A transfer box structure

A box structure and frame technology, which is applied in the transportation of passenger cars, transportation and packaging, railway car body parts, etc., can solve the problems of battery heat dissipation, easy discharge and heat generation of batteries, power supply damage and liquid leakage, etc., to reduce vibration impact The effect of transmission, ensuring service life and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

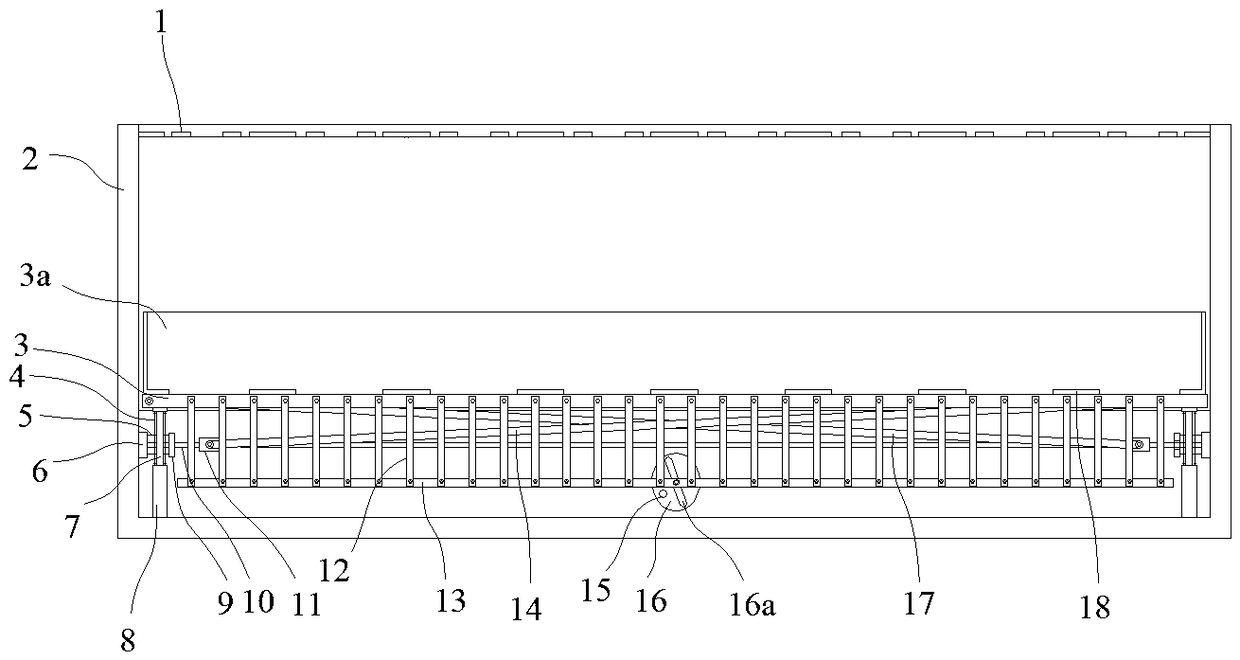

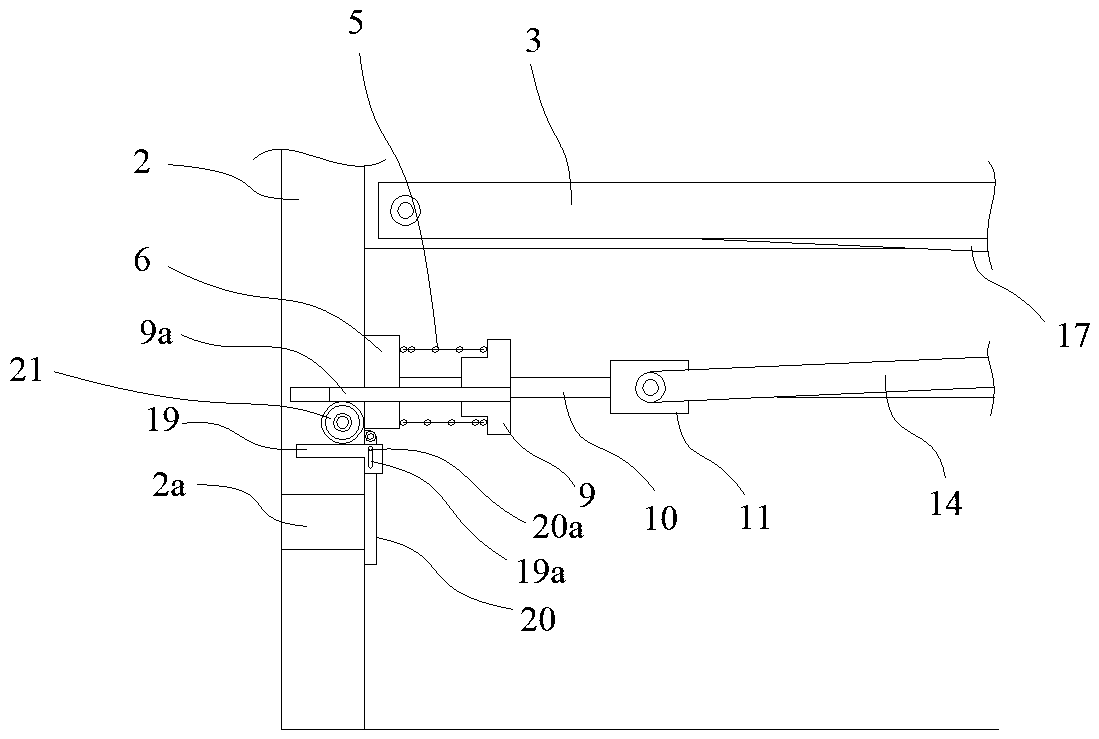

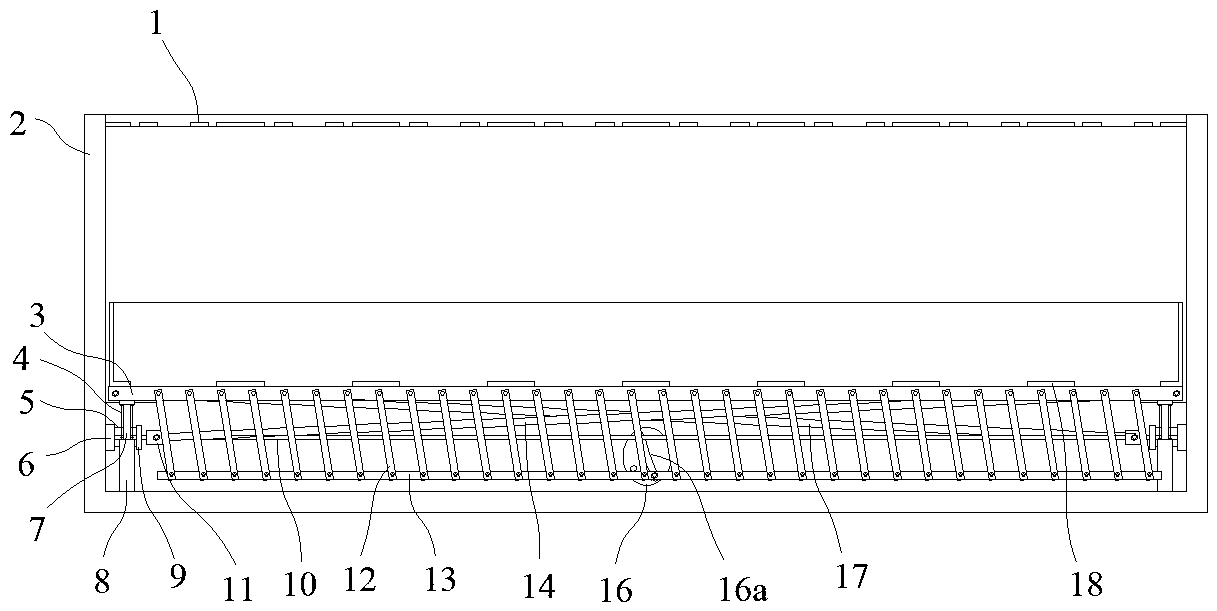

[0020] like figure 1 In the shown embodiment, a transfer box structure includes an outer casing 2, the top of the battery casing is provided with a number of upper vents 1 set to the side, and a shock-absorbing frame 3 is arranged in the outer casing, and the shock-absorbing frame The lower end is provided with a vertically arranged guide column 7, and the inner bottom of the outer shell is provided with a guide sleeve 8. The guide column and the guide sleeve are slidably matched so that the shock-absorbing frame can move up and down in the outer shell, and the guide column is provided with a shock-absorbing spring. 4. When the shock-absorbing frame moves down, the shock-absorbing spring will be compressed. The battery is arranged on the shock-absorbing frame, and the edge of the upper surface of the shock-absorbing frame is provided with an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com