Brake disc punching auxiliary tool

A technology for auxiliary tooling and brake discs. It is applied in the direction of manufacturing tools, positioning devices, boring/drilling, etc. It can solve problems such as inappropriate drilling positions, easy shaking, and inaccurate prediction of the position of the screw-out point. Achieve the effect of simple and convenient punching operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

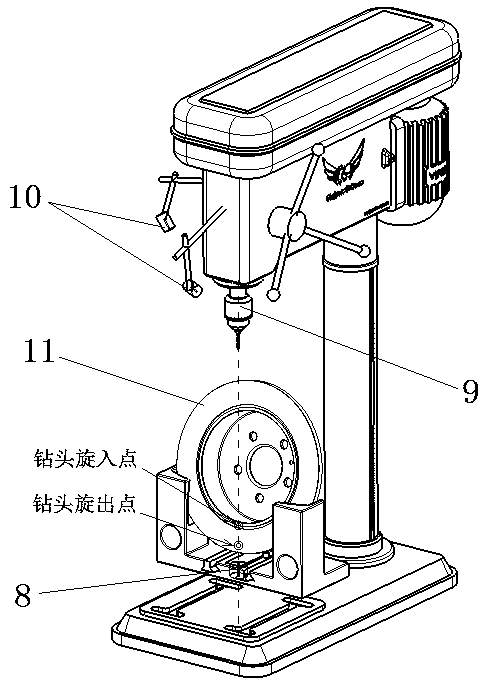

[0022] This embodiment proposes an auxiliary tool for drilling holes in the brake disc to facilitate the drilling of the brake disc and improve the accuracy of drilling.

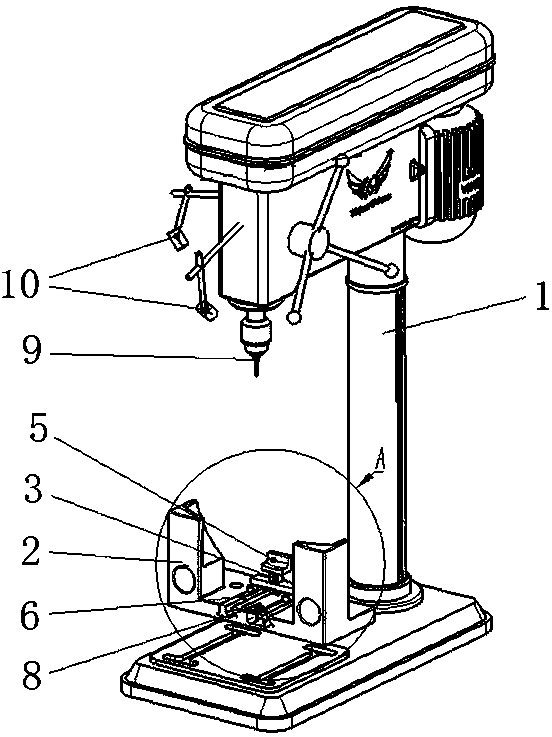

[0023] Such as figure 1 , 2 As shown, the auxiliary tooling for drilling the brake disc in this embodiment includes a bench drill 1 and a brake disc fixing mechanism fixedly installed on the base of the bench drill 1; wherein:

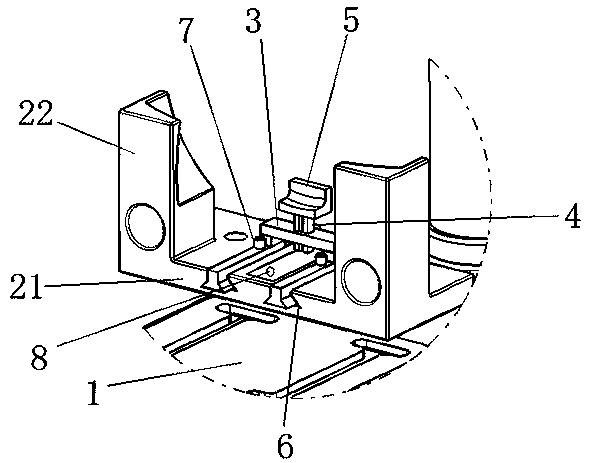

[0024] The brake disc fixing mechanism is composed of the rim support seat 2, the slider 3, and the disc cap support seat. The disc cap support seat is fixedly connected by the lower support rod 4 and the upper disc cap adapter part 5. The part 5 is provided with a curved surface matching the surface of the brake disc cap; the slider 3 is provided with a vertical through hole, and fastening bolts are installed through the hole wall of the vertical through hole, and the support rod 4 Down through the vertical through hole of the slide block 3, the side of the support rod 4 is agains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com