Perforating device for food packaging paperboard

A food packaging and punching device technology, applied in metal processing and other directions, can solve the problems of expensive maintenance, trouble, palm fatigue and other problems of punching machines, and achieve the effect of convenient installation, convenient adjustment and long-term protection of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

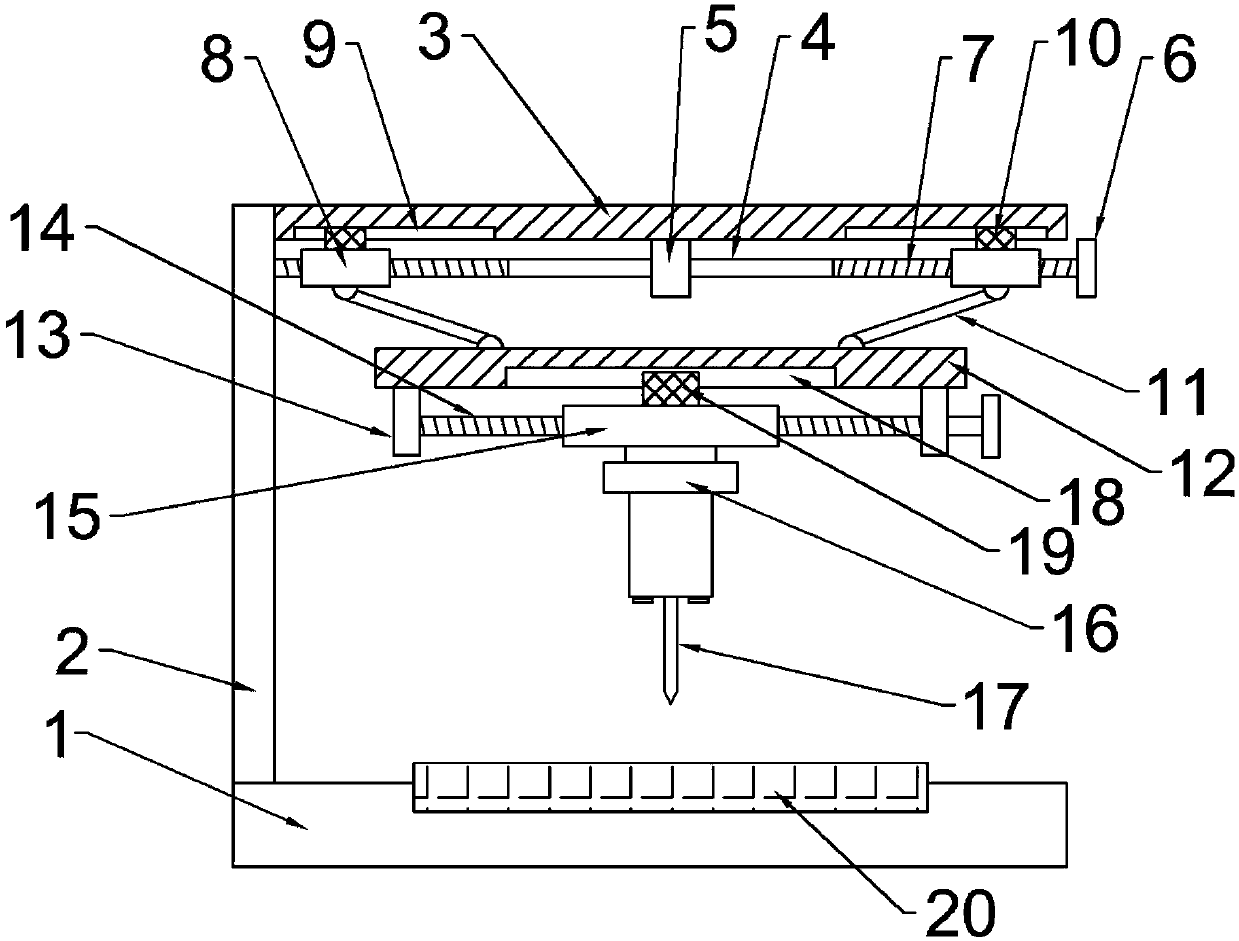

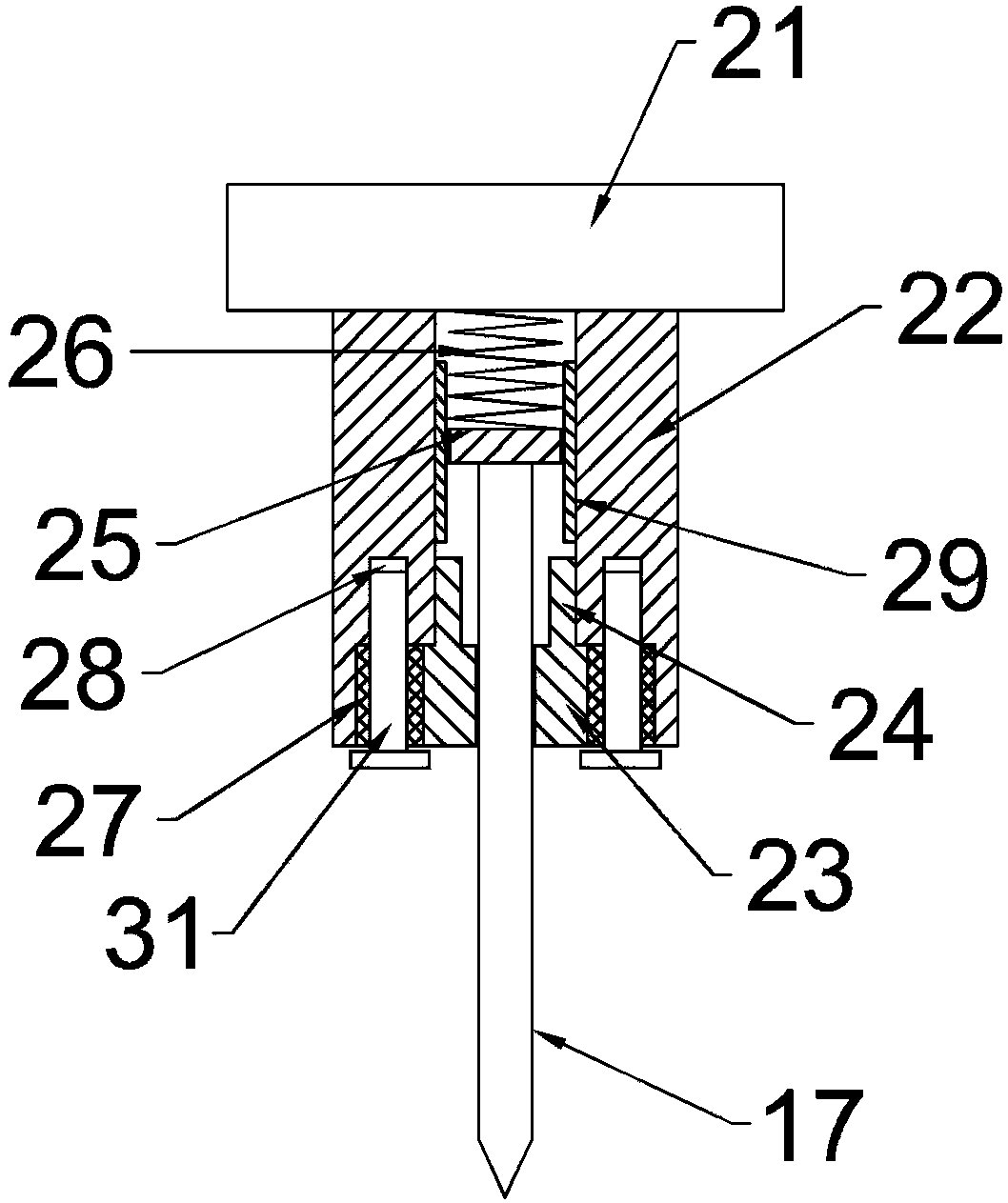

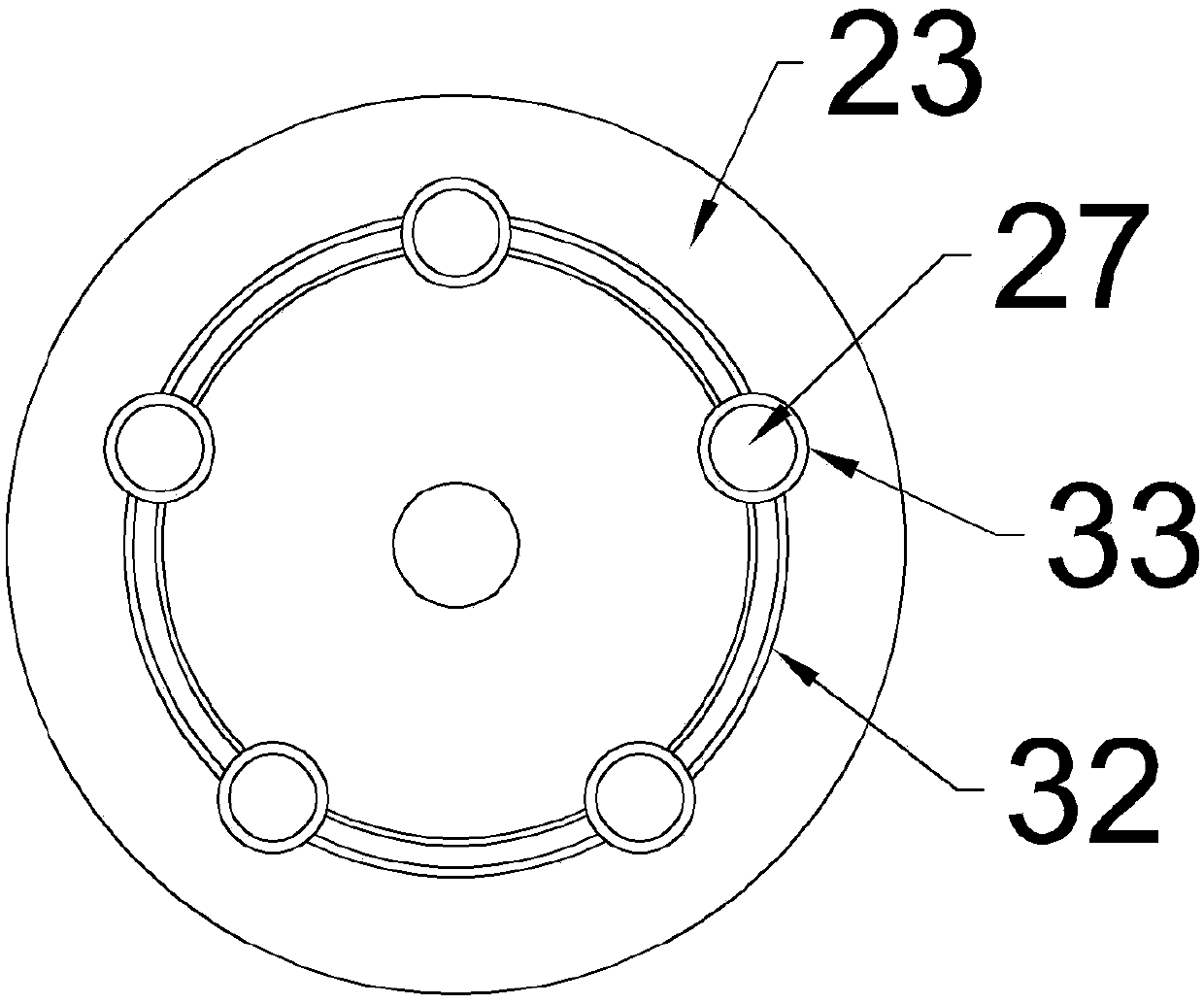

[0022] see Figure 1-4 , a punching device for food packaging cardboard, comprising a base plate 1, a support column 2 is fixedly installed on the left side of the upper end of the base plate 1, the support column 2 is perpendicular to the base plate 1, and a top plate 3 is installed on the top of the support column 2, and the top plate 3 Located directly above the bottom plate 1 and directly below the top plate 3 is an adjustment shaft 4, the adjustment shaft 4 is parallel to the top plate 3, and the adjustment shaft 4 is arranged along the length direction of the top plate 3, and a support block 5 is installed in the middle of the adjustment shaft 4. The block 5 is fixed on the lower end of the top plate 3, and both ends of the adjustment shaft 4 are provided with threaded parts 7, and the two threaded parts 7 are arranged symmetrically along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com