Self-locking snap ring

A self-locking, clasp technology, applied in the direction of connecting components, mechanical equipment, friction-clamped removable fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

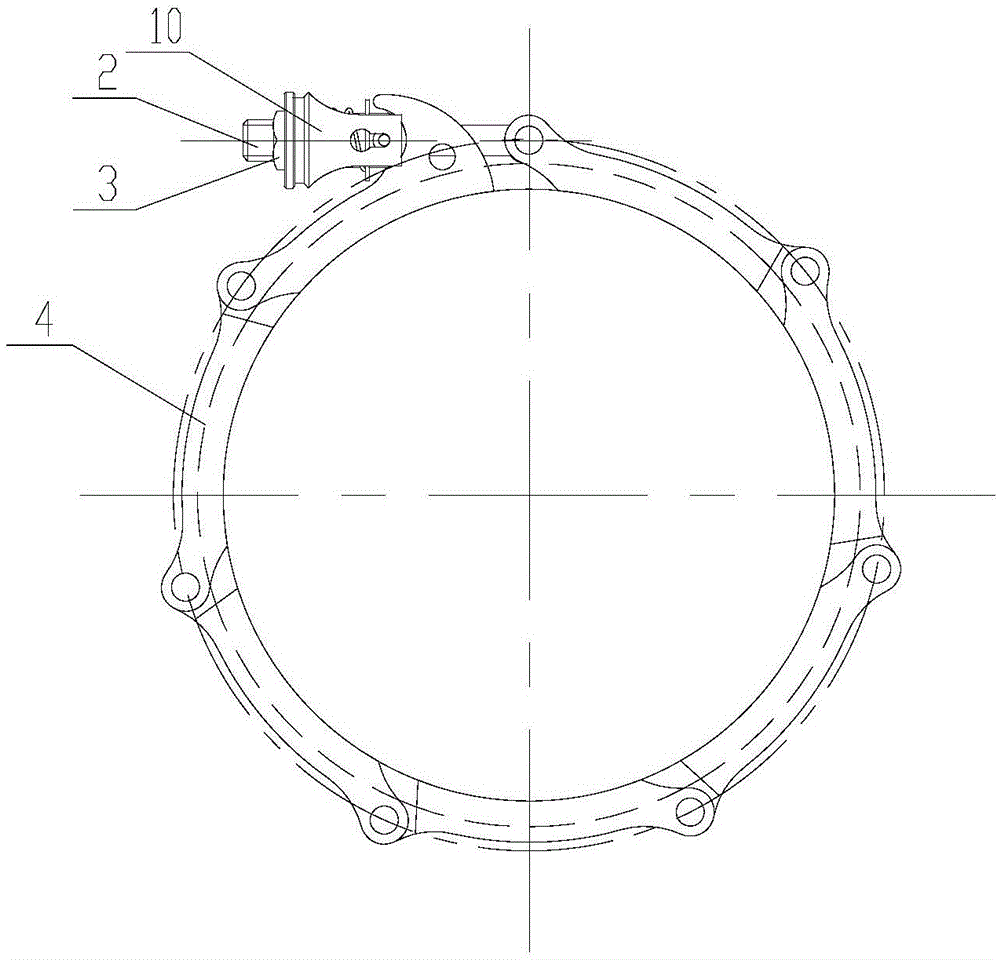

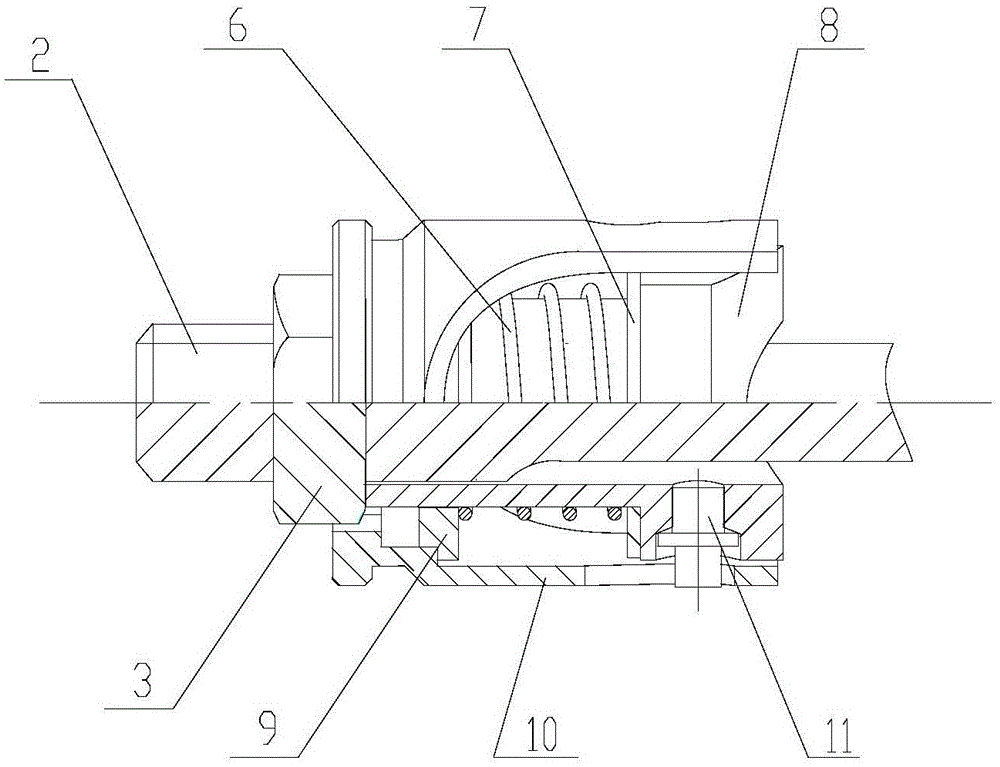

[0008] As shown in the figure, the self-locking snap ring includes a snap ring body and a lock assembly. The snap ring body is composed of several joints 4 spliced together in sequence. The lock assembly includes bolts 2, nuts 3, and springs 6. , screw sleeve 8, lock housing 10, one end of the bolt 2 is hinged on one end of the snap ring body, and the other end passes through the other end of the snap ring body and the screw sleeve 8 to install the nut 3, and the nut 3 passes through the screw sleeve 8 Tighten the clasp body, the lock housing 10 is arranged outside the screw sleeve 8, the spring 6 is respectively pressed on the steps inside the lock housing 10 and the outside of the screw sleeve 8, and the end of the lock housing 10 is positioned under the action of the spring 6. The outside of the nut 3 is matched with the outer contour of the nut 3, the screw sleeve 8 is provided with a pin 11, the bolt 2 is provided with an axial groove, and the lock housing 10 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com