Perforating device capable of achieving automatic and rapid perforating

A drilling device and transmission technology, applied in the direction of boring/drilling, drilling/drilling equipment, maintenance and safety accessories, etc., can solve the problems of reduced efficiency, reduced efficiency, small waste volume, etc., and achieve faster drilling Hole speed, reduction of production cost, effect of fast drilling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

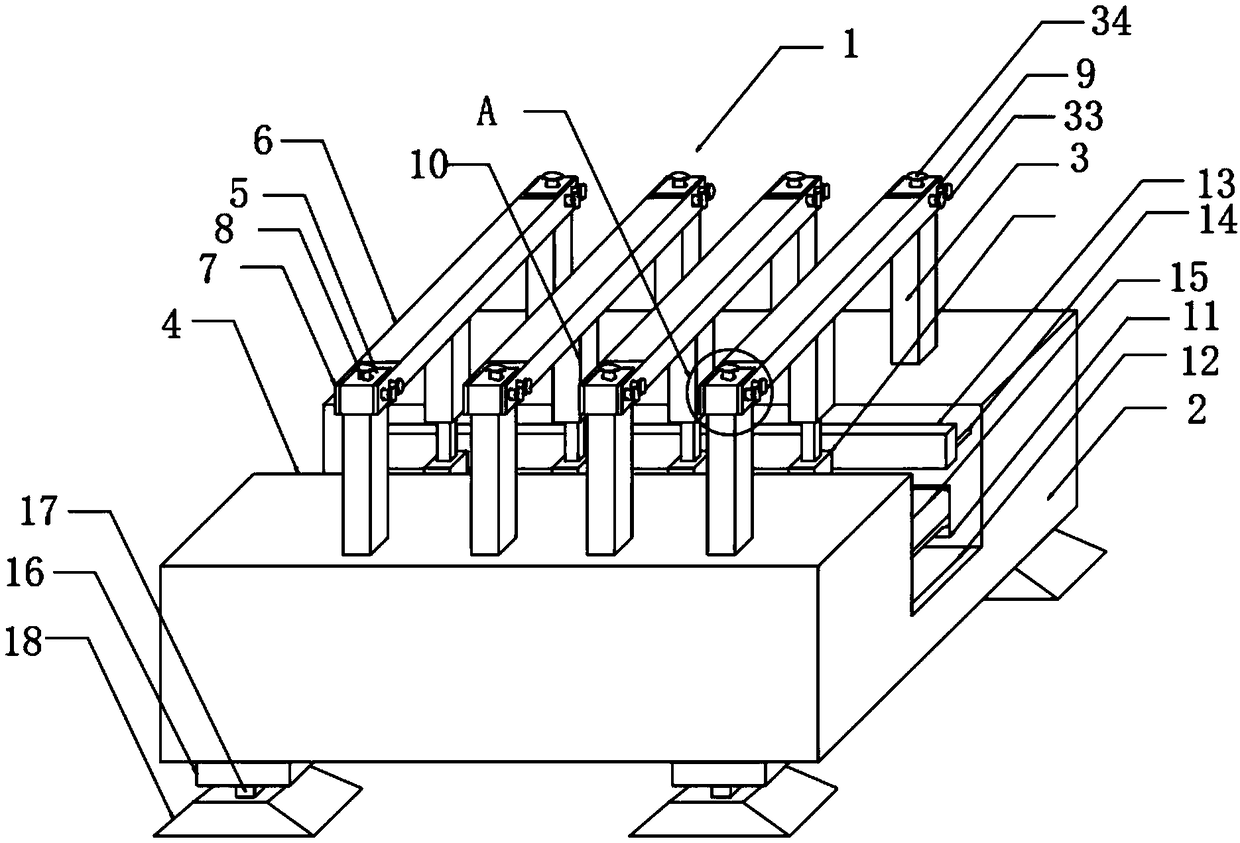

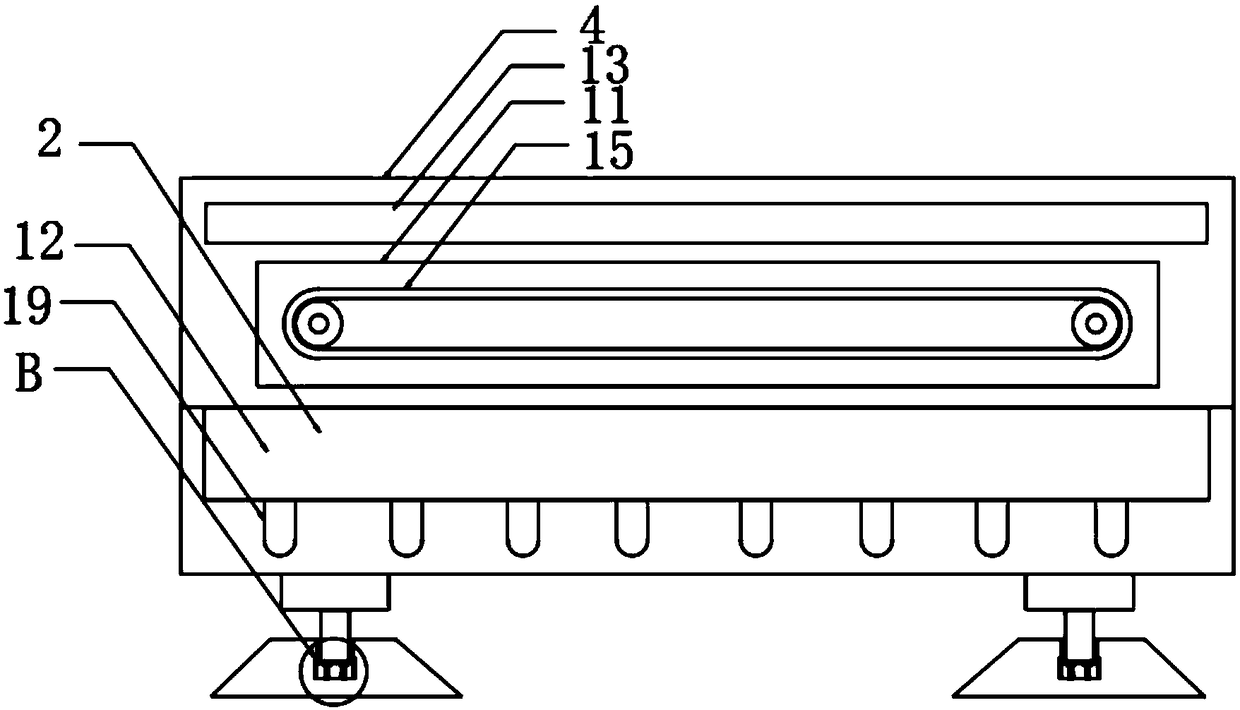

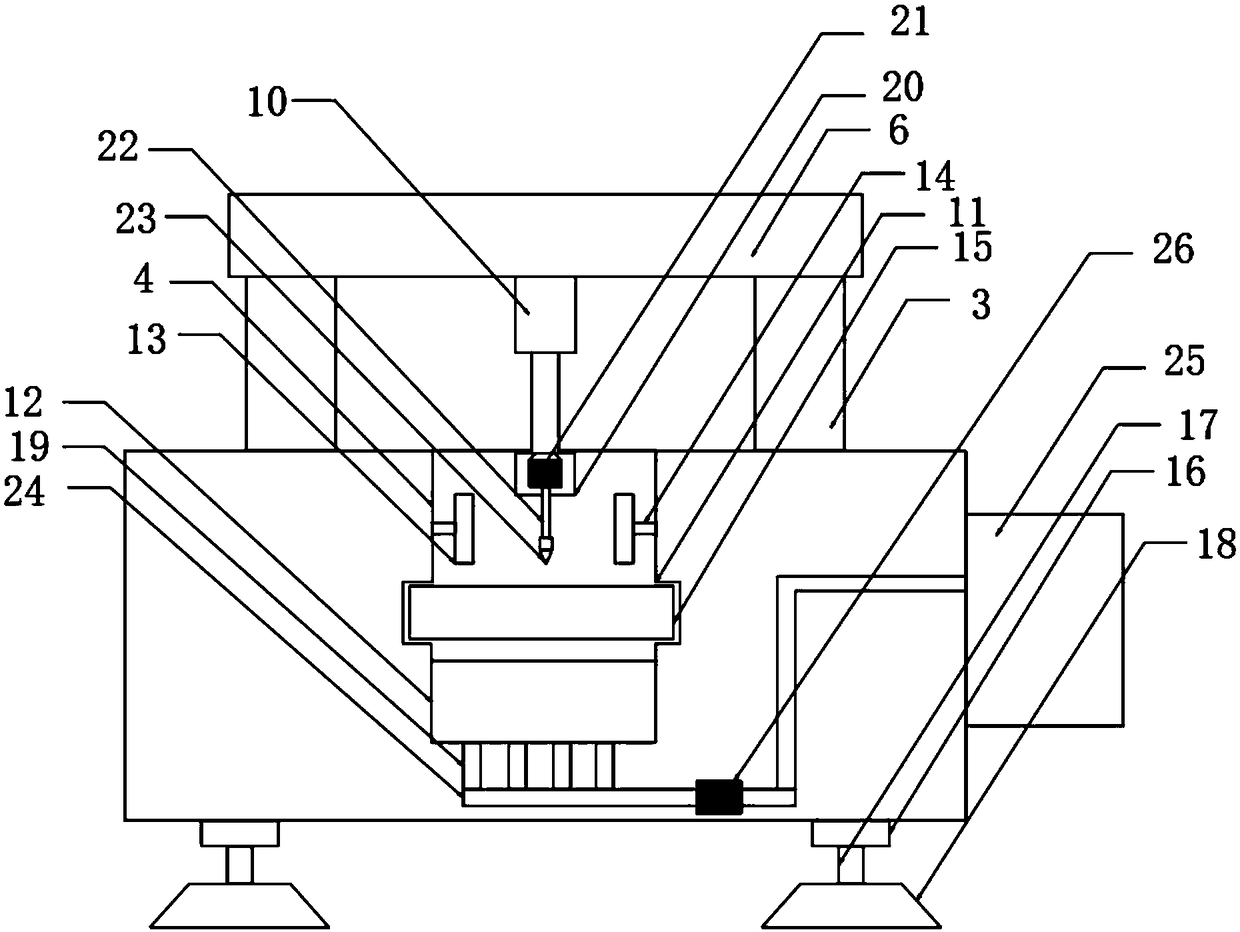

[0024] Such as Figure 1-5 As shown, a punching device for automatic fast punching includes a device body 1, and the device body 1 includes a support box 2 and a waste collection box 25, the support box 2 is located on one side of the waste collection box 25, and the support The top of the box 2 is provided with a first groove 4, and the top of the support box 2 is provided with a plurality of support rods 3, and a plurality of the support rods 3 are respectively located on both sides of the first groove 4, and a plurality of the support rods 3. First connection blocks 5 are provided on the top, and second connection blocks 6 are provided between the plurality of support rods 3, and second grooves 7 are provided at both ends of the plurality of second connection blocks 6, A plurality of the second grooves 7 are plugged with a plurality of first connecting blocks 5, the bottom of the second connecting block 6 is provided with a first hydraulic cylinder 10, and the hydraulic rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com