Machining and punching equipment for plastic plate

A technology of mechanical processing and plastic sheet, which is applied in metal processing and other directions, can solve the problem of difficult processing and punching of foam plastic sheet, and achieve the effect of promoting the effect of reciprocating sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

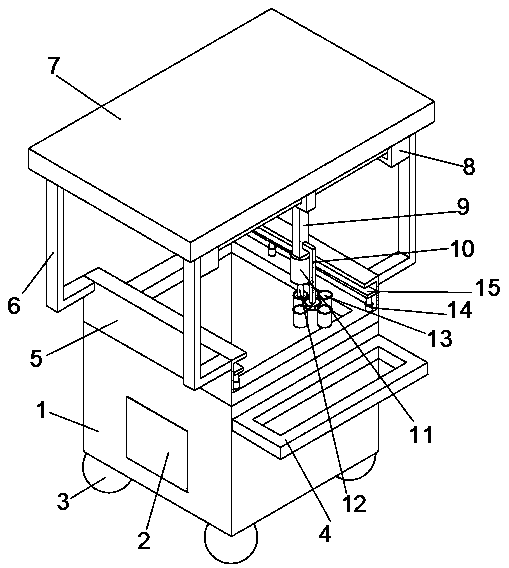

[0029] Embodiment 1: refer to figure 1 ;

[0030] A punching device for mechanical processing of plastic sheets, comprising a waste collection box 1 and a control panel 2, the left side of the waste collection box 1 is provided with an opening for waste cleaning, and the middle part of the front side of the waste collection box 1 is fixed to the control panel 2 Connection, the bottom of the waste collection box 1 is fixedly equipped with shifting wheels 3 for easy movement, the top of the right side of the waste collection box 1 is fixedly connected with a push handle 4, and the upper port of the waste collection box 1 is fixedly connected with the bottom surface of the fixed seat 5 along the surface. The middle part of the seat 5 is provided with a through opening, the front and rear sides of the fixed seat 5 are provided with card slots, the bottom surface of the card slot groove is fixedly equipped with an electric control telescopic rod 14, and the upper end of the electri...

Embodiment 2

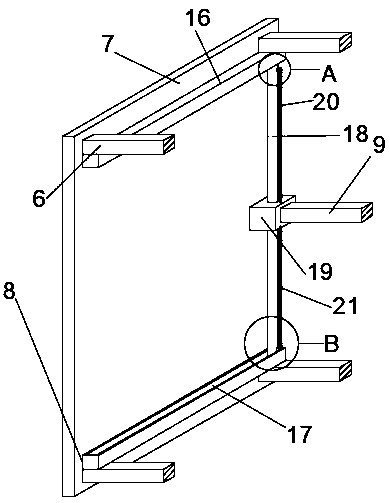

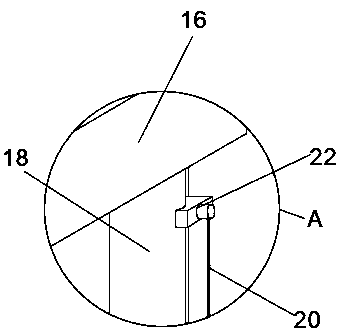

[0034] Embodiment 2: refer to Figure 2-5 , the basis of the embodiment 1 is different in that;

[0035] The moving device 8 includes a first chute 16 and a second chute 17, the first chute 16 is fixedly connected to one side of the bottom surface of the support plate 7, the second chute 17 is fixedly connected to the other side of the bottom surface of the support plate 7, and the second chute 17 is fixedly connected to the other side of the bottom surface of the support plate 7. The chute 17 is slidably connected with one end of the sliding connecting rod 18, and the other end of the sliding connecting rod 18 is slidably connected with the first chute 16 through an electric control drive block, and the outer surface of the middle part of the sliding connecting rod 18 is slidably connected with a connecting block 19. The lower side is fixedly connected with the upper end of the connecting rod 9, and one end of the sliding connecting rod 18 is fixedly installed with a micromot...

Embodiment 3

[0038] Embodiment 3: refer to Figure 6-8 , the basis of the embodiment 1 is different in that;

[0039] The adjusting tool device 13 includes a driving swivel base 24, the driving swivel base 24 is electrically connected to the control panel 2, the upper surface of the driving swivel base 24 is fixedly connected with the vertical end of the L-shaped connecting rod 10, and the peripheral surface of the driving swivel base 24 is fixedly connected. There are multiple groups of connecting rods 25, the outer ends of the connecting rods 25 are fixedly connected with a supporting sleeve 26, the lower opening of the supporting sleeve 26 is provided with a retaining ring 27, the upper surface of the retaining ring 27 is fixedly connected with a spring 28, and the upper end of the spring 28 is connected with the extruding block 29 lower surfaces are fixedly connected around, the extrusion block 29 peripheral surfaces are slidingly connected with the support sleeve 26 inner walls, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com