Positioning support for positioning ring of textile machine

A technology for positioning brackets and positioning rings, which is applied in textiles, looms, textiles, and papermaking, etc. It can solve the problems of high use limitations, inability to locate textile wires, and difficulty in meeting the installation and use requirements of complex textile environments, so as to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

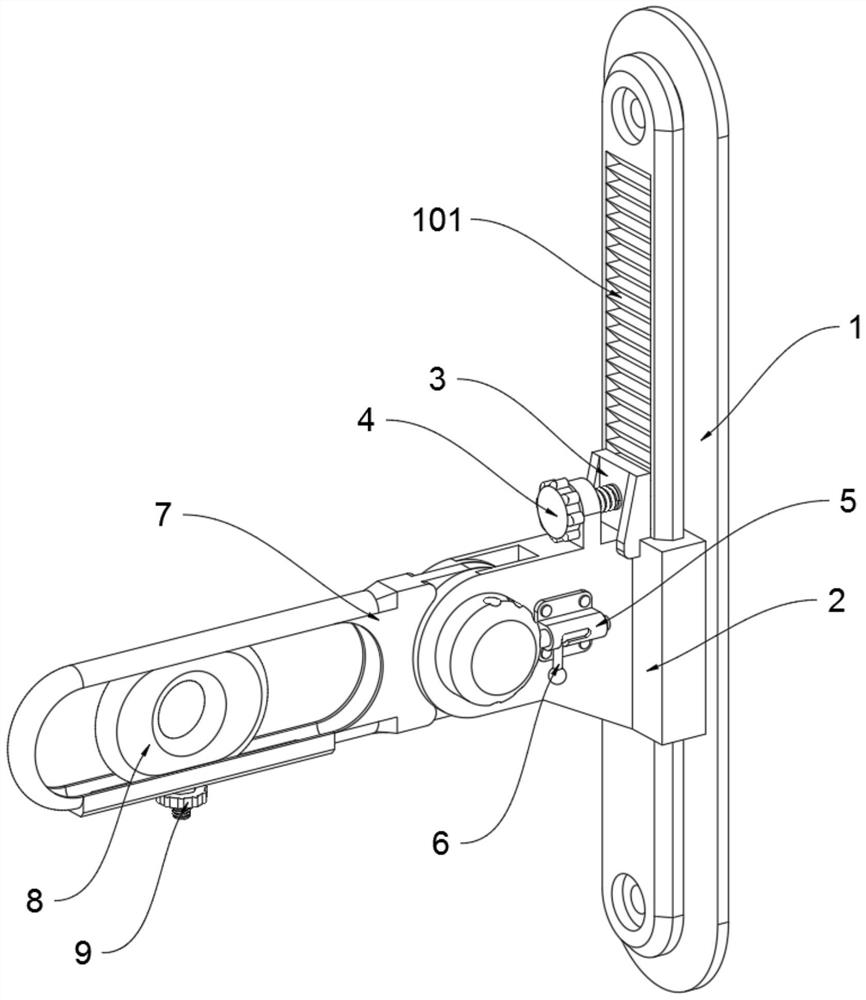

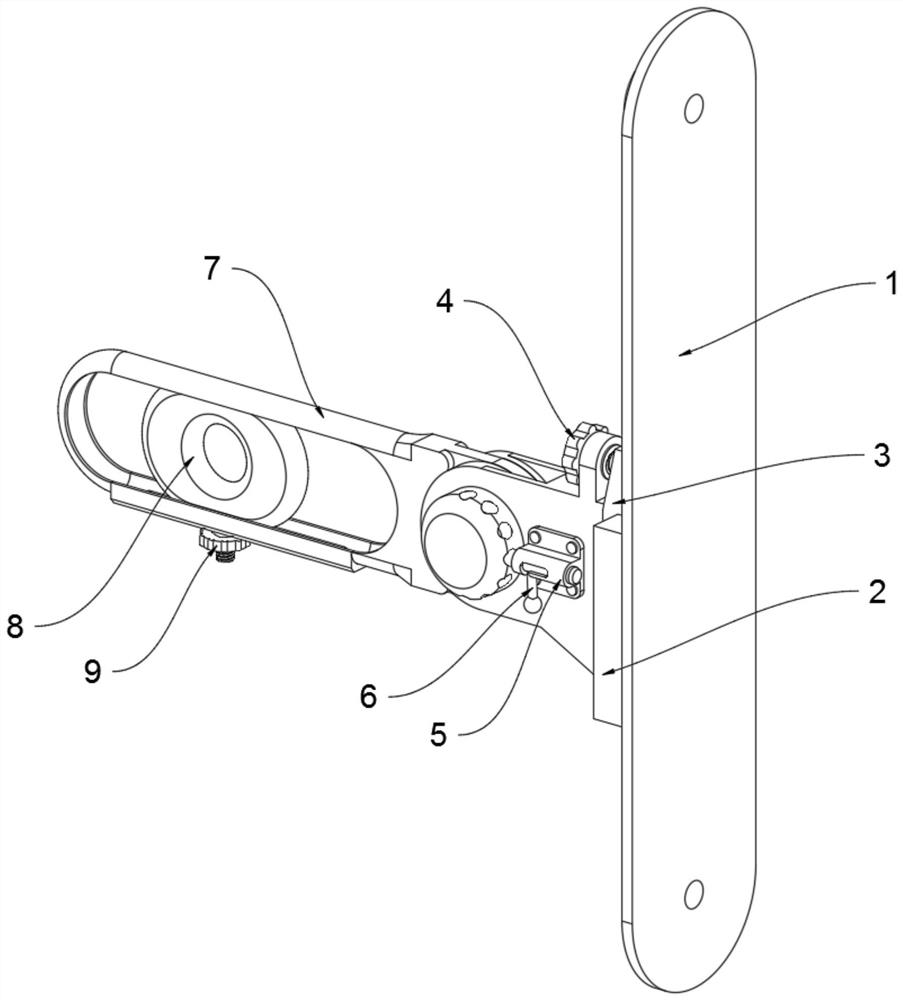

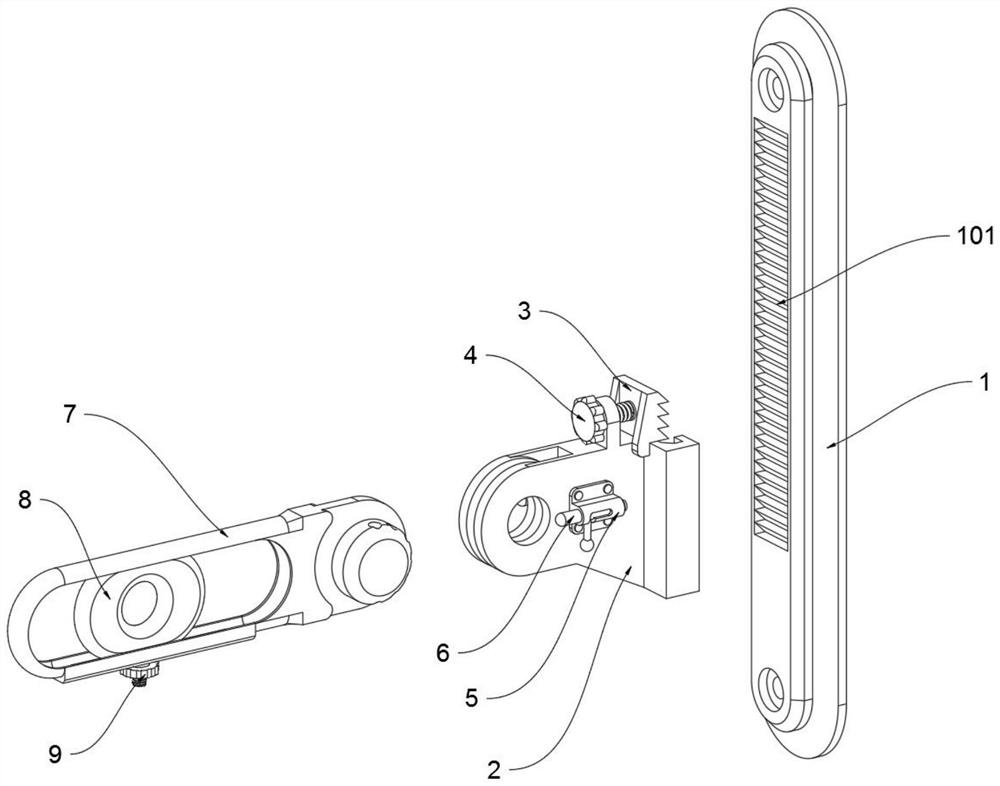

[0030] as attached figure 1 to attach Figure 7 Shown:

[0031] The invention provides a positioning bracket for a positioning ring of a textile machine, which includes a slide rail seat 1, a tooth block 3 and a mounting plate 7; the slide rail seat 1 is fixedly installed on the textile machine, and the movable seat 2 is connected to the front side of the slide rail seat 1; The tooth block 3 and the manual bolt 4 are connected to the top of the movable seat 2, and a pin seat 5 is respectively installed on both sides of the movable seat 2; a rack 101 is embedded in the front side of the slide rail seat 1, and the tooth block 3 is slidably connected to the movable seat 2 on the top side, and a screw hole 202 is opened on the top of the movable seat 2, and the manual bolt 4 is threaded into the screw hole 202 on the top of the movable seat 2, and the rear end of the manual bolt 4 is rotatably connected to the tooth block 3, and the rear end of the tooth block 3 It is plugged an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com