Thin-wall steel pipe symmetrical hole machining method

A technology of thin-walled steel pipe and processing method, which is applied in the field of press processing, can solve the problems of low efficiency and poor symmetry precision, and achieve the effects of convenient installation and adjustment, good punching symmetry precision, and reasonable die structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

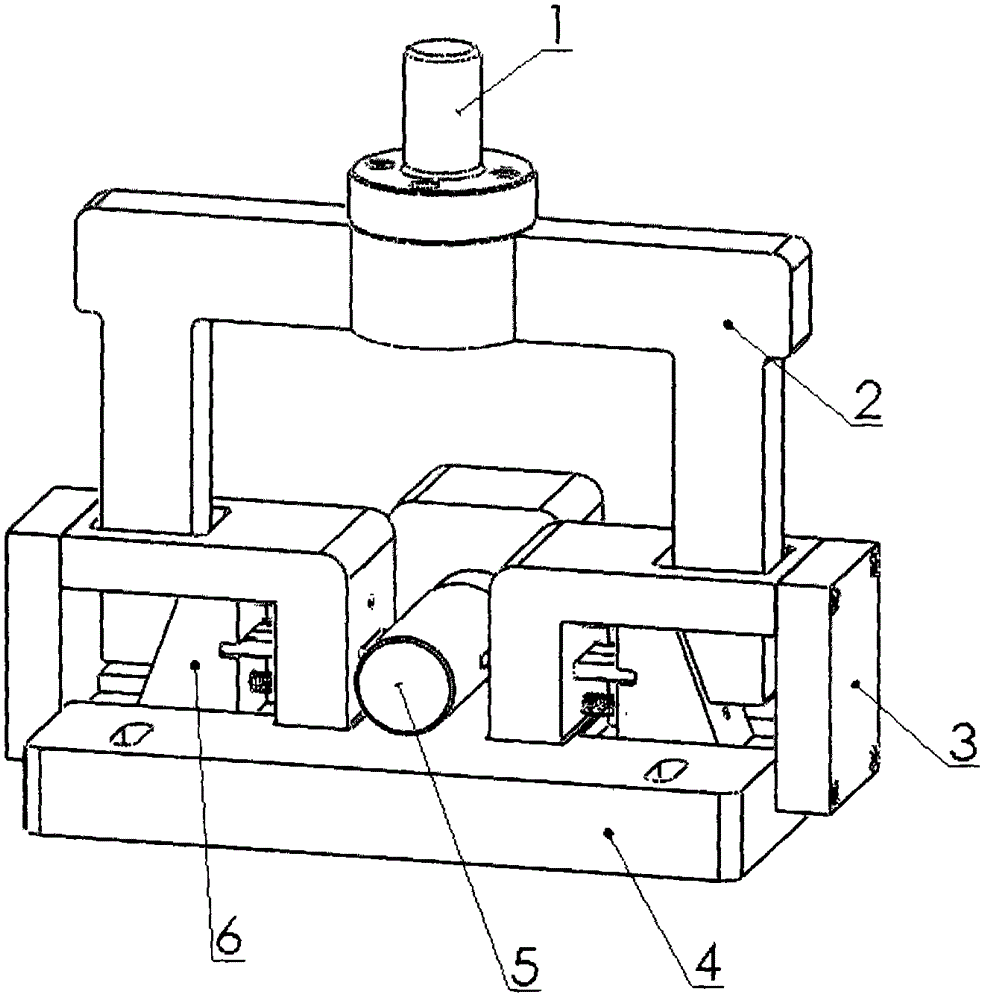

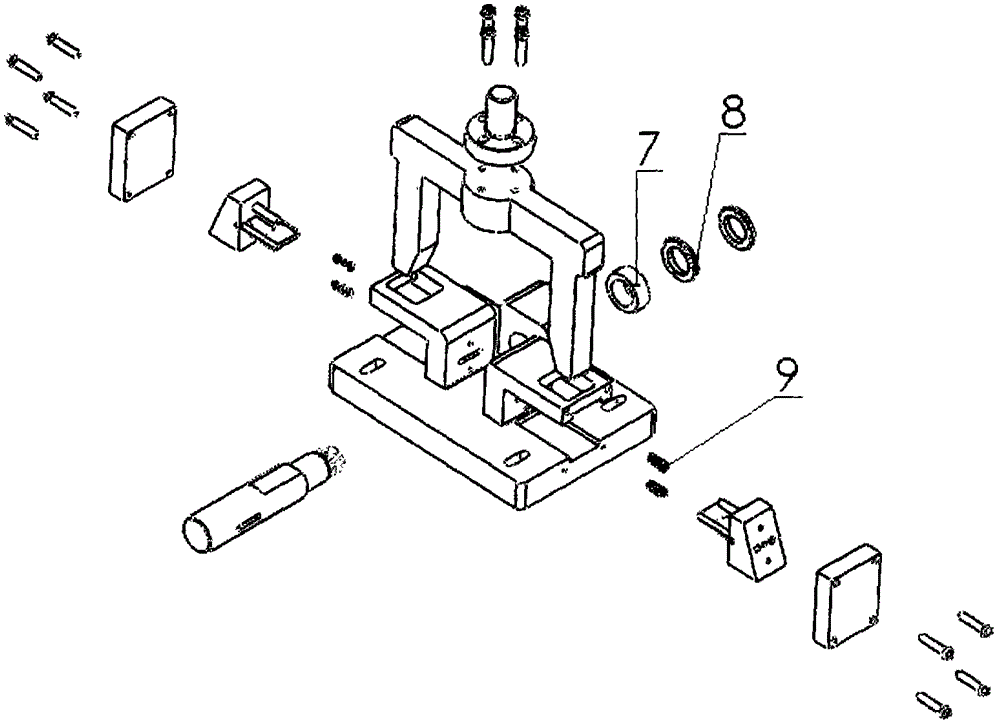

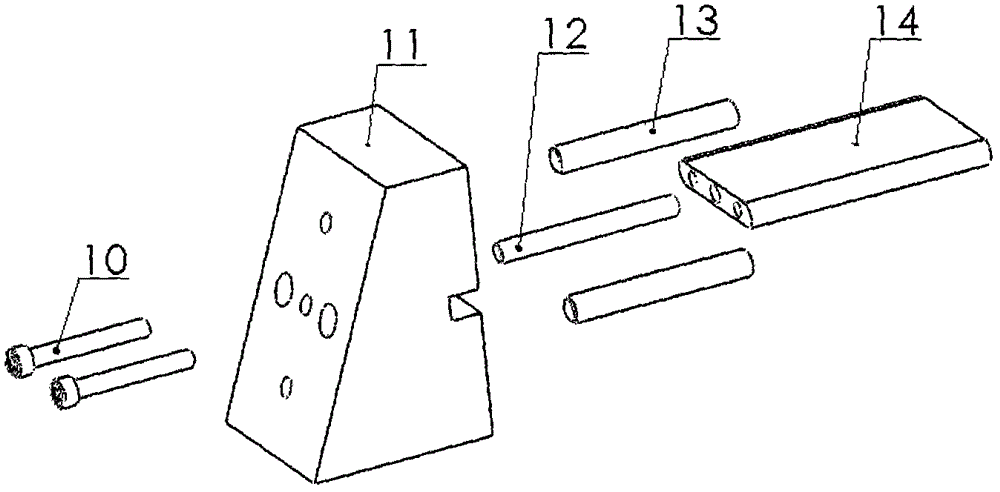

[0019] The method for processing symmetrical holes in thin-walled steel pipes is to use the die to process the symmetrical holes on the thin-walled steel pipe on a press, and the die is mainly composed of the die handle (1), the upper template (2), The side plate (3), the base (4), the die (5), the punch mechanism (6), the round washer (7), the round nut (8) and the Spring I (9) constitutes, and described punch mechanism (6) mainly is by described screw I (10), described moving base (11), described cylindrical pin (12), described guide post (13) and all Said punch (14) constitutes. The mold handle (1) is connected with the upper template (2) by four screws. The upper template (2) has the slope I (15). The moving seat (11) has the slope II (16) and the groove I (17). The die (5) has the die groove (18) and the plane I (19), and the die groove (18) is equipped with an elastic body matched with the die groove (18). The base (4) has the guide rail groove (20), the groove II (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com