Paper processing and punching device

A punching device and paper technology, applied in the direction of metal processing, etc., can solve the problems of complicated paper punching operation, insufficient natural connection of paper, and inability to punch multiple sheets of paper, so as to prevent wrinkles, smooth punching operation, and avoid offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

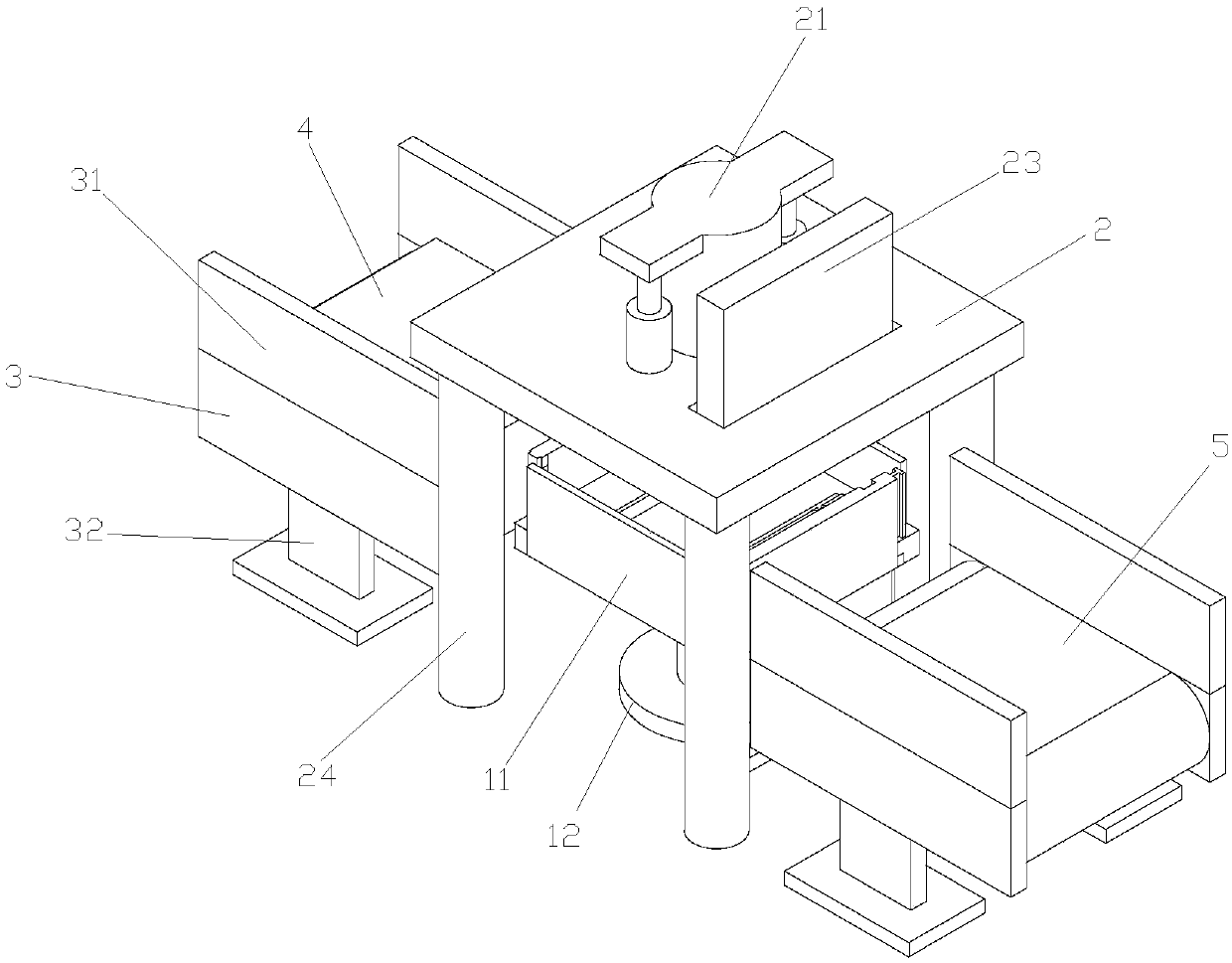

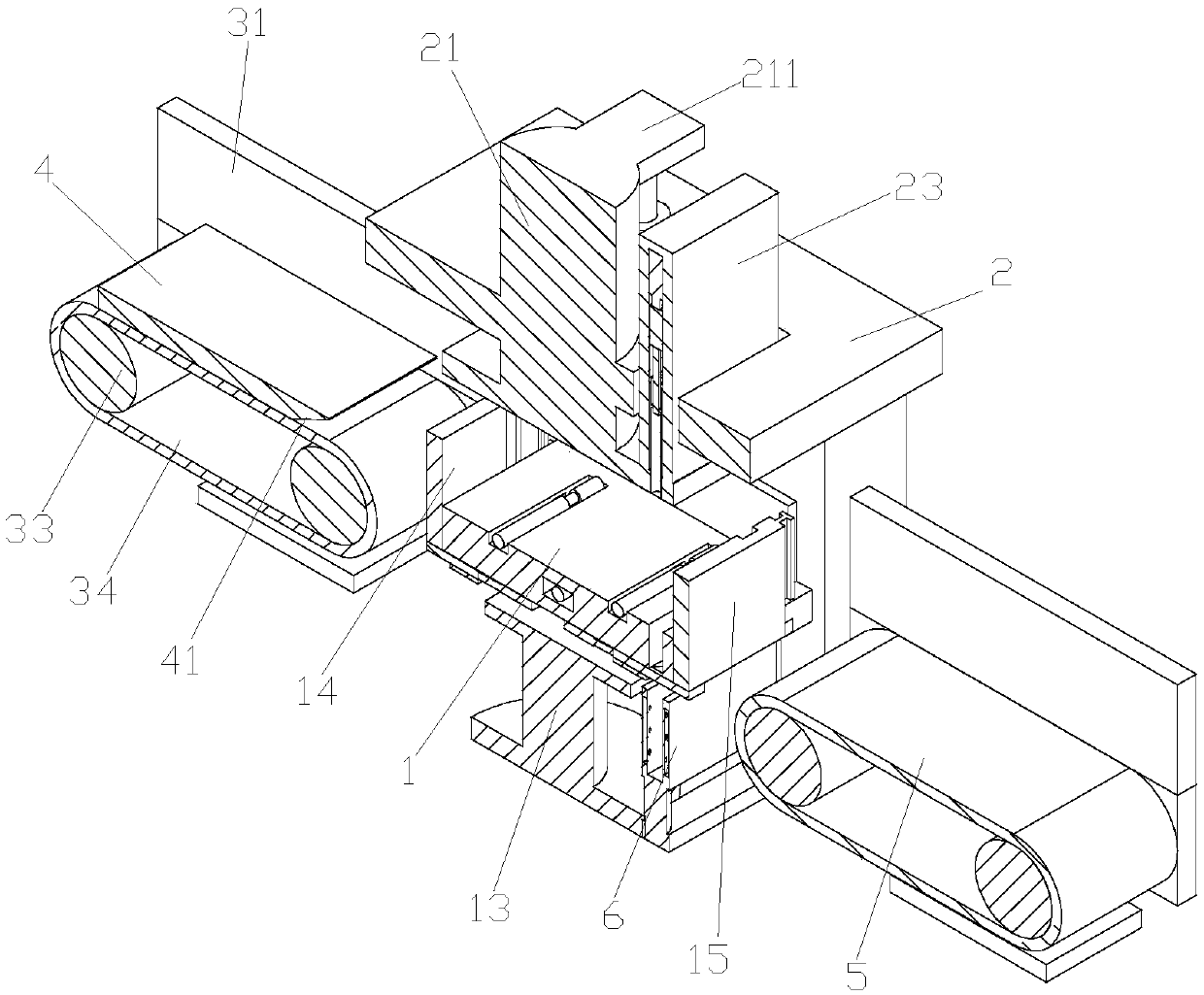

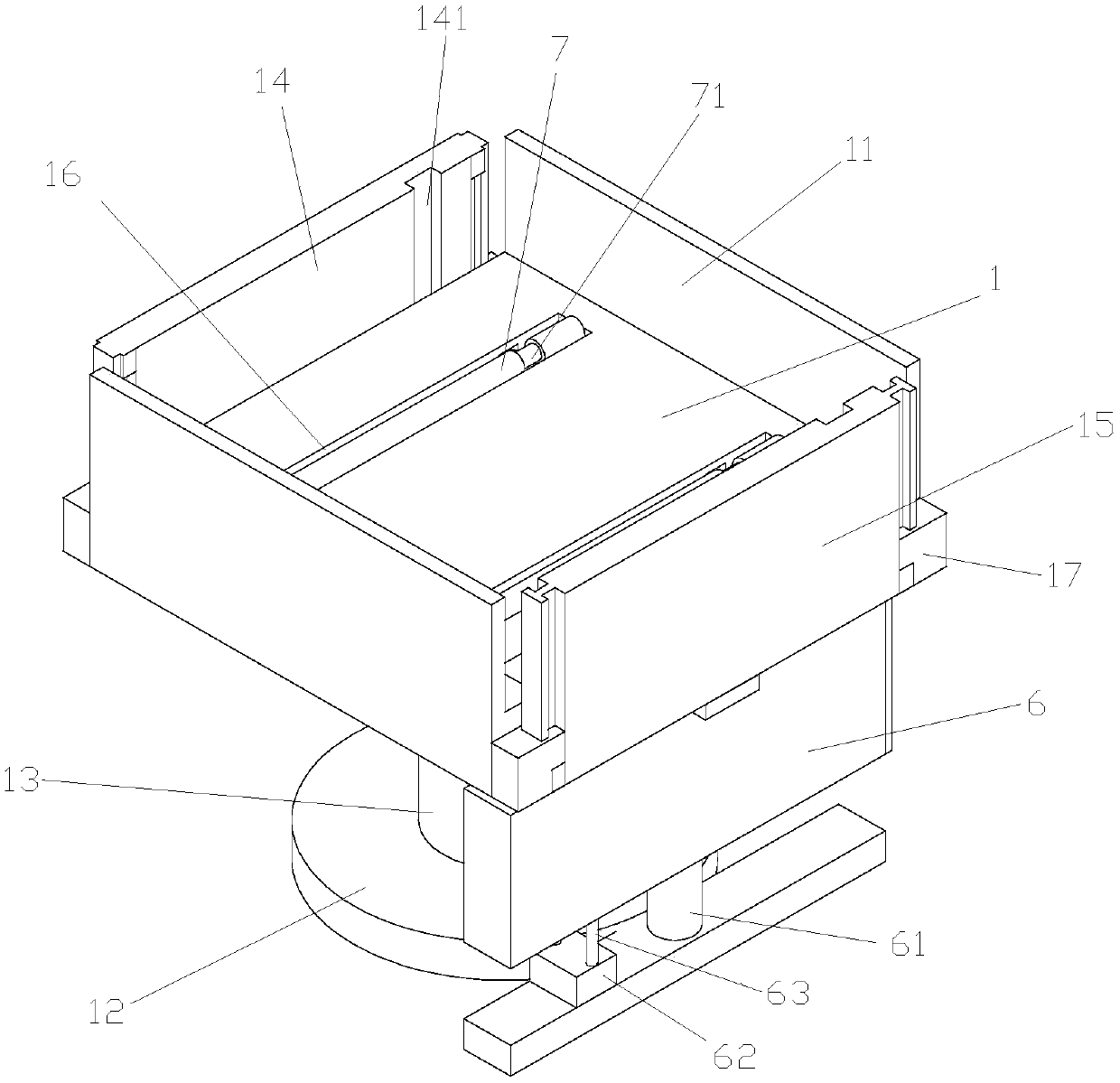

[0038] Such as Figure 1-22 As shown, a punching device for paper processing includes a first conveying device 3, a receiving platform 1 arranged on one side of the first conveying device 1, a punching device arranged above the receiving platform 1, and a The second conveying device 5 on the other side of the receiving platform 1, the first conveying device 3 includes a connecting frame, a first rotating roller 33 arranged on the connecting frame and sleeved on the first rotating roller 33 A conveyor belt 34, the conveyor belt 34 is provided with a tray 4 for placing paper, and the bottom surface of the tray near one side of the receiving platform is provided with a guide groove 41, so that the tray is convenient to enter into the receiving platform after moving to the receiving platform position; The top of the rack is provided with a fourth baffle 31, and the fourth baffles are respectively arranged on both sides of the conveyor belt. The fourth baffle acts as a limiter for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com