Mounting method of torsion bar component and torsion bar component mounting structure

An installation method and torsion bar technology, which is applied in the field of anti-roll torsion bar system installation, can solve problems such as high cost and complex structure, and achieve the effects of easy connection, high compact structure, and small space occupancy rate of the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

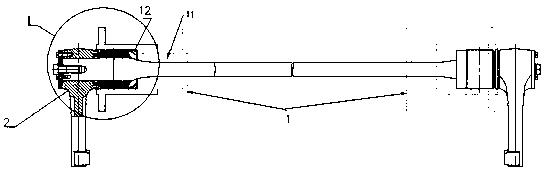

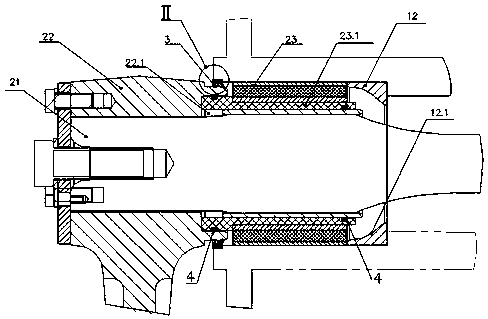

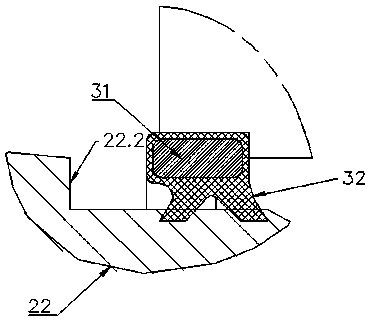

[0030] Combine below Figure 1 to Figure 5 The embodiments of the present invention will be described in detail.

[0031] The installation method of the torsion bar assembly is characterized in that the installation hole 11 corresponding to the torsion bar assembly 2 is processed on the frame 1 of the bogie, the torsion bar assembly 2 is traversed in the installation hole 11 and the torsion bar assembly 2 is installed with the torsion bar assembly. The holes 11 are connected by interference fit, and a stop 12 for axially limiting the torsion bar assembly 2 is provided in the installation hole 11 , and the stop 12 is in close contact with the torsion bar assembly 2 .

[0032] Such as figure 1 As shown, the installation hole 11 corresponding to the torsion bar assembly 2 is processed on the frame 1 of the bogie, and the torsion bar assembly 2 and the installation hole 11 are connected by interference fit, that is, the torsion bar assembly 2 is directly installed on the frame, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com