Collection and analysis device for different-height samples of solid waste heap

A solid waste and sample collection technology, applied in sampling devices and other directions, can solve the problems of limited sampling data, inability to change the height of solid waste filling, and inaccurate analysis data, so as to increase work efficiency and facilitate disassembly. , the effect of increasing the opening space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

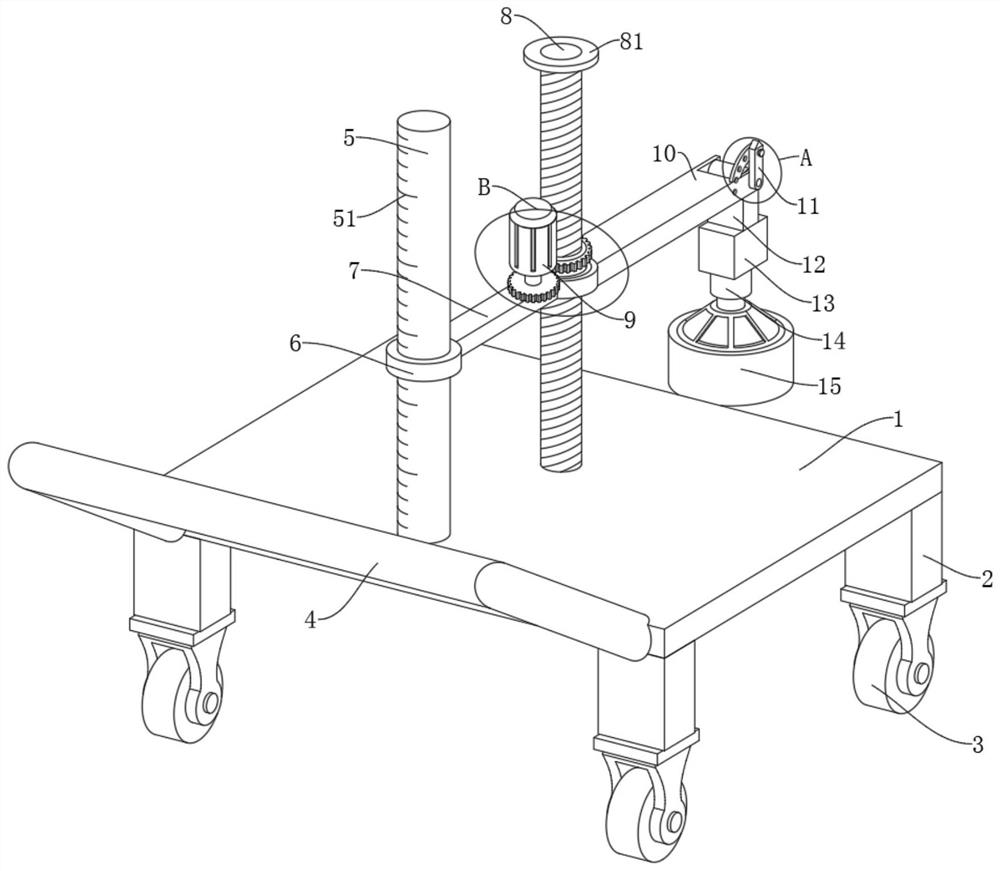

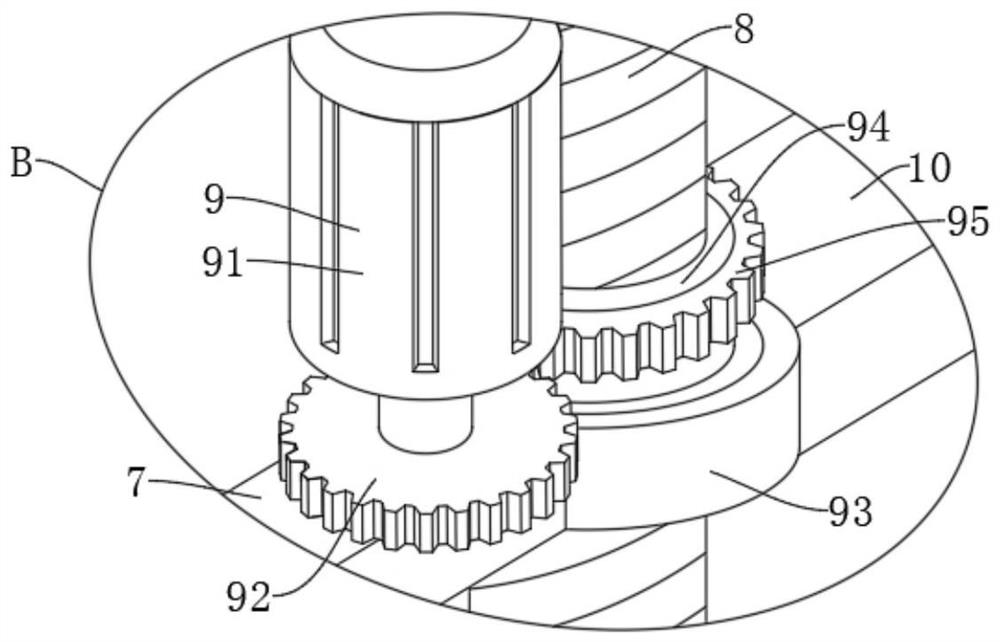

[0023] refer to figure 1 , is the first embodiment of the present invention, which provides a sample collection and analysis device for different heights of solid waste filling, including a workbench 1, a scale rod 5 is fixedly connected to the top side of the workbench 1, and the scale The outer sliding sleeve of the rod 5 is provided with a sliding cylinder 6, and one end of the sliding cylinder 6 is fixedly connected with a connecting rod 7, and the end of the connecting rod 7 away from the sliding cylinder 6 is fixedly connected with a transmission mechanism 9, and the transmission mechanism 9 rotates and is provided with a threaded rod 8 inside. The bottom end of the threaded rod 8 is fixedly connected to the other side of the top of the workbench 1;

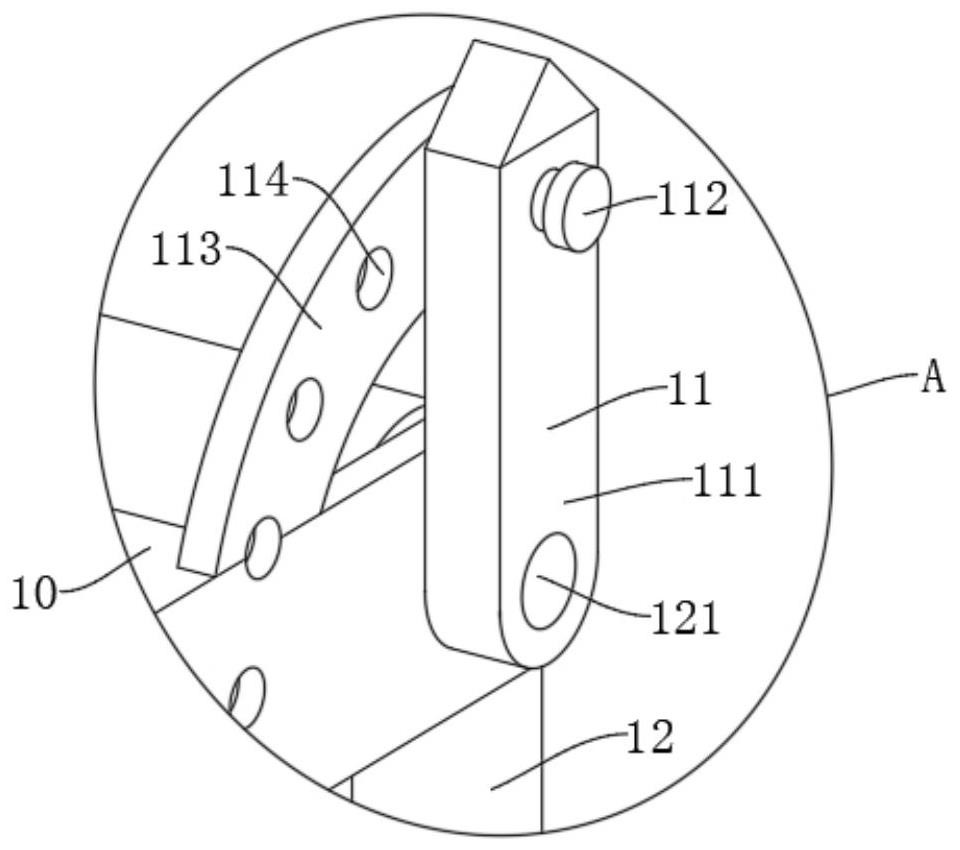

[0024] One end of the transmission mechanism 9 away from the connecting rod 7 is fixedly connected with a support rod 10, one end of the support rod 10 is rotatably connected with a rotating rod 12, one end of the rotating ...

Embodiment 2

[0026] refer to Figure 1-5 , which is the second embodiment of the present invention. This embodiment is based on the previous embodiment. Specifically, the four corners of the bottom end of the workbench 1 are fixedly connected with support legs 2, and the bottom ends of the support legs 2 are rotatably connected with universal wheels 3. One end of the workbench 1 is fixedly connected with a handle 4, which is convenient for the operator to push the present invention to a solid waste landfill site, and the universal wheel 3 provided at the bottom of the support leg 2 facilitates the movement of the present invention and saves manpower.

[0027] Specifically, a scale 51 is provided on the side of the scale rod 5 close to the handle 4, and the scale 51 is convenient for the operator to confirm the sampling depth or height.

[0028] Specifically, the top end of the threaded rod 8 is coaxially fixedly connected to the limit ring 81, and the limit ring 81 limits the transmission ...

Embodiment 3

[0033] refer to Figure 1-5 , which is the third embodiment of the present invention. This embodiment is based on the above two embodiments. When in use, hold the handle 4 to push the workbench 1 to the solid waste landfill site. The steering wheel 3 facilitates the movement of the present invention and saves manpower. When it is necessary to sample and analyze the landfilled solid waste, the present invention is pushed onto the solid waste landfill, and the locking bolt 112 of the switching assembly 11 is inserted into the One end of the limit plate 113, and then drives the rotating rod 12 to be perpendicular to the support rod 10, according to the depth of the sample to be sampled, the forward and reverse motor 91 of the transmission mechanism 9 is started, and then the threaded sleeve 94 is driven to rotate by gear engagement, and the threaded sleeve 94 The rotation drives the connecting ring 93 to cooperate with the connecting rod 7 and the sliding cylinder 6 to move linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com