Hard alloy material and high-end hard alloy cutter manufacturing technology equipment

A cemented carbide and manufacturing technology, applied in the direction of metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of pollution, difficult collection of powder chips, excessive manual operation, etc., and achieve simple structure of the device, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

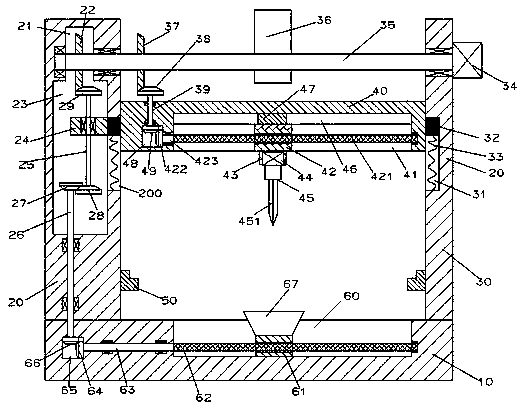

[0015] Such as figure 1 As shown, a kind of manufacturing technical equipment such as cemented carbide materials and high-end cemented carbide cutting tools of the present invention includes a base 10, a left bracket 20 that is arranged on the left side of the base 10 and extends upward, and is fixedly arranged on the The right side end of the base 10 and the right support 30 extending upwards, the left support 20 is provided with a left lifting groove 200 in the inner end surface, and the right lifting groove 31 is arranged in the inner end surface of the right support 30. Lifting blocks 32 are slidably installed in the lifting groove 31 and the left lifting groove 200 respectively, and a lifting frame 40 is fixedly arranged between the two lifting blocks 32 on the left and right sides. The left bracket 20 above the lifting frame 40 and the Between the right brackets 30, a rotating column 35 is arranged transversely, and the right side end of the rotating column 35 runs throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com