Balance weight device of boring-milling machine

A technology of a counterweight device and a boring and milling machine, which is used in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of falling counterweight blocks, swinging counterweight blocks from side to side, and easy breakage of connecting ropes. achieve the effect of avoiding falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

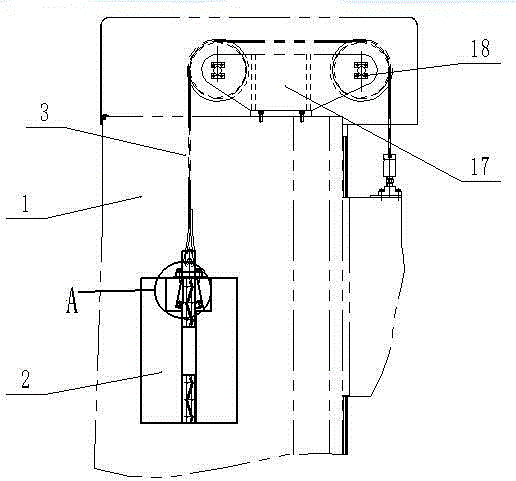

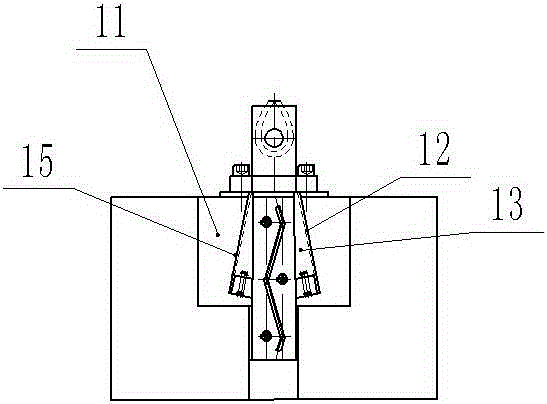

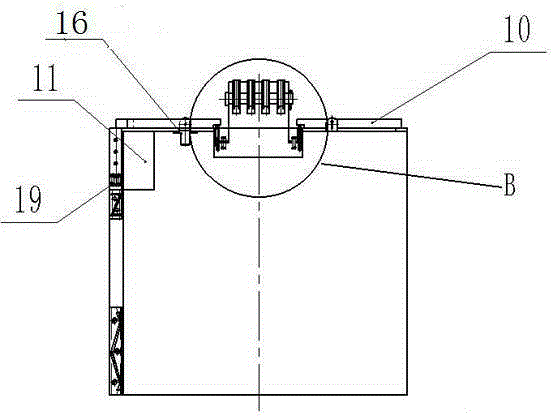

[0022] A counterweight device for a boring and milling machine includes a hollow column 1, a counterweight 2 arranged in the column, a support device positioned above the column 1, and a connecting rope 3 connecting the counterweight 2 and the driving device through the support device, which It is characterized in that a vertical guide rail 4 is provided opposite to each other on the inner wall of the column 1, grooves 5 corresponding to the guide rails 4 are provided on both sides of the counterweight 2, and grooves 5 are provided on the grooves 5. A buckle device that can fix the counterweight 2 on the guide rail 4, and the counterweight 2 is provided with a control structure for controlling the buckle device.

[0023] Specifically, the control structure includes a load-bearing block 6 located at the upper end of the counterweight 2, the two sides of the load-bearing block 6 are protruding flanges 7, and each of the flanges 7 is provided with a snap-on The briquetting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com