Hand-held mulching film puncher

A hole puncher and handheld technology, which is applied in the field of hand-held mulch punchers, can solve the problems that the distance between rows and plants is too large, it cannot meet the requirements of multiple people to perform hole punching at the same time, and it cannot meet the requirements of planting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

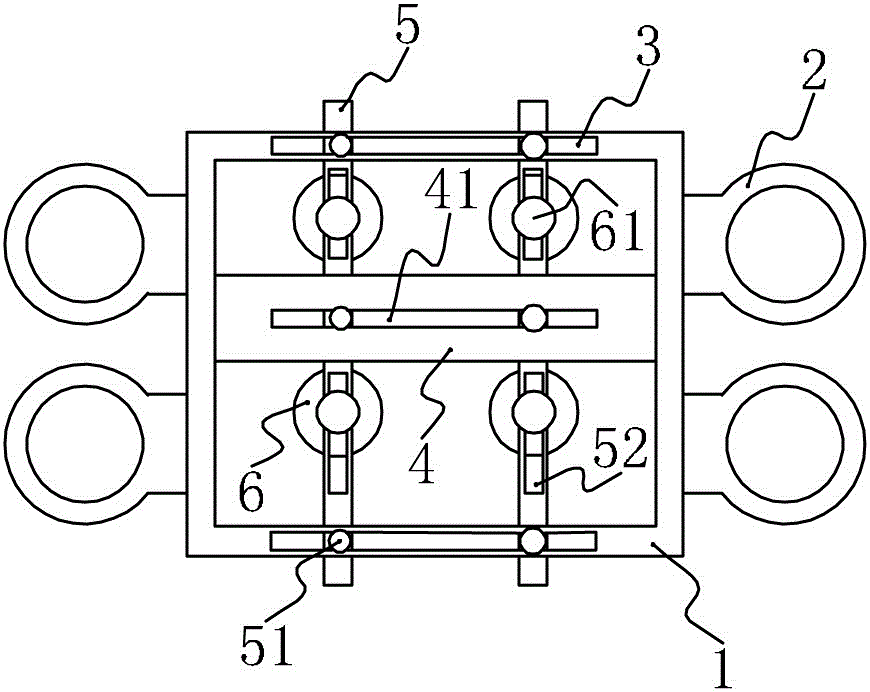

[0015] Such as figure 1 As shown, the handheld mulch puncher of the present invention includes a rectangular frame 1, handles 2 are welded on two opposite sides of the frame 1, and there are four handles 2 in total, and there are two handles on each side 2. And the four handles 2 are symmetrically distributed on the frame 1 . The handle 2 includes a rectangular welding part and an annular handle part. Slide grooves 11 are symmetrically opened on the other two sides of the frame 1 . A support plate 4 is also welded inside the frame 1, and a positioning groove 41 is opened on the support plate 4, and the positioning groove 41 is parallel to the sliding groove 11 and has the same width and length. Two slide plates 5 are also installed on the frame 1, the slide plates 5 are located below the frame 1, and a plurality of mounting screw holes are arranged on the slide plate 5, and locking bolts 51 are correspondingly installed in each mounting screw hole for locking. Bolts 51 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com