Environment-friendly metal composite plate production device

A technology for metal composite boards and production equipment, applied in metal processing equipment, safety equipment, feeding devices, etc., can solve problems affecting the production efficiency and production quality of composite boards, achieve convenient and fast drilling operations, reduce workload, The effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

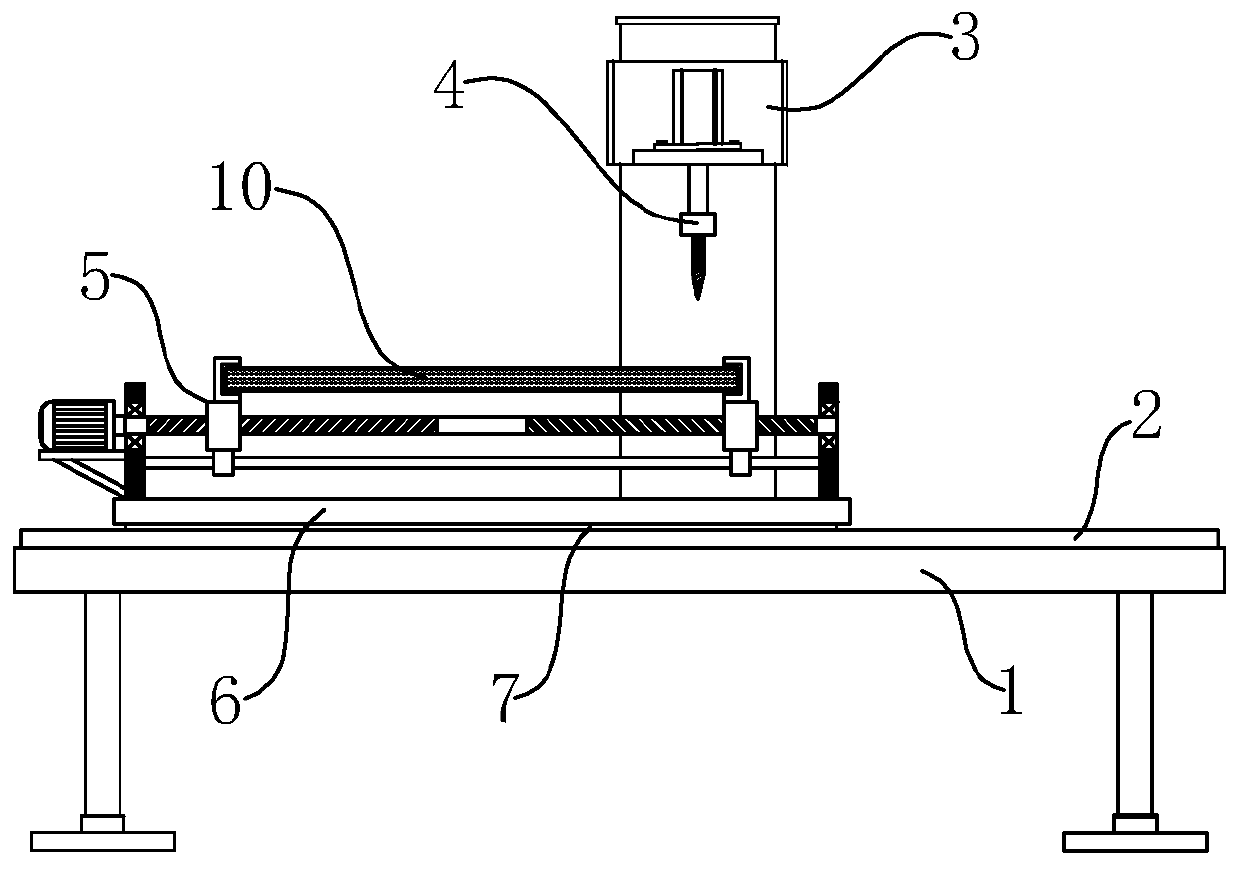

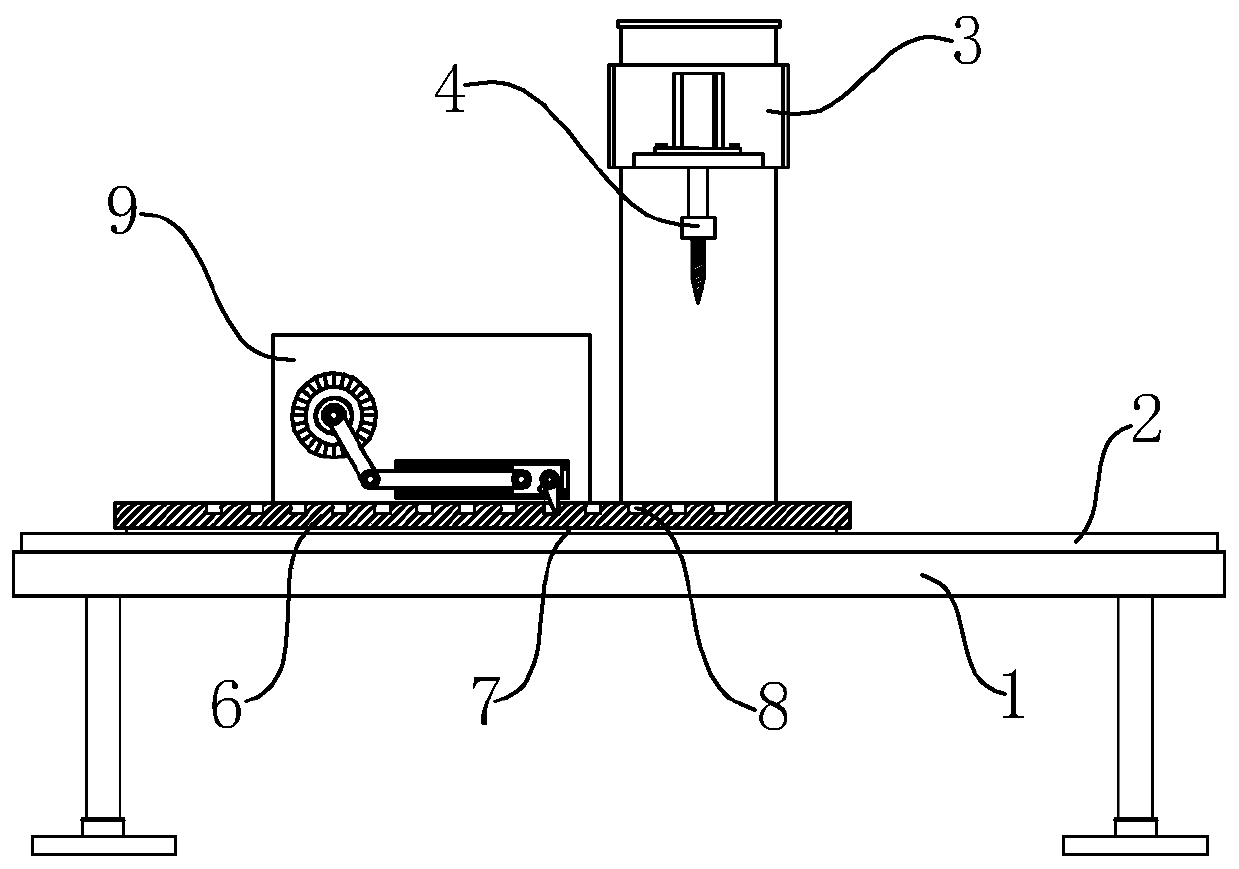

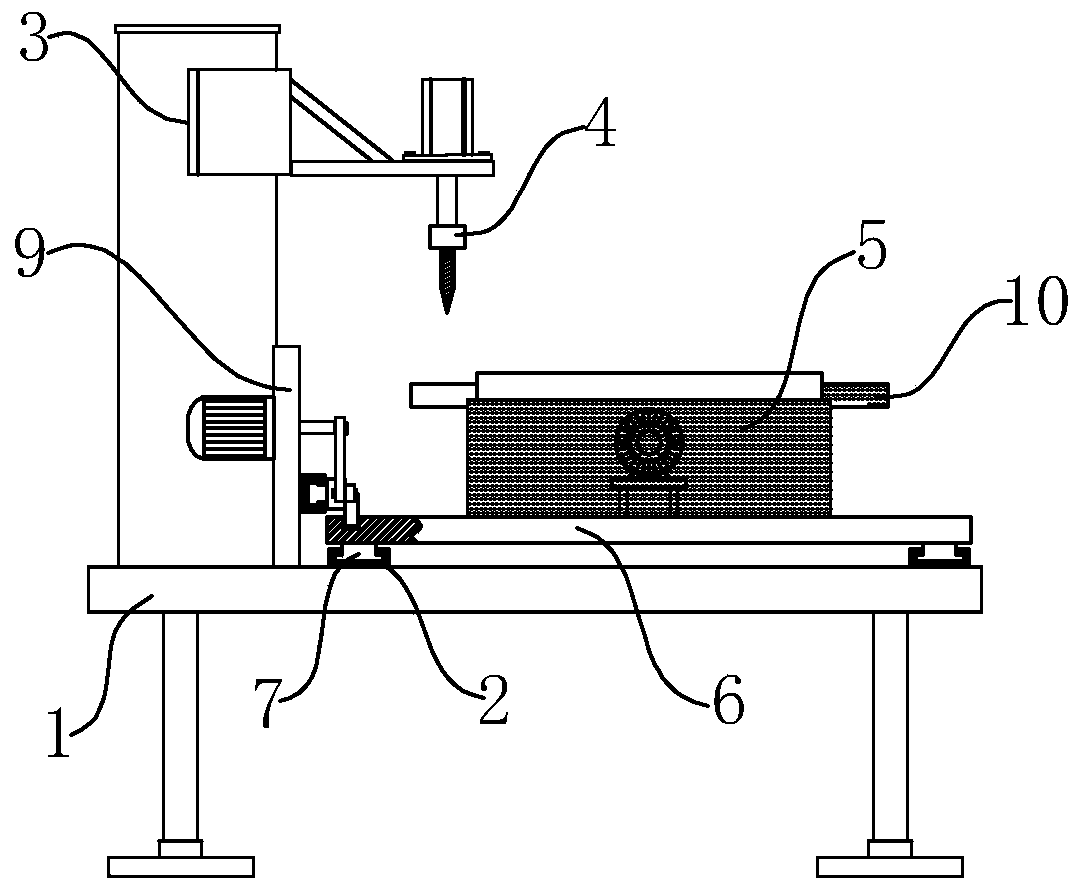

[0028] refer to Figure 1-8 , an environment-friendly metal composite board production equipment, comprising a frame 1 and a punching device body 3, the punching device body 3 is fixedly installed on the upper surface of the frame 1, and a punching head 4 is fixedly installed on the punching device body 3, The punching equipment body 3 can adjust the height of the punching head 4, and the punching head 4 is connected with a hydraulic telescopic rod, so as to realize the punching operation on the metal composite board. Two sliding mechanisms are installed on the upper surface of the frame 1 , and the two sliding mechanisms are slidably connected with the operating platform 6, the operating platform 6 can slide back and forth on the frame 1 through the two sliding mechanisms, and the operating platform 6 can only slide along the horizontal axis direction of the sliding mechanism , the console 6 will not break away from the frame 1 during the sliding process.

[0029] The two sl...

Embodiment 2

[0031] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the sliding mechanism includes a first slideway 2 and a first slide bar 7, the first slideway 2 is fixedly installed on the upper surface of the frame 1, the second A slide bar 7 is fixedly installed on the lower surface of the operating table 6, and the first slide bar 7 is slidably limited in the first slideway 2, and both the first slideway 2 and the first slide bar 7 are T-shaped structures , the first slide bar 7 can move in the first slideway 2 and along its axis direction, and during the movement of the first slide bar 7, the first slide bar 7 will be limited in the first slideway 2 , the first slide bar 7 will not break away from the first slideway 2, thereby ensuring the stability of the operating table 6 during movement.

Embodiment 3

[0033] refer to Figure 5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the fixing mechanism 5 includes two vertical plates 12, and the two vertical plates 12 are respectively fixedly connected to both sides of the upper surface of the operating table 6, and the two vertical plates The upper parts of 12 are fixedly connected with bearings 20 through respectively, and an adjusting rod 18 is rotatably connected between the two bearings 20, the first thread 14 is arranged on one side of the outer surface of the adjusting rod 18, and the other side of the outer surface of the adjusting rod 18 is arranged There is a second thread 16, and the thread directions of the first thread 14 and the second thread 16 are just opposite, and one side of one riser 12 is fixedly installed with the first motor 11, and one end of the output shaft of the first motor 11 is rotatably Connected to one end of the adjustment rod 18, the first motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com