Bamboo processing perforating device

A punching device, bamboo and wood technology, applied to fixed drilling machines, etc., can solve the problems of inconvenient operation, inability to process, and inconvenient disassembly of drill bits, etc., and achieve the effect of convenient use and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

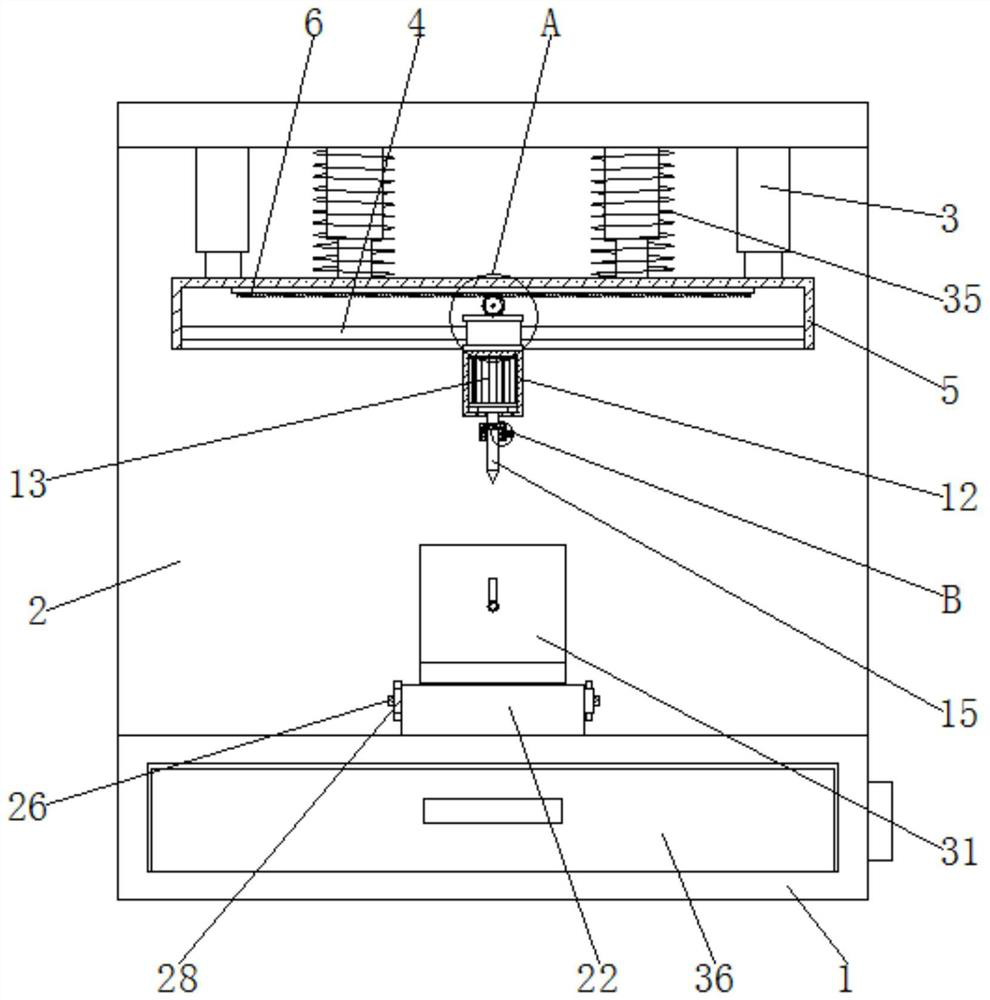

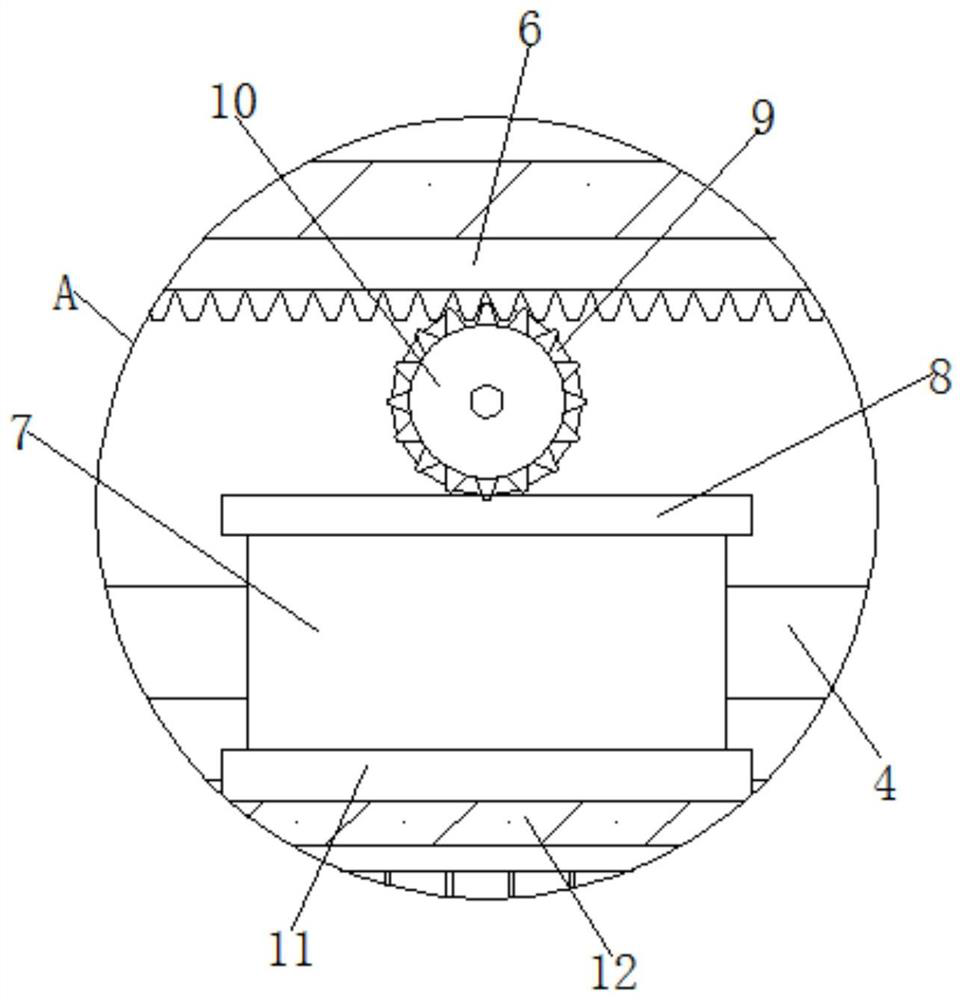

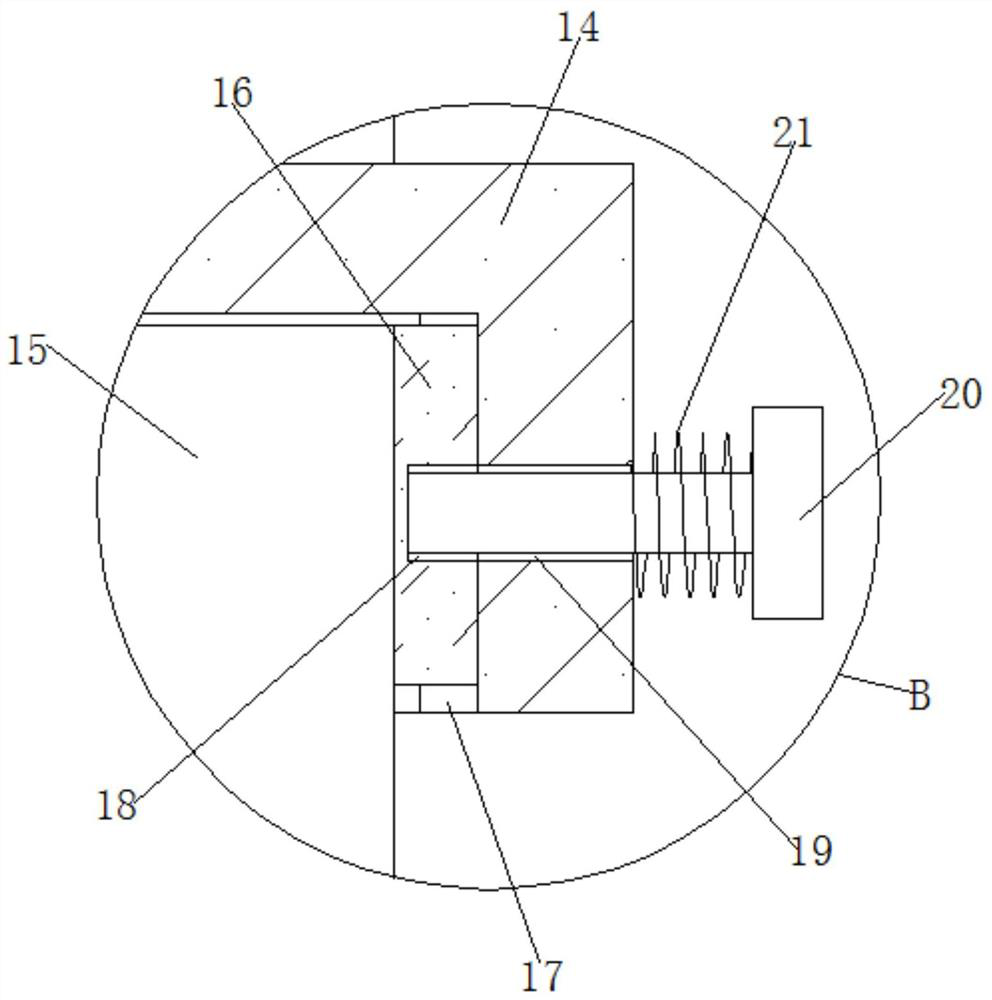

[0028] see Figure 1-7 The present invention provides the following technical solutions: a bamboo and wood processing punching device, comprising a bottom shell 1 and a drill bit 15, the top of the bottom shell 1 is fixedly connected with a first fixed shell 2, and the inner wall of the first fixed shell 2 The top is fixedly connected with the electric push rod 3 and the telescopic assembly 35, and the bottom end of the electric push rod 3 and the telescopic assembly 35 is fixedly connected with the same second fixed shell 5, and the opposite inner wall of the second fixed shell 5 is fixedly connected There is the same sliding rod 4, the number of the sliding rods 4 is two, the two sliding rods 4 are movably sleeved with a sliding tube 7, and the surfaces of the two sliding tubes 7 are fixedly connected with the same first A fixed plate 8 and a second fixed plate 11, the top of the first fixed plate 8 is fixedly connected with a first motor 9, the output shaft of the first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com