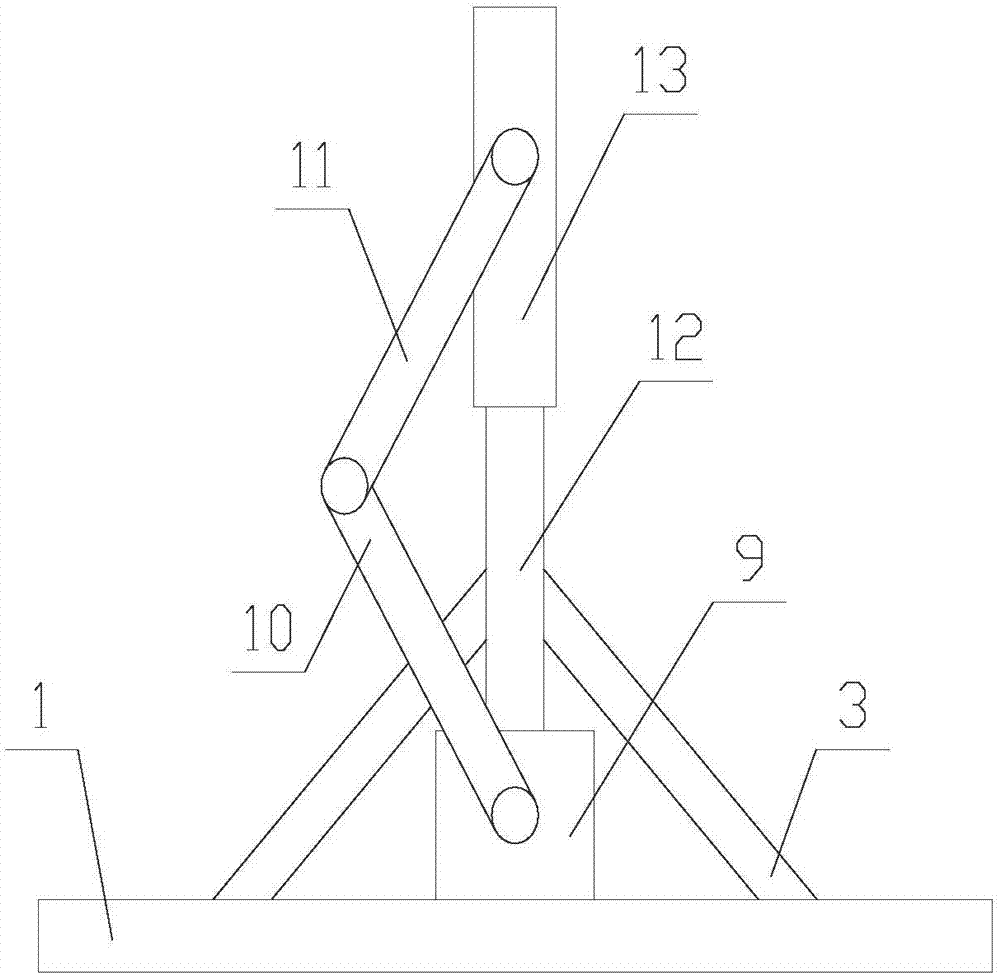

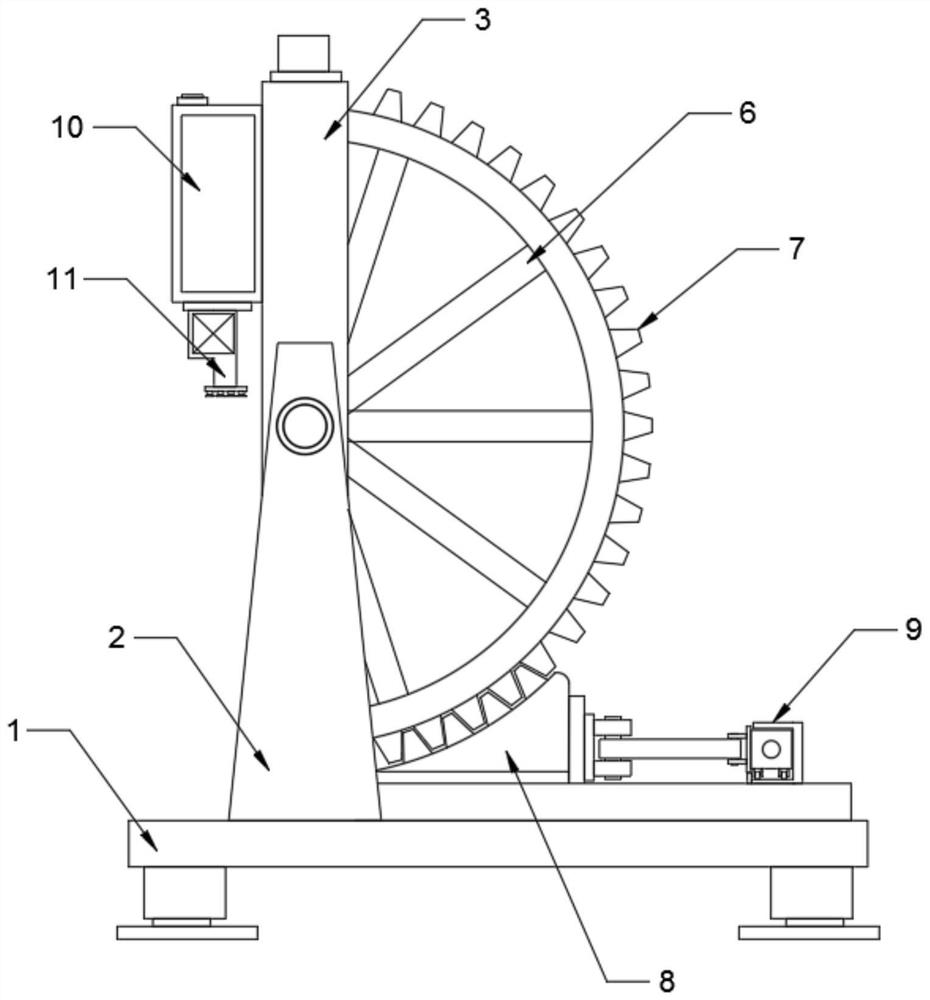

Rock stratum punching device for deep hole blasting

PendingCN114382409AEasy to fixConvenient punching operationDrilling rodsConstructionsClassical mechanicsCrushed stone

The invention discloses a rock stratum perforating device for deep hole blasting, and relates to the technical field of rock stratum perforating, the rock stratum perforating device comprises a base, a positioning frame and a perforating mechanism, and the perforating mechanism comprises a supporting frame, a drilling assembly, a driving assembly, a rotating frame, a first rack, a positioning assembly and a displacement assembly; a positioning frame is fixedly installed on the base, and the inner side of the positioning frame is rotationally connected with the supporting frame. A drilling assembly and a driving assembly are mounted on the supporting frame, so that drilling operation can be conveniently performed on a rock stratum, and gravel generated by drilling can be conveniently discharged; a rotating frame and a first rack are fixedly mounted on one side of the supporting frame, rotation along with the supporting frame is facilitated, and adjustment of the drilling angle is achieved; a displacement assembly and a positioning assembly are further installed on the base, when the positioning assembly is connected with the first rack, the drilling angle can be conveniently fixed, the displacement assembly can control the positioning assembly and the first rack to be connected and separated, the drilling angle can be conveniently adjusted and fixed, and rock stratum drilling operation is convenient.

Owner:CHINA RAILWAY 19TH BUREAU GRP RAIL TRANSIT ENG +1

Machining and punching equipment for plastic plate

InactiveCN110126014APromote reciprocating sliding effectMeet punching requirementsMetal working apparatusPunchingWaste collection

The invention discloses machining and punching equipment for a plastic plate, and belongs to that field of plastic punching equipment. The machining and punching equipment comprises a waste collectionbox and a control panel; the waste collection box is connected with the control panel; movable wheels are mounted at the bottom of the waste collection box; the right side of the waste collection boxis connected with a pushing handle; the upper end of the waste collection box is connected with a fixed seat; the fixed seat is provided with a through opening; clamping grooves are formed in the twosides of the fixed seat; electric control telescopic rods are mounted in the clamping grooves; clamping plates are connected with the electric control telescopic rods; the front outer surface and therear outer surface of the fixed seat are connected with L-shaped supporting rods; the L-shaped supporting rods are connected with a supporting plate; a moving device is mounted on the supporting plate; the moving device is connected with a connecting rod; the connecting rod is connected with an air cylinder; the air cylinder sleeves an air pressure rod; the connecting rod is connected with an L-shaped connecting rod; and the L-shaped connecting rod is connected with a cutter adjusting device. The machining and punching equipment can realize fast and accurate punching of the plastic plate, isconvenient to operate and improves production efficiency.

Owner:LINAN LEILUO PLASTIC FACTORY

An anti-deflection hand electric drill for conveniently controlling the drilling depth

ActiveCN108465842BEasy to drillAvoid breakingPortable power-driven toolsWork benchesEngineeringSlide plate

The invention discloses a leaning-preventing electric portable drill facilitating drilling depth control. The leaning-preventing electric portable drill comprises an electric portable drill body, a handle is arranged below the side of the electric portable drill body, a switch key is arranged on the side face of the handle, a horizontal rail groove is formed in the bottom of the electric portabledrill body, a U-shaped top plate standing on the side is arranged at the bottom of the electric portable drill body, a second sliding way is arranged on a top horizontal face of the U-shaped top plate, the rail groove is in sliding fit with the second sliding way, and therefore the electric portable drill body can horizontally slide on the U-shaped top plate, and a supporting plate is arranged atan opening of the side face of the U-shaped top plate. The leaning-preventing electric portable drill has the beneficial effects that the U-shaped top plate is attached to the surface of an object, and therefore a drill bit is perpendicular to the object all the time when the electric portable drill body drills a hole, and drill bit breaking or hole leaning is avoided; and the position of a positioning plate is adjusted, a sliding plate is limited, and the hole drilling depth is accurately controlled.

Owner:浙江富翼科技有限公司

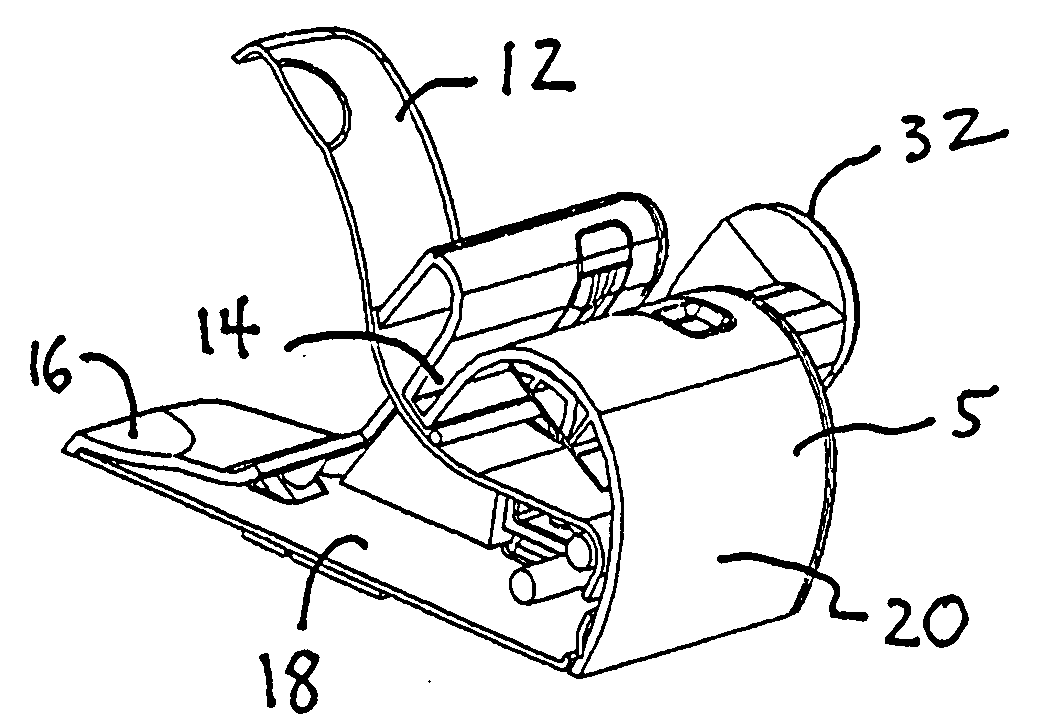

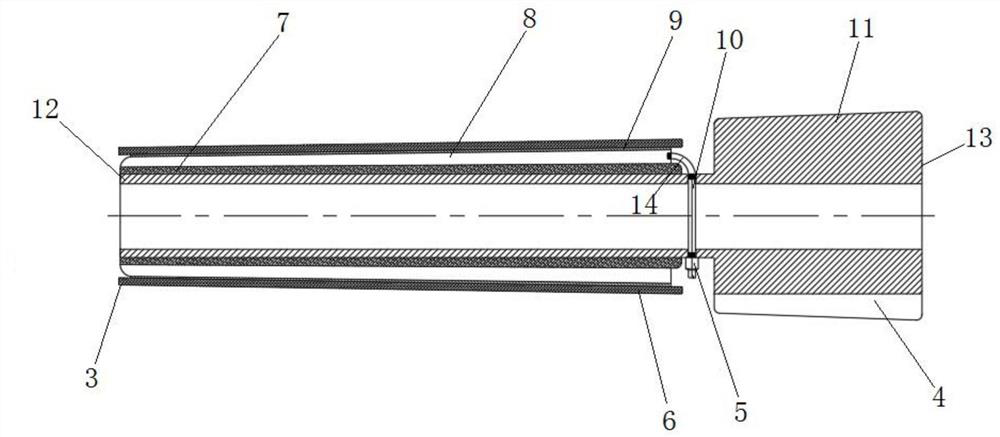

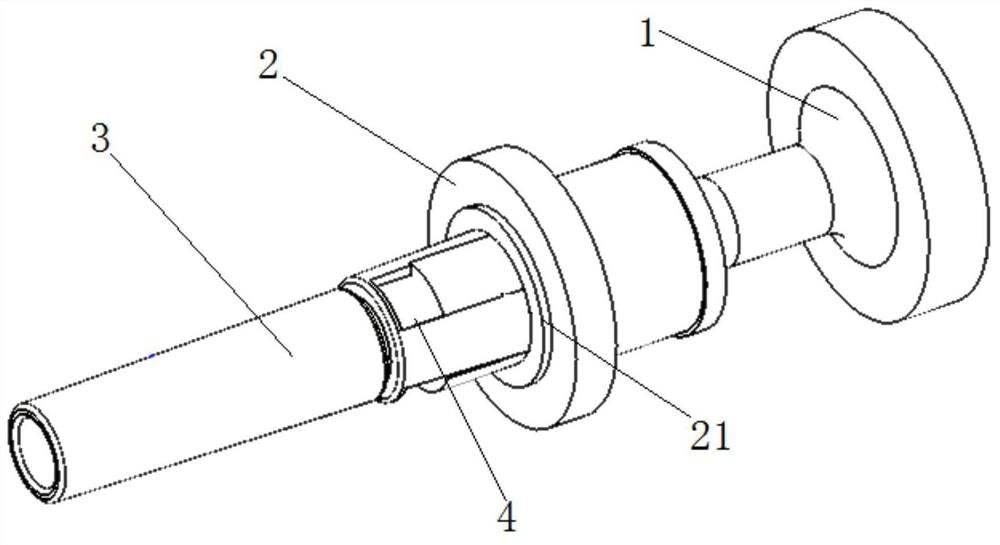

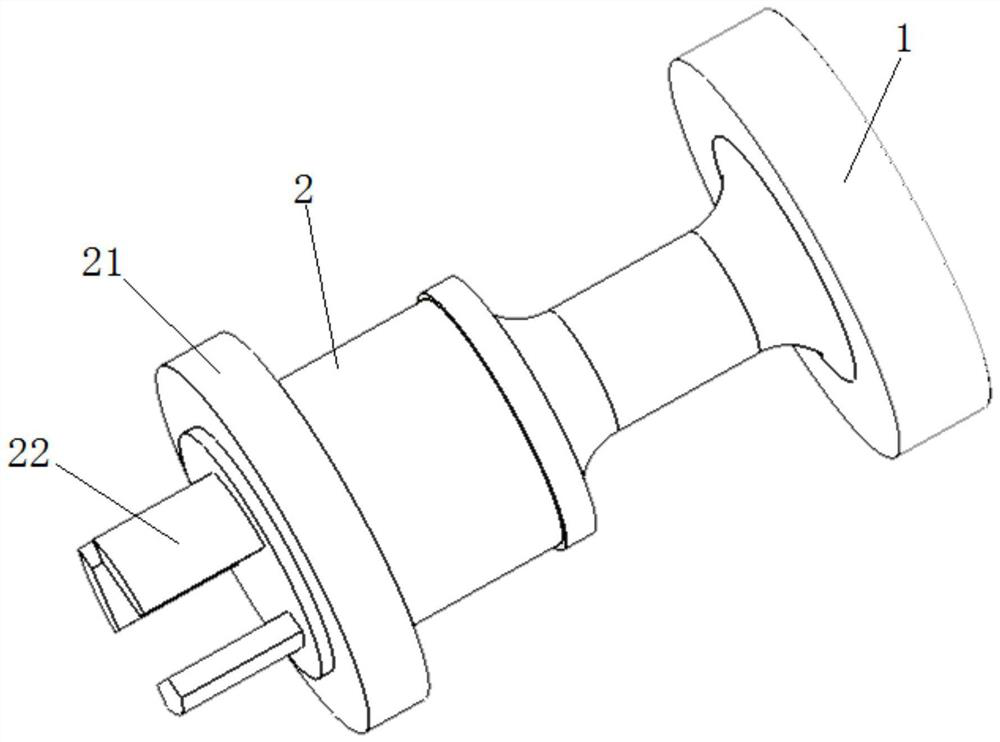

Clamping mechanism and method for laser drilling of artificial soft-bodied artery vessel stent

ActiveCN111728662ARealize the clamping and positioning functionReduce mistakesWound clampsMedicineEngineering

The invention discloses a clamping mechanism and method for laser drilling of an artificial soft-bodied artery vessel stent. The clamping mechanism comprises a mounting seat, an electric clamping jawand a pneumatic elastic mandril, wherein one end of the electric clamping jaw is connected with a mounting seat, a plurality of clamping arms are arranged at the other end of the electric clamping jaw; the pneumatic elastic mandril comprises a mandril body, a pneumatic assembly and an inflating and exhausting assembly; the mandril body comprises a clamping segment and a support segment; a plurality of clamping grooves are formed in the clamping segment, and each clamping arm can be clamped in the corresponding clamping groove; the pneumatic assembly comprises an elastic air bag and an elasticexternal connecting layer; the elastic air bag is used for wrapping the support segment, and a vent hole is formed; the elastic external connecting layer sleeves the elastic air bag, and can be inserted into the vessel stent; and the inflating and exhausting assembly is used for inflating air into the elastic air bag, so that the elastic air bag expands to enable the elastic external connecting layer to be abutted against the vessel stent. The positioning errors of the vessel stent in the circumferential direction and in the axial direction can be reduced, the laser drilling accuracy and the drilling quality are improved, the operation is simple, and the laser drilling efficiency is improved.

Owner:HEFEI UNIV OF TECH

Hardware product perforating machine with good clamping effect

InactiveCN111790931AEasy to adjustFacilitates continuous drilling operationsPositioning apparatusBoring/drilling componentsElectric machineryEngineering

The invention discloses a hardware product perforating machine with a good clamping effect. The hardware product perforating machine comprises a base plate; the lower surface of the base plate is provided with six struts distributed in a rectangular shape; the upper surface of the base plate is provided with a base; the middle part of the side surface of the base is provided with a first nut; a driving device is arranged inside the first nut; a screw of the driving device is threadedly connected with the first nut; an operating table is placed on the upper surface of the base; and the front surface of the operating table is provided with a moving device. The hardware product perforating machine with a good clamping effect can be used for storing, limiting, clamping, pressing and fixing a hardware product, achieves a good clamping effect, can prevent movement of the hardware product, can also prevent waste of the hardware product, can also indirectly regulate the position of the hardware product in the plane by virtue of a stepping motor and a first electric telescopic rod, realizes convenient perforation of different positions of the hardware product, and is simple to operate and convenient to use.

Owner:东阳市俊华电器销售有限公司

Locking and punching device for power solar cell panel

PendingCN107984640AEasy to moveImprove mobile stabilityWorking accessoriesFine working devicesHydraulic cylinderPunching

The invention provides a locking and punching device for a power solar cell panel. The device comprises a side frame, a side base is arranged on the side portion of the side frame, an abut-joint plateis arranged between the side base and the side frame, a top plate is arranged on the top of the side frame, a supporting plate is arranged between the top plate and the side wall position of the topof the side frame, a moving plate is arranged on the top plate, a moving base is arranged on the front portion of the moving plate, a first hydraulic cylinder is arranged on the back of the moving base, a first piston rod is arranged on the front of the first hydraulic cylinder, the inner end of the first piston rod and the front of the first hydraulic cylinder are connected, a pressing disc is arranged at the outer end of the first piston rod, a top base is arranged on the top plate, a second hydraulic cylinder is arranged on the other side of the top base, a second piston rod is arranged onthe front of the second hydraulic cylinder, and the end of the second piston rod is in a tip angular shape. The punching operation efficiency of the power solar cell panel can be greatly improved.

Owner:国网江苏省电力有限公司淮安供电分公司 +1

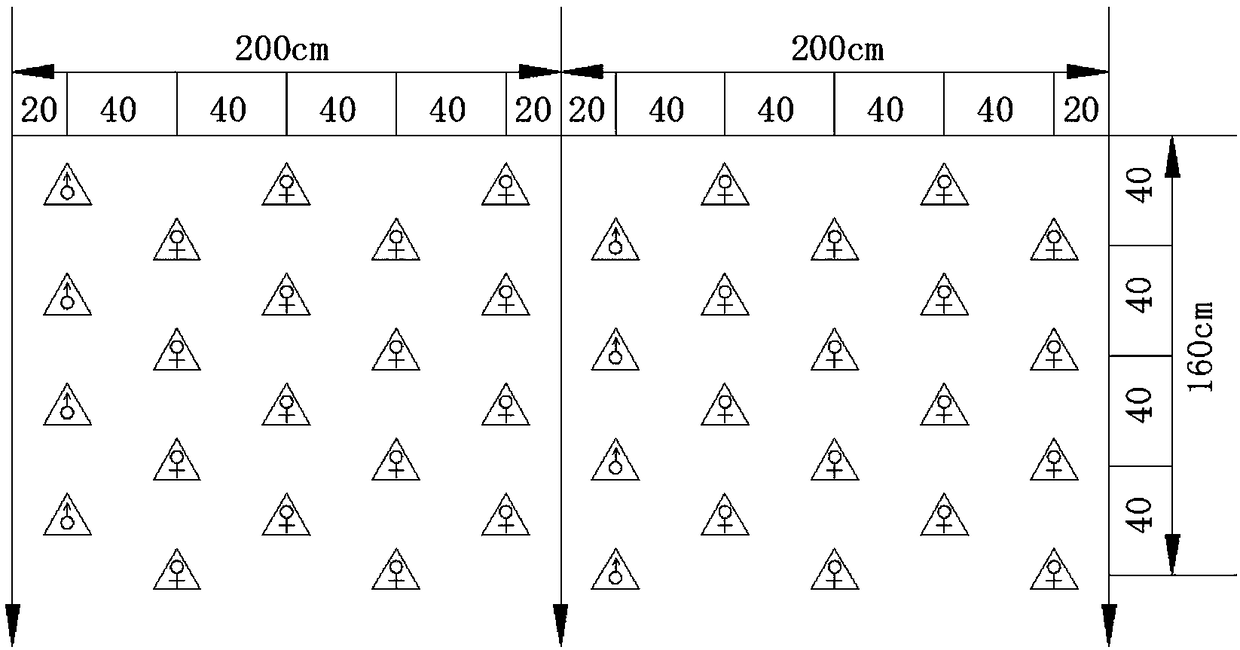

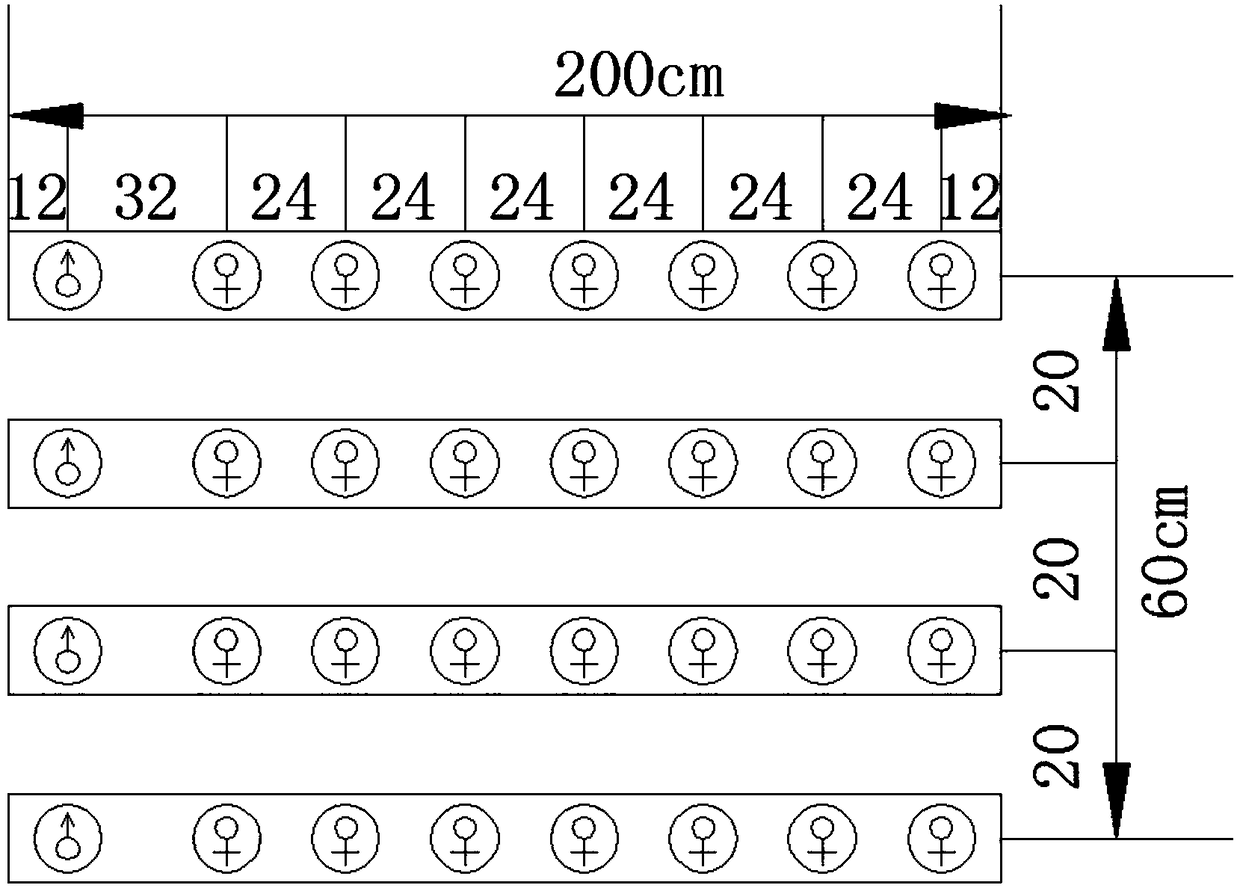

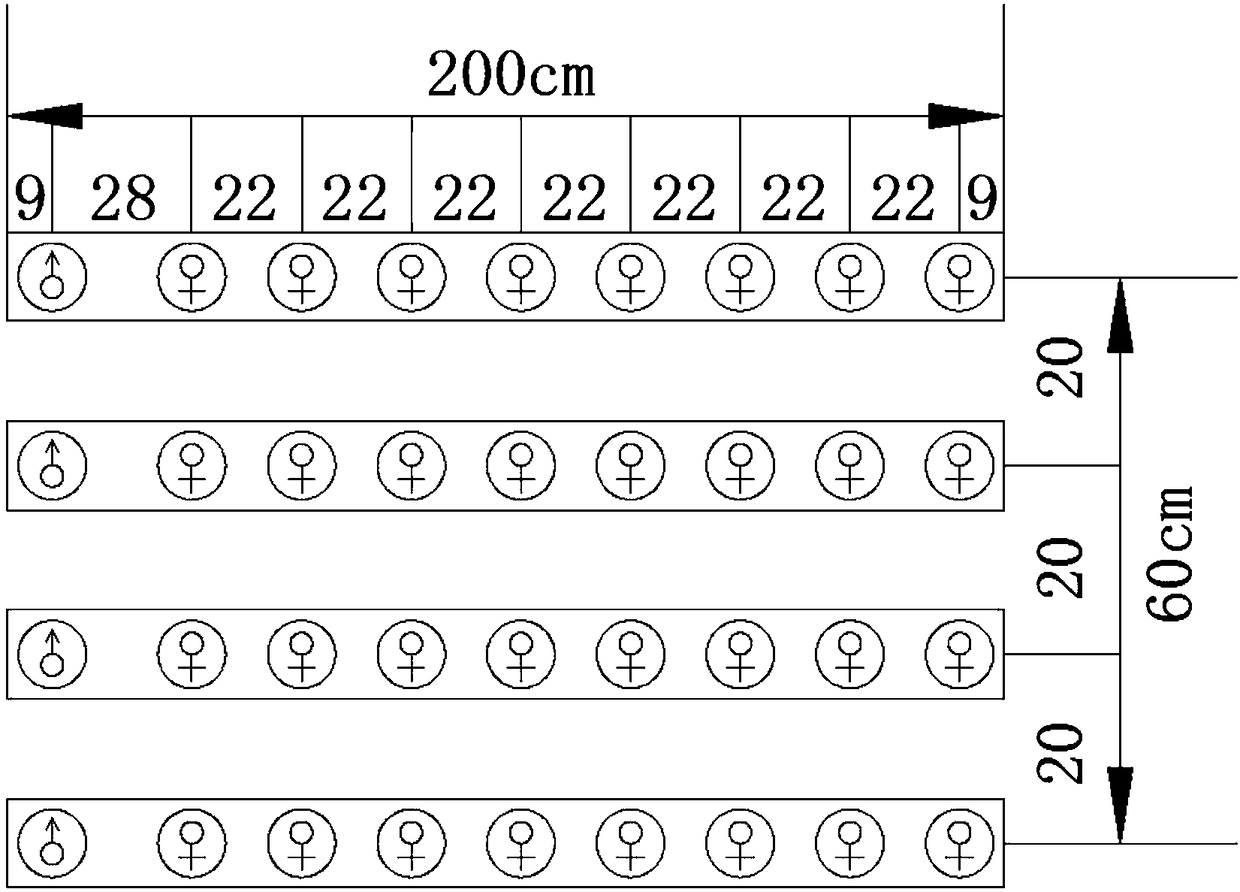

Method for producing hybrid seeds of rice by seedbed seedling raising and field film mulching intensified cultivation

InactiveCN108323392AIncrease humidityIncrease productionClimate change adaptationHorticulture methodsDiseaseHybrid seed

The invention discloses a method for producing hybrid seeds of rice by seedbed seedling raising and field film mulching intensified cultivation. The method comprises the operation steps: selecting a dry field as a seedbed for cultivating seedlings; mulching a film, and transplanting a male parent and a female parent; carrying out field water management, topdressing as well as disease and pest prevention and control; spraying gibberellin on the female parent and the male parent; removing hybrid seeds and retaining pure seeds; and carrying out artificial pollination; and the hybrid seeds of riceare produced in a plastic film or biodegradable film mulching way, a large three-dimensional intensified cultivation way or a conventional-density planting way, wherein the hybrid seeds of rice include sterile parent seeds. By using the method, rice hybrid seed production can be realized, the purity of the propagated seeds is increased by 0.2-0.5%, the yield per mu of the seeds is increased by 8-15%, the growth speeds of the male parent and the female parent are increased under the heat insulation action of a plastic film or a biodegradable film, so that the mature period is earlier, a variety with a long growth period, such as II-32A, can be matured 7-10 days ahead of time, and a variety with a short growth period, such as Wufeng A, can be matured 2-3 days ahead of time, the area of a rice field is reduced, the management expense of the rice field is reduced, the use amount of female parent seeds is reduced, and 1-1.5kg of female parent seeds are saved per mu.

Owner:四川益邦种业有限责任公司

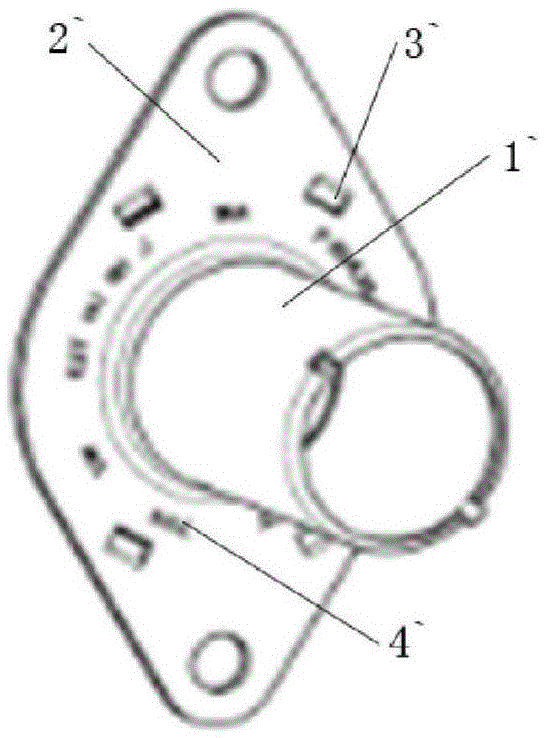

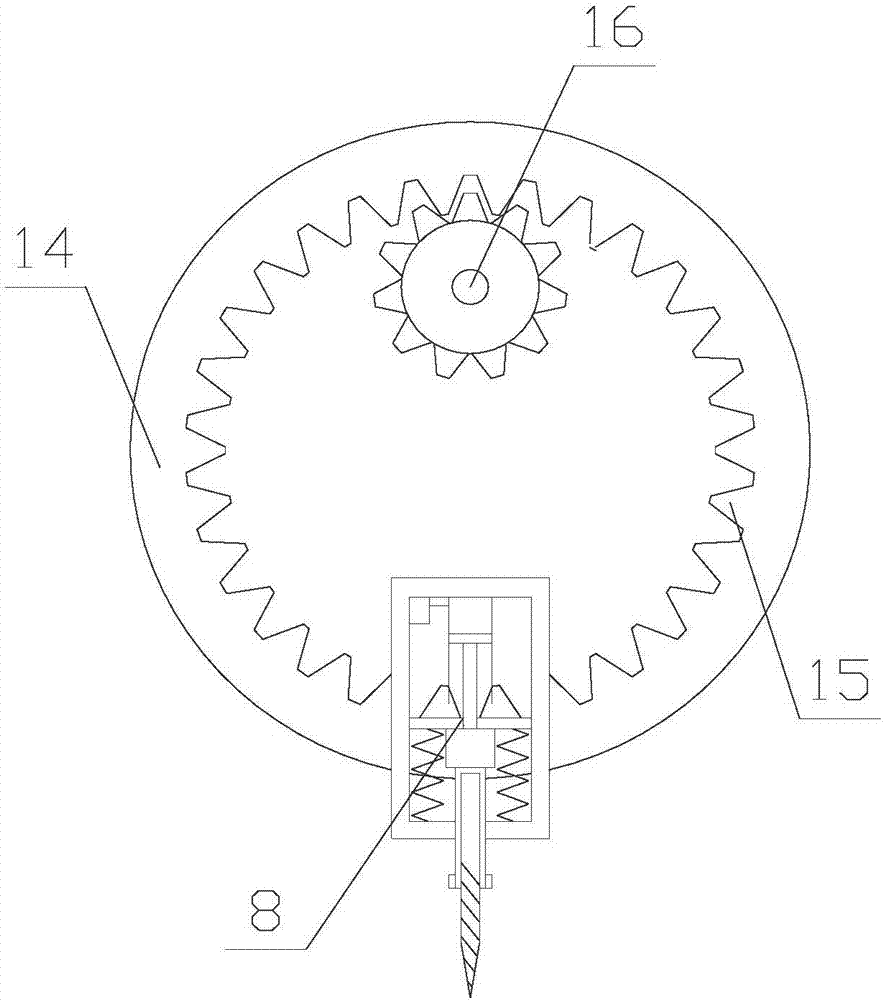

Three-phase asynchronous motor end cover hole punching device

PendingCN108696072AControl punching speedImprove yieldManufacturing dynamo-electric machinesThree phase asynchronous motorEngineering

The invention discloses a three-phase asynchronous motor end cover hole punching device, which comprises a base, a telescopic cavity, a telescopic column, a fixed seat and a motor. Rotation of a tiller is operated manually, mutual clamping between a gear and a tooth is combined, a bit is thus controlled to move downwardly, and hole punching operation is then carried out on the end cover in a groove; when the end cover is not in the middle or not firmly fixed, the manual operation of rotating the tiller is not required, after the end cover is adjusted to a proper position or is firmly fixed, the bit is then controlled to move downwardly, the tiller is rotated slowly, the hole punching speed can be controlled, and the hole punching finished product is thus improved; the bottom part of the telescopic cavity is provided with a rotating seat, when the end cover needs to be placed, a front-end support can be pushed towards the right, the bit, the motor and the like can rotate for 90 DEG towards the right with the telescopic cavity as a circle center, placing of the end cover can be prevented from being blocked, the front-end support is rotated back after placing, hole punching can be carried out on the end cover, and the hole punching operation process is better facilitated.

Owner:JIANGSU HUAYUAN EXPLOSION PROOF MOTOR

Environment-friendly metal composite plate production device

InactiveCN110814156AEasy to clamp and fixImprove product qualityMetal-working feeding devicesShaping safety devicesPunchingStructural engineering

The invention relates to the technical field of metal composite plate production, and particularly relates to an environment-friendly metal composite plate production device. The environment-friendlymetal composite plate production device comprises a rack and a punching equipment body, wherein the punching equipment body is fixedly mounted on the upper surface of the rack; a punching head is fixedly mounted on the punching equipment body; two sliding mechanisms are mounted on the upper surface of the rack and arranged on the two sides of the lower surface of an operation table correspondingly; a fixing mechanism is fixedly mounted on the operation table; a composite plate is fixedly connected to the fixing mechanism and positioned below the punching head; a plurality of first grooves areevenly formed in the side, close to the punching equipment body, of the upper surface of the operation table; and an adjusting mechanism is fixedly mounted on the side, close to the punching equipmentbody, of the upper surface of the rack. According to the environment-friendly metal composite plate production device, punching operation can be conveniently and rapidly conducted on the same horizontal linear position on the composite plate, and different punching positions of the composite plate do not need to be adjusted manually and continuously.

Owner:OKUMTEC TECH WENZHOU CO LTD

Cloth punching equipment for textile and garment manufacturing

InactiveCN112621885AAchieve positioningConvenient punching operationMetal working apparatusHydraulic cylinderPull force

The invention discloses cloth punching equipment for textile and garment manufacturing. The cloth punching equipment comprises a base and an upper support, wherein the center of the bottom of the upper support is connected with a first hydraulic cylinder; the bottom of the first hydraulic cylinder is fixedly connected with a punching drill bit; the two sides of the first hydraulic cylinder are each provided with a second hydraulic cylinder; the bottom of each second hydraulic cylinder is fixedly connected with a pressing plate; the top of each second hydraulic cylinder is fixedly connected with a moving block; a cavity is formed in the upper support; a sliding groove is formed in the side wall of the cavity and slidably connected with the moving blocks through a T-shaped sliding block structure; a two-way screw rod is arranged above the sliding groove; the two ends of the two-way screw rod are rotationally connected with the two side walls of the cavity respectively; one end of the two-way screw rod penetrates through the side wall of the cavity in a sealed mode; and a driving motor is fixedly connected to the portion, outside the upper support, of the two-way screw rod. The cloth punching device has the advantages that the pressing plate applies pulling force to cloth, so that the cloth has tensile force with determined magnitude, the cloth can be fully stretched conveniently, and punching operation is facilitated.

Owner:武汉沃美康科技有限公司

Shaving board hand-operated perforating device for furniture making

InactiveCN109203093AImprove efficiencyConvenient punching operationStationary drilling machinesRotational axisEngineering

The invention discloses a shaving board hand-operated perforating device for furniture making. The shaving board hand-operated perforating device comprises a base, and the base is provided with a machine frame; the top of the machine frame is provided with a guide barrel, a guide groove is arranged at the axial position of the guide barrel, and the guide groove is sleeved with a rotation mechanism; the rotation mechanism comprises a rotation shaft and a hand wheel, and the hand wheel is connected with the rotation shaft; the periphery of the rotation shaft is sleeved with a sleeve pipe, and the sleeve pipe is installed in the guide groove of the guide barrel in a sleeved mode; one end of the rotation shaft is connected with the axis center of the hand wheel, and the other end of the rotation shaft is provided with a perforating shaft; and the inner end of the perforating shaft is installed in the end of the sleeve pipe, and the outer end of the perforating shaft is provided with a perforating head. According to the shaving board hand-operated perforating device for furniture making, the rotation shaft can be controlled to rotate through the hand wheel, the rotation shaft can control the perforating head to rotate through the perforating shaft, perforating operation can be conveniently conducted on a shaving board through the perforating head, and the efficiency of perforating operation conducted on the shaving board is greatly improved.

Owner:黄春梅

Perforating device for wood decoration

PendingCN107263619AImprove accuracySolve the lack of punching accuracyStationary drilling machinesEngineering

The invention discloses a perforating device for wood decoration. The perforating device comprises a lower supporting plate. Fixing supporting legs are fixedly connected with the outer wall of the lower end of the lower supporting plate. A transmission plate is fixedly connected with the outer wall of the upper end of the lower supporting plate. A fixing baffle is fixedly connected with the outer wall of the upper end of the transmission plate. An upper cushion plate is fixedly connected with the outer wall of the lower end of the fixing baffle. A transmission belt is fixedly connected with the outer wall of the lower end of the upper cushion plate. A rotary shaft is fixedly connected with the lower end of one end of the transmission belt in a sleeving mode. Fixing supporting columns are fixedly connected with the side walls of the two ends of the lower supporting plate. A connecting cross beam is fixedly connected with the outer walls of the upper ends of the fixing supporting columns. An outer track is fixedly connected with the outer wall of one end of the connecting cross beam. An adjustable driller is fixedly embedded into the side wall of an inner cavity of the outer track. Through the adjustable driller and the transmission plate, an operator can conduct drilling operation on planks rapidly, accurately and conveniently, and meanwhile, a drilling tool bit can be protected.

Owner:德清县兴拓木板厂(普通合伙)

Novel fixture for machining of assembly holes of forklift portal frame support

InactiveCN109483276AConvenient punching operationPunch EffectPositioning apparatusMaintainance and safety accessoriesPunchingCoupling

The invention discloses a novel fixture for machining of assembly holes of a forklift portal frame support. The novel fixture for machining of the assembly holes of the forklift portal frame support comprises a machining plate, a cavity is formed in the machining plate, a support plate is fixedly connected to the vertical outer side wall of one side of the machining plate, the support plate is fixedly connected with a drive motor, and a rotating shaft is connected to the output end of the drive motor through a coupling; a rotating hole is formed in the cavity wall, close to one side of the drive motor, of the cavity, and a bearing seat is fixedly connected to the cavity bottom inside the cavity; the end, away from the drive motor, of the rotating shaft penetrates through the rotating holeand extends into the bearing seat, and the rotating shaft is fixedly and rotatably connected to an inner ring of the bearing seat; and threads with opposite directions are symmetrically disposed on the shaft wall, located in the cavity, of the rotating shaft, and nuts matched with the threads are connected with the shaft wall, located in the cavity, of the rotating shaft in a symmetric threaded mode. The forklift portal frame support located between two clamping plates is clamped and fixed to facilitate subsequent punching operations, and debris are prevented from remaining in the assembly holes and affecting punching of the assembly holes.

Owner:YUEXI COUNTY YONGTAI MACHINERY MFG

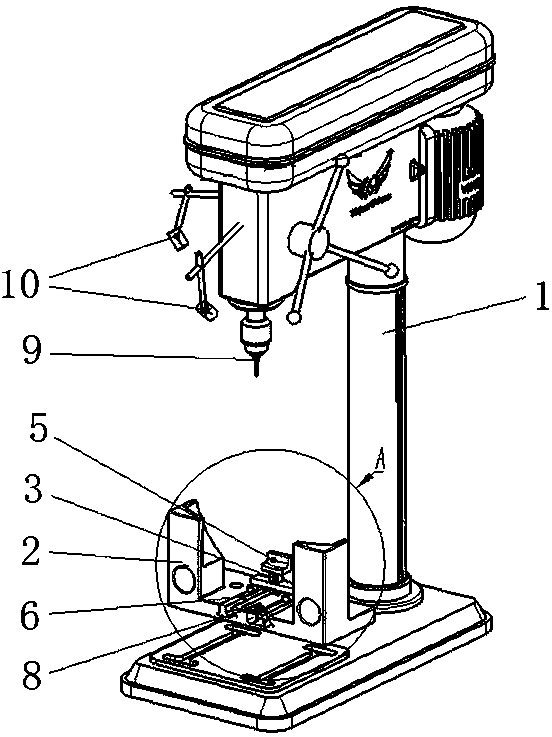

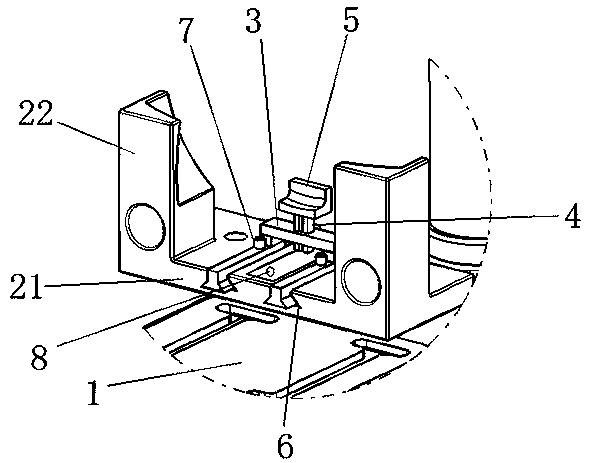

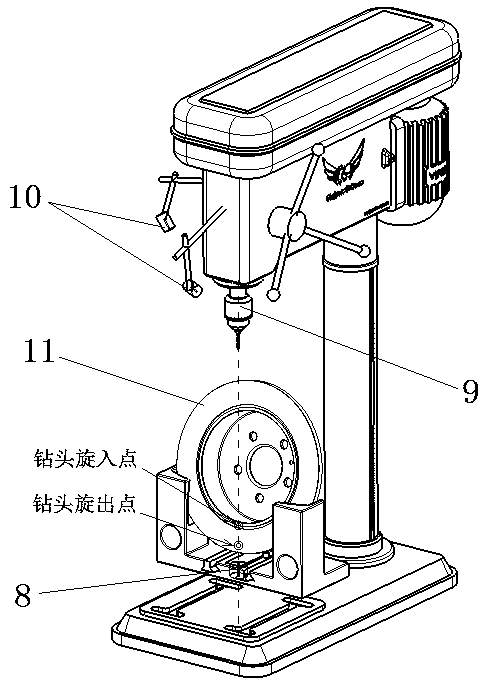

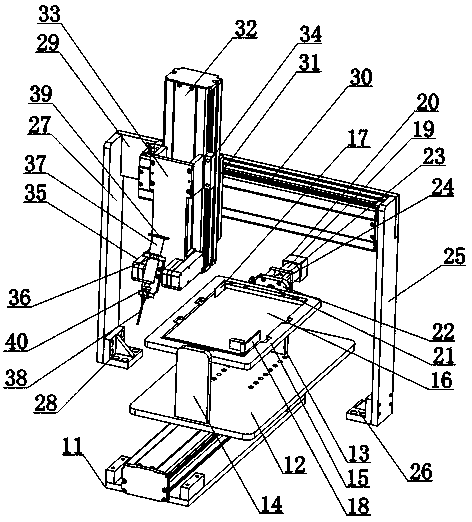

Brake disc punching auxiliary tool

ActiveCN108856811AConvenient punching operationSimple and convenient drilling operationMeasurement/indication equipmentsPositioning apparatusPunchingInfrared beam

The invention aims at providing a brake disc punching auxiliary tool. By means of the brake disc punching auxiliary tool, a brake disc can be conveniently punched, and punching accuracy is improved. The brake disc punching auxiliary tool disclosed by the invention comprises a bench drill and a brake disc fixing mechanism fixedly arranged on a bench drill base, wherein two screwed-in point infraredgenerator are arranged on the sides of a drill bit of the bench drill, a central-axis infrared generator is arranged on the brake disc fixing mechanism, a linear infrared beam upwards sent out by thecentral-axis infrared generator coincides with the central axis of the drill bit, infrared rays emitted out by the two screwed-in point infrared generators are planar linear beams, and the two planarlinear beams intersect with each other at the straight line on which the central axis of the drill bit. The brake disc punching auxiliary tool disclosed by the invention is provided with a rim supporting seat and a disc cap supporting seat, so that brake disc posture can be adjusted according to need; furthermore, a plurality of infrared generators are utilized for accurately locating a screwed-in point and a screwed-out point of the drill bit on the brake disc before drilling; thus, punching operation can be conveniently performed, and the punching operation is simple and convenient and cansucceed in one time.

Owner:CHERY AUTOMOBILE CO LTD

Fixed-point punching device for solar photovoltaic cell panel

ActiveCN110154128AConvenient and flexible mobile adjustmentGood drilling efficiencyFinal product manufactureMetal working apparatusCells panelSlide plate

The invention discloses a fixed-point punching device for a solar photovoltaic cell panel. The fixed-point punching device comprises a horizontal moving adjusting mechanism and a plane moving adjusting mechanism, wherein a moving plate is arranged on the upper portion of the horizontal moving adjusting mechanism; a slide plate is arranged on one side of the moving plate; a limiting plate is arranged on the other side of the moving plate; a locating frame is arranged between the tops of the limiting plate and the side plate; a locating cavity is formed on the locating frame; a hydraulic cylinder is arranged at the top of the side plate; a piston rod is arranged at the front part of the hydraulic cylinder; the end part of the piston rod is connected with the back part of the locating frame;a support frame is arranged on one side of the horizontal moving adjusting mechanism; a supporting base is arranged at the bottom end of the support frame; and the plane moving adjusting mechanism isarranged between the end parts of the support frame. According to the fixed-point punching device, a punching cylinder can be vertically moved and adjusted conveniently, so that the punching cylindercan be flexibly moved and adjusted conveniently; and the punching cylinder can control a punching piston rod to achieve vertical extension and retraction control, the solar photovoltaic cell panel canbe conveniently punched through the lower end part of the punching piston rod, and punching operation efficiency is higher.

Owner:武汉美格科技股份有限公司

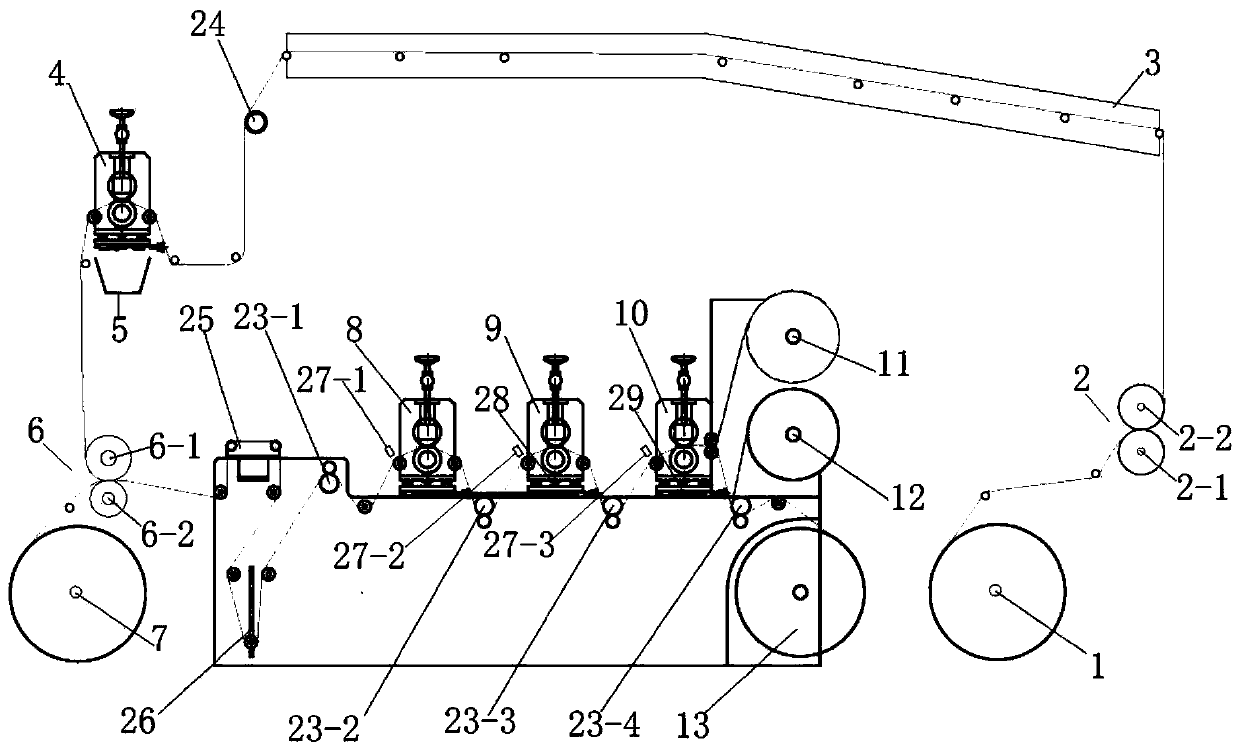

Composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method

PendingCN111275155AReduce pollutionDoes not affect the processing effectLiquid surface applicatorsLamination ancillary operationsTag antennaElectronic tagging

The invention provides a composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method. An antenna body of an ultrahigh-frequency tag antenna is provided with achip binding positioning point formed in a die cutting mode and a chip binding point formed in a die cutting mode. The processing equipment is characterized by comprising a first die cutting mechanism, a second die cutting mechanism and a floating roller device. The invention solves the following problems in the prior art: 1, problems in the prior art are solved; the problem of how to produce a chip binding point and a chip binding positioning point of an ultrahigh-frequency electronic tag antenna by using an etching process is solved. Problem 2: how to completely avoid the application of anetching process in the production process of the ultrahigh frequency electronic tag antenna. 3, how to prevent the position of the antenna layer from deviating during movement or transmission in the machining process; 4, how to help the antenna layer to better move or transmit while maintaining tension; and 5, how to help the chip binding point and the chip binding positioning point to be accurately machined.

Owner:黄光伟

Bamboo processing perforating device

InactiveCN112549196AHorizontal displacement stabilityEasy to adjust the horizontal positionStationary drilling machinesScrew threadDrill bit

The invention belongs to the technical field of bamboo processing perforating devices, and particularly relates to a bamboo processing perforating device which comprises a bottom shell and a drill bit. A first fixing shell is fixedly connected to the top of the bottom shell, and an electric push rod and a telescopic assembly are fixedly connected to the top of the inner wall of the first fixing shell; and the bottom end of the electric push rod and the bottom end of the telescopic assembly are fixedly connected with one second fixing shell, the opposite inner walls of the second fixing shell are fixedly connected with same sliding rods, and the number of the sliding rods is two. According to the bamboo processing perforating device, by arranging a movable block, a movable groove, a first threaded column and a threaded cap, the movable block moves in the movable groove by unscrewing the threaded cap, so that the movable plate drives two arc-shaped limiting plates to move, a fixing device is convenient to move, bamboos are convenient to punch side by side, and punching operation in various modes is convenient; and when the movable plate is moved to a proper position, the movable plate can be conveniently fixed by tightening the threaded cap.

Owner:朱达平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com