Low-voltage coil winding tool for transformer

A technology of low-voltage coils and transformers, applied in the field of transformers, can solve the problems of starting deviation, wasting time, affecting product quality, etc., and achieve the effect of improving product quality, reducing quantity, and reliable compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

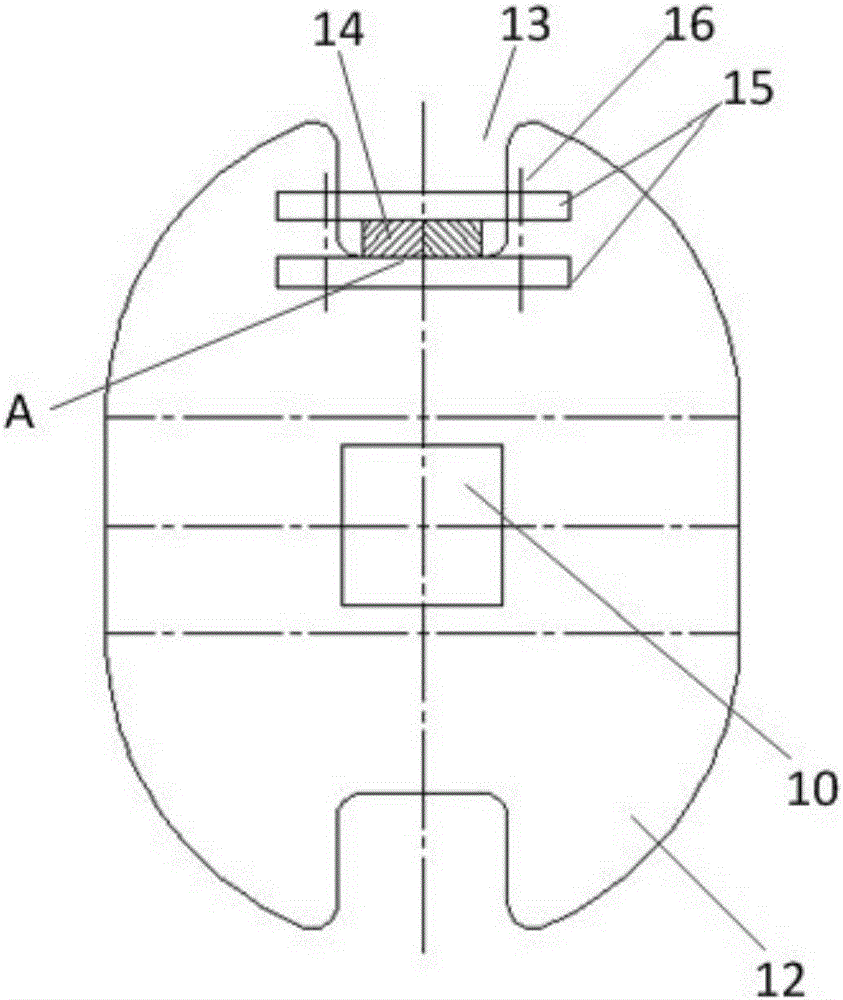

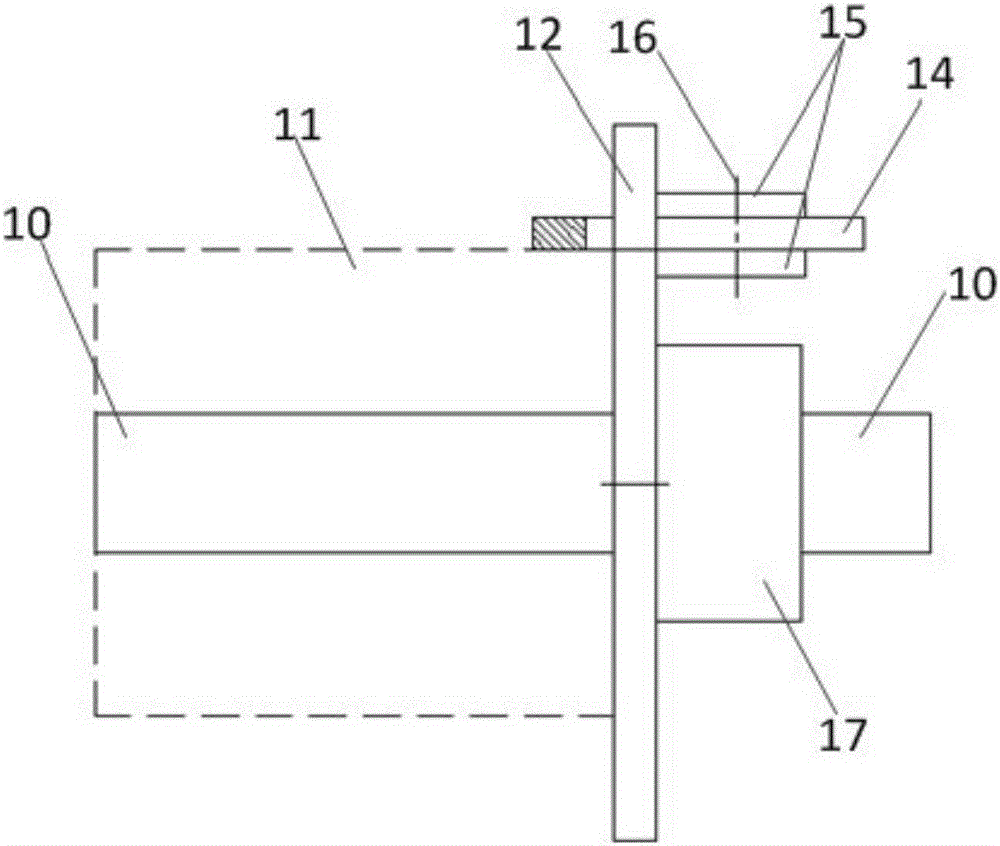

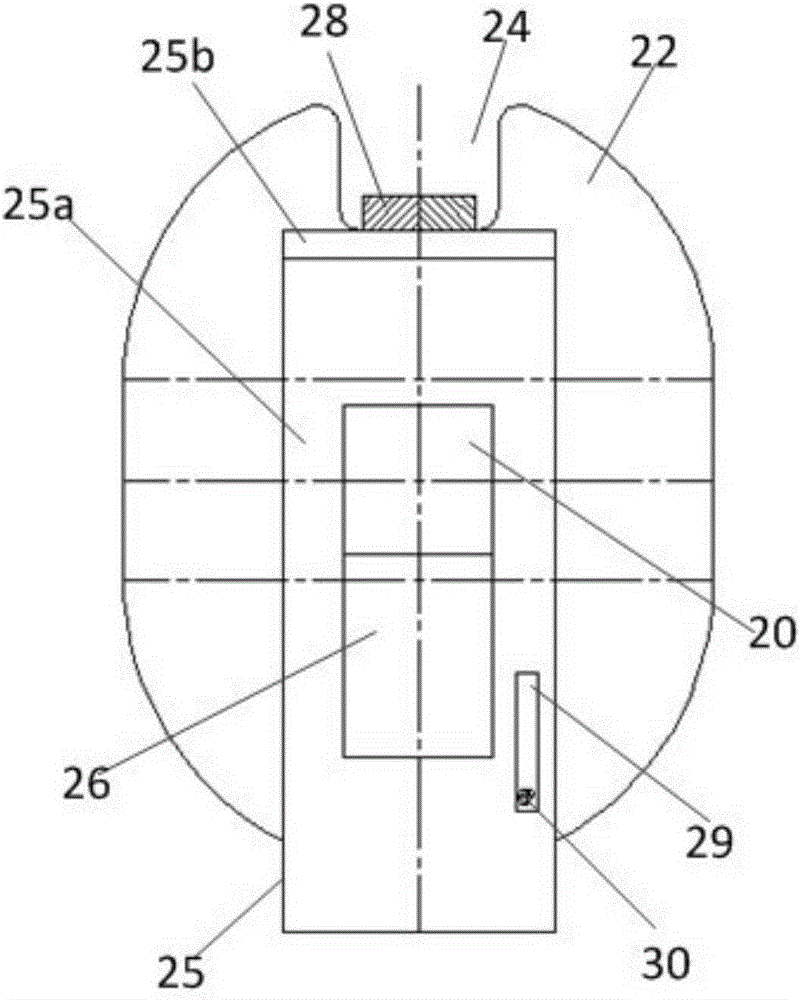

[0016] Such as Figure 3-6 As shown, the present invention provides a transformer low-voltage coil winding tool, including a low-voltage winding die 21 sleeved on the winding machine shaft 20, one end of the low-voltage winding die 21 is provided with a baffle 22, the baffle The center of the plate 22 is provided with a through hole 23, and is installed on the winding machine shaft 20 through the through hole 23. The edge position of the baffle 22 is provided with a baffle gap 24 for the low-voltage coil outlet 28 to lead out, which also includes :

[0017] A positioning plate 25 with an inverted L-shaped longitudinal section is located outside the baffle plate 22. A strip hole 26 is opened in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com