Ventilation box for battery module

A technology of air circulation and battery components, which is applied in the direction of battery pack parts, batteries, electrical components, etc., can solve the problems of easily exceeding the heat dissipation performance of the shell, the decrease of battery safety, and the shortening of service life, so as to reduce the temperature, reduce the loss, The effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

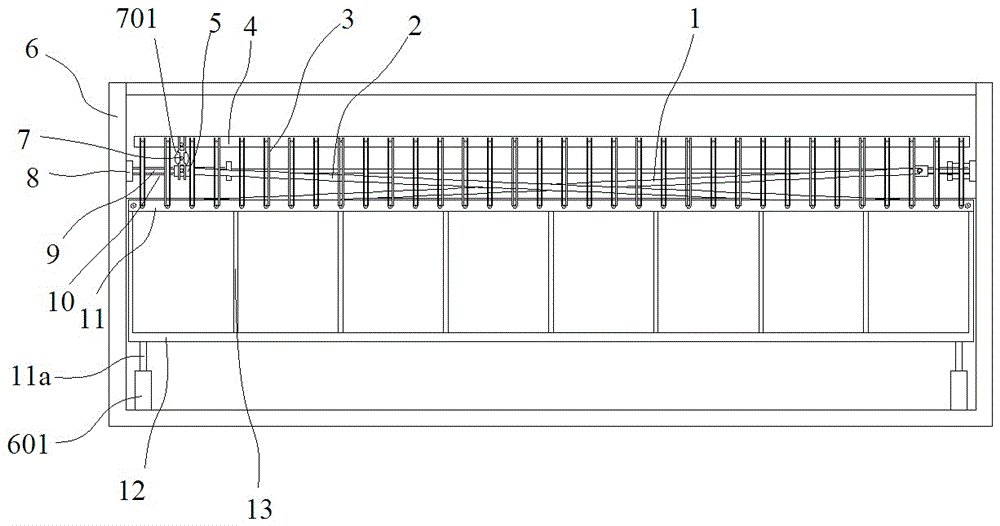

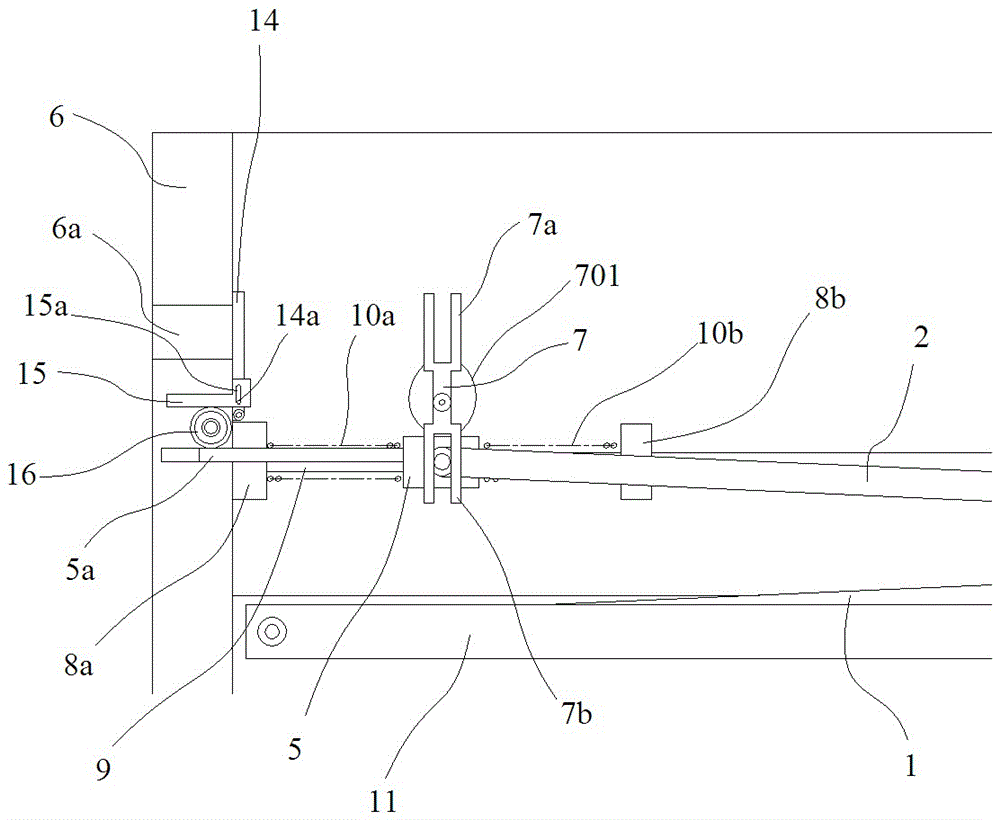

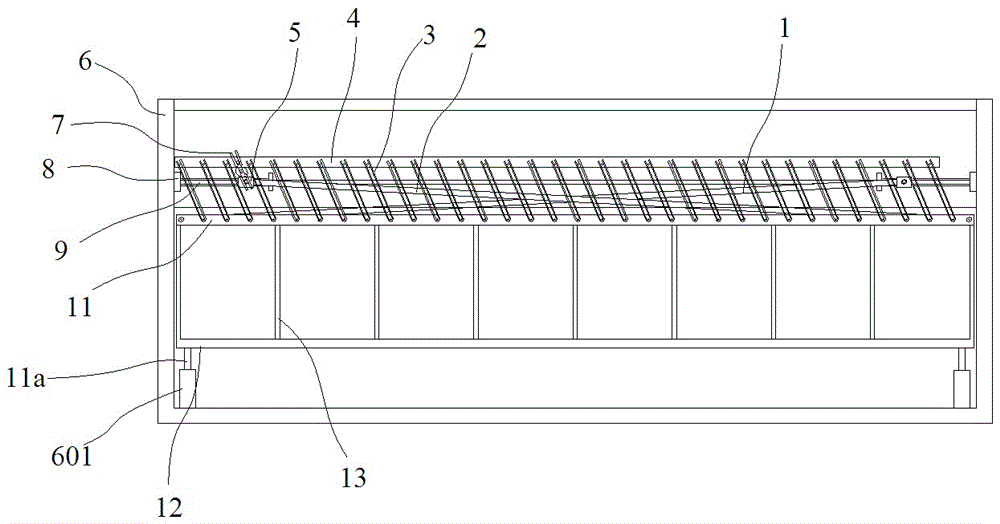

[0020] Such as figure 1 In the illustrated embodiment, an air circulation box for a battery assembly includes a box body 6 and a shock-absorbing hanger 11, wherein the shock-absorbing hanger is located inside the box. The shock-absorbing hanger is provided with frame body 12 and positioning bar 13, and wherein the positioning bar is on the lower surface of the shock-absorbing hanger, and the positioning bars are arranged in parallel, and are connected by bolts between the frame body, the positioning bar and the shock-absorbing hanger, and both can Disassemble. Frames are arranged at intervals below the shock-absorbing hangers, and gaps are left between adjacent frames to facilitate air circulation and take away heat. Positioning strips are located between the frames and the shock-absorbing hangers, so that The hangers are separated, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com