Insulated sealing structure of electrode

A technology of sealing structure and electrode insulation, which is applied in the direction of structural parts, circuits, capacitors, etc., can solve the problems of the influence of insulation and sealing performance of insulating sealing body, long assembly process, low production efficiency, etc., so as to simplify the assembly process and solve the problem of assembly process Long, reduce the loss of material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

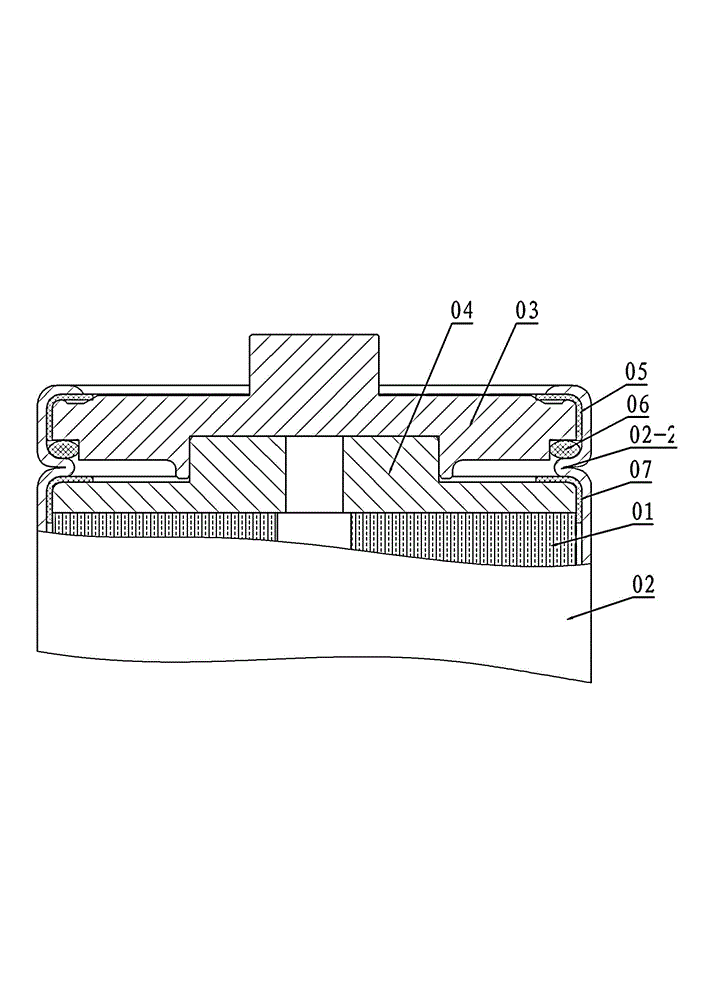

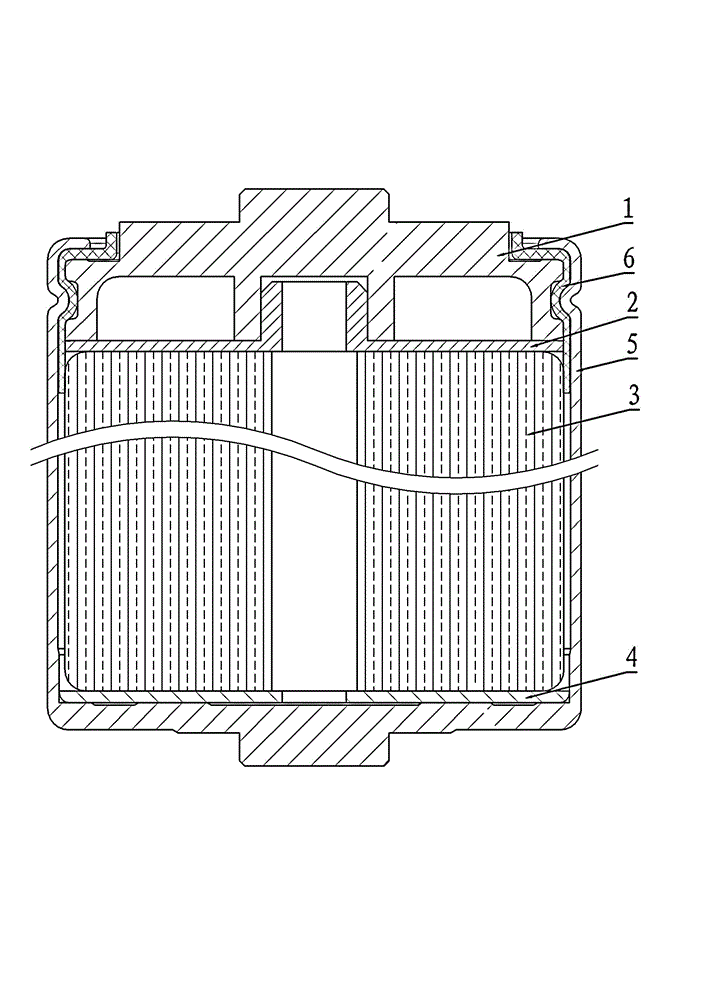

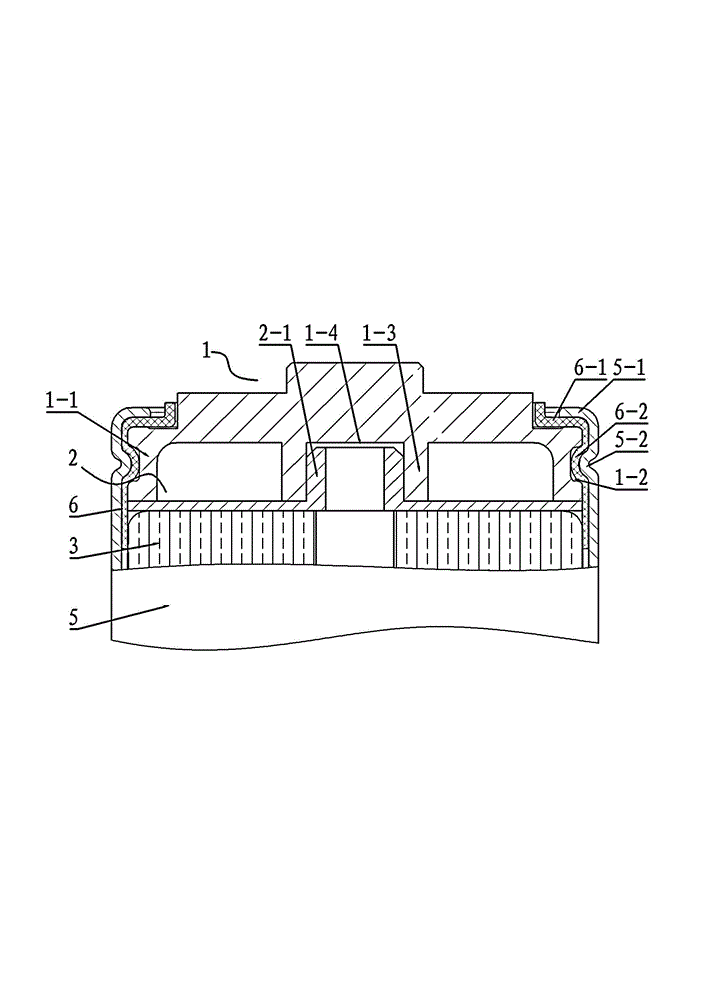

[0029] Embodiment 1 of the electrode insulation sealing structure of the present invention, as figure 2 and image 3 As shown, the electrode insulation and sealing structure is composed of an electrode lead-out structure, an insulating sealing sleeve 6 and a housing 5 , and the electrode lead-out structure is composed of an end cover 1 and an upper current collecting plate 2 . The upper current collecting plate 2 is welded on the upper end surface of the electric core 3, and is in electrical contact with the electric core 3, and the end cover 1 is conductively fixed on the upper end surface of the current collecting plate, and the end cover is composed of an end cover plate body, an end cover plate The lower end surface of the body is composed of a positioning column protruding from the central position and an end cover protrusion protruding from the edge position, and an annular end cover protrusion 1-1 is protruding from the edge position of the lower end surface of the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com