High-place operation safety rope fixing suite

A safety rope and kit technology, used in seat belts, life-saving equipment, etc., can solve the problems of operators violating regulations, unable to fix safety ropes, and hitting in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

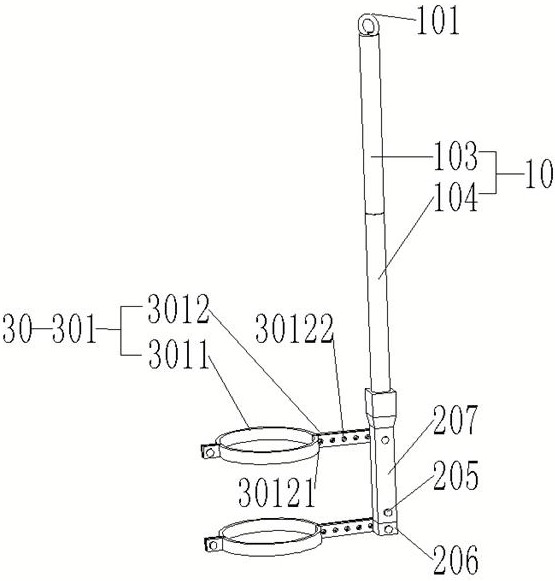

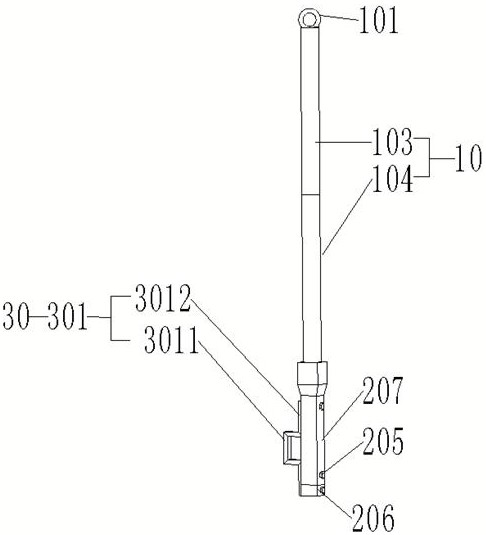

[0028] Such as figure 1 , 4 , 5, 6, 7, and 8, a safety rope fixing kit for high-altitude operations, including a support rod 10, a top ring 101 is fixed on the top of the support rod 10, and a threaded rod A102 is fixed on the bottom; the fixed rod 20, One end of the fixed rod 20 is provided with a thread groove A209 matching the size of the threaded rod A102, and the shaft body of the fixed rod 20 is provided with a bolt hole A201 and a bolt hole B202 perpendicular to the fixed rod 20 along the length direction; the locking member 30 , the locking member 30 is used to fix the support during the connection operation, and the fixing rod 20 is fixedly connected to the locking member 30 through bolt holes A201 and bolt holes B202.

[0029] Specifically, the locking member 30 is fixed on the support, the fixing rod 20 and the locking member 30 are locked by bolts, and the support rod 10 is fixed on the fixing rod 20 through the threaded cooperation of the threaded rod A102 and th...

Embodiment approach 2

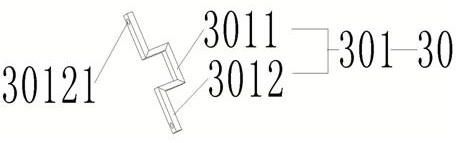

[0037] Such as figure 2 , 3 As shown, when the support is a channel steel, the locking member 30 includes a rectangular clamping portion 3011 matching the cross-sectional size of the channel steel, and connecting rods 3012 are respectively fixed at both ends of the clamping portion 3011, and the connecting rods 3012 has bolt holes C30122 respectively, and the bolt holes C30122, bolt holes A201, and bolt holes B202 have the same size. The locking member 30 and the fixing rod 20 can be clamped on the channel steel to serve as the supporting seat of the supporting rod 10, which is convenient and quick. Apart from this, this implementation mode is completely the same as the first implementation mode, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com