Pushing perforating device used for furniture wood board machining

A technology of punching device and wood board, which is applied to fixed drilling machines and other directions, can solve the problem of manual pushing for wood board punching and conveying, and achieve the effect of improving punching efficiency and being easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

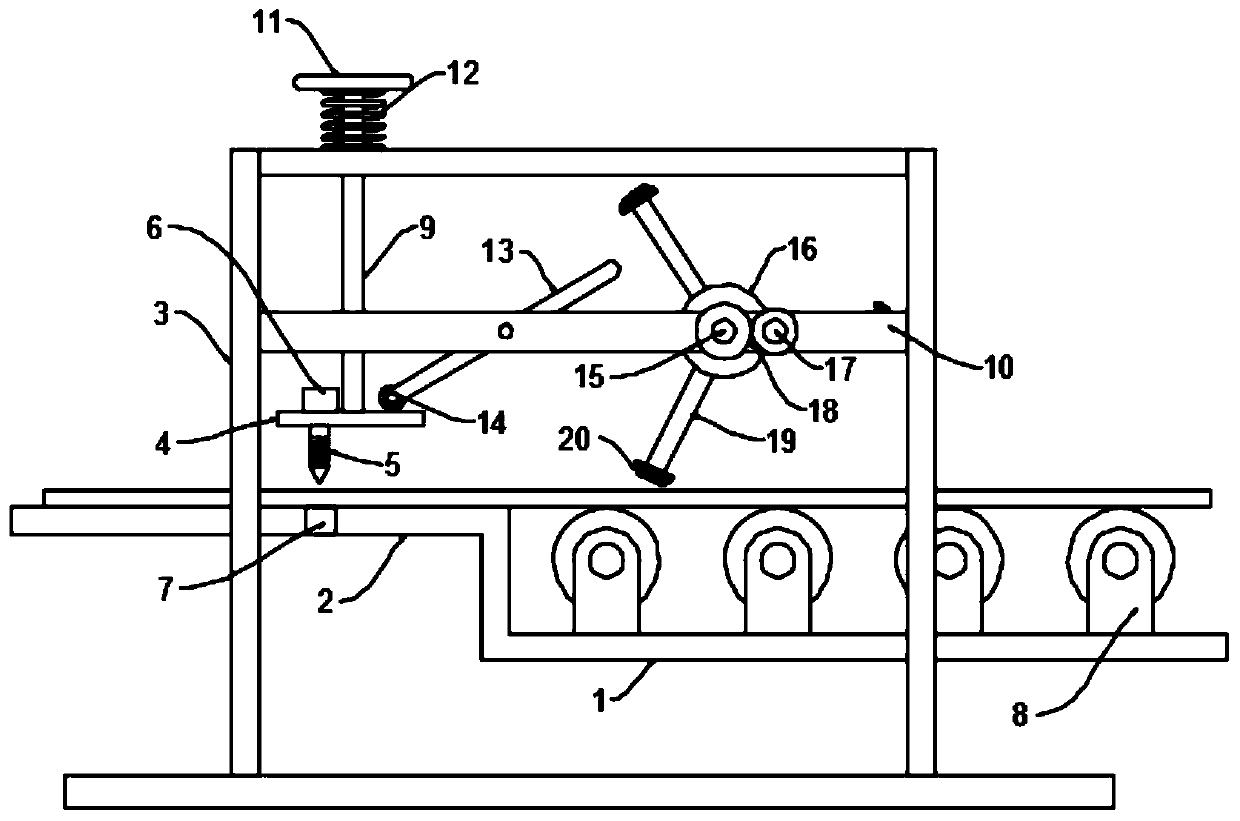

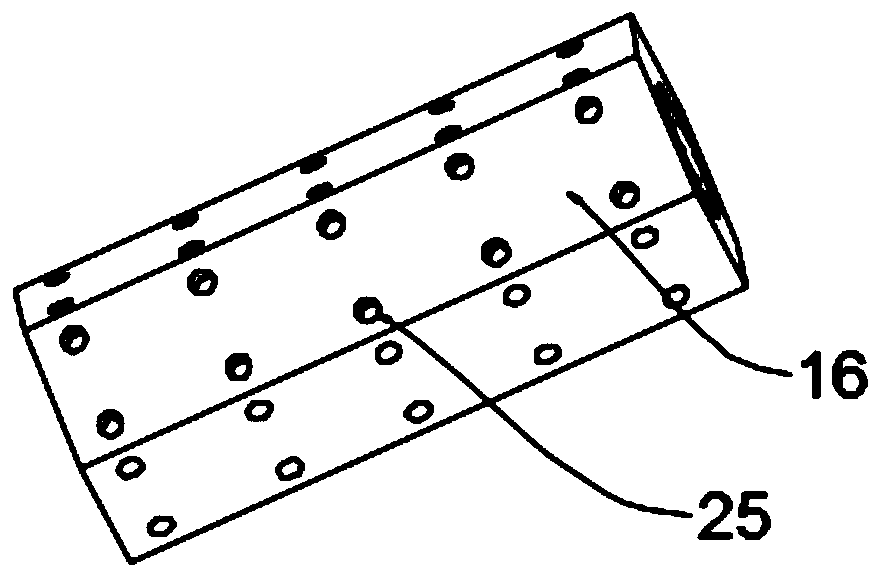

[0022] see Figure 1~3 , in an embodiment of the present invention, a pushing and punching device for furniture board processing includes a base substrate, an installation outer frame 3 arranged on the base substrate, and a conveying platform for conveying wooden boards, and the conveying platform includes horizontal state of the first pallet 1 and the second pallet 2, the first pallet 1 and the second pallet 2 are installed on the installation frame 3, the first pallet 1 and the second pallet 2 are close to the end Connected as a whole to form a Z-shaped structure, the first pallet 1 is provided with a plurality of equidistantly distributed idlers 8, and the arc top of the idler 8 is at the same height as the upper end surface of the second pallet 2. The middle part of the outer frame 3 is provided with a horizontal frame 10 and a drilling assembly and a pushing assembly are installed on the horizontal frame 10. The drilling assembly includes a mounting plate 4 and a drilling...

Embodiment 2

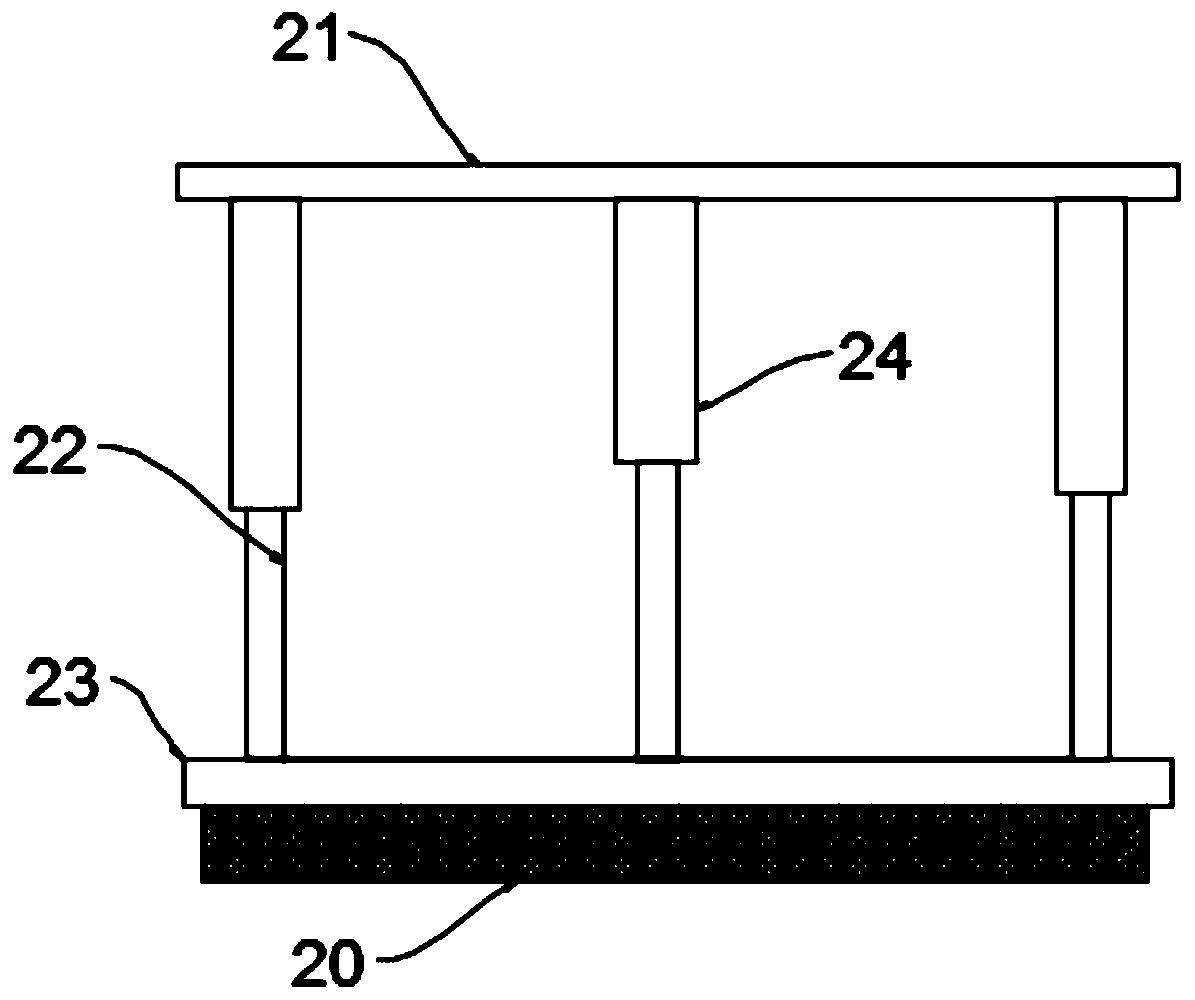

[0026] The difference between the embodiment of the present invention and embodiment 1 is that the push rod 19 includes a push rod 23 and a connecting cross bar 21 connected to the outer wall of the installation roller 16, and the two ends of the connecting cross rod 21 are connected by telescopic rods. 22 is connected to the two ends of the push rod 23, the connecting rod 21 is also provided with an adjustment cylinder 24 and the telescopic end of the adjustment cylinder 24 is fixed on the outer wall of the push rod 23, and the rubber spring pad 20 is installed on the push rod 23 Above, the length of the push rod 19 can be adjusted by adjusting the expansion and contraction of the cylinder 24, and then the time when the rubber elastic pad 20 is in contact with the wood board can be adjusted to adjust the distance that the board is pushed, and then the distance between the holes can be adjusted, which is convenient and quick. The connecting cross bar 21 is detachably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com