Cutting equipment for rubber processing

A cutting equipment and rubber technology, applied in the field of rubber processing, can solve the problems of the size deviation of the rubber pad, the positional deviation of the upper rubber sheet and the lower rubber sheet, etc., to achieve the effect of enhancing the grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

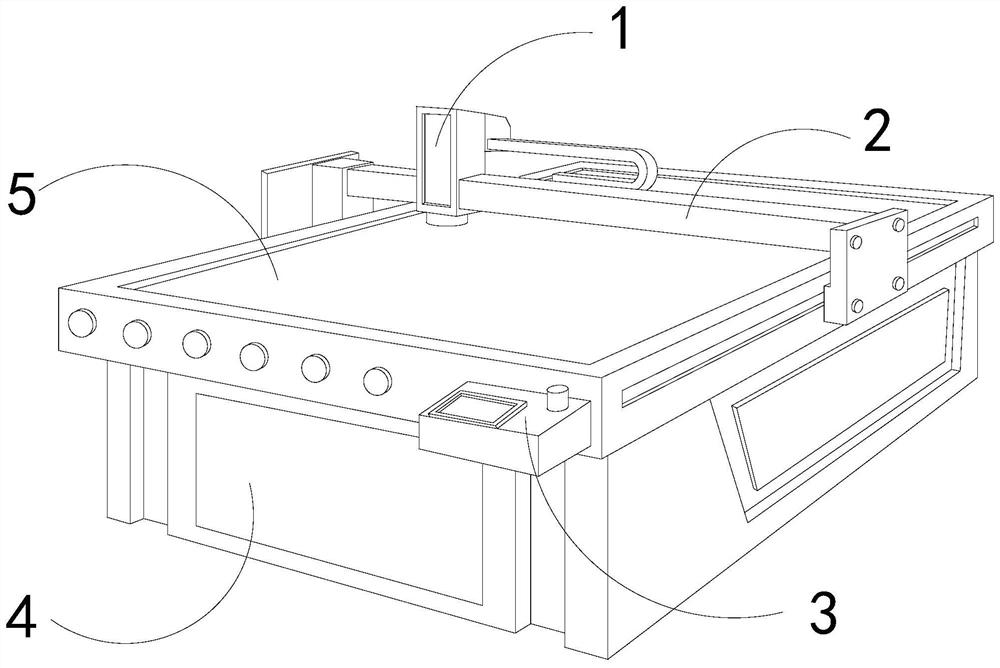

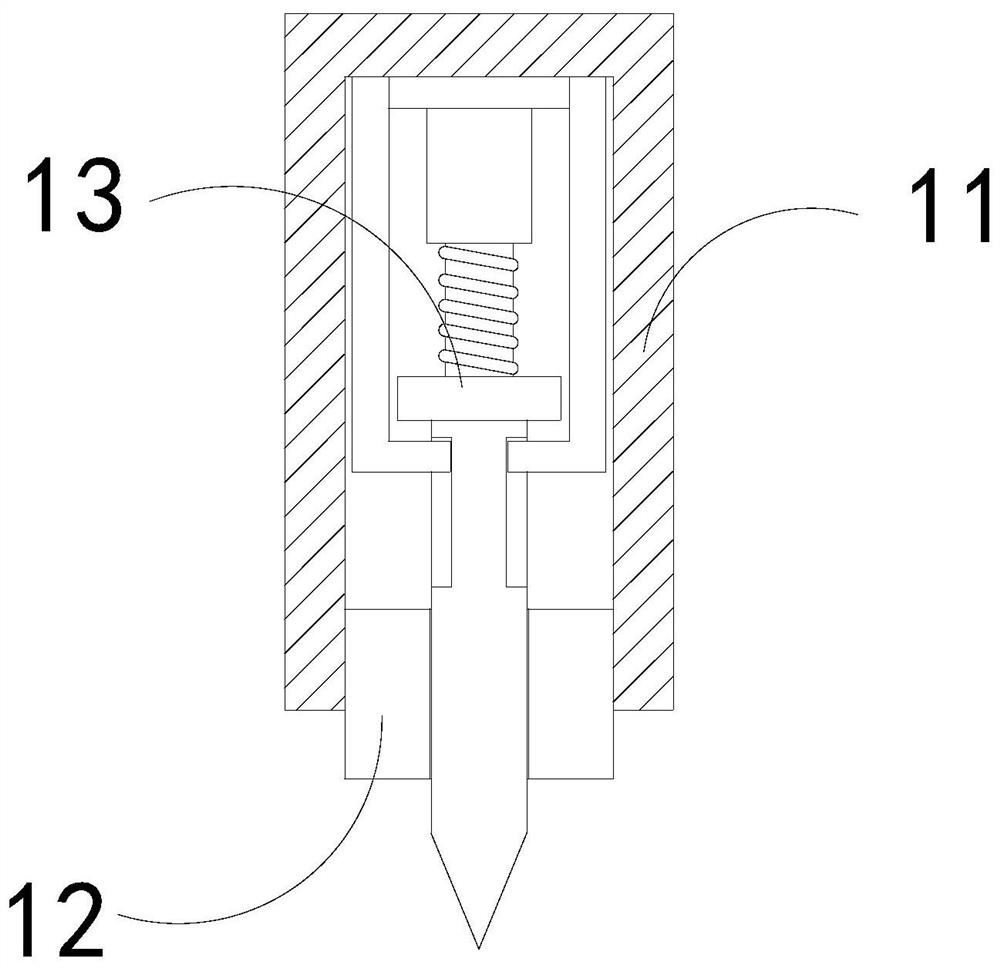

[0027] The invention provides a cutting device for rubber processing, the structure of which includes a cutting mechanism 1, a driving frame 2, a console 3, a base 4, and an operating table 5, and the driving frame 2 is installed at the upper end of the operating table 5, so that The console 3 is embedded and fixed at the front end of the console 5, the base 4 and the console 5 are an integrated structure, the cutting mechanism 1 is movably engaged with the drive frame 2; the cutting mechanism 1 includes an outer frame 11, The lower block 12 and the cutting tool 13 , the lower block 12 is embedded and connected with the lower end of the inner wall of the outer frame 11 , and the cutting tool 13 is movably engaged with the inner part of the outer frame 11 .

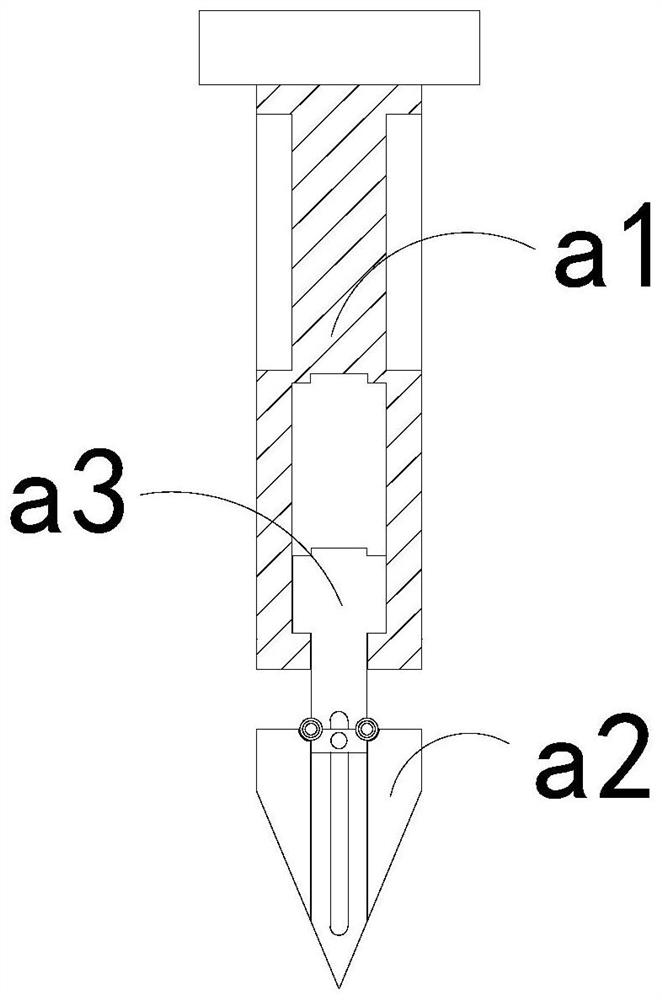

[0028] Wherein, the cutting tool 13 includes a knife bar a1, a fixed frame a2, and a blade a3. The fixed frame a2 is movably engaged with the blade a3, and the blad...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the blade a3 includes a receiving plate c1, a reset piece c2, and an outward expansion plate c3, the reset plate c2 is installed between the outward expansion plate c3 and the receiving plate c1, and the outward expansion plate c3 is hingedly connected to the side of the receiving plate c1 , there are three outer panels c3, which are evenly distributed symmetrically on the left and right sides of the lower end of the receiving panel c1, through the reverse pulling force generated by the cut surface of the rubber sheet on the outer panel c3, the outer panel c3 can be moved along the receiving panel c1 swing down.

[0036] Wherein, the outward expansion board c3 includes a board body c31, an elastic piece c32, a bearing plate c33, and a grip groove c34. c33 is an integrated structure, and the gripping groove c34 has a triangular concave structure, and the frictional force generated by the cut surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com