Patents

Literature

47results about How to "Quick punch operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel workshop equipment

InactiveCN108311724ASimple structureEasy to useBoring/drilling componentsBoring/drilling machinesEngineeringRotating disc

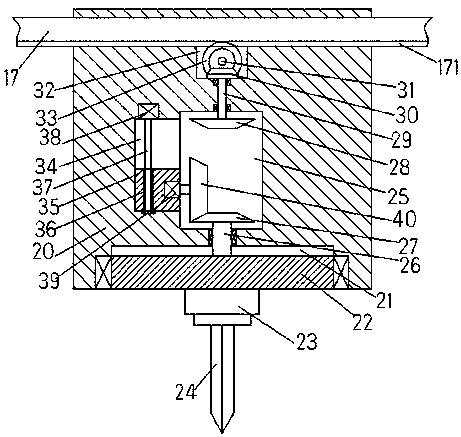

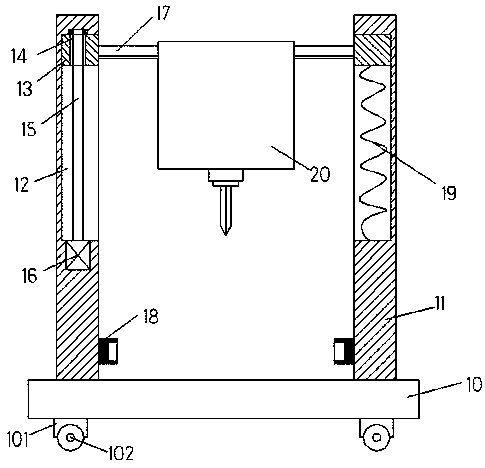

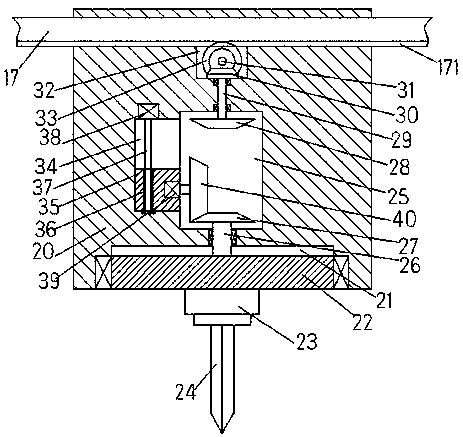

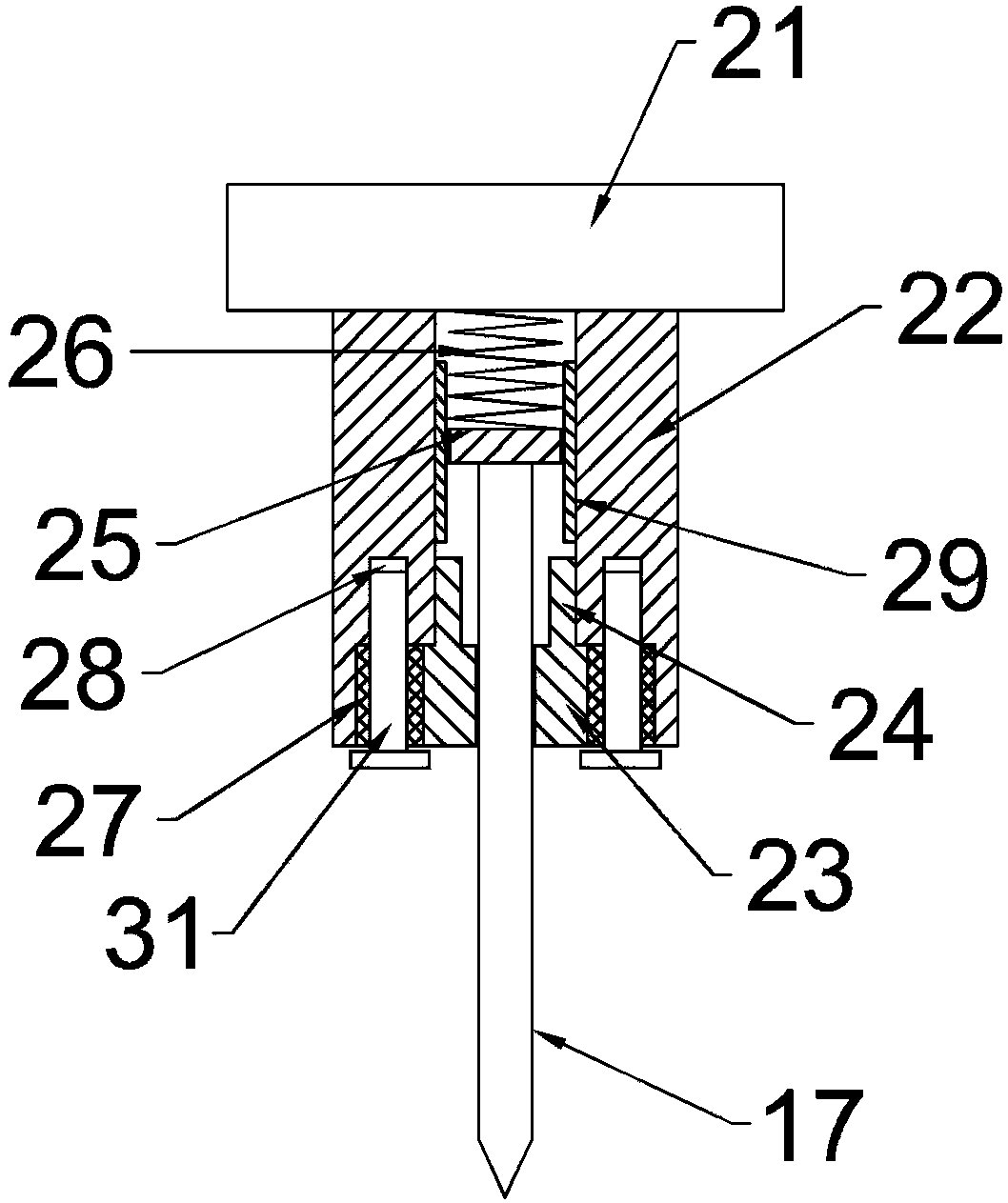

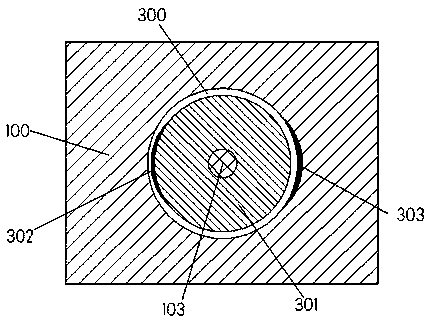

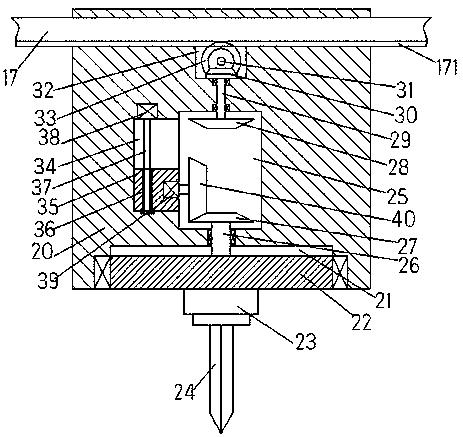

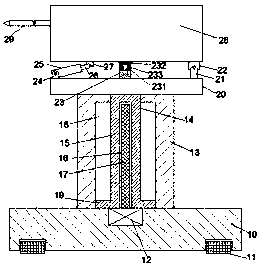

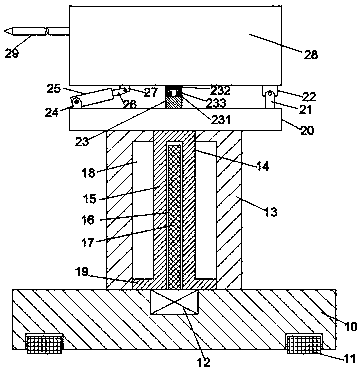

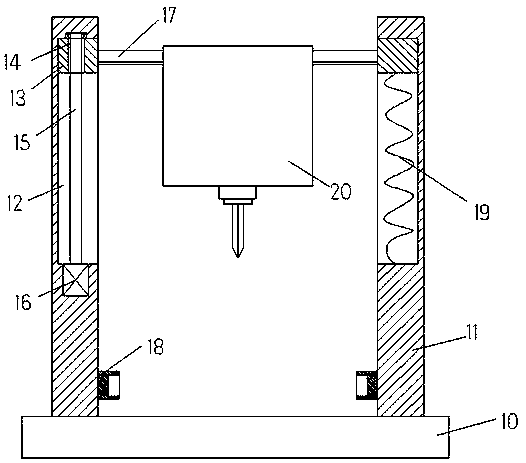

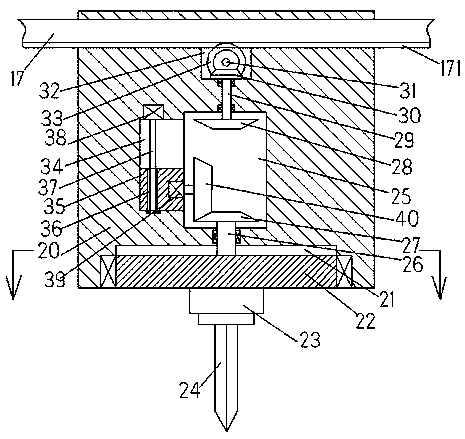

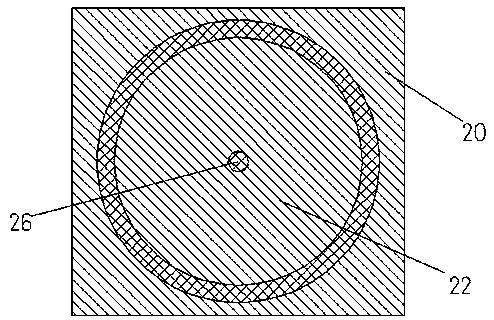

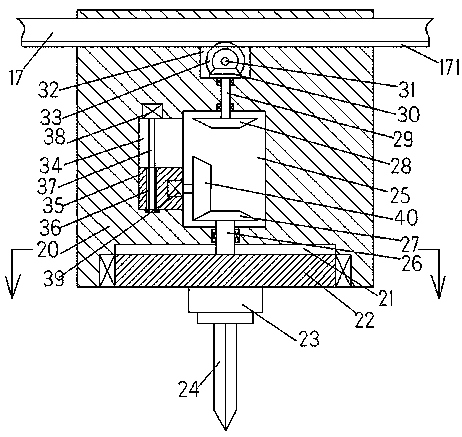

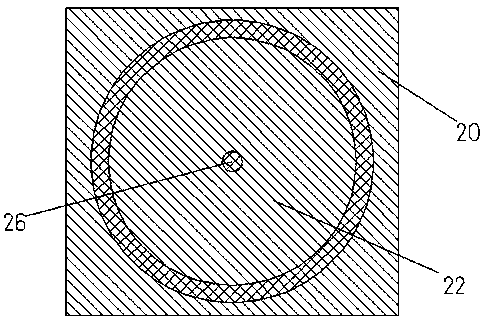

The invention discloses novel workshop equipment which comprises a machine base, brackets and a tank shell body, wherein the brackets are arranged at two ends of the top of the machine base in a left-right symmetric manner; the tank shell body is arranged between the left and right brackets through a pushing-lifting device; a first rotating cavity of which the end port faces down is arranged at the inner bottom of the tank shell body; a second rotating cavity is arranged in the tank shell body in an up-down extending manner and positioned above the first rotating cavity; a first sliding troughis arranged in the inner wall of the left side of the second rotating cavity in a communicating manner; a rotating disc is rotatably mounted in the first rotating cavity through a bearing; a first rotating shaft which extends into the second rotating cavity is fixedly arranged at the top of the rotating disc; a first conical wheel is fixedly mounted on the first rotating shaft in the second rotating cavity; and a first sliding block is arranged in the first sliding trough in an up-down slidable manner.

Owner:楼碧云

Workshop equipment

InactiveCN108161056ASimple structureEasy to useBoring/drilling componentsBoring/drilling machinesMechanical engineeringEngineering

The invention discloses workshop equipment. The equipment comprises a machine base, supports which are left and right symmetrically arranged at the two ends of the top of the machine base and a box shell which is arranged between the left and right supports through a pushing device; a first rotation cavity with a downward port is formed in the inner bottom of the box shell, a second rotation cavity which extends up and down is formed in the portion, above the first rotation cavity, in the box shell, and a first sliding groove is communicated with the interior of the inner wall of the left sideof the second rotation cavity; a rotation disc is rotatably arranged in the first rotation cavity through bearings, a first rotation shaft which extends into the second rotation cavity is fixedly arranged at the top of the rotation disc, a first conical wheel is fixedly arranged on the first rotation shaft in the second rotation cavity, and a first sliding block which can slide up and down is arranged in the first sliding groove.

Owner:楼碧云

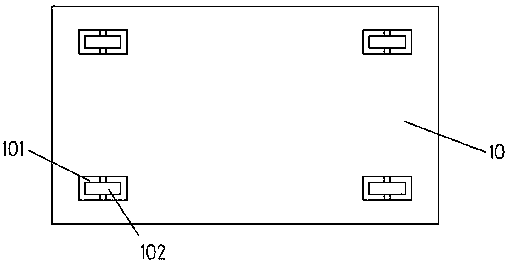

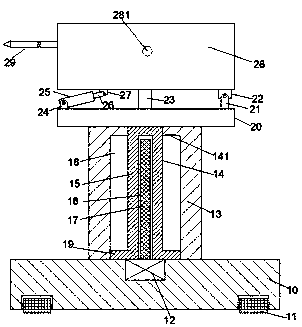

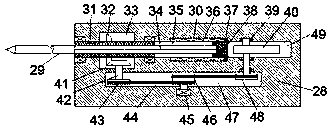

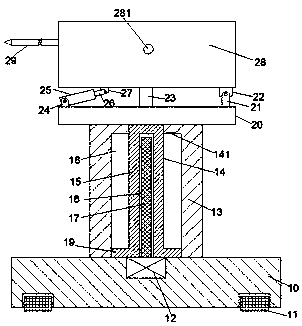

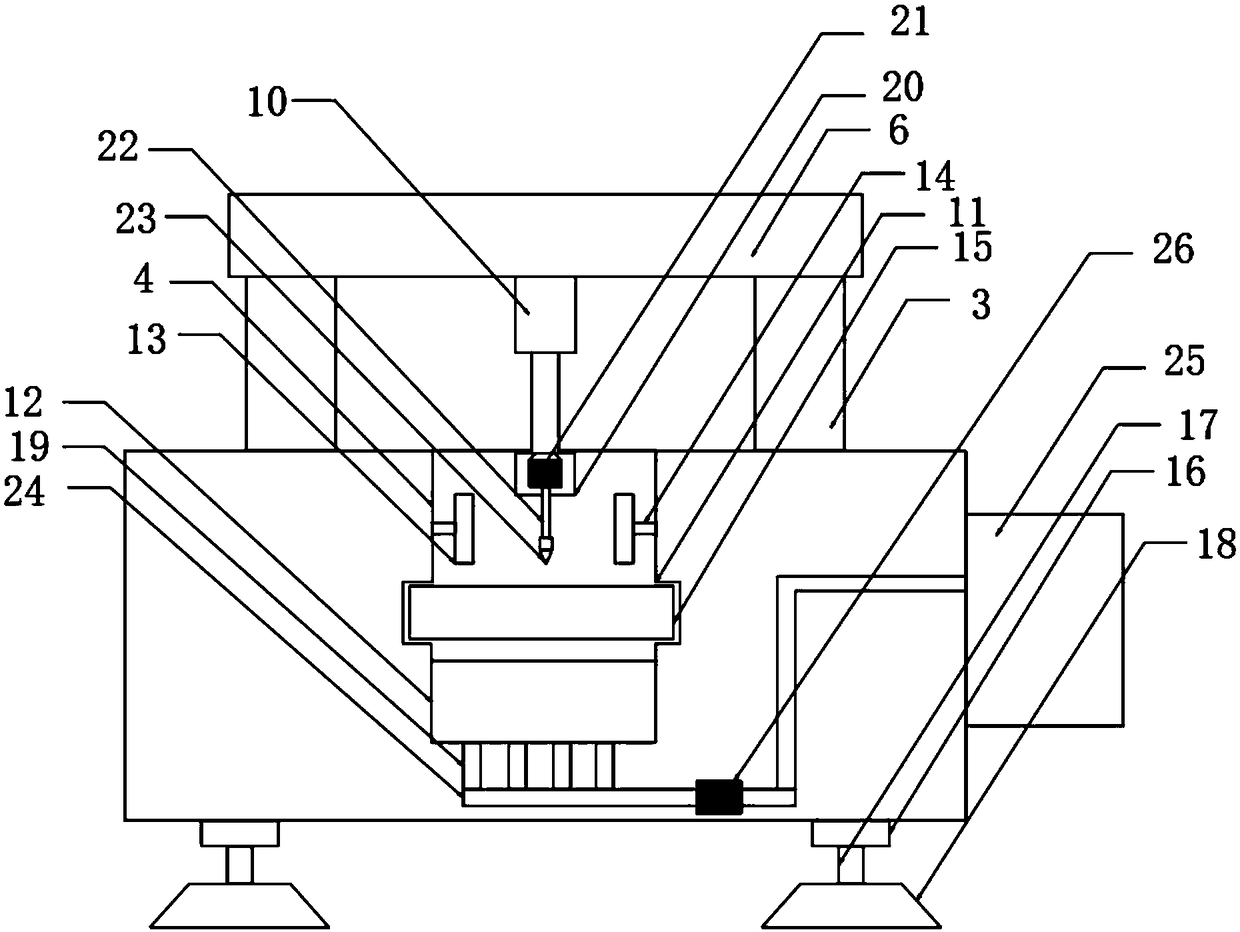

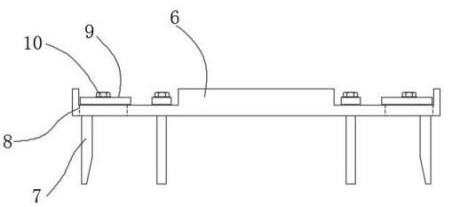

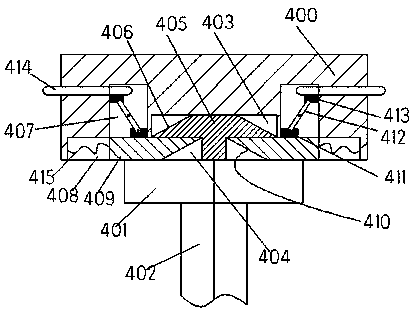

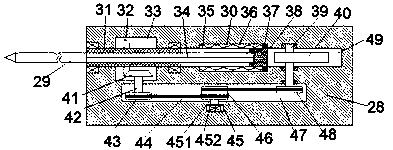

Perforating device for food packaging paperboard

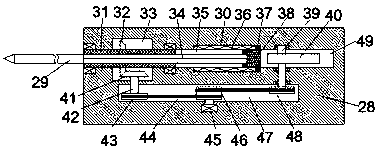

InactiveCN107825518ARealize all-round drillingQuick punch operationMetal working apparatusControl systemPaperboard

The invention discloses a perforating device for a food packaging paperboard. The perforating device for the food packaging paperboard comprises a bottom plate, a supporting column, a top plate, an adjusting shaft, a supporting block, threaded parts, a first threaded sleeve, a first sliding groove, a first sliding block, a connecting rod, a lifting plate, a fixing plate and a lead screw. A secondthreaded sleeve is mounted on the lead screw. The two threaded parts are in central symmetry along the adjusting shaft. The spiral directions of threads of the two threaded parts are opposite. A mounting device is mounted on the outer wall of the lower end of the second threaded sleeve through a connecting part. A perforating rod is mounted in the lower end of the mounting device. The overall structure of the perforating device adopts the mechanical principles well known by people skilled in the art, any complex electrical equipment or control system is not used, paperboard perforating operation can be achieved rapidly through simple manual operation, the position adjustment of the perforation rod can be achieved through the lead screw, omnidirectional perforating of the paperboard can beachieved, the paperboard does not need to be moved after being fixed, and the perforating position can be changed just by changing the position of the perforating rod.

Owner:陈式好

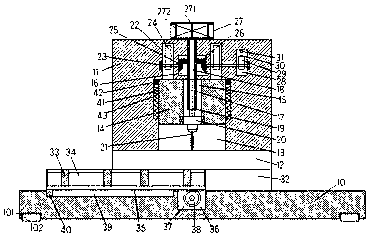

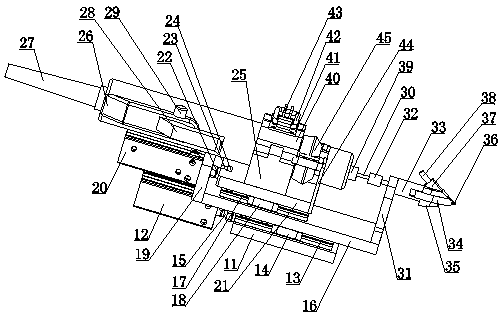

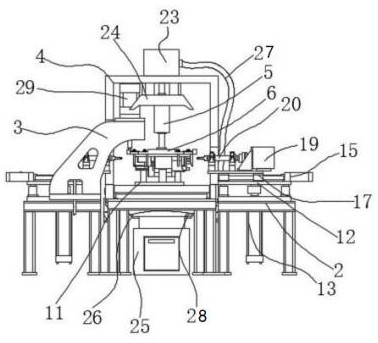

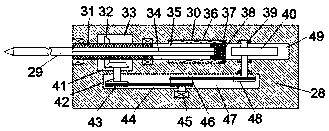

Novel process equipment for copper-aluminum composite pipe

InactiveCN108480697ASimple structureSimple and fast operationMaintainance and safety accessoriesBoring/drilling machinesProcess equipmentEngineering

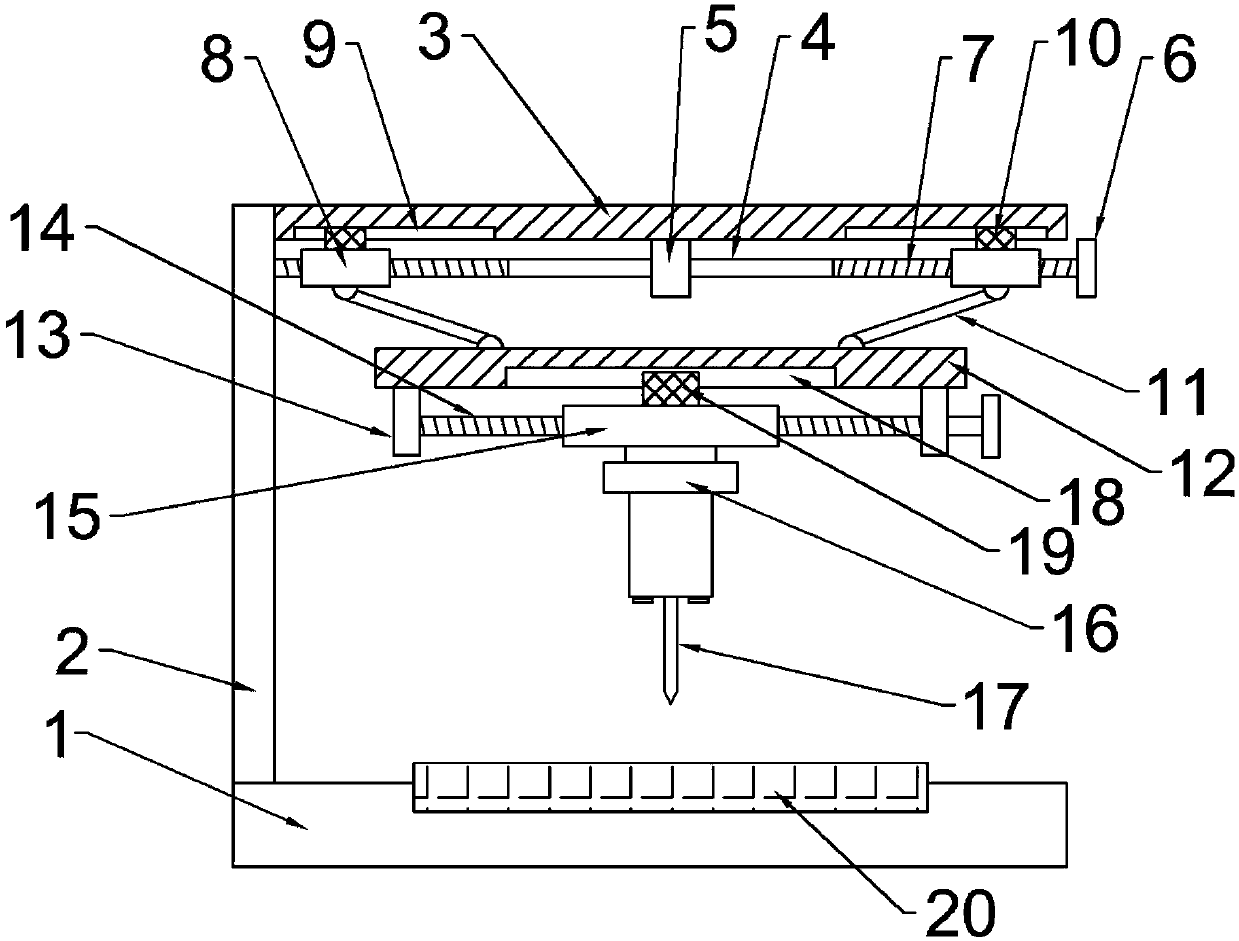

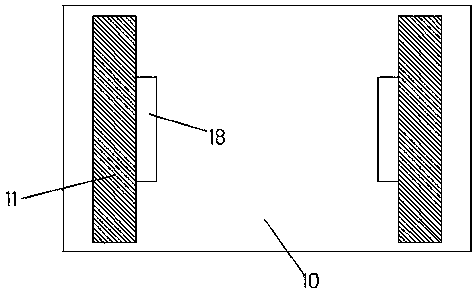

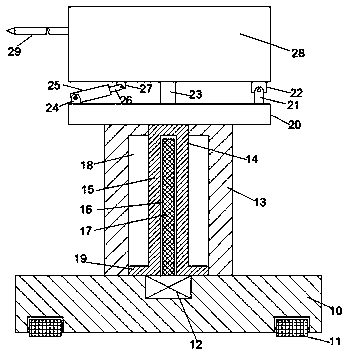

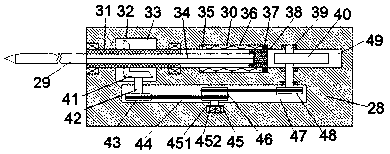

The invention discloses novel process equipment for a copper-aluminum composite pipe. The novel process equipment comprises a base, a left supporting frame and a right supporting frame, wherein the left supporting frame is arranged at the left end of the base and extends upwards, and the right supporting frame is fixedly arranged at the right end of the base and extends upwards; a left lifting groove is formed in the inner side end face of the left supporting frame, a right lifting groove is formed in the inner side end face of the right supporting frame, lifting blocks are arranged in the right lifting groove and the left lifting groove respectively in a sliding mode, and a lifting frame is fixedly arranged between the left lifting block and the right lifting block; a transverse-extendingrotating column is arranged at the position, located at above the lifting frame, between the left supporting frame and the right supporting frame, and the right end of the rotating column penetratesthrough the exterior of the right end surface of the right supporting frame to be in power connection with a first motor which is fixedly arranged on the top of the right end surface of the right supporting frame; and a cam which is in jacking sliding fit with the lifting frame is fixedly arranged on the rotating column arranged above the lifting frame, and a first friction wheel is fixedly arranged on the position, located on the left side of the cam, of the rotating column.

Owner:陈 玉玲

Letter box device

ActiveCN108356318ASimple structureEasy to useBoring/drilling machinesPower modeMechanical engineering

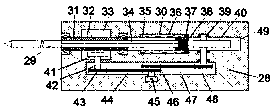

The invention discloses a letter box device. The letter box device comprises a base and a machine body fixedly arranged above the base. The machine body is internally provided with an installation cavity in a left-right penetrating mode. A first sliding cavity is formed in the top wall of the installation cavity, a sliding frame which can side up end down is arranged in the first sliding cavity, afirst transferring cavity with an upward opening is arranged in the sliding frame, and a second transferring cavity is formed in the top wall of the first sliding cavity, and the second transferringcavity is rotatably provided with a spline housing extending up end down. The top extending end of the top of the spline housing penetrates through the inner top wall of the second transferring cavityand is connected with a first motor fixedly arranged on the top end face of a machine body in a power mode, and the bottom extending end of the spline housing penetrates through the inner bottom wallof the second transferring cavity and extends into the first transferring cavity. A rotating block is rotatably arranged on the bottom in the first transferring cavity through a bearing.

Owner:YANGZHOU SHENGYE MACHINERY

Automatic electronic substrate machining equipment

InactiveCN108656209AQuick punch operationSimple structureMetal working apparatusHydraulic cylinderEngineering

The invention discloses automatic electronic substrate machining equipment. The automatic electronic substrate machining equipment comprises a base, a supporting column fixedly arranged on the top ofthe base, and a rack arranged above the top of the supporting column. A supporting plate is erected on the top of the supporting column. A supporting table is fixedly arranged at the center position of the top of the supporting plate. The top of the supporting table abuts against the top end face of the rack. The top end faces of the parts, on the left side and the right side of the supporting table, of the supporting plate are provided with a first connecting arm and a second connecting arm correspondingly. A first connecting block and a second connecting block are fixedly arranged on the twosides of the bottom end face of the rack correspondingly. A hydraulic cylinder is hinged and installed to the first connecting arm, and a hydraulic rod of the hydraulic cylinder is hinged to the first connecting block. The second connecting arm and the second connecting block are installed in a hinged manner, a sliding cavity with a leftward opening is formed in the rack in a left-right extendingmanner, and a sliding block is arranged in the sliding cavity in a sliding manner.

Owner:江苏卓燃高新科技有限公司

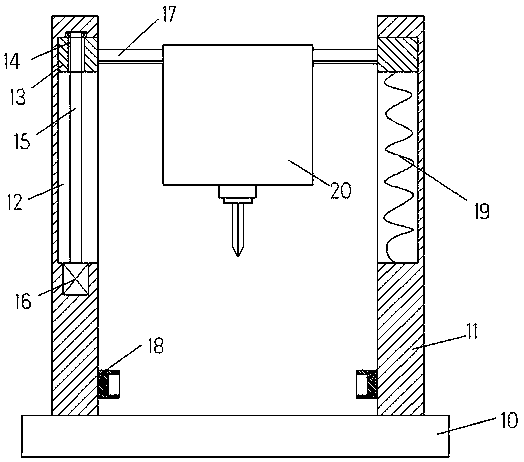

Hard alloy material and high-end hard alloy cutter manufacturing technology equipment

InactiveCN108500312ASimple device structureSimple and efficient operationBoring/drilling componentsMaintainance and safety accessoriesCamMaterials science

The invention discloses hard alloy material and high-end hard alloy cutter manufacturing technology equipment. The hard alloy material and high-end hard alloy cutter manufacturing technology equipmentcomprises a base, a left bracket and a right bracket; the left bracket is arranged at the left side end of the base and extends upwards; the right bracket is fixedly arranged at the right side end ofthe base and extends upwards; a left lifting groove is formed in the inner side end face of the left bracket; a right lifting groove is formed in the inner side end face of the right bracket; liftingblocks are mounted in the right lifting groove and the left lifting groove in a sliding manner correspondingly; a lifting stand is fixedly arranged between the two lifting blocks at left and right; arotating column is arranged between the parts, above the lifting stand, of the left bracket and the right bracket in a transversely extending manner; the right side end of the rotating column penetrates out of the right side end face of the right bracket and is in power connection with a first motor fixedly arranged at the top of the right side end face of the right bracket; a cam in top pressuresliding fit with the lifting stand is fixedly arranged on the rotating column above the lifting stand; and a first friction wheel is fixedly arranged on the part, on the left side of the cam, of therotating column.

Owner:陈 玉玲

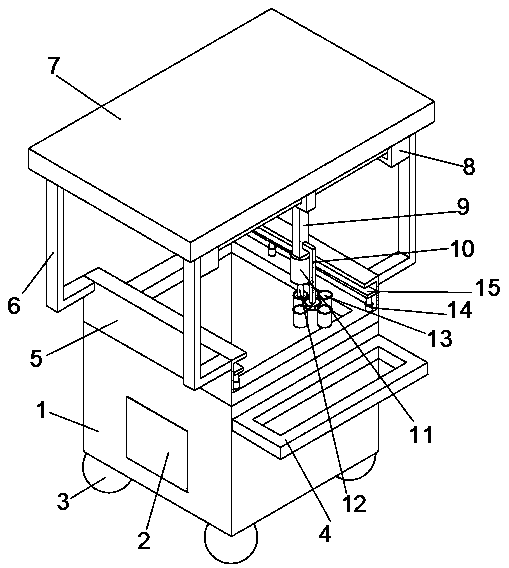

Machining and punching equipment for plastic plate

InactiveCN110126014APromote reciprocating sliding effectMeet punching requirementsMetal working apparatusPunchingWaste collection

The invention discloses machining and punching equipment for a plastic plate, and belongs to that field of plastic punching equipment. The machining and punching equipment comprises a waste collectionbox and a control panel; the waste collection box is connected with the control panel; movable wheels are mounted at the bottom of the waste collection box; the right side of the waste collection boxis connected with a pushing handle; the upper end of the waste collection box is connected with a fixed seat; the fixed seat is provided with a through opening; clamping grooves are formed in the twosides of the fixed seat; electric control telescopic rods are mounted in the clamping grooves; clamping plates are connected with the electric control telescopic rods; the front outer surface and therear outer surface of the fixed seat are connected with L-shaped supporting rods; the L-shaped supporting rods are connected with a supporting plate; a moving device is mounted on the supporting plate; the moving device is connected with a connecting rod; the connecting rod is connected with an air cylinder; the air cylinder sleeves an air pressure rod; the connecting rod is connected with an L-shaped connecting rod; and the L-shaped connecting rod is connected with a cutter adjusting device. The machining and punching equipment can realize fast and accurate punching of the plastic plate, isconvenient to operate and improves production efficiency.

Owner:LINAN LEILUO PLASTIC FACTORY

Low-cost high-performance strengthening agent production technology equipment

InactiveCN108481572ASimple structureSimple and fast operationWorking accessoriesStone-like material working toolsEngineeringCam

The invention discloses low-cost high-performance strengthening agent production technology equipment. The low-cost high-performance strengthening agent production technology equipment comprises a base, a left supporting frame and a right supporting frame, wherein the left supporting frame is arranged at the left end of the base and extends upwards, and the right supporting frame is fixedly arranged at the right end of the base and extends upwards; a left lifting groove is formed in the inner side end face of the left supporting frame, a right lifting groove is formed in the inner side end face of the right supporting frame, lifting blocks are arranged in the right lifting groove and the left lifting groove respectively in a sliding mode, and a lifting frame is fixedly arranged between theleft lifting block and the right lifting block; a transverse-extending rotating column is arranged at the position, located at above the lifting frame, between the left supporting frame and the rightsupporting frame, and the right end of the rotating column penetrates through the exterior of the right end surface of the right supporting frame to be in power connection with a first motor which isfixedly arranged on the top of the right end surface of the right supporting frame; and a cam which is in jacking sliding fit with the lifting frame is fixedly arranged on the rotating column arranged above the lifting frame, and a first friction wheel is fixedly arranged on the position, located on the left side of the cam, of the rotating column.

Owner:陈 玉玲

Metal functional material manufacturing technology equipment for novel electronic component

ActiveCN108376864AQuick installationSimple structureLive contact access preventionManufacturing technologyEngineering

The invention discloses metal functional material manufacturing technology equipment for a novel electronic component. The equipment comprises a body, wherein the body is provided with a first rotation chamber, the body is provided with a second rotation chamber at an upper side of the first rotation chamber, the first rotation chamber is rotatably provided with a rotation cylinder through a rotation bearing, an inner top wall of the rotation cylinder extends upwards and is provided with an axial hole which penetrates through the second rotation chamber and stretches out of a top end surface of the body, the axial hole is rotatably equipped with a rotation column, a bottom portion of the rotation column is fixedly connected with a top end surface of the rotation cylinder, a top portion ofthe rotation column is in power connection with a rotation motor fixedly arranged at a top end surface of the body, a bottom end surface of the rotation cylinder is internally provided with a telescoping chamber opening downwards, the telescoping chamber is equipped with a telescoping plate capable of sliding up and down, a top end surface of the telescoping plate is internally provided with a permanent magnet, and an inner top wall of the telescoping chamber is provided with an electromagnetic device matched with the permanent magnet.

Owner:上海华承光电科技有限公司

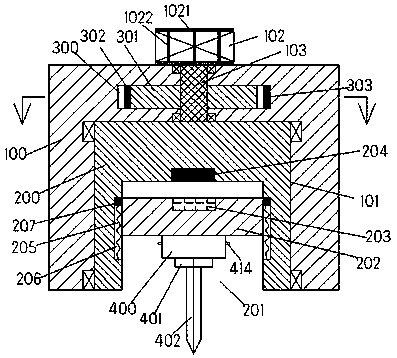

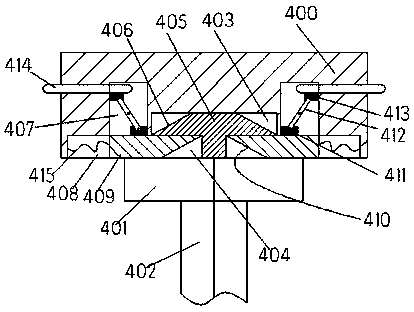

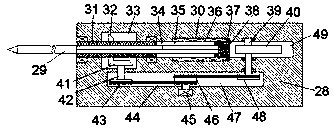

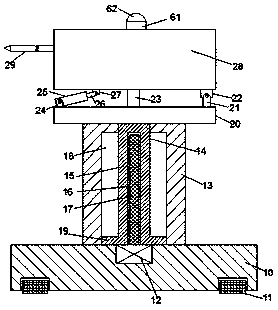

Method for punching LED lamp holder

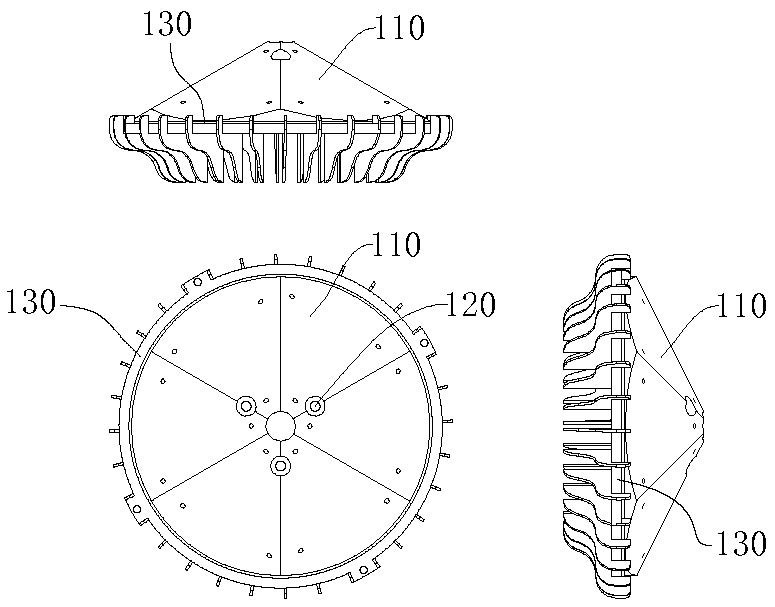

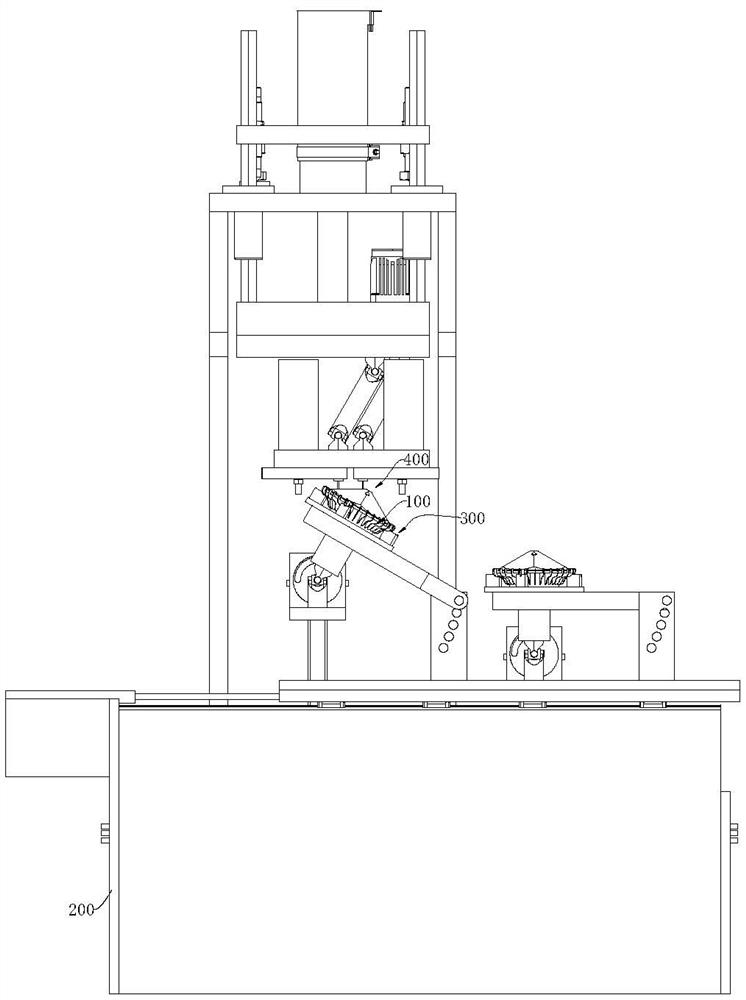

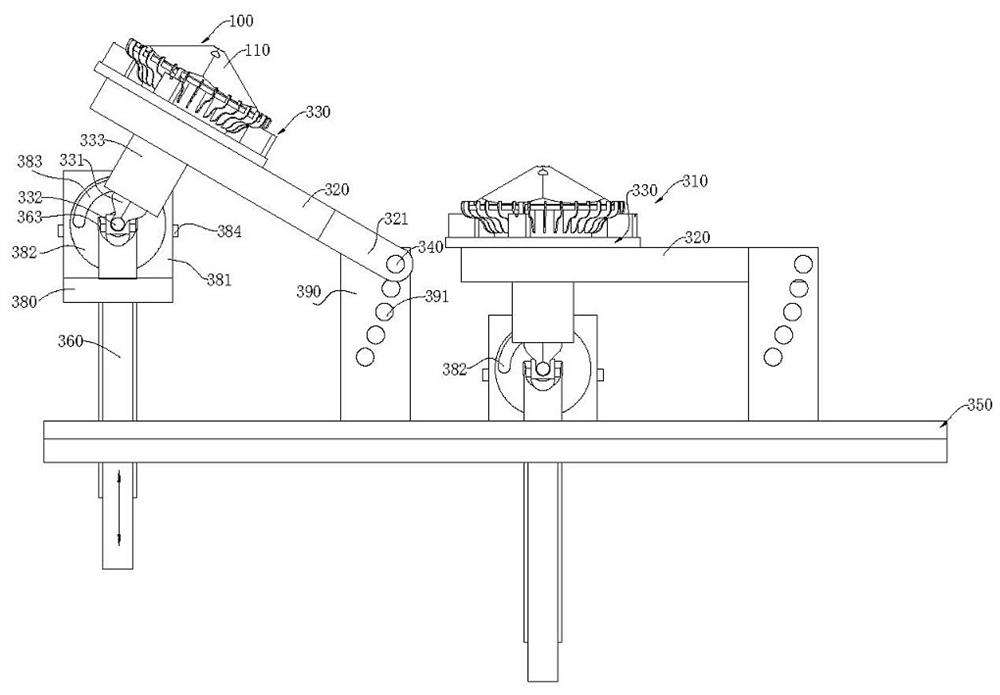

ActiveCN113579304AAdjustable lengthQuick punch operationElectrical apparatusElectroluminescent light sourcesLED lampMaterials science

The invention relates to a method for punching an LED lamp holder. The method comprises the following steps on punching production equipment: a lamp base is assembled on a clamping structure A, at least one machining surface on the lamp base is horizontally arranged, a punching unit on the upper side of the horizontally arranged machining surface is adjusted to move downwards, the horizontally arranged machining surface is punched by the punching unit, the clamping structure A is adjusted to rotate around the center line of the clamping structure A after punching is finished, so that the other machining surface which is not punched on the clamping structure A is adjusted to be horizontally arranged and punched, the operation is repeated in this way until all the machining surfaces on the lamp base are punched, and then the lamp base is detached from the clamping mechanism A. According to the method, rapid and automatic punching operation on lamp bases of different sizes and models can be effectively realized, the production efficiency is improved, and the labor intensity is reduced.

Owner:安徽川越通信科技有限责任公司

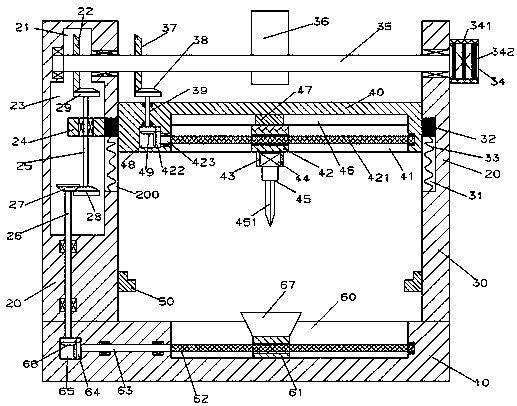

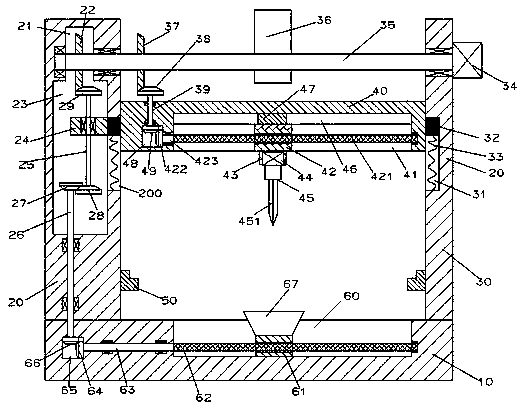

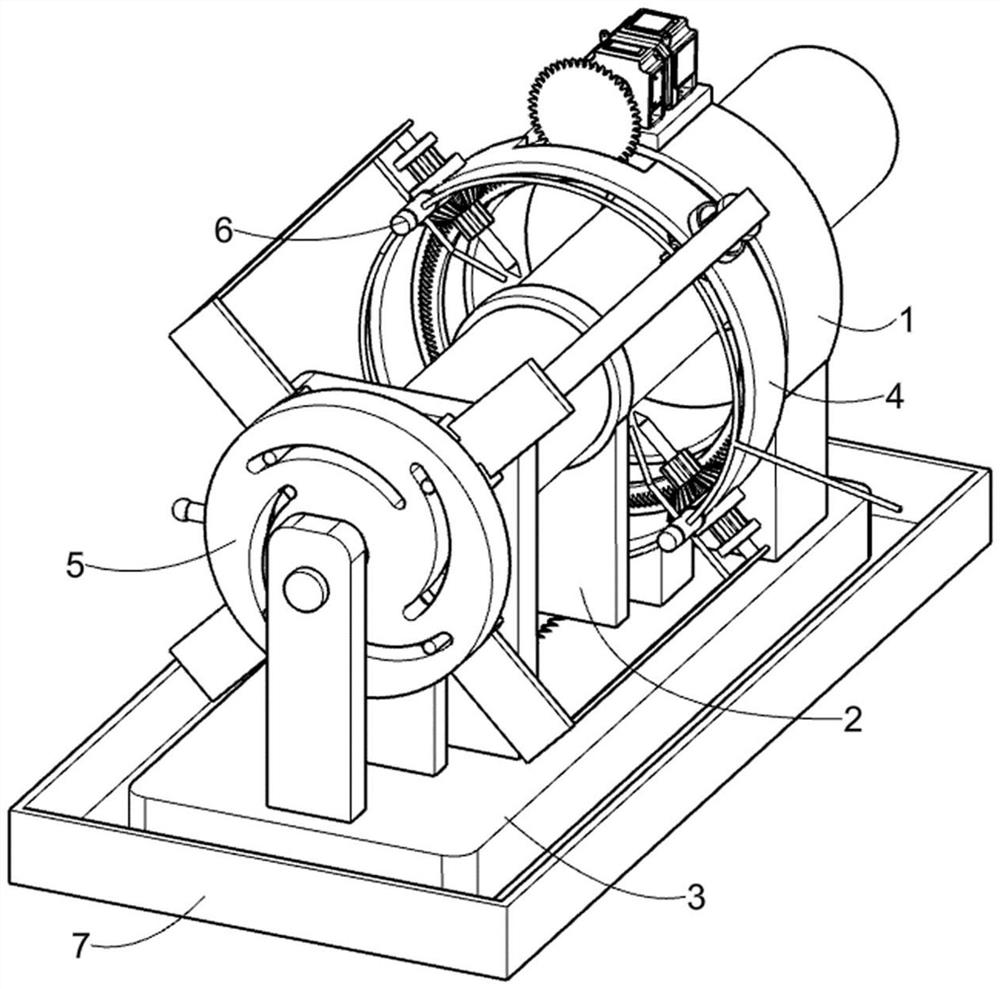

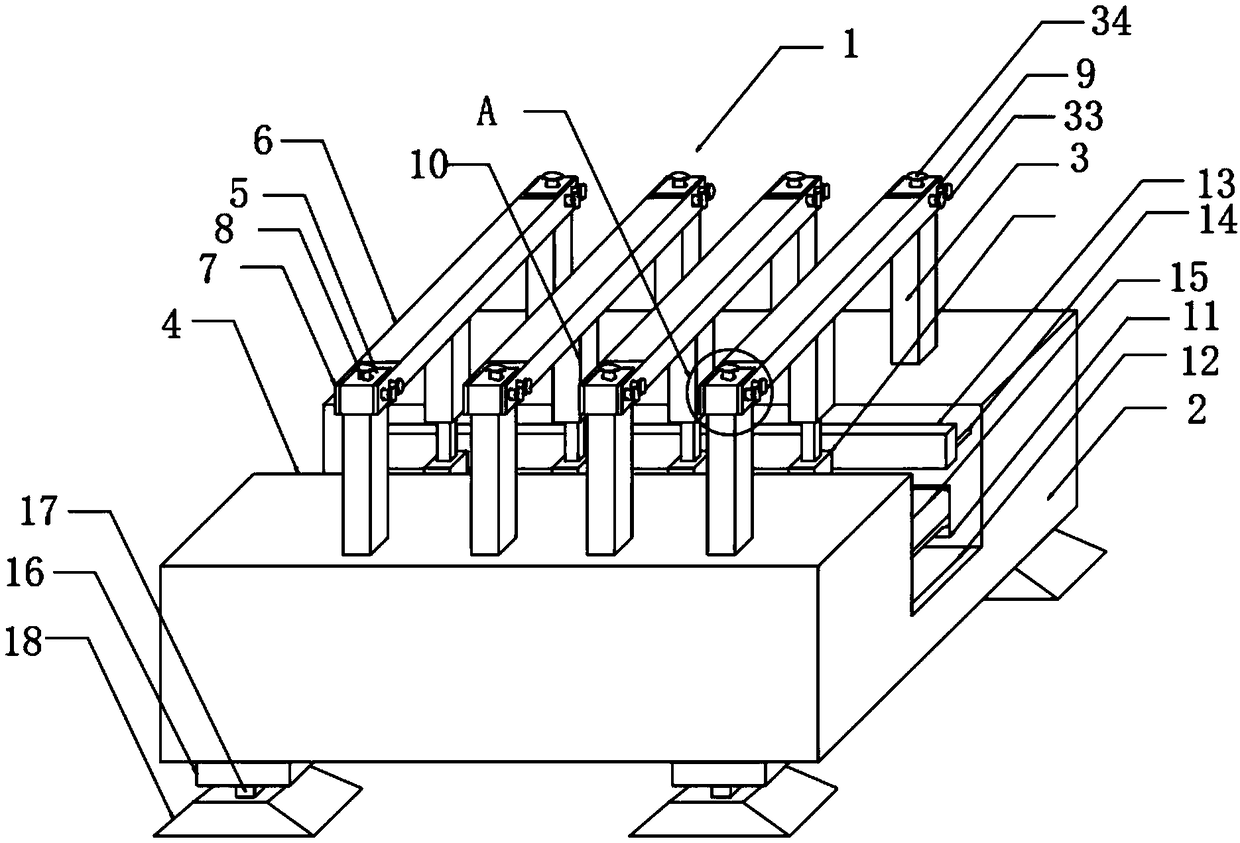

A dust-removing FRP hole punching machine that is easy to customize the number of holes and adjust the hole spacing

ActiveCN112171778BQuick punch operationTo meet the different needs of the number of single punchingMetal working apparatusGlass fiberPunching

The invention relates to a glass steel pipe punching device, more particularly a dust-removing glass steel pipe punching machine which is convenient for customizing the number of punching holes and adjusting the hole spacing, so as to solve the problem that the existing glass steel pipe punching equipment cannot be used in a single punching operation. The problem of punching different numbers of holes, and the distance of punching holes cannot be adjusted according to the actual needs of FRP pipes. A dust-removing glass fiber reinforced plastic pipe punching machine that is convenient for customizing the number of holes and adjusting the hole spacing, including a first support frame, a second support frame, a distance precision mechanism, a drilling mechanism, etc.; the distance precision mechanism is set in the first On the support frame, the two second supports are set on the distance accurate mechanism, and the drilling mechanism is set on the first support frame and the distance accurate mechanism. The invention can carry out the drilling operation according to the requirement of the number of holes perforated in the glass steel pipe, and can also punch equidistant holes on the glass steel pipe, and can adjust the distance of the holes.

Owner:DONGYING WEIMA PETROLEUM DRILLING TOOLS +1

Alloy material device

InactiveCN108311723ASimple structureEasy to useFeeding apparatusBoring/drilling componentsAlloyMaterials science

The invention discloses an alloy material device. The alloy material device comprises a base, support frames symmetrically arranged at the two ends of the top of the base left and right, and a chassisarranged between the left and right support frames through a jacking device; a first rotating groove with a downward notch is formed in the bottom in the chassis; a second rotating groove, extendingup and down, is formed in the chassis above the first rotating groove; a first slide groove is formed in the inner wall of the left side of the second rotating groove in a communicating manner; a turntable is rotationally mounted in the first rotating groove through a bearing; a first rotating rod, extending into the second rotating groove, is fixedly arranged at the top of the turntable; a firstconical wheel is fixedly mounted on the first rotating rod in the second rotating groove; and a first slide block capable of sliding up and down is arranged in the first slide groove.

Owner:汪涛

Novel hardware building material laminating equipment

InactiveCN108527675ASimple structureEasy to useDerricks/mastsStone-like material working toolsBuilding materialArchitectural engineering

The invention discloses novel hardware building material laminating equipment which comprises a bottom plate, a vertical column fixedly arranged at the top of the bottom plate, and an operating framearranged above the top of the vertical column. A mounting plate is erected at the top of the vertical column, and a supporting table is fixedly arranged in the center of the top of the mounting plate.The top of the supporting table abuts against the end face of the top of the operating frame, and a first joint arm and a second joint arm are arranged on the positions, on the left side and the right side of the supporting table, of the end face of the top of the supporting table correspondingly. A first joint block and a second joint block are fixedly arranged on the two sides of the end face of the bottom of the operating frame correspondingly, and a hydraulic cylinder is mounted on the first joint arm in a hinged mode. A hydraulic rod of the hydraulic cylinder is hinged to the first jointblock, and the second joint arm and the second joint block are mounted in a hinged mode. A sliding pushing cavity with the leftward open end is formed in the operating frame in a left-right extensionmode, and a sliding pushing block is movably mounted in the sliding pushing cavity.

Owner:新沂市草桥工业集聚区发展有限公司

Preparation method for high-end fiber composite

InactiveCN108789625ASimple structureEasy to useMetal working apparatusFibrous compositesArchitectural engineering

The invention discloses a high-end fiber composite device comprising a seat, a support arm fixedly arranged at the top of the seat, and a machine body arranged above the top of the support arm. A transverse plate is erected at the top of the support arm. A support table is fixedly arranged in the center of the top of the transverse plate. The top of the support table abuts against the top end faceof the machine body. A first connecting column and a second connecting column are arranged on the left and right sides of the support table and at the top end face of the support table correspondingly. A first lug and a second lug are fixedly arranged on the two sides of the bottom end face of the machine body correspondingly. A hydraulic cylinder is installed on the first connecting column in ahinged mode. A hydraulic rod of the hydraulic cylinder is hinged to the first lug. The second connecting column is hinged to the second lug. A sliding-connecting cavity with a leftward through openingis formed in the machine body in a left-right extending mode. A sliding-connecting block is installed in the sliding-connecting cavity in a sliding-connecting mode.

Owner:广州绿能智能科技有限公司

Intelligent mailbox device

InactiveCN108526530ASimple structureEasy to useMeasurement/indication equipmentsBoring/drilling componentsEngineeringMechanical engineering

The invention discloses an intelligent mailbox device comprising a base and a machine body arranged above the base. The machine body is internally provided with a mounting cavity in a left-and-right run-through manner, and the top wall of the mounting cavity is internally provided with a first sliding cavity; the first sliding cavity is internally provided with a sliding frame in an up-and-down slidable manner, and the sliding frame is internally provided with a first rotating cavity with an opening upward; the top wall of the first sliding cavity is internally provided with a second rotatingcavity which is rotatably provided with a spline housing extending up and down, and the top extension end of the spline housing runs through the inner top wall of the second rotating cavity, and is inpower connection with a first motor fixedly arranged on the top end face of the machine body; the bottom extension end of the spline housing runs through the inner bottom wall of the second rotatingcavity, and extends into the first rotating cavity; and the inner bottom of the first rotating cavity is rotatably provided with a rotating block through a bearing.

Owner:苏州瑞非通信息科技有限公司

Environment-friendly double progressive perforating device for aluminized zinc plate

InactiveCN108247143AEasy slide adjustmentImprove sliding stabilityFeeding apparatusHydraulic cylinderEngineering

The invention discloses an environment-friendly double progressive perforating device for an aluminized zinc plate. The device comprises a bottom plate, wherein a first hydraulic cylinder is arrangedon the back part of the bottom plate; a pair of first guide rails is arranged on the top surface of the bottom plate; a first slide block is arranged on each first guide rail; a piston rod is arrangedon the front part of the first hydraulic cylinder; a slide plate is arranged on the first slide block; and the front end of the first piston rod is mounted on the back part of the slide plate; a pairof second guide rails is arranged on the top surface of the slide plate, a second slide block is arranged on each second guide rail, a side base is arranged on the back part of the slide plate, a second hydraulic cylinder is arranged on the back of the side base, a slide is arranged on the slide block, a second piston rod is arranged on the front part of the second hydraulic cylinder, the secondpiston rod passes through the side base, and the front part of the second piston rod is mounted on the back part of the slide; a positioning seat is arranged on the slide, a driving motor is arrangedon the positioning seat, a rotary shaft is arranged on the front part of the driving motor, a spiral tube is arranged at the outer end of the rotary shaft, and a perforating head is arranged on the end part of the spiral tube. The device can perforate the aluminized zinc plate conveniently through the perforating head.

Owner:SUZHOU PISI SOFTWARE DESIGN CO LTD

Environment-friendly fiber composite material preparing method

InactiveCN108943129AQuick punch operationSimple structureMetal working apparatusHydraulic cylinderEngineering

The invention discloses an environment-friendly fiber composite material device. The environment-friendly fiber composite material device comprises a base, a support arm fixedly arranged on the top ofthe base, and a machine body arranged above the top of the support arm. A transverse plate is erected on the top of the support arm. A supporting table is fixedly arranged at the center position of the top of the transverse plate. The top of the supporting table abuts against the top end face of the machine body. The top end faces of the parts, on the left side and the right side of the supporting table, of the transverse plate are provided with a first connecting column and a second connecting column correspondingly. The two sides of the bottom end face of the machine body are fixedly provided with a first protruding block and a second protruding block correspondingly. A hydraulic cylinder is hinged and installed to the first connecting column. A hydraulic rod of the hydraulic cylinder is hinged to the first protruding block. The second connecting column is hinged and installed to the second protruding block. The machine body is internally provided with a sliding connecting cavity with a leftward through port in a left-right-stretching manner, and the sliding connecting cavity is internally provided with a sliding connecting block in a sliding connecting manner.

Owner:广州绿能智能科技有限公司

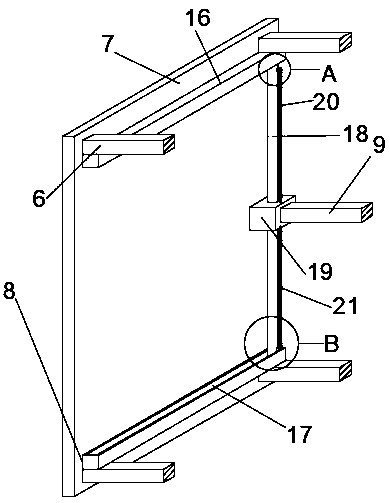

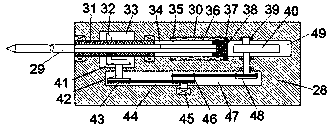

Perforating device capable of achieving automatic and rapid perforating

InactiveCN109175442AEffective punching operationQuick punch operationMaintainance and safety accessoriesBoring/drilling machinesElectric machineryProduction rate

The invention discloses a perforating device capable of achieving automatic and rapid perforating. The automatic perforating device comprises a device body; the device body comprises a support box anda waste collection box; a plurality of support rods are arranged at the top of the support box; the multiple support rods are located on the two sides of a first groove correspondingly; a plurality of first connecting blocks are arranged at the top of the multiple supporting rods; second connecting blocks are arranged between the multiple supporting rods; the two ends of the multiple second connecting blocks are provided with second grooves correspondingly; the multiple second grooves are connected with the first connecting blocks in an inserting mode; the bottoms of the second connecting blocks are provided with first hydraulic cylinders; the hydraulic rod ends of the first hydraulic cylinders are provided with motor boxes; the motor boxes are internally provided with motors; the outputends of the motors are provided with rotating shafts; the other ends of the rotating shafts are provided with drill bits; and the drill bits are located in the first groove. The perforating device iscompact in structure and convenient to use, by arranging the multiple drill bits, raw materials can be perforated more effectively and rapidly, the perforating speed is increased, the perforating efficiency is improved, the productivity is increased, and the production cost is reduced.

Owner:黄钟葳

Energy-saving light guide plate assembling device

InactiveCN108526531ASimple structureEasy to useMetal working apparatusBoring/drilling componentsEngineeringLight guide

The invention discloses an energy-saving light guide plate assembling device. The energy-saving light guide plate assembling device comprises a base and a machine frame fixedly arranged over the base;the machine frame is internally provided with an installation groove in a left-right penetrating mode; a first slide groove is formed in the top wall of the installation groove, and a slide frame isinstalled in the first slide groove in an up-down sliding mode and internally provided with a first rotary cavity with an upward opening; the top wall of the first slide groove is internally providedwith a second rotary cavity, and the second rotary cavity is rotationally provided with a spline housing extending in the vertical direction; the extending end of the top of the spline housing penetrates through the inner top wall of the second rotary cavity and is in power connection with a first motor which is fixedly arranged on the end face of the top of the machine frame, and the extending end of the bottom of the spline housing penetrates through the inner bottom wall of the second rotary cavity and stretches into the first rotary cavity; and a rotary block is rotatably installed at theinner bottom of the first rotary cavity through a bearing.

Owner:温岭市兴庆机械设备有限公司

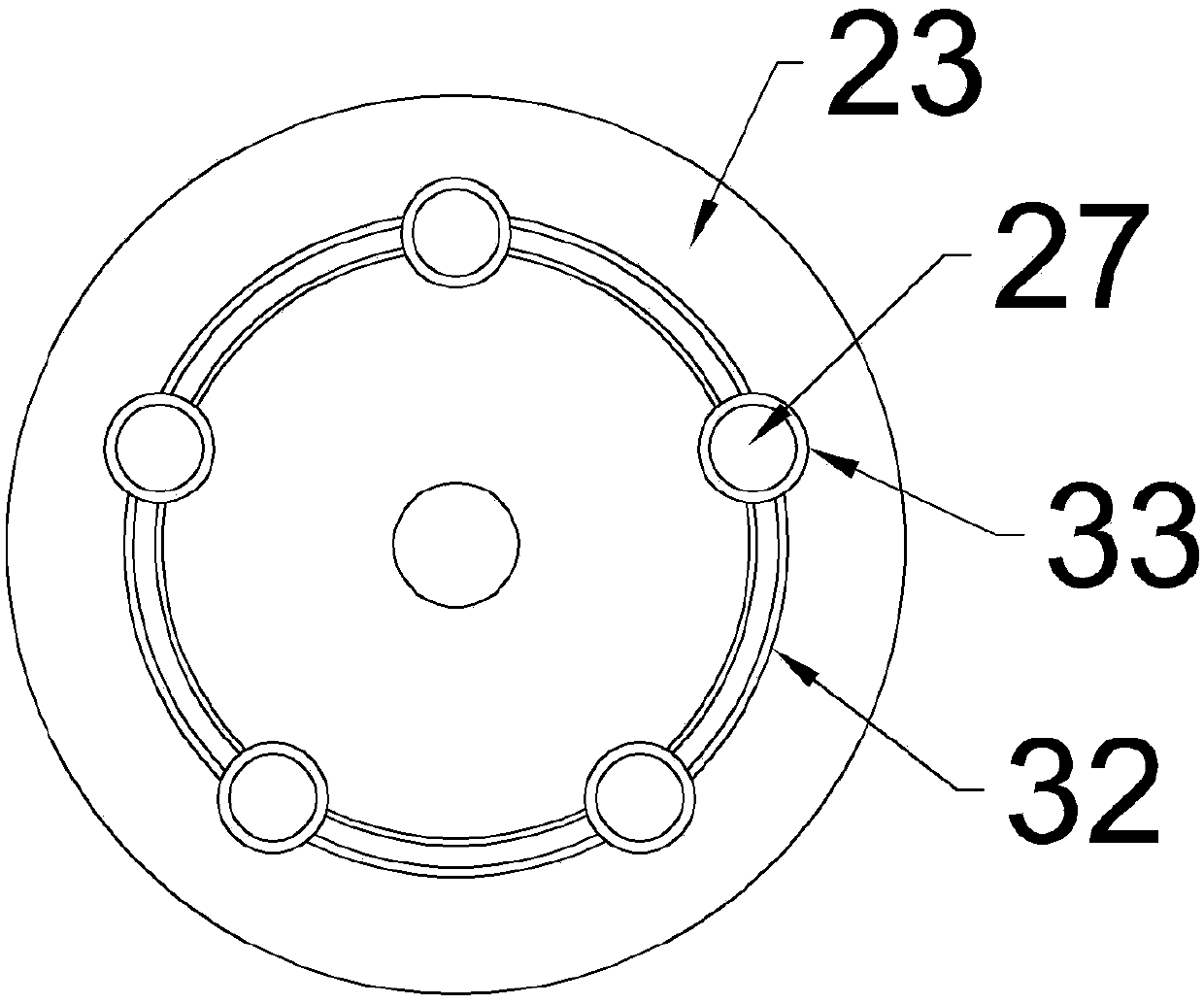

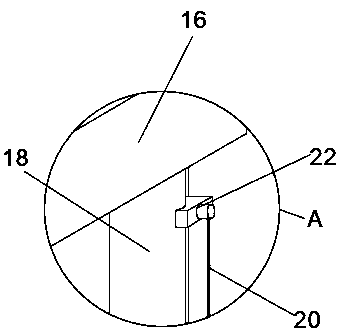

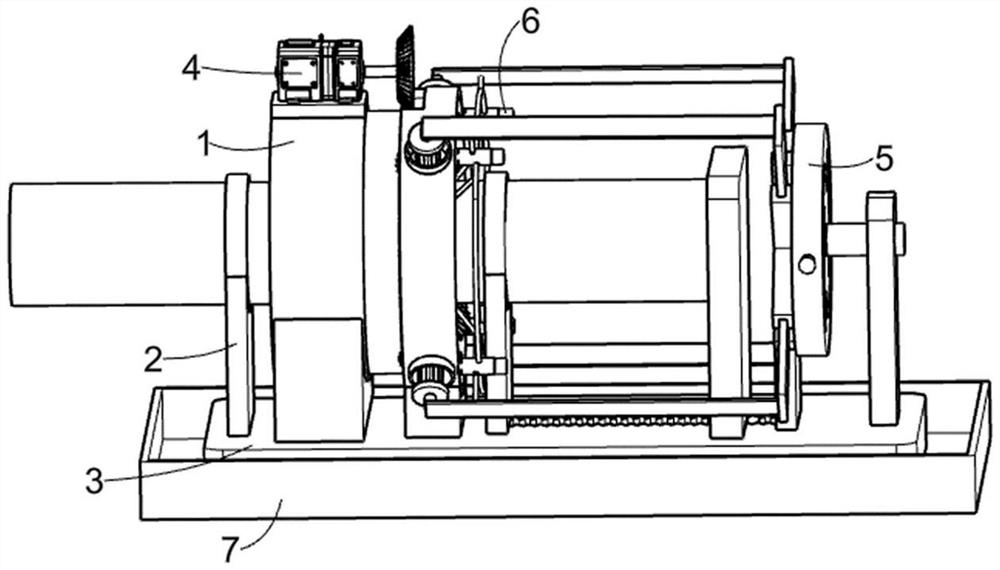

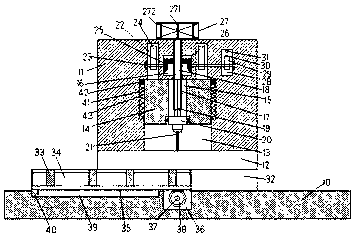

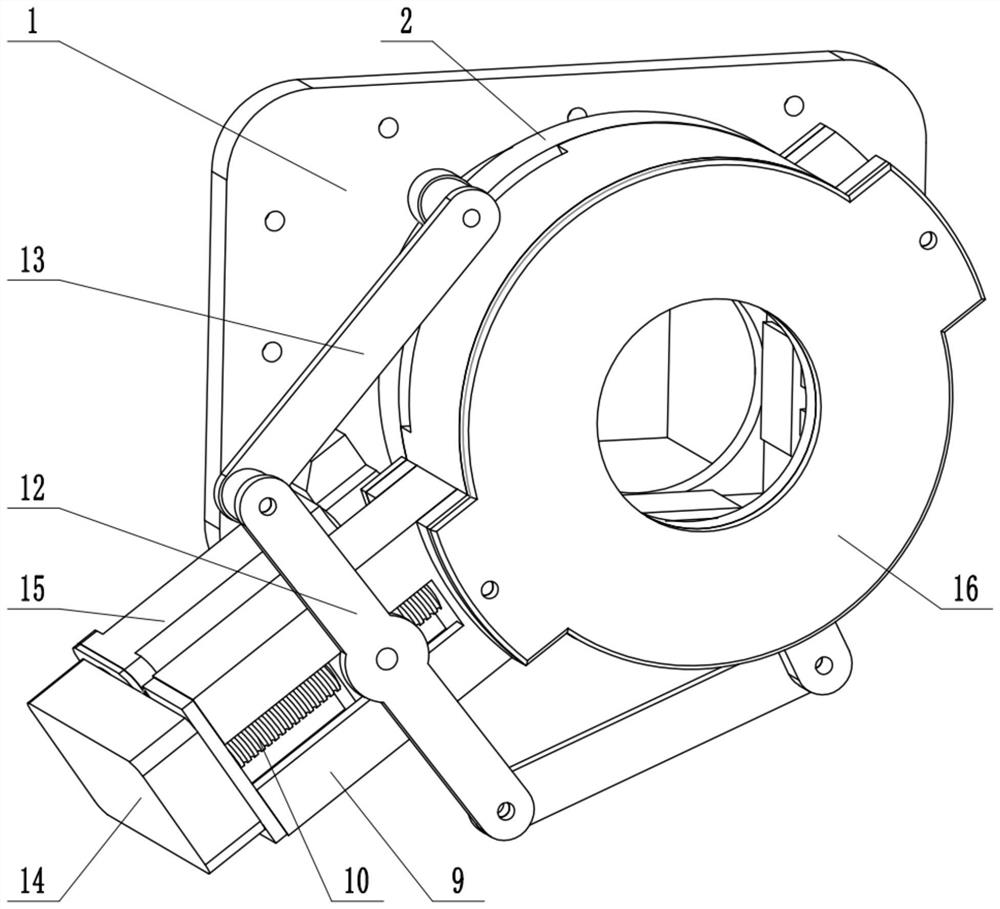

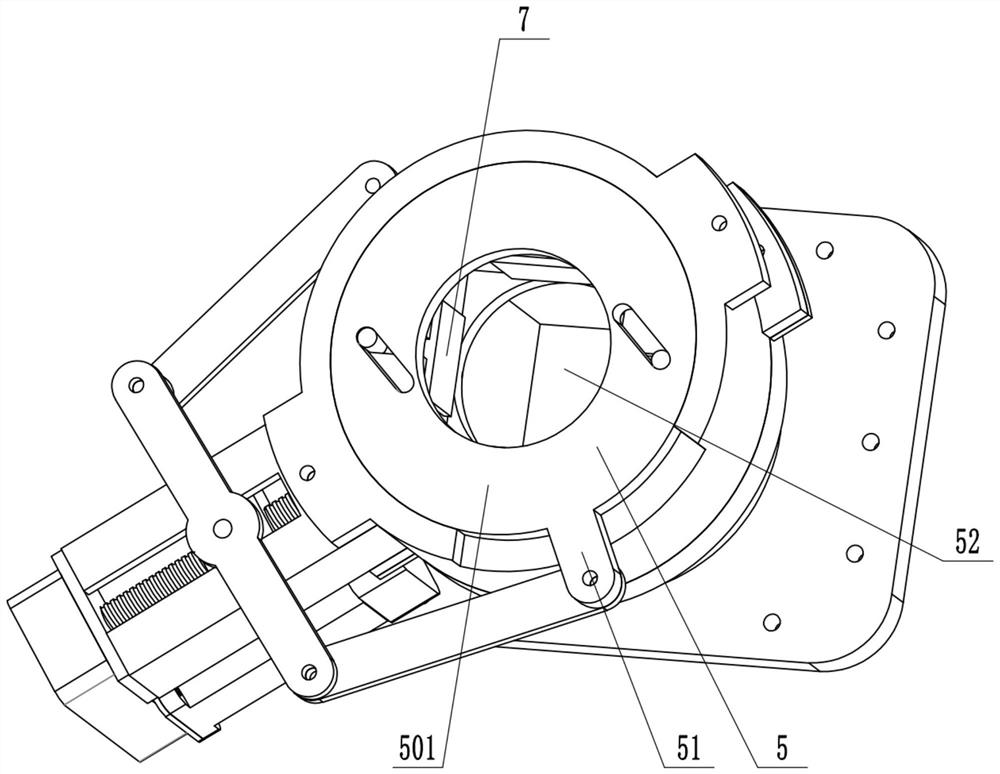

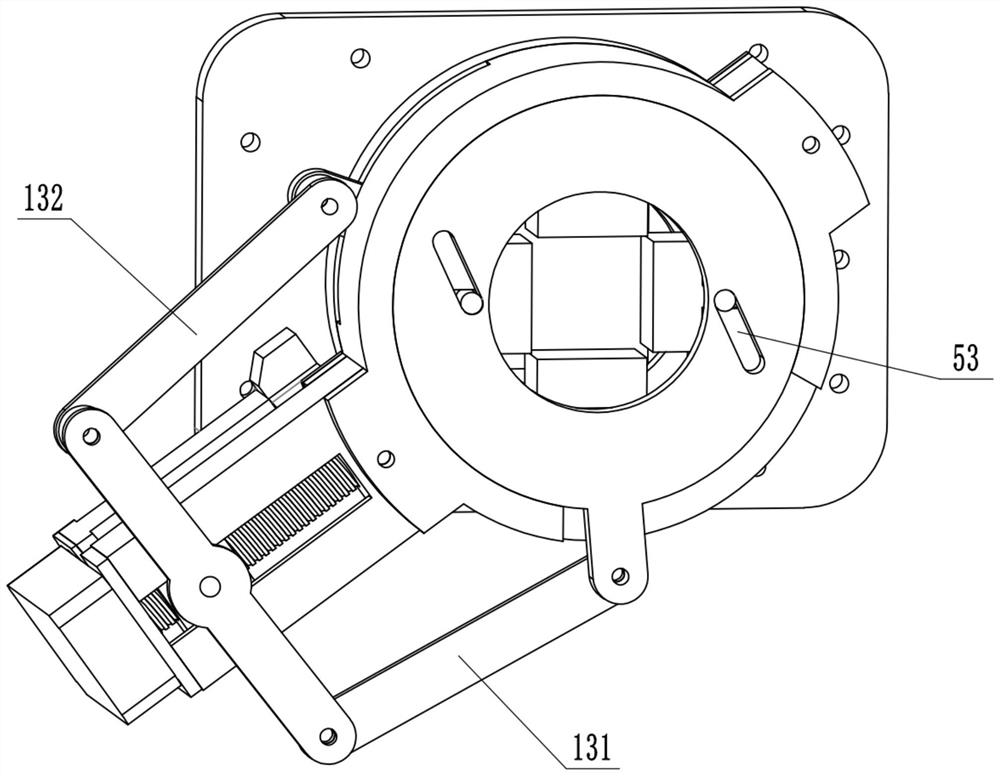

Clamping mechanism of electrical automatic drilling device

InactiveCN114227297ARapid positioningQuick punch operationPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention provides a clamping mechanism of an electric automatic drilling device, and mainly relates to the field of drilling clamping equipment. A clamping mechanism of an electrical automatic drilling device comprises a base, the base comprises a clamping mechanism body fixedly installed on the base through bolts, rotating disc grooves are formed in the two sides of the clamping mechanism body, movable openings are formed in one sides of the rotating disc grooves, driving rotating discs are rotatably installed in the rotating disc grooves, and a containing cavity is formed in the clamping mechanism body. A sliding block is slidably installed in the containing cavity, one side of the sliding block is fixedly connected with a push rod, the outer portion of the clamping mechanism is fixedly connected with a driving base, a threaded rod is rotatably installed in the driving base, and a threaded sleeve is movably installed on the threaded rod. The clamping device has the beneficial effects that rectangular rod type workpieces can be rapidly and accurately clamped, the axes of the workpieces can be kept at the center position of the through hole of the driving rotary disc after the workpieces of different sizes are clamped, rapid positioning and punching operation of an automatic drilling device are facilitated, and the punching positioning precision can be effectively improved.

Owner:山东电子职业技术学院

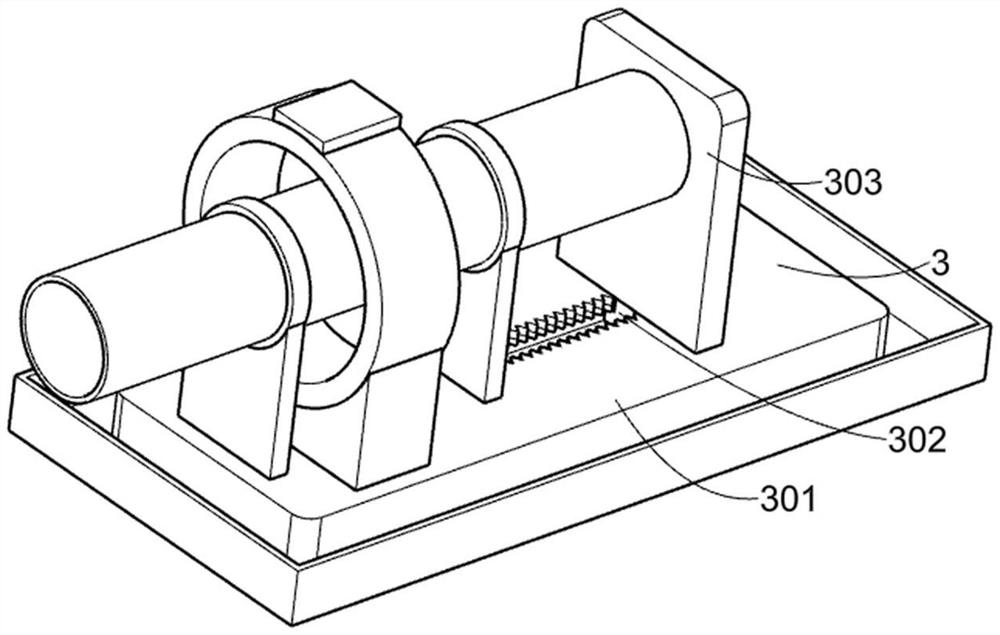

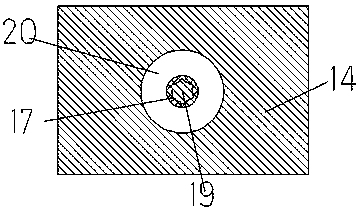

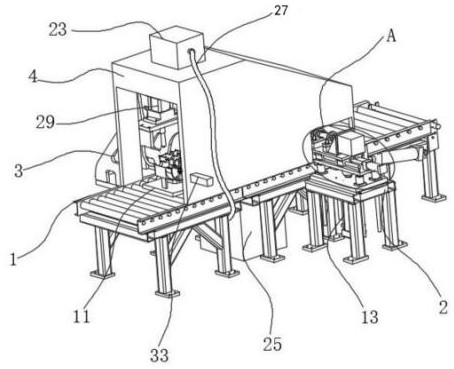

A new energy gearbox housing boring device

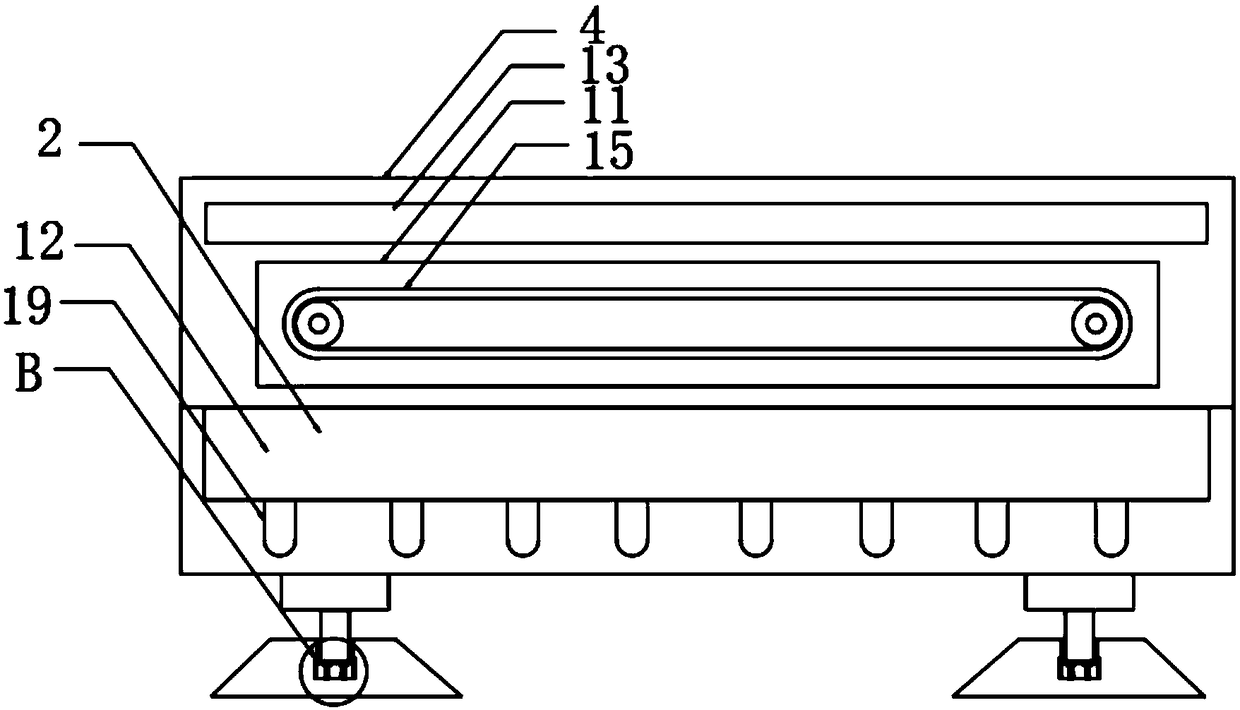

ActiveCN112692331BEasy to cleanPrevent splashWork clamping meansPositioning apparatusNew energyConveyor belt

The invention discloses a new energy gearbox casing boring device, which comprises a conveyor belt and a first support frame and a second support frame respectively fixed on both sides of the conveyor belt, a protective box is fixedly connected to the top of the conveyor belt, and the protective box The top of the inner cavity is fixedly connected with a first lifting cylinder, and the bottom end of the piston rod of the first lifting cylinder is fixedly connected with a connecting plate. The present invention relates to the technical field of gearbox housing processing. In this new energy gearbox casing boring device, the connecting plate moves downward, driving eight limiters to squeeze on the side of the gearbox casing, adjusting the position of the gearbox casing, and limiting its position. Align the position of the boring hole with the position of the horizontal boring bit, which can quickly and accurately position the gearbox case, and cooperate with the horizontal boring bit to quickly perform drilling operations, and can quickly It can be adjusted to adapt to the processing of various gearbox housings. It is easy to operate and easy to use.

Owner:LIUAN LONGXING AUTO PARTS

Panel manufacturing method with decorative surface

InactiveCN108724326AQuick punch operationSimple structureMetal working apparatusHydraulic cylinderEngineering

The invention discloses panel equipment with a decorative surface. The panel equipment comprises a base, a supporting column fixedly arranged on the top of the base and a rack body arranged above thetop of the supporting column, wherein a supporting plate is arranged on the top of the supporting column; a supporting table is fixedly arranged in the central position of the top of the supporting plate; the top of the supporting table leans against the end surface of the top of the rack body; a first connecting arm and a second connecting arm are separately arranged on the end surfaces on the top of the supporting table on the left and right side of the supporting table; a first connecting block and a second connecting block are fixedly arranged on two sides of the bottom end surfaces of therack body, separately; a hydraulic cylinder is hinged and mounted to the first connecting arm; a hydraulic rod of the hydraulic cylinder is hinged to the first connecting block; a second connecting arm is hinged and mounted to the second hinge block; a sliding cavity opened leftward is formed in the rack body an extended manner left and right; and a sliding block is slidably mounted in the sliding cavity.

Owner:广州凡凡贸易有限公司

Modern hardware and building material bonding device

InactiveCN108527674AImprove drilling efficiencyReduce labor intensityDerricks/mastsStone-like material working toolsHydraulic cylinderEngineering

The invention discloses a modern hardware and building material bonding device. The modern hardware and building material bonding device comprises a bottom plate, a vertical column fixedly disposed atthe top of the bottom plate and an operation frame disposed above the top of the vertical column. A mounting plate is erected at the top of the vertical column, a support platform is fixedly disposedat the top center position of the mounting plate, and the top of the support platform abuts against the end surface of the top of the operation frame. A first joint arm and a second joint arm are separately arranged on the top end faces, on the left and right sides of the support platform, of the support platform. A first joint block and a second joint block are separately fixedly disposed on twosides of the bottom end surface of the operation frame, and a hydraulic cylinder is hinged to the first joint arm. A hydraulic rod of the hydraulic cylinder is hinged to the first joint block, and the second joint arm is hinged to the second joint block. The operating frame is provided with a sliding push cavity with an opening end towards left in a left-and-right extending mode, and a sliding push block is movably mounted in the sliding push cavity.

Owner:新沂市草桥工业集聚区发展有限公司

A punching device suitable for bacteria bags of different specifications

ActiveCN111587740BQuick punch operationEasy to operateCultivating equipmentsMushroom cultivationPunchingStructural engineering

The invention discloses a punching device applicable to fungus bags of different specifications, relates to the technical field of edible fungus planting, and solves the problem that the existing fungus bag punching equipment cannot perform punching operations on fungus bags of different specifications and sizes, resulting in the It is necessary to purchase a variety of punching equipment to meet the punching needs of bacteria bags. A punching device applicable to bacteria bags of different specifications, including a gravity base, a support column and a position adjustment part of a punching assembly, etc.; one side of the gravity base is fixedly equipped with two parallel support columns, and the punching The assembly position adjustment part is installed at one end of the two support columns. In the present invention, through the cooperation of the guide plate and the punching frame, the punching operation can be completed during the sliding process of the bacteria bag, which improves the punching efficiency of the bacteria bag; and by turning the rotating handle, the device can make the diameter smaller The bacteria bag is punched.

Owner:WUZHOU LINCHUAN JINSHAN BIOLOGICAL TECH CO LTD

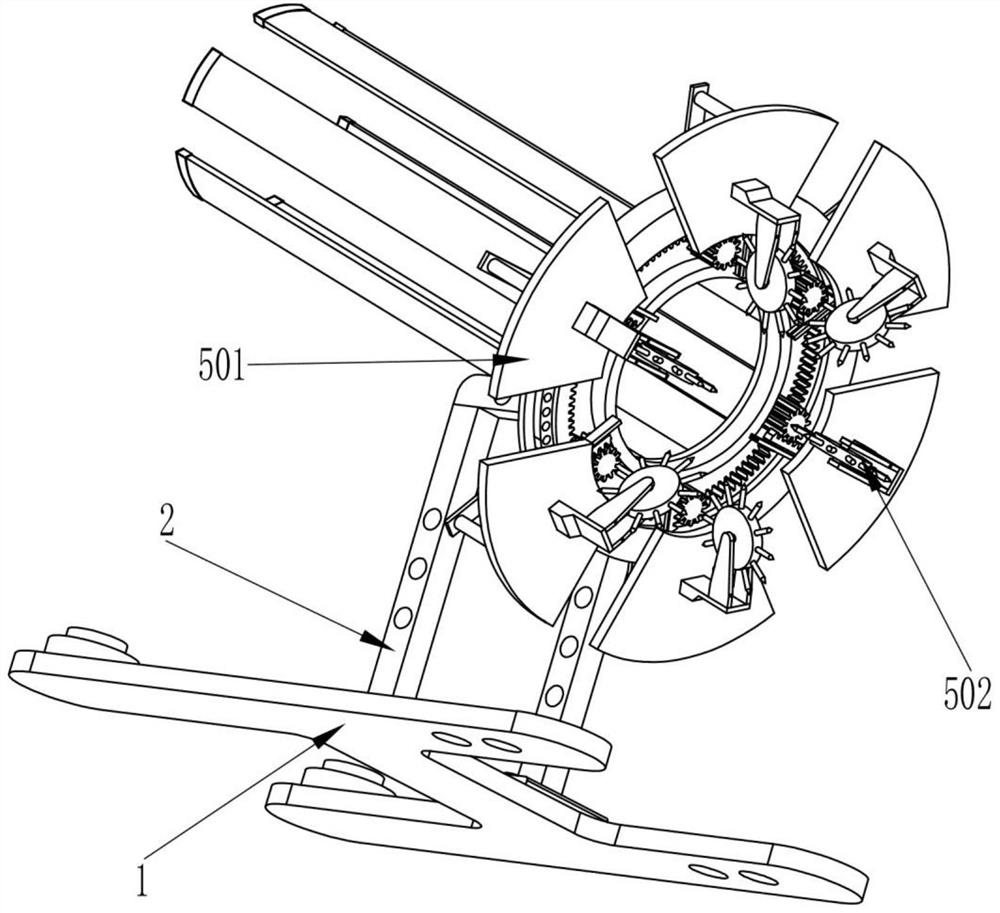

A drilling robot

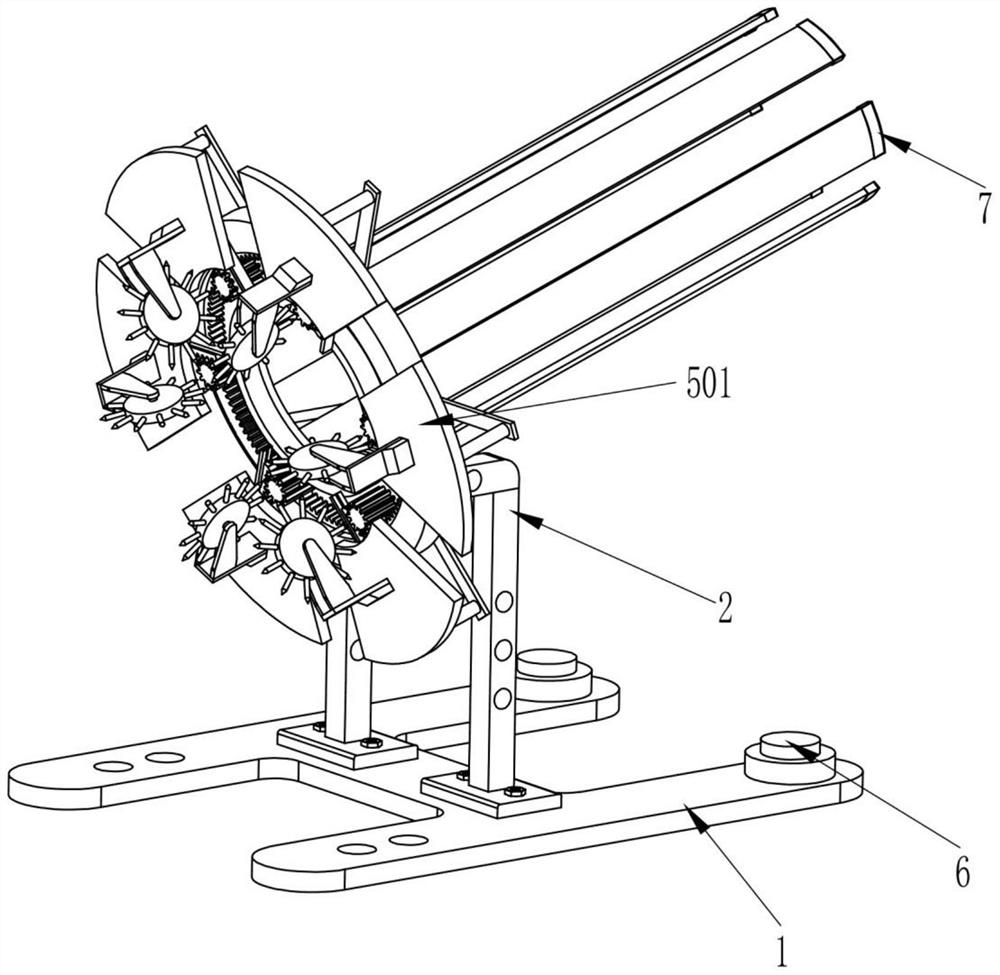

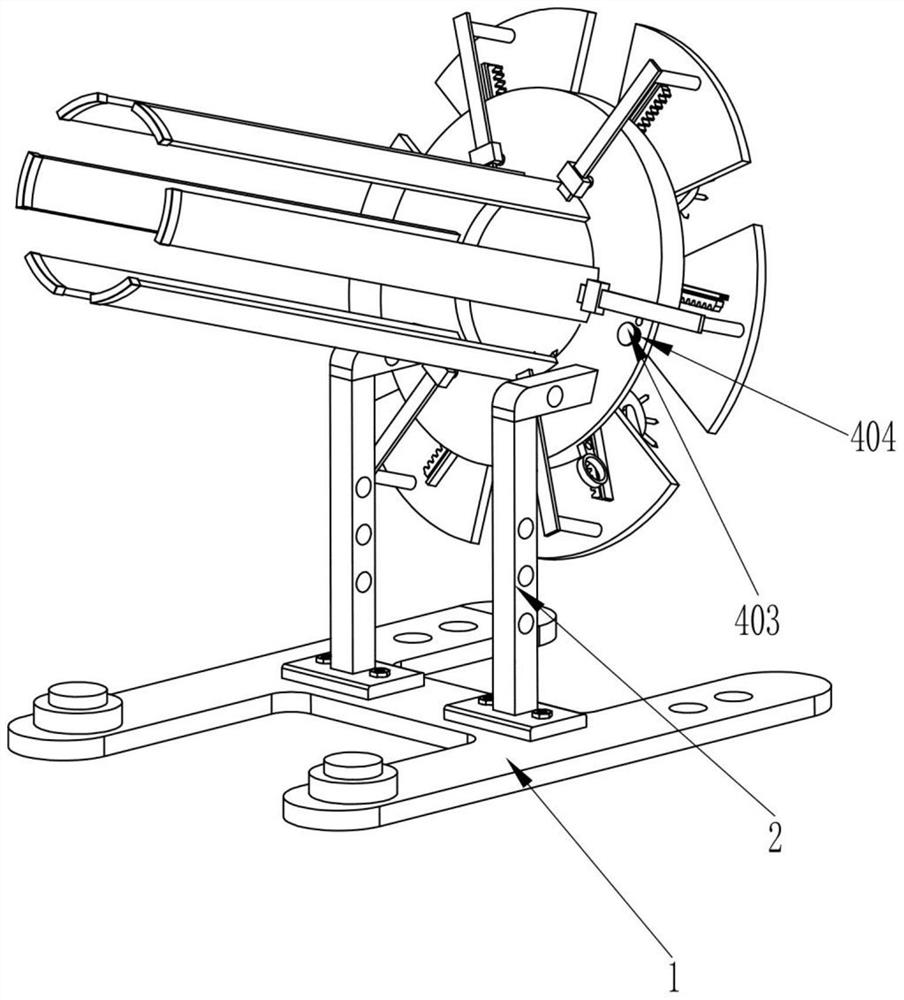

ActiveCN108405915BSimple structureEasy to useManipulatorBoring/drilling componentsGear wheelEngineering

Owner:涡阳万达汽车制动器有限公司

A manufacturing equipment for metal functional materials used in electronic components

ActiveCN108376864BQuick installationSimple structureLive contact access preventionManufacturing technologyElectronic component

The invention discloses metal functional material manufacturing technology equipment for a novel electronic component. The equipment comprises a body, wherein the body is provided with a first rotation chamber, the body is provided with a second rotation chamber at an upper side of the first rotation chamber, the first rotation chamber is rotatably provided with a rotation cylinder through a rotation bearing, an inner top wall of the rotation cylinder extends upwards and is provided with an axial hole which penetrates through the second rotation chamber and stretches out of a top end surface of the body, the axial hole is rotatably equipped with a rotation column, a bottom portion of the rotation column is fixedly connected with a top end surface of the rotation cylinder, a top portion ofthe rotation column is in power connection with a rotation motor fixedly arranged at a top end surface of the body, a bottom end surface of the rotation cylinder is internally provided with a telescoping chamber opening downwards, the telescoping chamber is equipped with a telescoping plate capable of sliding up and down, a top end surface of the telescoping plate is internally provided with a permanent magnet, and an inner top wall of the telescoping chamber is provided with an electromagnetic device matched with the permanent magnet.

Owner:上海华承光电科技有限公司

Novel hardware building material attachment equipment

InactiveCN108436145AQuick punch operationSimple structureWork benchesLarge fixed membersHydraulic cylinderArchitectural engineering

The invention discloses novel hardware building material attachment equipment. The novel hardware building material attachment equipment comprises a bottom plate, a stand column fixedly arranged at the top of the bottom plate and an operation frame arranged above the top of the stand column. A mounting plate is erected at the top of the stand column. A supporting table is fixedly arranged at the center position of the top of the mounting plate. The top of the supporting table abuts against the end face of the top of the operation frame. A first joint arm and a second joint arm are arranged atthe positions, on the left side and the right side of the supporting table, of the end face of the top of the supporting table correspondingly. A first joint block and a second joint block are fixedlyarranged on the two sides of the end face of the bottom of the operation frame correspondingly. A hydraulic cylinder is mounted on the first joint arm in a hinged manner, a hydraulic rod of the hydraulic cylinder is hinged to the first joint block, and the second joint arm and the second joint block are mounted in a hinged manner. A sliding-pushing cavity with the open end being leftward is arranged in the operation frame in a manner of extending left and right, and a sliding-pushing block is movably mounted in the sliding-pushing cavity.

Owner:新沂市草桥工业集聚区发展有限公司

Automatic industrial robot and frame unit thereof

InactiveCN108500649AImprove drilling efficiencyReduce labor intensityLarge fixed membersDriving apparatusHydraulic cylinderEngineering

The invention discloses an automatic industrial robot and a frame unit thereof. The automatic industrial robot comprises a support base, a strut fixedly arranged at the top of the support base and a frame arranged above the top of the strut, a flat plate is erected on the top of the strut, a supporting table is fixedly arranged at the center position of the top of the flat plate, the top of the supporting table abuts against the end face of the top of the frame, the supporting table top end faces of the left and right sides of the supporting table are provided with a first connecting rod and asecond connecting rod correspondingly, a first protruding block and a second protruding block are fixedly arranged on the two sides of the bottom end face of the frame, a hydraulic cylinder is installed on the first connecting rod in a hinged manner, a hydraulic rod of the hydraulic cylinder is hinged to the first protruding block, the second connecting rod is installed on the second connecting rod in a hinged manner, a sliding cavity with a leftward opening part is formed in the frame in a left-and-right extending manner, and a sliding block is installed in the sliding cavity in a smooth manner.

Owner:广州星引科技有限公司

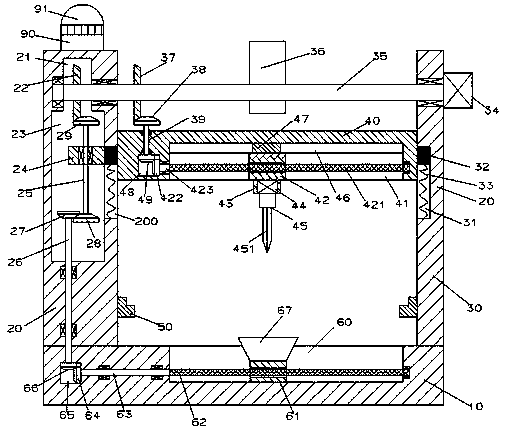

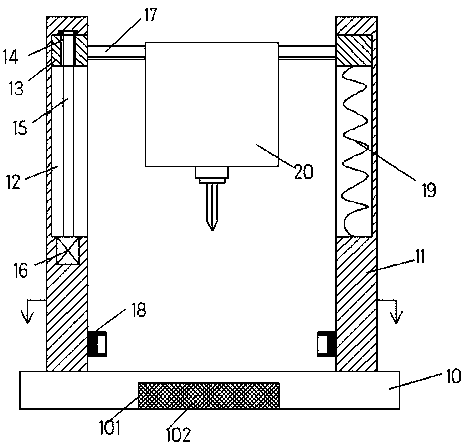

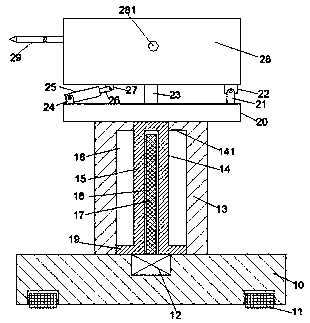

Drilling robot

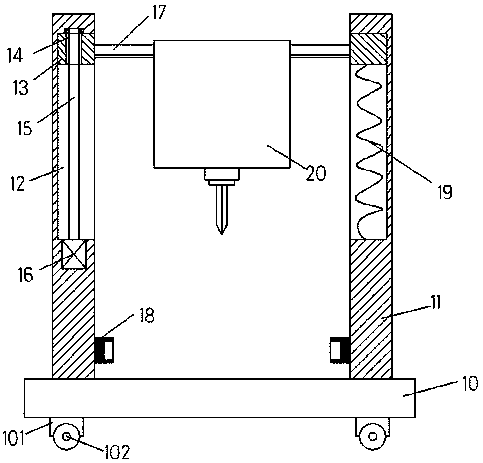

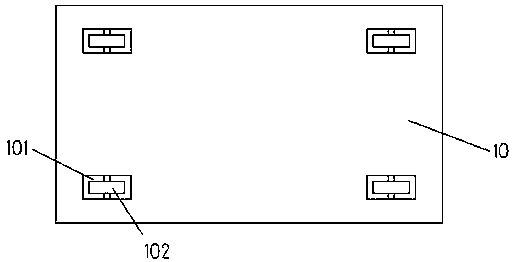

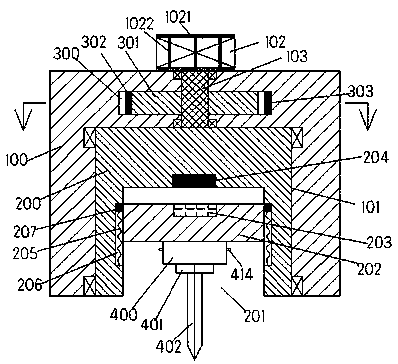

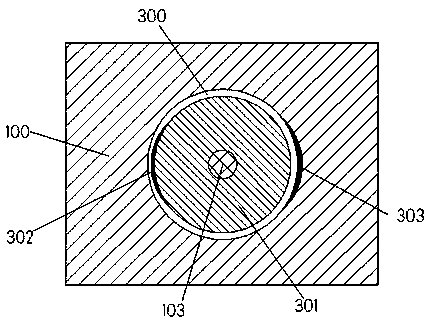

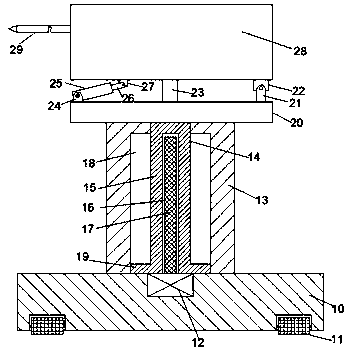

ActiveCN108405915ASimple structureEasy to useBoring/drilling componentsBoring/drilling machinesEngineeringSupport plane

The invention discloses a drilling robot. The drilling robot comprises a base, supporting frames symmetrically arranged at the two ends of the top of the base left and right, and a main machine body arranged between the left supporting frame and the right supporting frame through a lifting device. A first rotary cavity with an opening facing downwards is formed in the inner bottom of the main machine body. A second rotary cavity extending up and down is formed in the part, above the first rotary cavity, of the main machine body. A first sliding groove is formed in the inner wall of the left side of the second rotary cavity in a communicating mode. A rotary plate is rotationally mounted in the first rotary cavity through a rotary bearing. A first rotary shaft extending into the second rotary cavity is fixedly arranged at the top of the rotary plate. A first bevel gear is fixedly mounted on the part, in the second rotary cavity, of the first rotary shaft. A first sliding block is arranged in the first sliding groove in an up-down sliding mode.

Owner:涡阳万达汽车制动器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com