Method for preparing hydrophilic ordered porous membrane material

A porous membrane and hydrophilic technology, applied in the field of preparation of hydrophilic ordered porous membrane materials, can solve the problems of increased cost, complicated post-processing, difficult operation, etc., and achieve the effect of less steps, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1: Dissolve polylactic acid and dodecyltrimethylammonium chloride in chloroform, and prepare polymer and dodecyltrimethylammonium chloride solutions with concentrations of 20 mg / mL and 0.2 mg / mL, respectively;

[0034] S2: Pipette 40 μL of the above solution on the glass substrate, and place it on the rotating platform of the homogenizer;

[0035] S3: Pass the humid air through the test tube filled with water at a rate of 100L / h, and control the internal temperature of the homogenizer chamber to 24°C and the relative humidity to 80%, and at the same time adjust the homogenizer to start at a speed of 20rpm.

[0036] S4: After about 2 minutes, the solvent is completely volatilized, the homogenizer is stopped, and the substrate is taken out to obtain a hydrophilic ordered porous membrane.

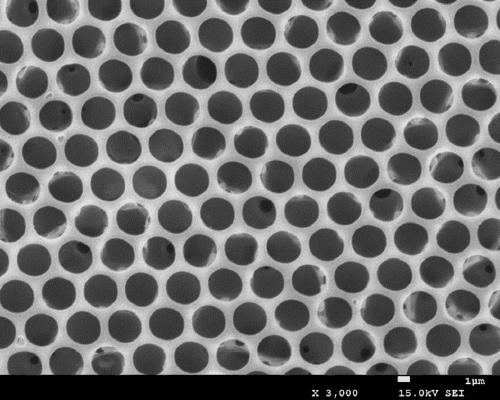

[0037] Scanning electron microscope observation (with figure 1 ) shows that the surface of the porous membrane is all distributed with ordered microporous structures, the diameter of ...

Embodiment 2

[0040] S1: Dissolve polylactic acid and dodecyltrimethylammonium chloride in chloroform, and prepare polymer and dodecyltrimethylammonium chloride solutions with concentrations of 20 mg / mL and 1 mg / mL, respectively;

[0041] S2: Pipette 40 μL of the above solution on the glass substrate, and place it on the rotating platform of the homogenizer;

[0042] S3: Pass the humid air through the test tube filled with water at a rate of 100L / h, and control the internal temperature of the homogenizer chamber to 24°C and the relative humidity to 80%, and at the same time adjust the homogenizer to start at a speed of 20rpm.

[0043] S4: After about 2 minutes, the solvent is completely volatilized, the homogenizer is stopped, and the substrate is taken out to obtain a hydrophilic ordered porous membrane.

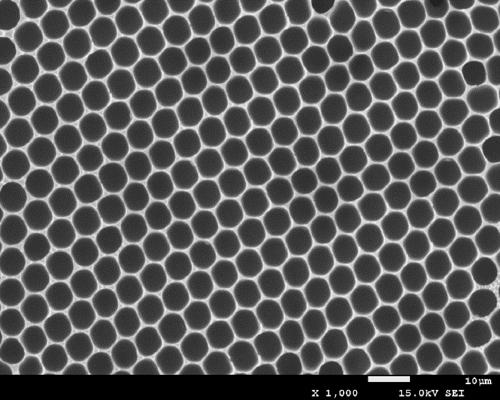

[0044] Scanning electron microscope observation (with figure 2 ) shows that the surface of the porous membrane is all distributed with ordered microporous structures, the diameter of t...

Embodiment 3

[0047] S1: Dissolve polylactic acid and dodecyltrimethylammonium chloride in chloroform, and prepare solutions with polymer and dodecyltrimethylammonium chloride concentrations of 30 mg / mL and 0.5 mg / mL, respectively;

[0048] S2: Pipette 80 μL of the above solution on the glass substrate, and place it on the rotating platform of the homogenizer;

[0049] S3: Pass the moist air passing through the test tube filled with water at a rate of 100L / h, and control the internal temperature of the homogenizer chamber to 26°C and the relative humidity to 80%, and at the same time adjust the homogenizer to start at a speed of 20rpm.

[0050] S4: After about 2 minutes, the solvent is completely volatilized, the homogenizer is stopped, and the substrate is taken out to obtain a hydrophilic ordered porous membrane.

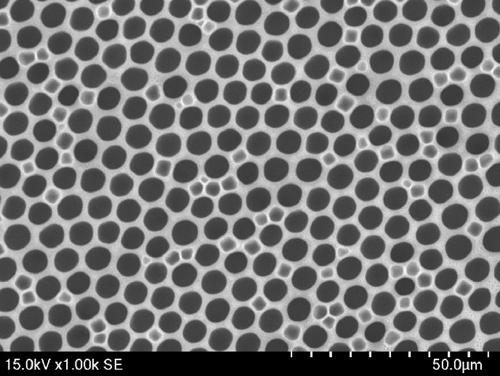

[0051] Scanning electron microscope observation (with image 3 ) shows that the surface of the porous membrane is all distributed with ordered microporous structures, the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com