Full-automatic glass packing paper machine and process

A glass pad, fully automatic technology, applied in the direction of packaging, etc., can solve the problems of glass offset, incomplete coverage of pad paper, and inability to complete pad paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

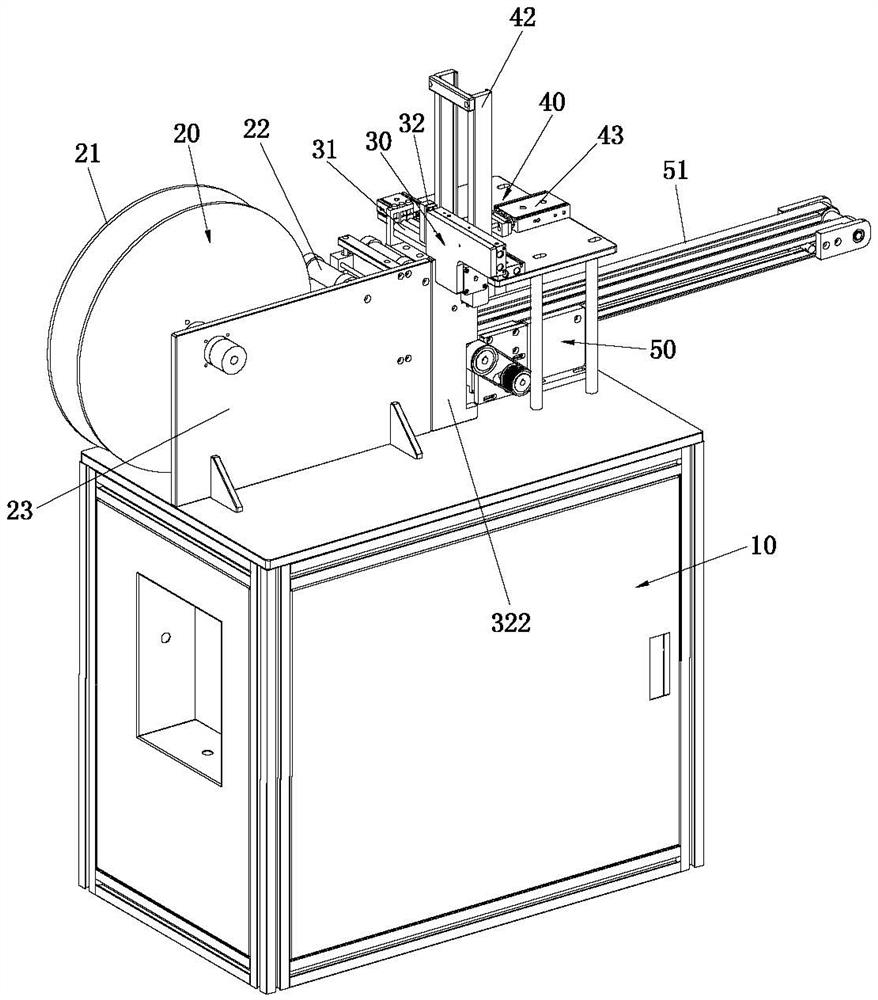

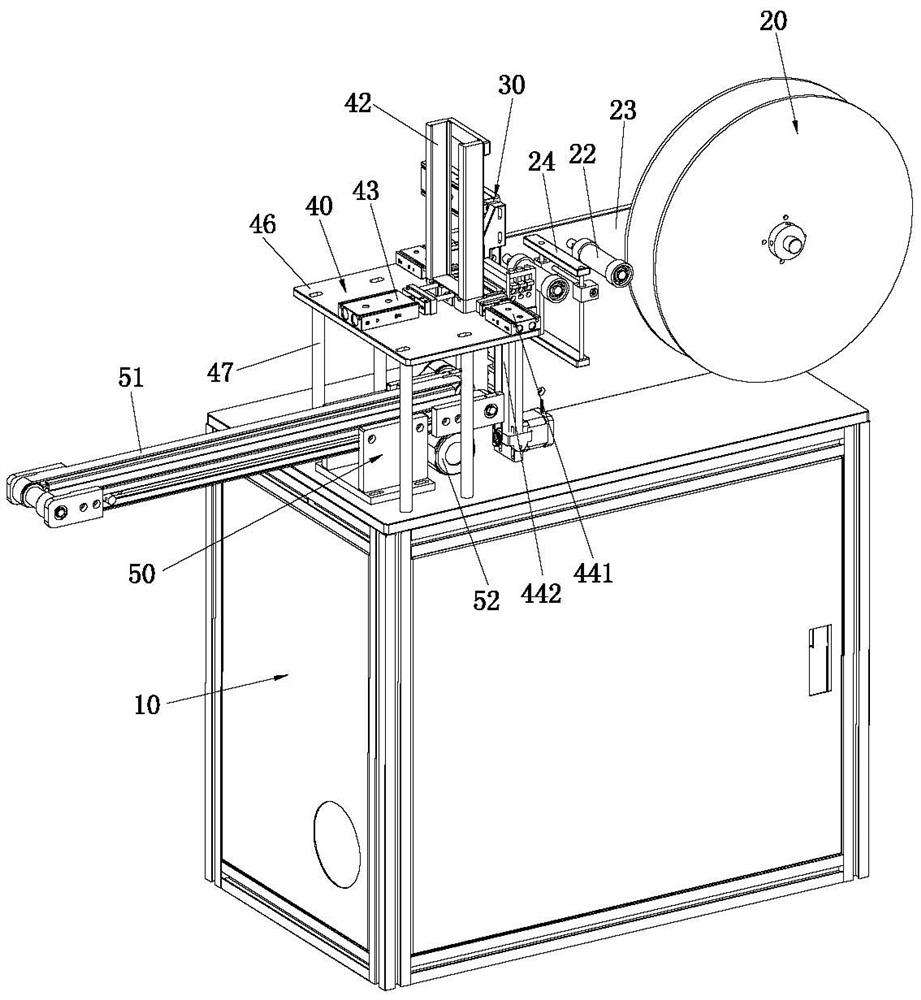

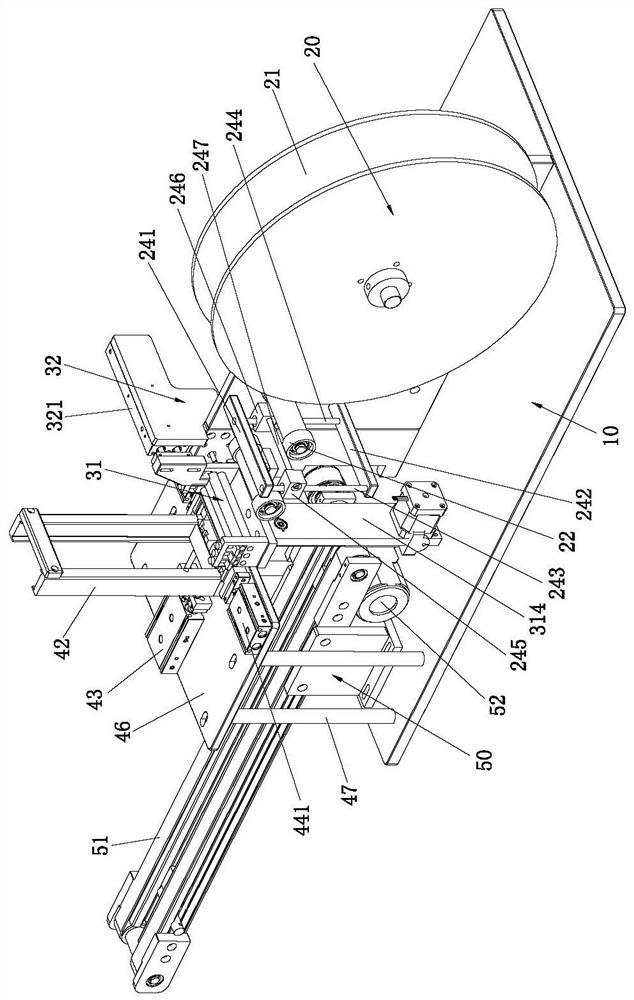

[0073] Please refer to Figure 1 to Figure 12 As shown, it shows the specific structure of the embodiment of the present invention.

[0074] A fully automatic glass pad paper machine, comprising a machine platform 10 and a paper feeding device 20, a paper cutting device 30, a glass pad paper device 40, and a discharge device 50 arranged on the machine platform 10; the fully automatic glass pad paper machine It also includes a control device that is electrically connected to the paper feeding device 20 , the paper cutting device 30 , the glass mat device 40 , and the discharging device 50 .

[0075] Specifically, the paper feeding device 20 includes a tray 21 and an engaging wheel 22, and the input end and output end of the engaging wheel 22 are connected to the feeding tray 21 and the paper cutting device 30 respectively; the paper feeding device 20 also includes a vertical Mounting plate 23, a tensioning mechanism 24 for tensioning the paper, the vertical mounting plate 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com