Environment-friendly double progressive perforating device for aluminized zinc plate

A punching device, a technology of galvanized zinc, which is applied to feeding devices, metal processing mechanical parts, metal processing equipment, etc. problem, to achieve the effect of good sliding stability and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0016] The technical scheme of concrete implementation of the present invention is:

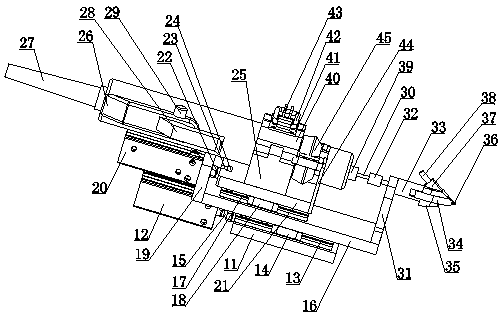

[0017] Such as figure 1 As shown, a double-stage punching device for an environmentally friendly galvanized sheet includes a bottom plate 11, the rear of the bottom plate 11 is provided with a first hydraulic cylinder 12, and the top surface of the bottom plate 11 is provided with a pair of first guide rails 13, the first guide rail 13 is provided with a first slider 14, the front of the first hydraulic cylinder 12 is provided with a first piston rod 15, the first slider 14 is provided with a slide plate 16, and the front end of the first piston rod 15 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com