Patents

Literature

55results about How to "Realize axial limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

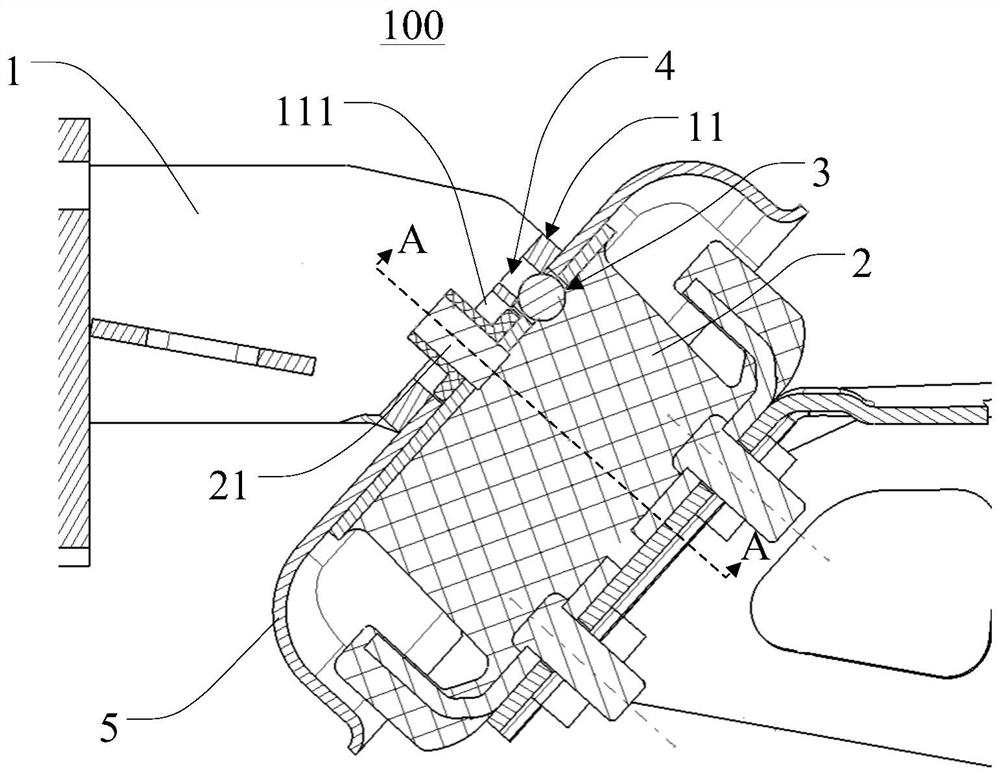

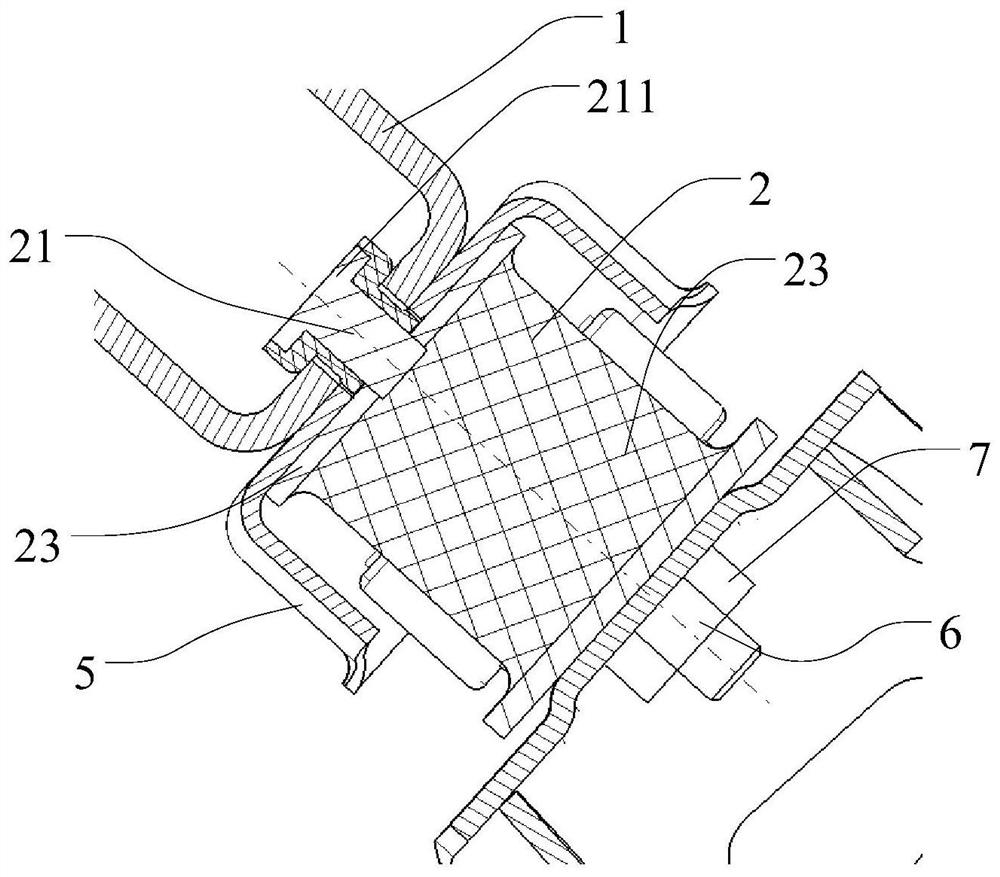

Check valve for engine

InactiveCN101881225ARealize axial limitImprove liquidityCheck valvesEngine controllersCheck valveAir tightness

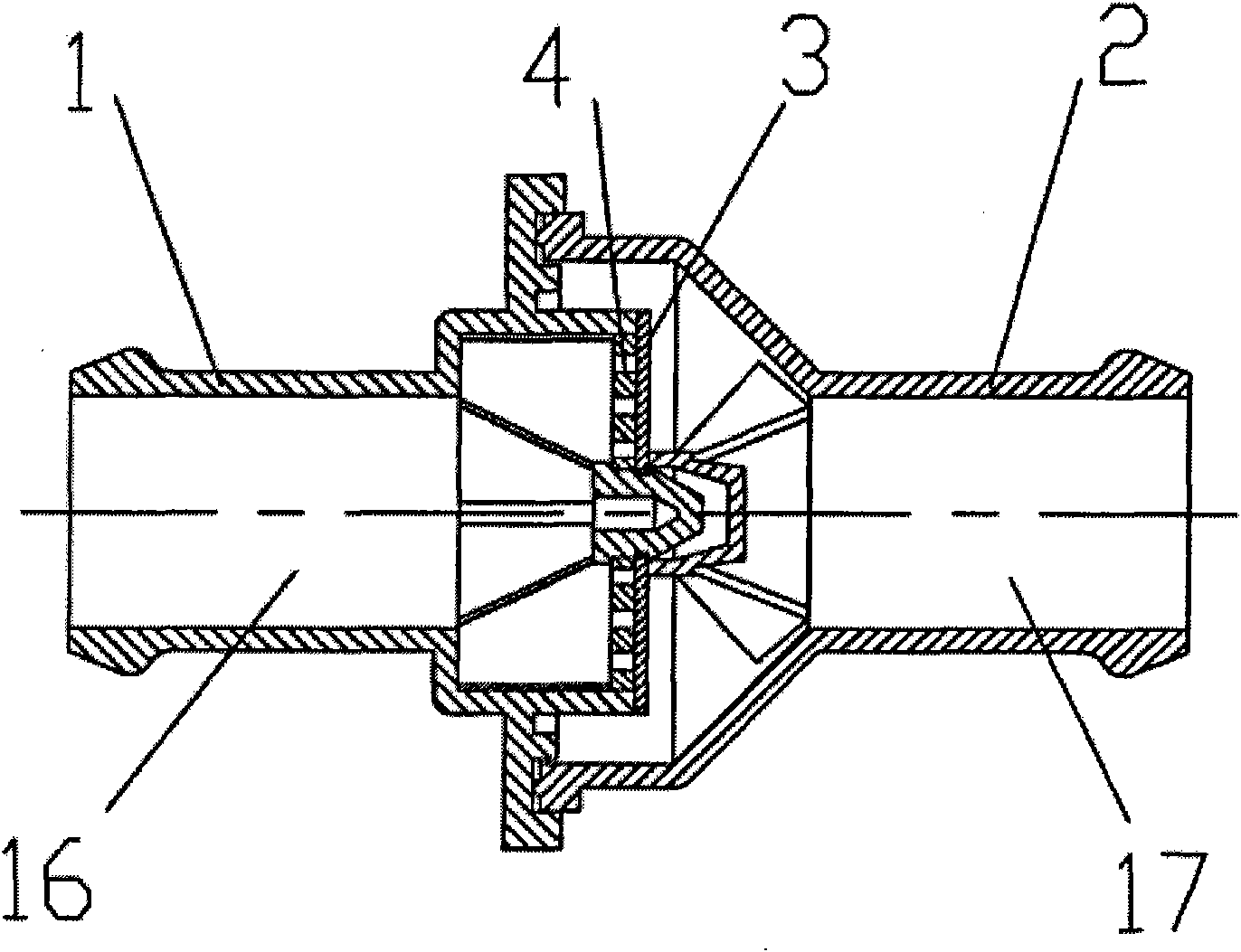

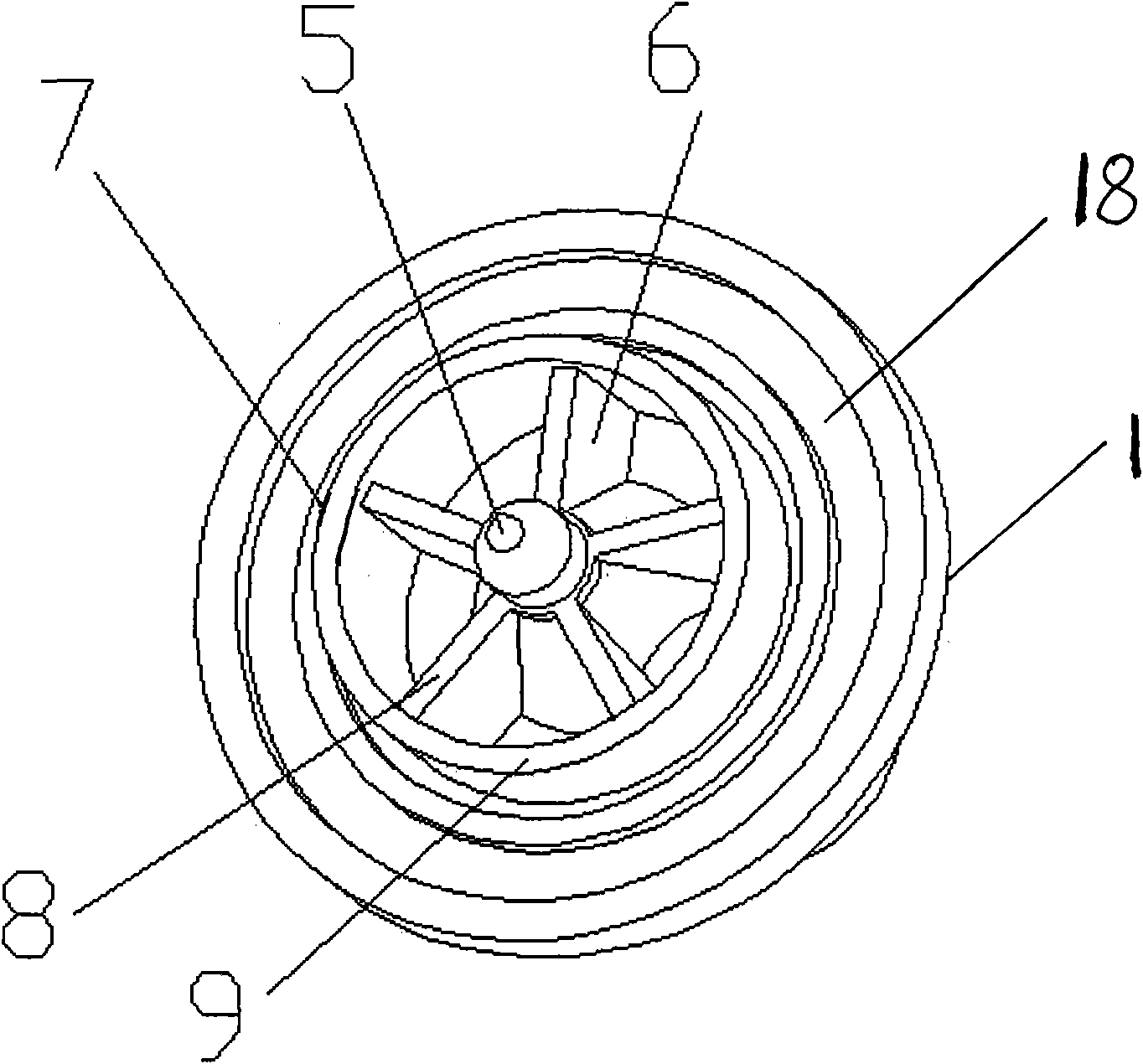

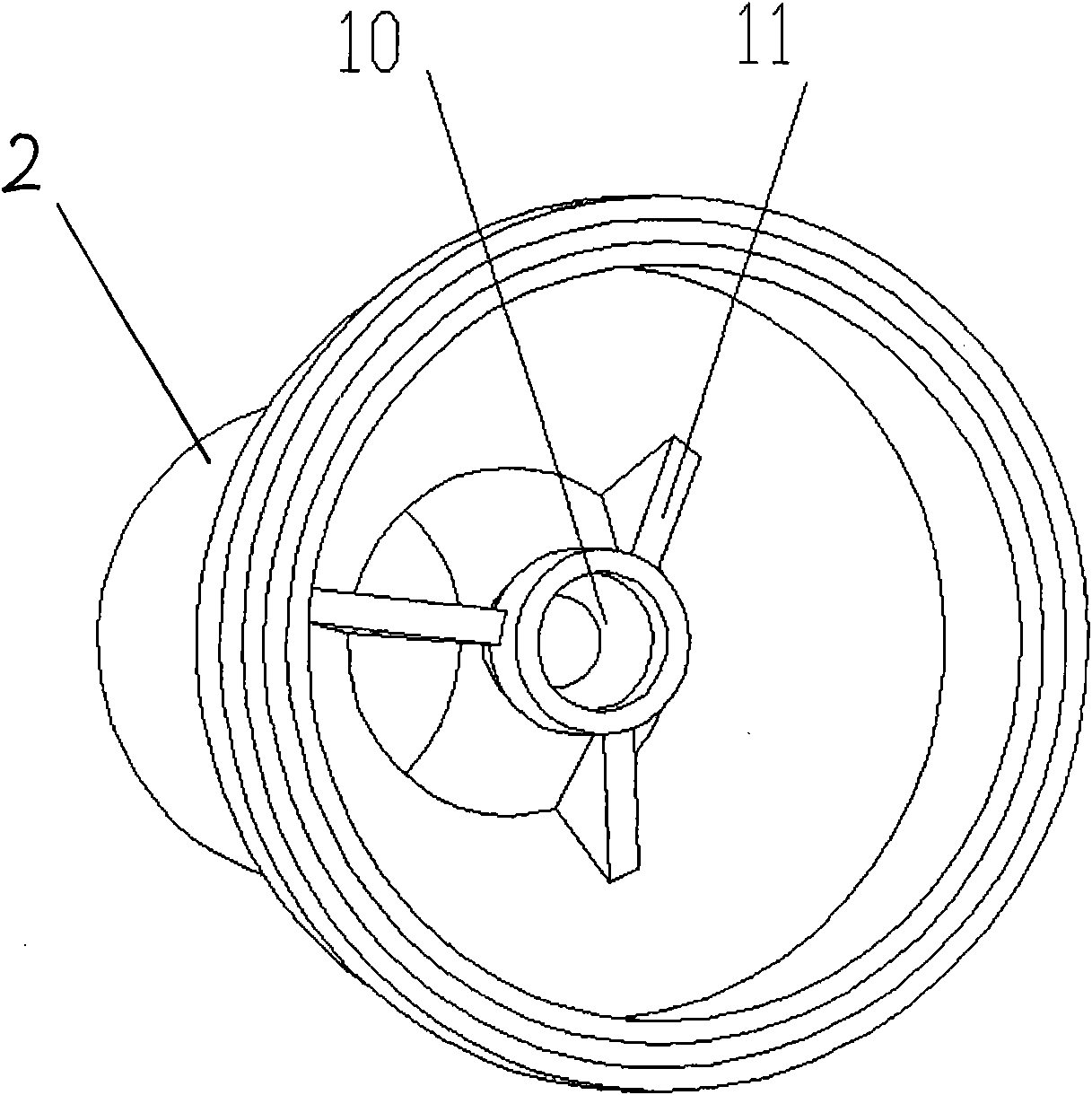

The invention provides a check valve for controlling air current to flow in one direction on an engine, which consists of an upper shell, a lower shell, a membrane and a support sheet. The support sheet and the membrane are matched with a positioning boss of the upper shell through a mounting hole and are matched with a positioning hole of the lower shell to realize axial limitation of the membrane through the positioning boss of the upper shell. Gas acts upon the membrane from an air inlet of the upper shell to an air pore on the support sheet, the membrane carries out structure deformation under the action of the air current to reserve a gap with the upper shell, and the air current passes through an air outlet of the lower shell to flow out through the gap to realize the flowing action of positive air current of the check valve. When the gas flows reversely, the membrane cannot deform due to the action of the air current, the reversed air current is stopped by the matched sealing action of the membrane and the upper shell, and the membrane has favorable sealing performance on the reversed air current. The check valve has the advantages of simple structure composition, easy assembly, light weight and small volume, can ensure that the air current is smooth when the air current positively flows, and has favorable airtightness when the air current reversely flows, thereby the requirements on related performance are satisfied.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

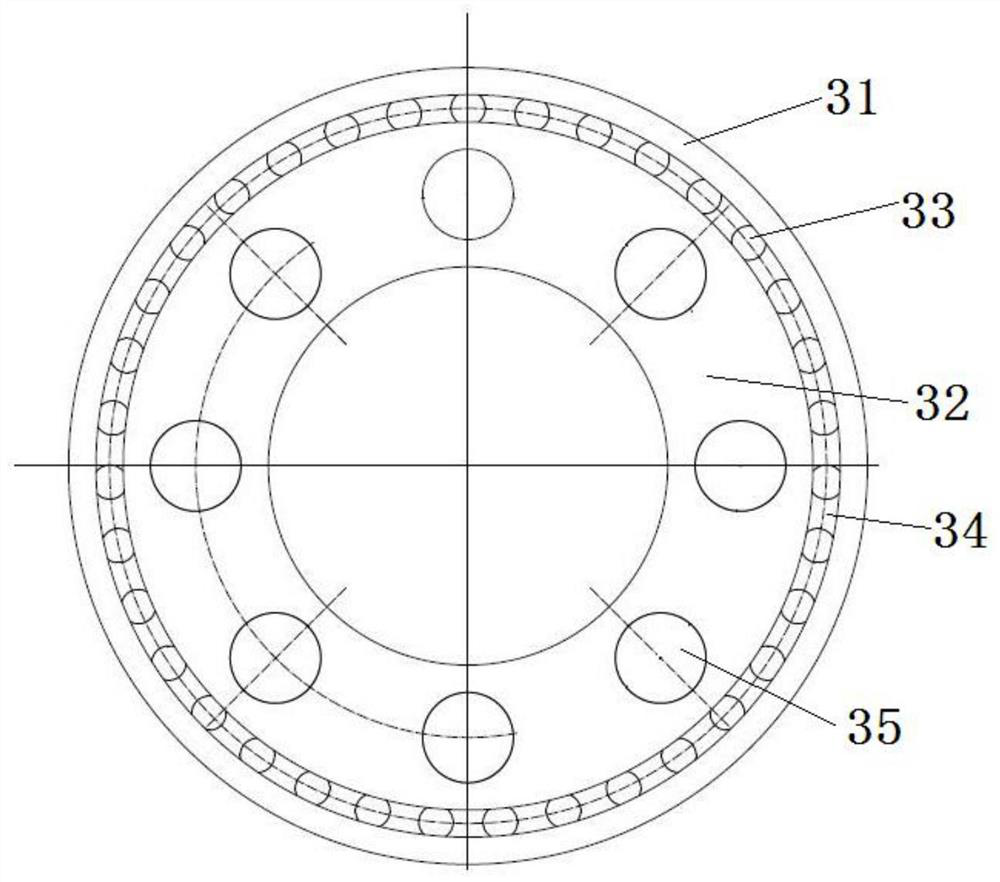

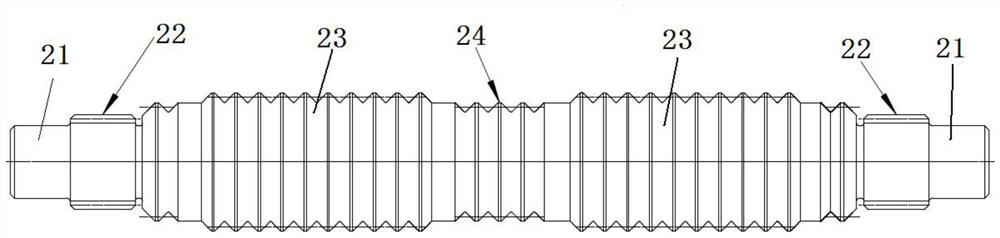

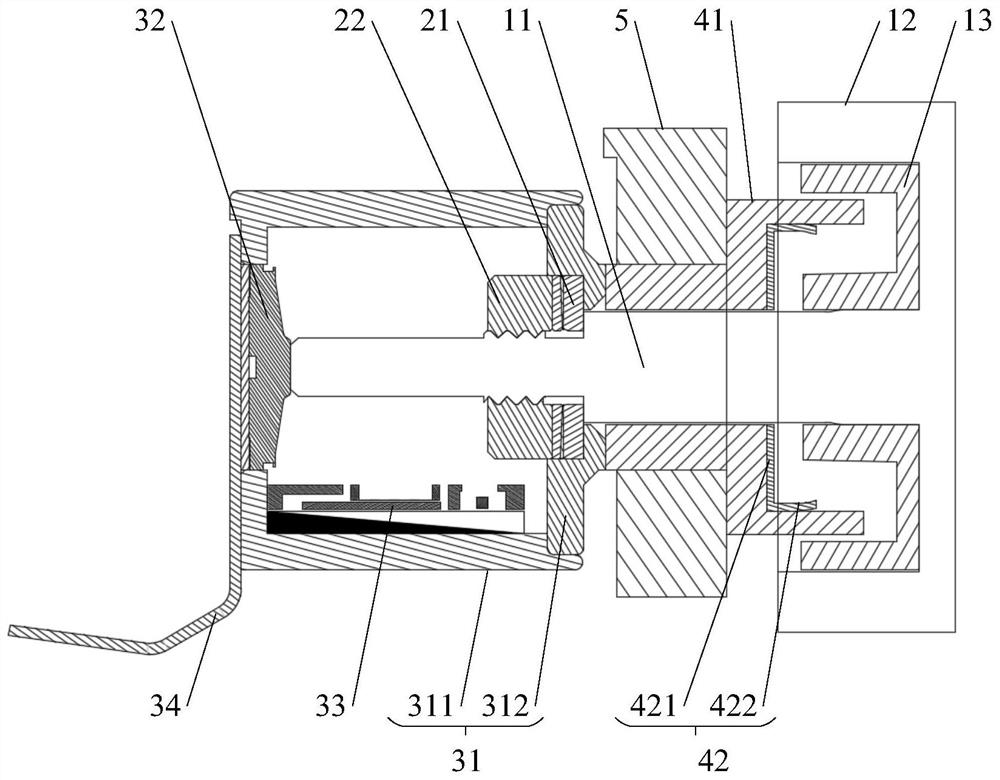

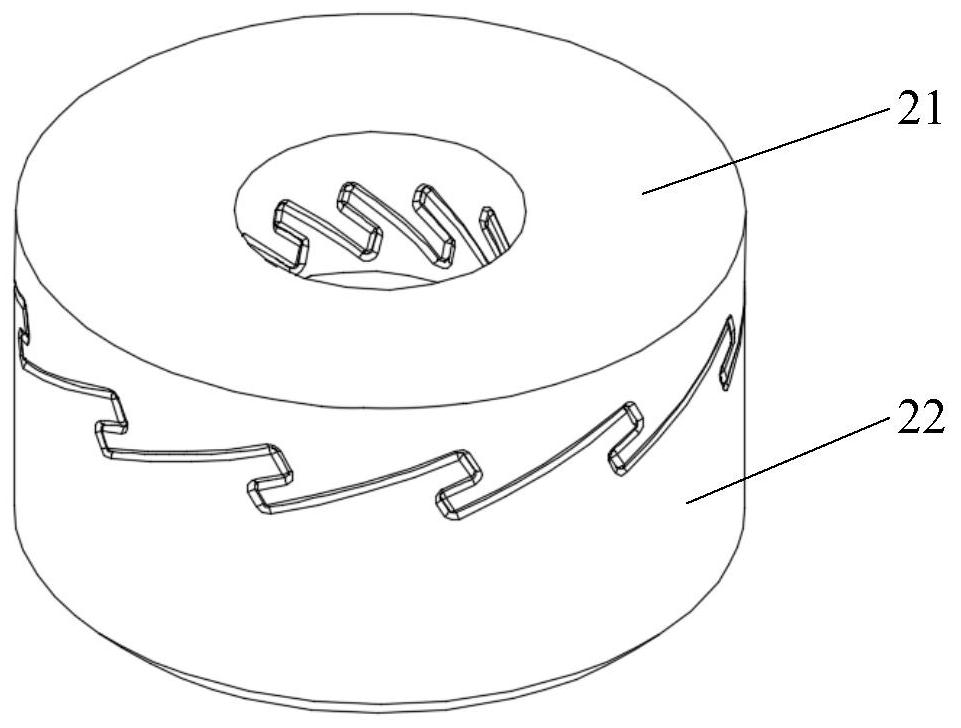

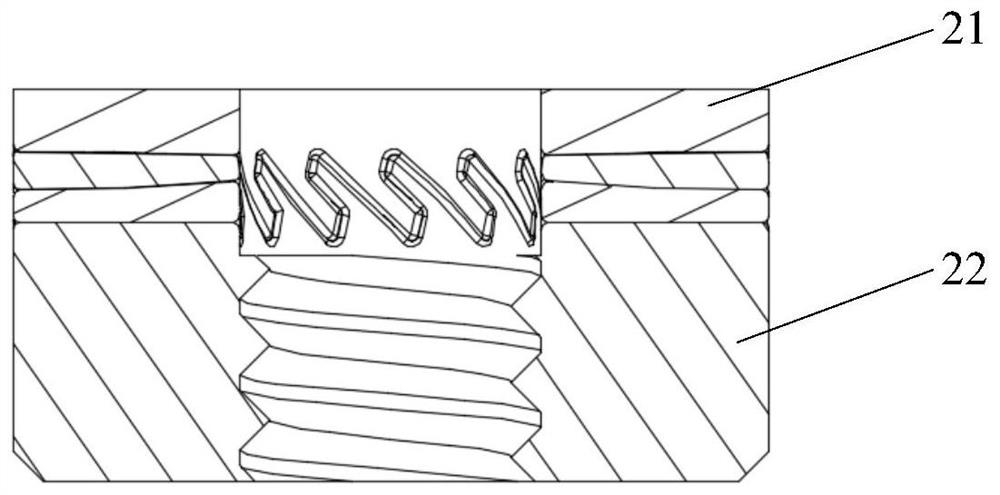

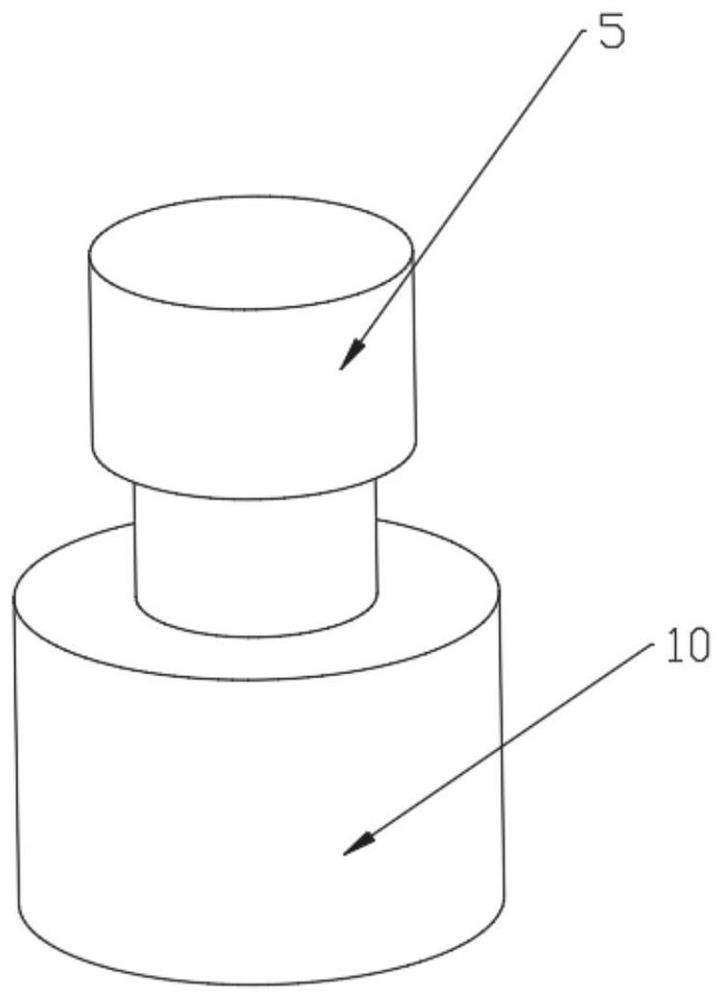

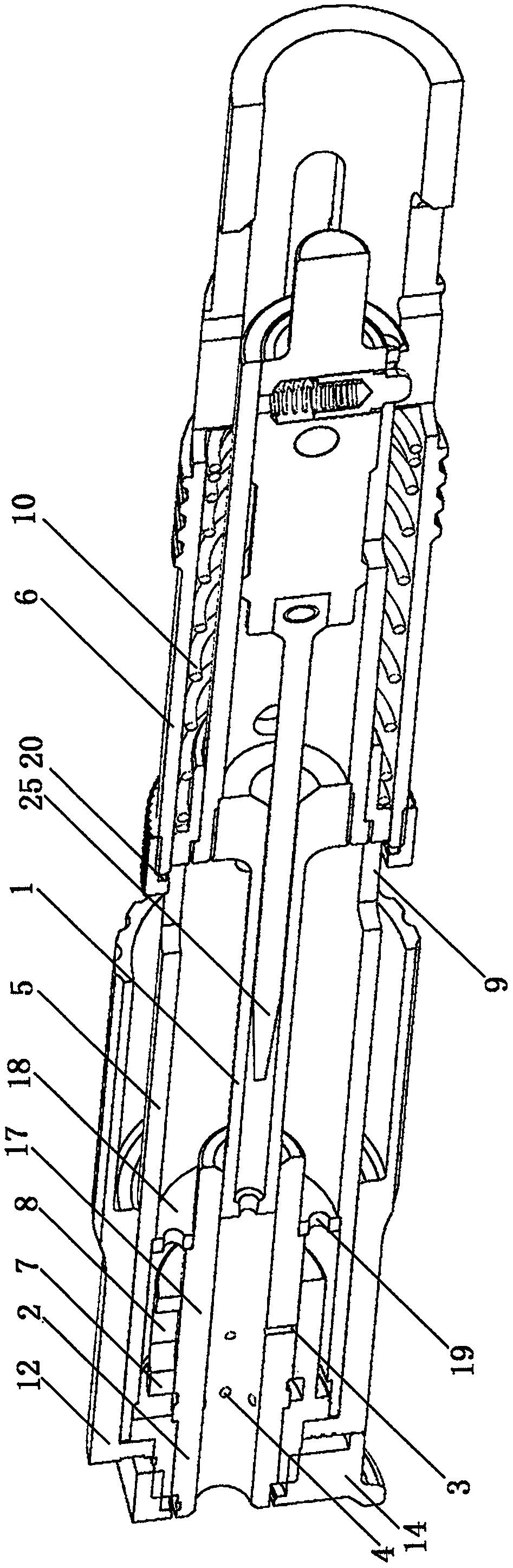

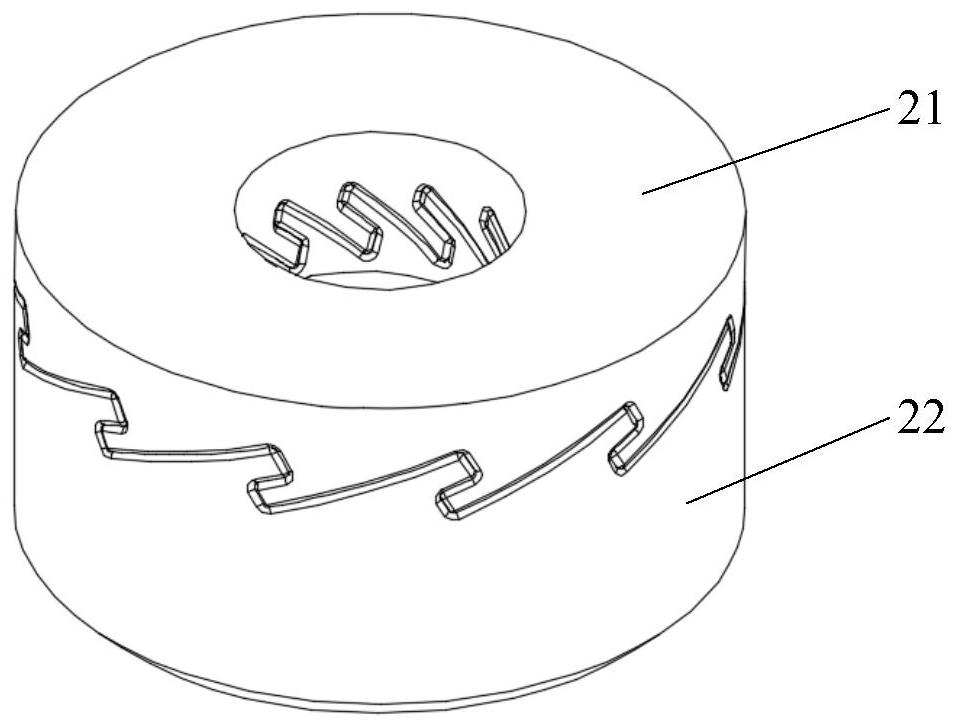

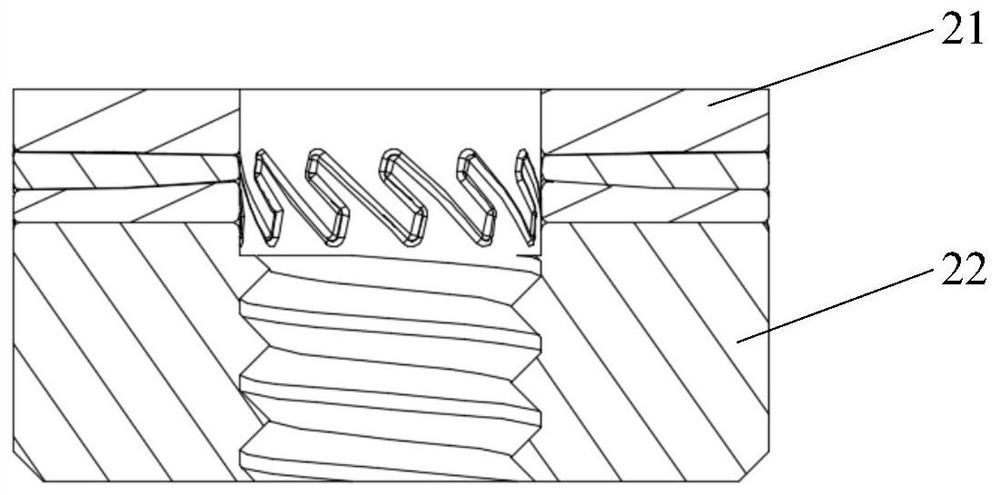

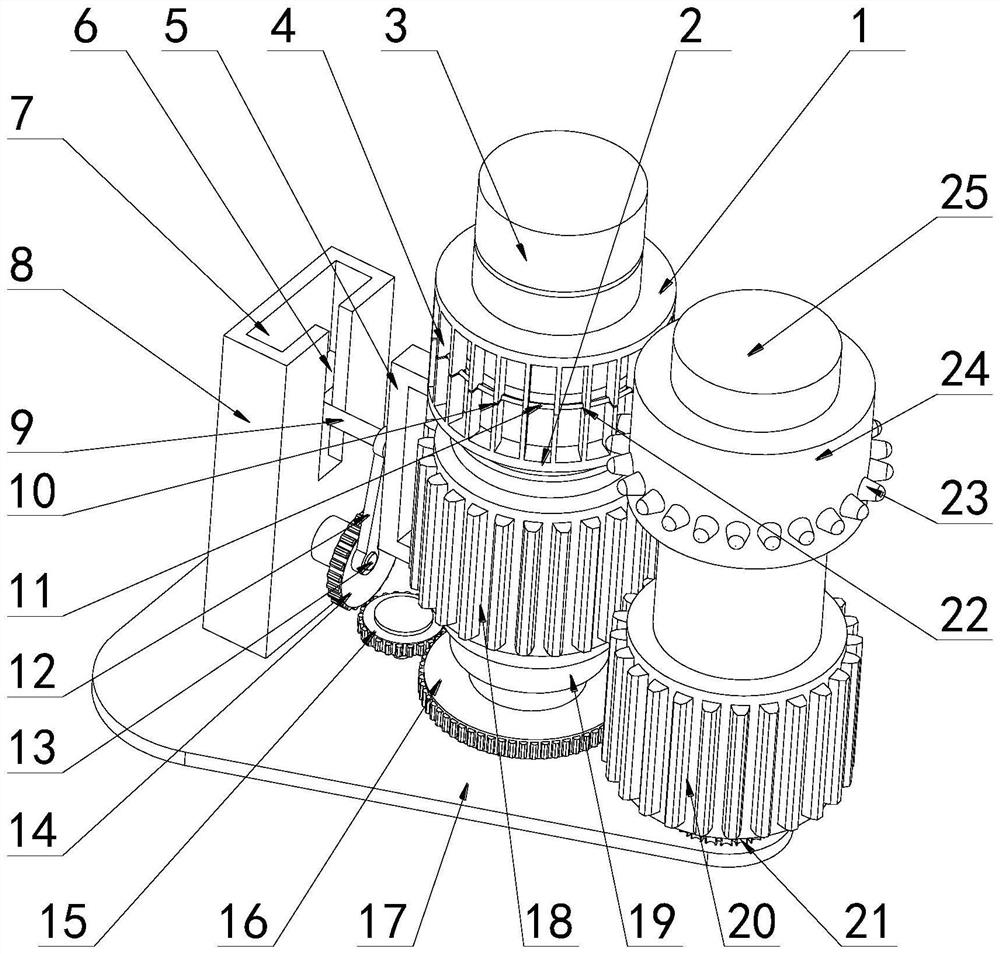

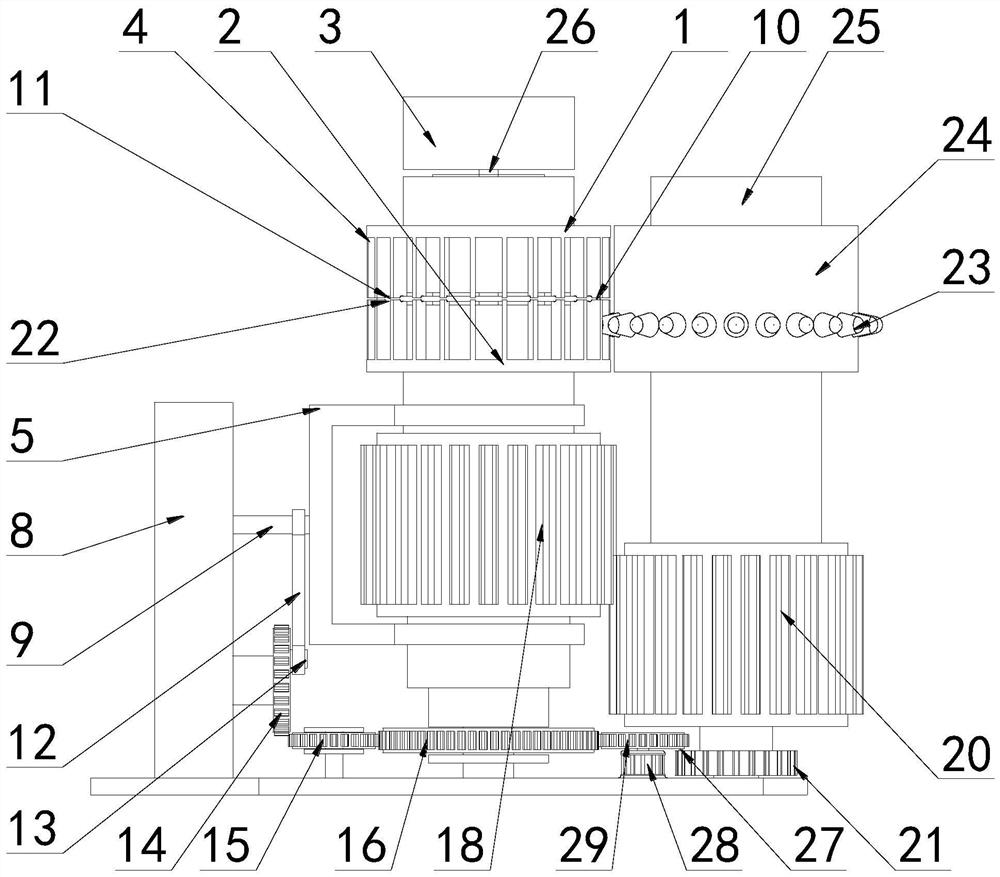

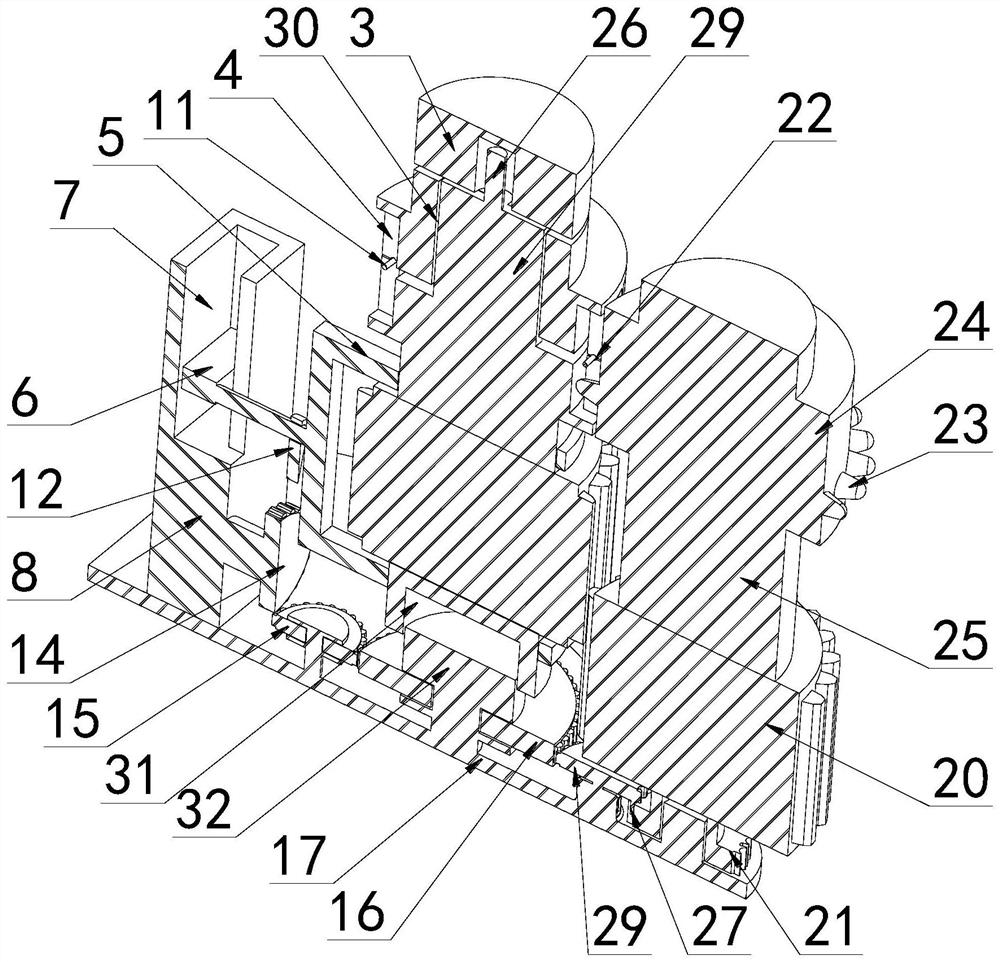

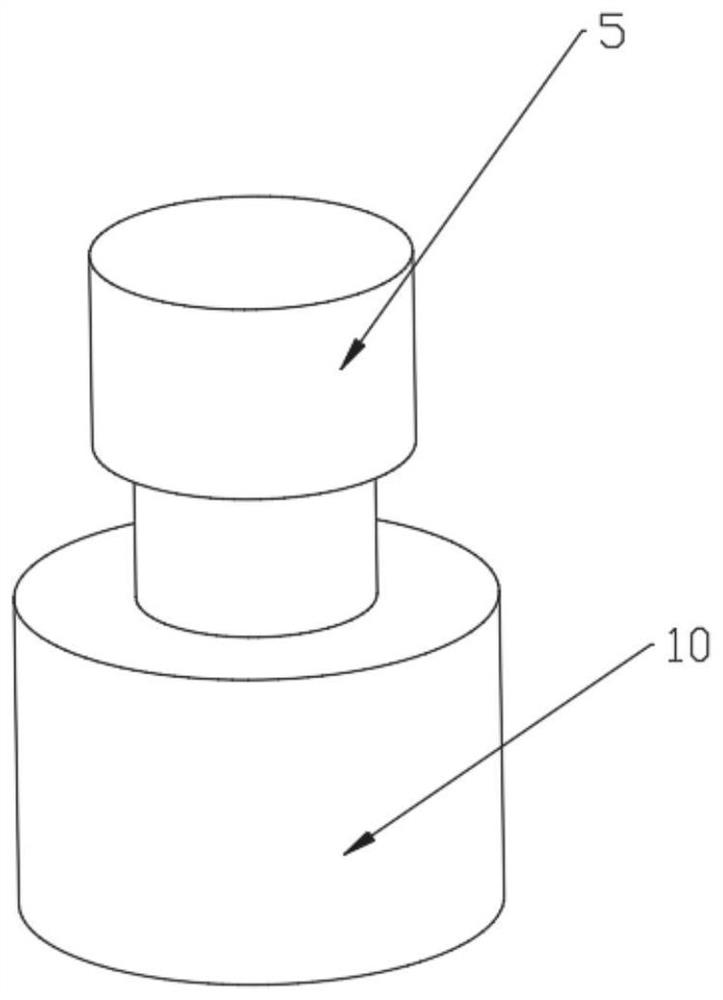

Planetary pin roller lead screw

ActiveCN111779810AAchieve planetary motionAchieve translational movementGearingRoller screwGear wheel

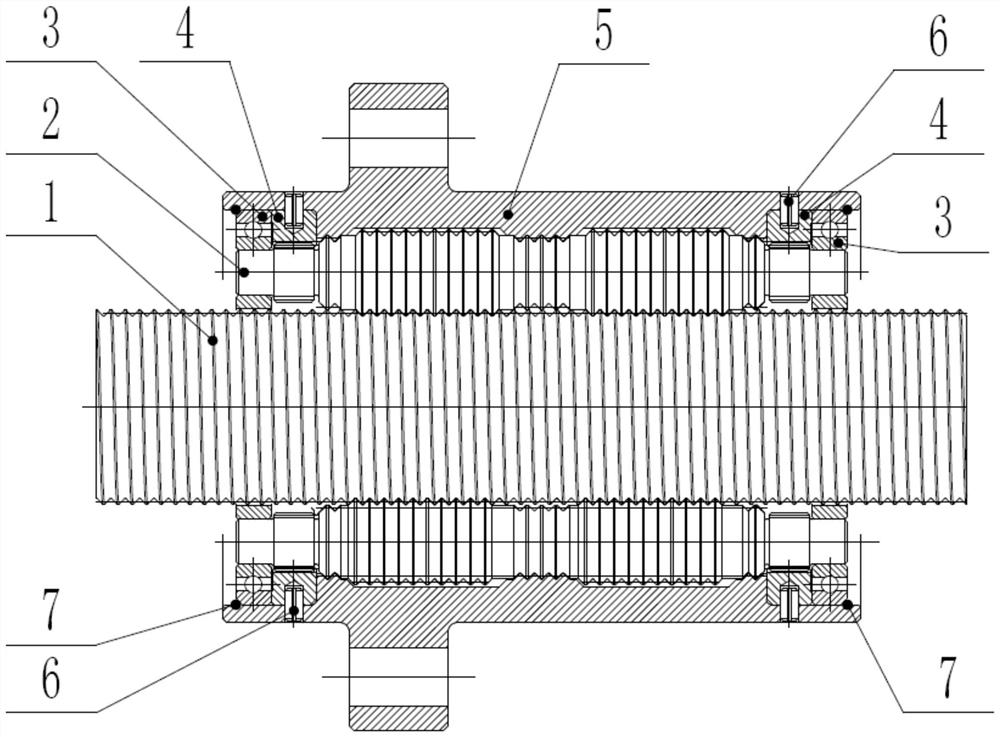

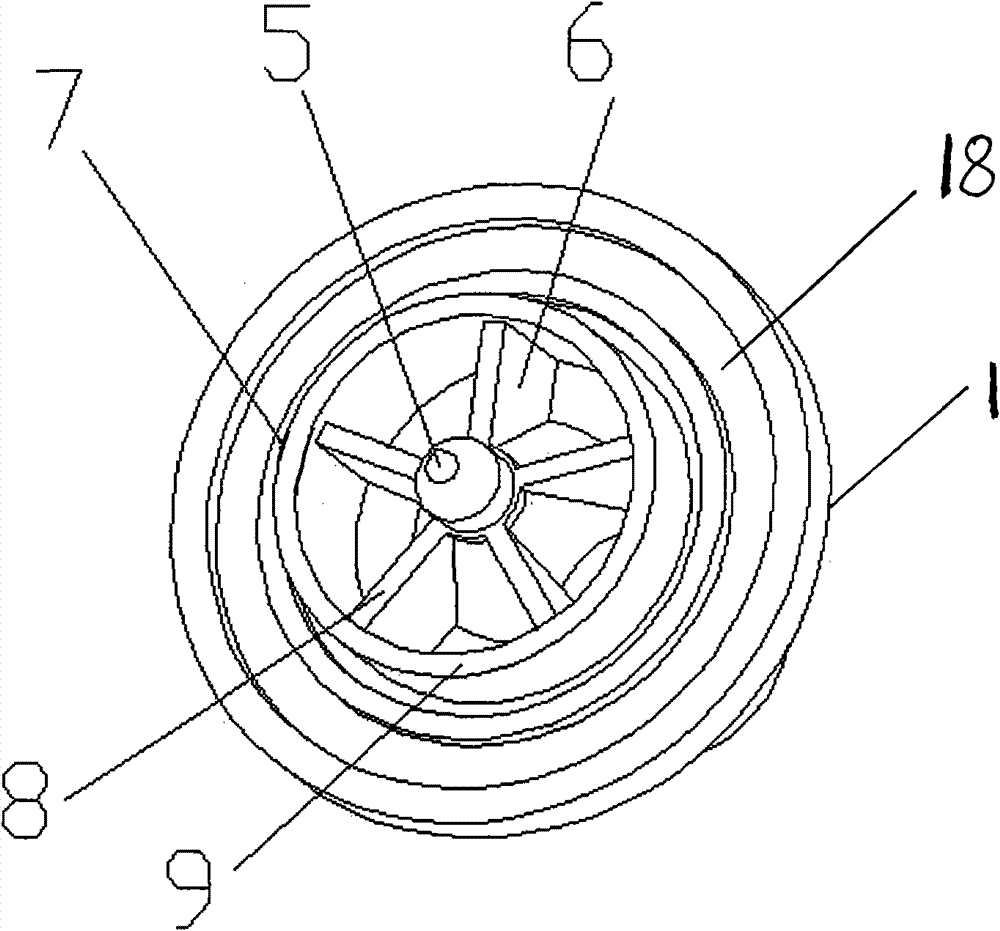

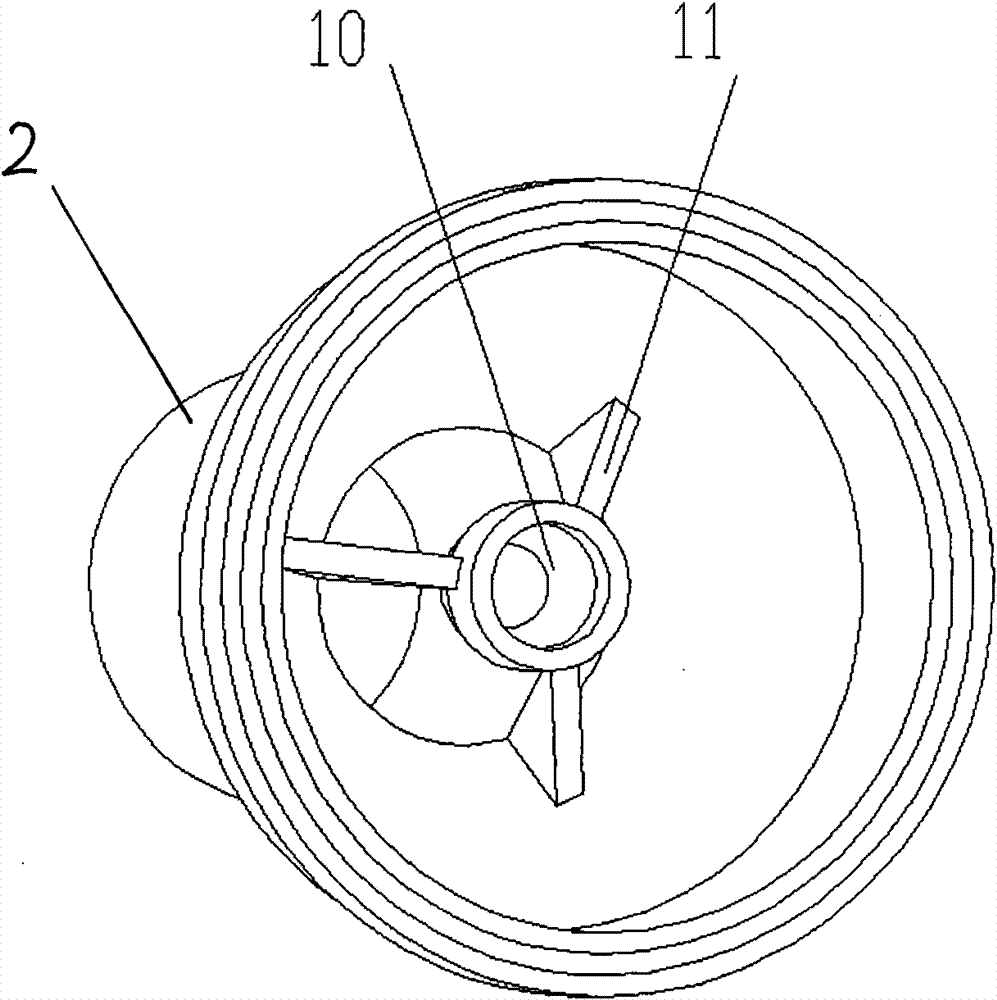

The invention relates to a planetary pin roller lead screw, and belongs to the field of pin roller lead screw design. The planetary pin roller lead screw comprises a lead screw body, two inner gear rings, a nut, two bearing retainers, two steel wire locking rings, N pin rollers and a positioning pin. The N pin rollers are evenly distributed circumferentially on the outer wall of the lead screw body; the outer wall of the lead screw body is sleeved with the two bearing retainers; the two bearing retainers are located at the two axial ends of the pin rollers respectively; the two axial ends of the pin rollers extend into the two bearing retainers respectively; the two inner gear rings sleeve the outer walls of the two axial ends of the N pin rollers respectively; the nut sleeves the outer walls of the N pin rollers; the nut is fixedly connected with the inner gear rings through the positioning pin; and the two steel wire locking rings are arranged at the axial outer ends of the contact positions of the corresponding bearing retainers and the nut. Axial limiting is realized. The lead screw integrates characteristics of planetary gear transmission and threaded transmission, and converts the rotary motion into the linear motion.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

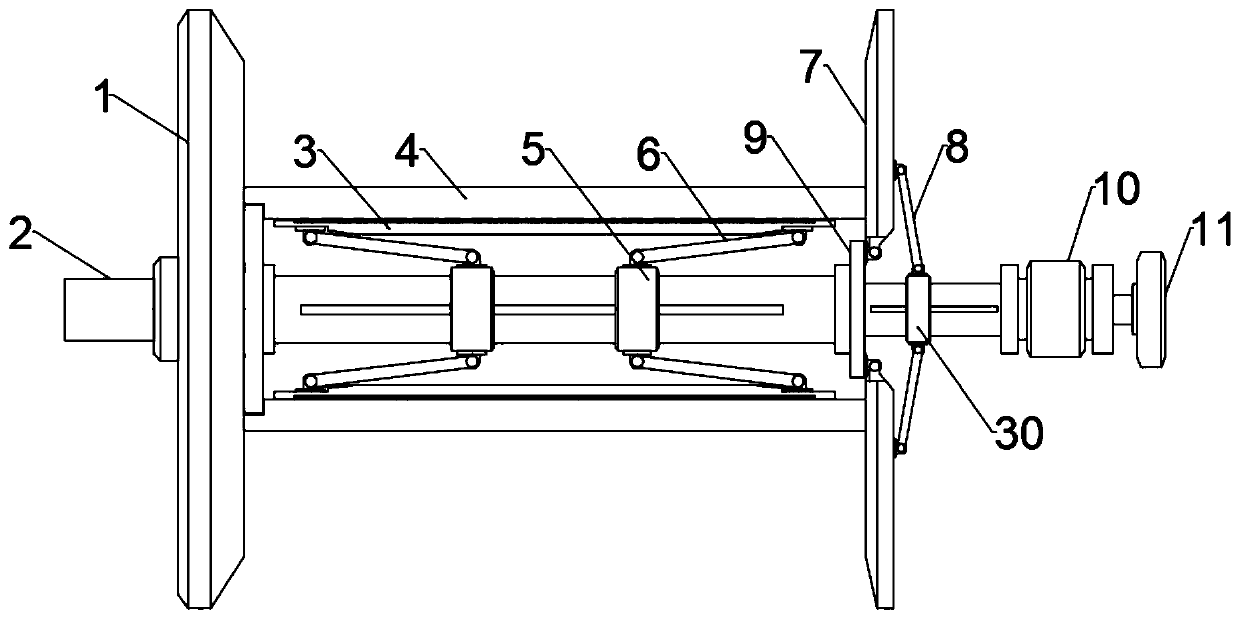

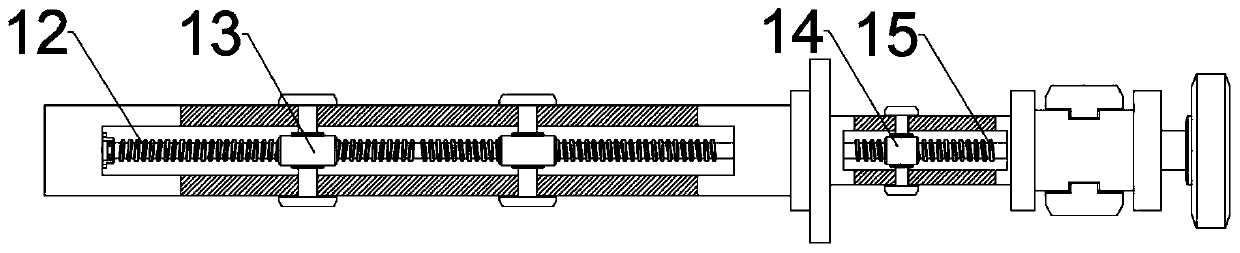

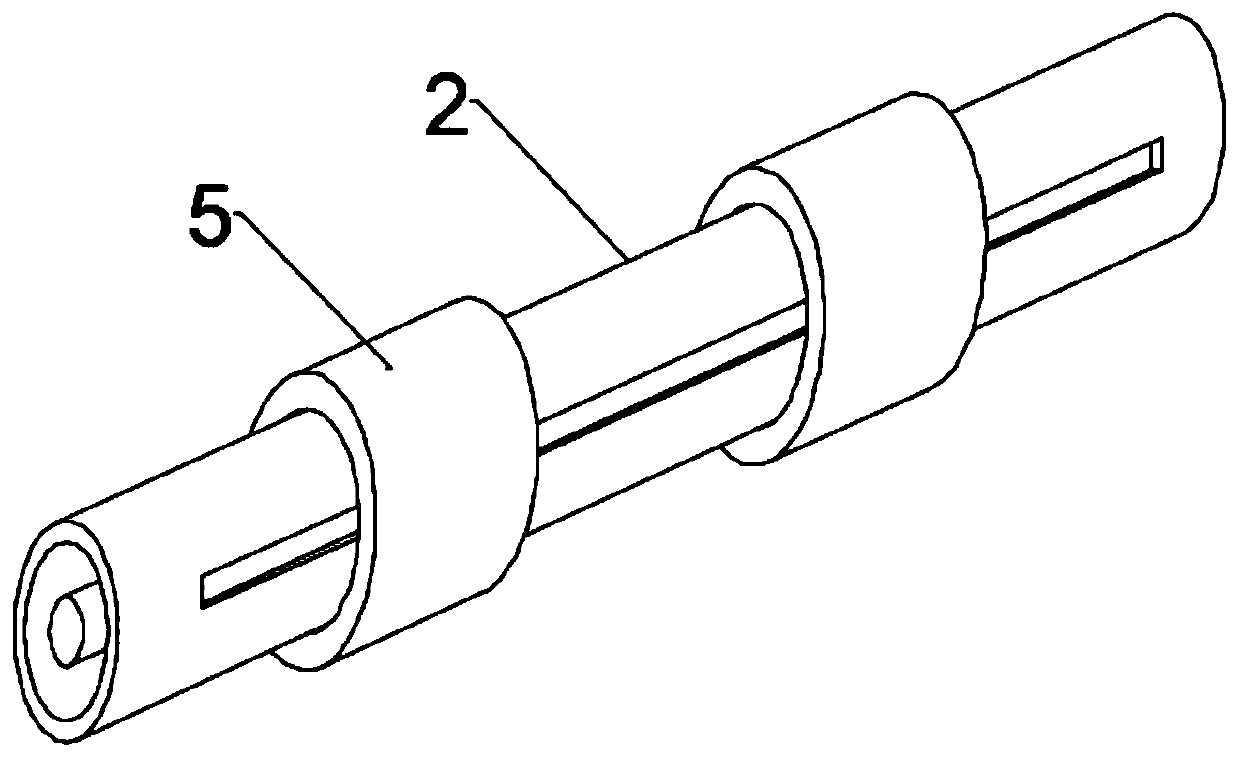

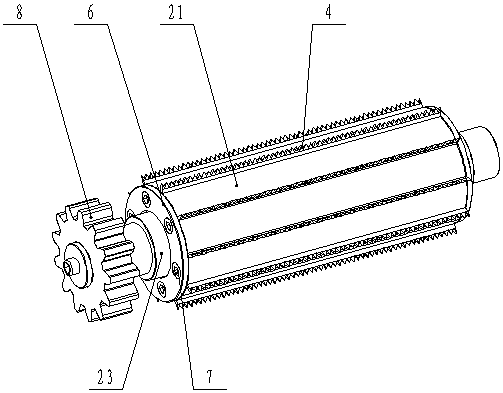

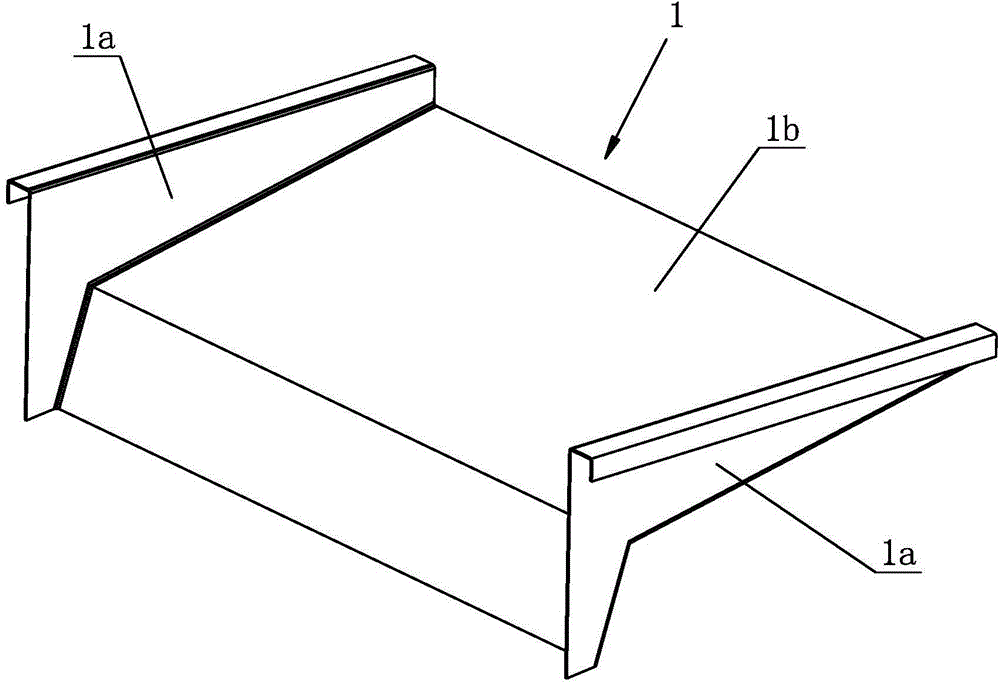

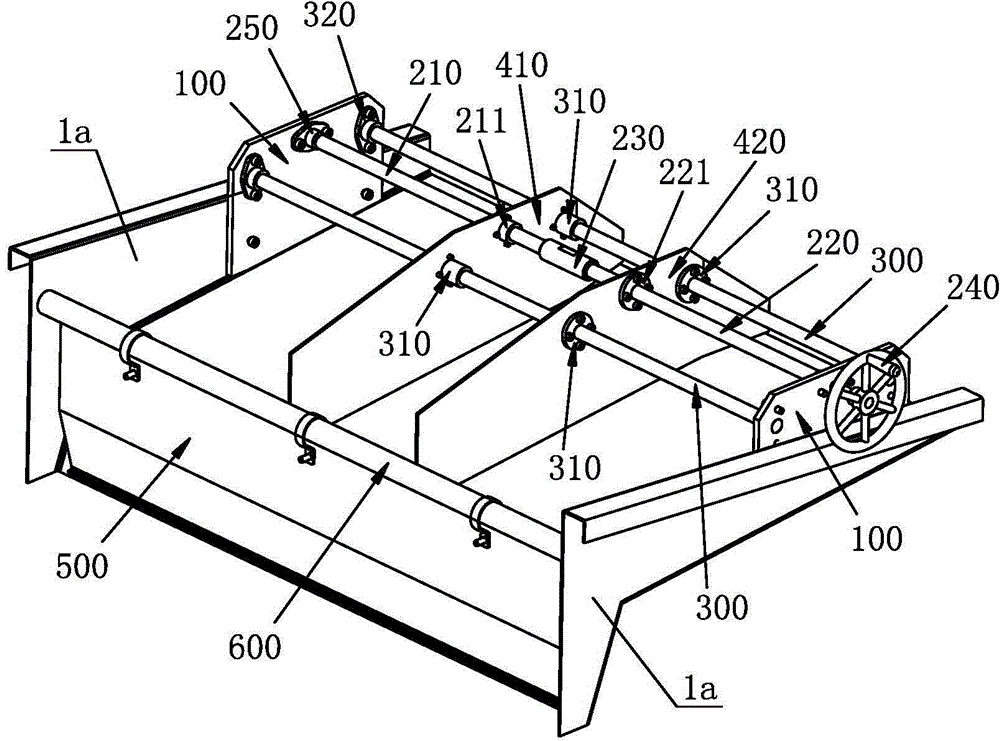

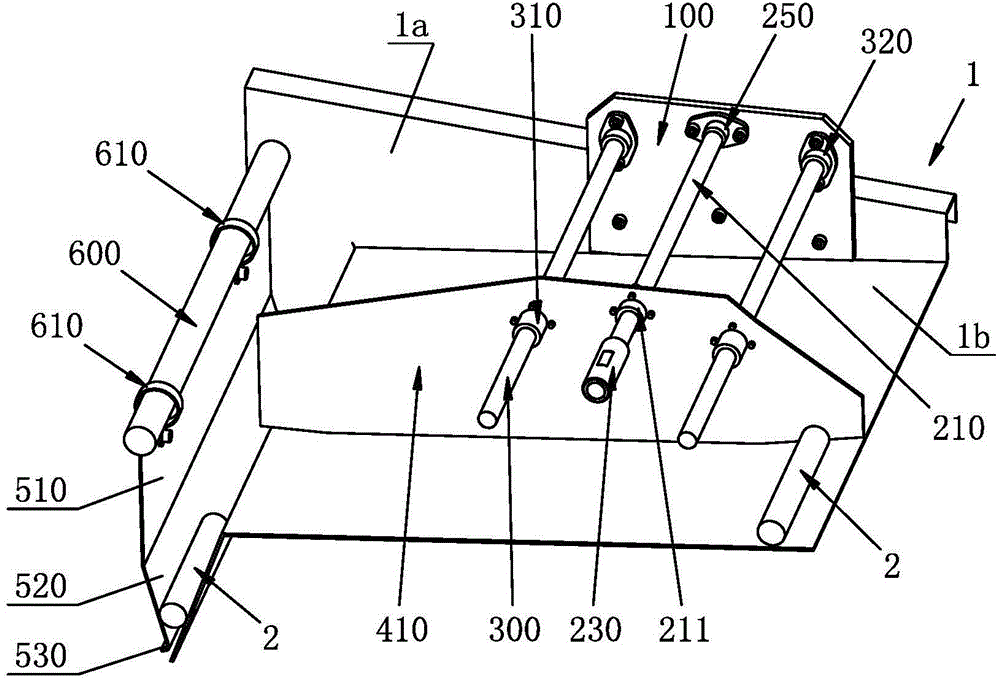

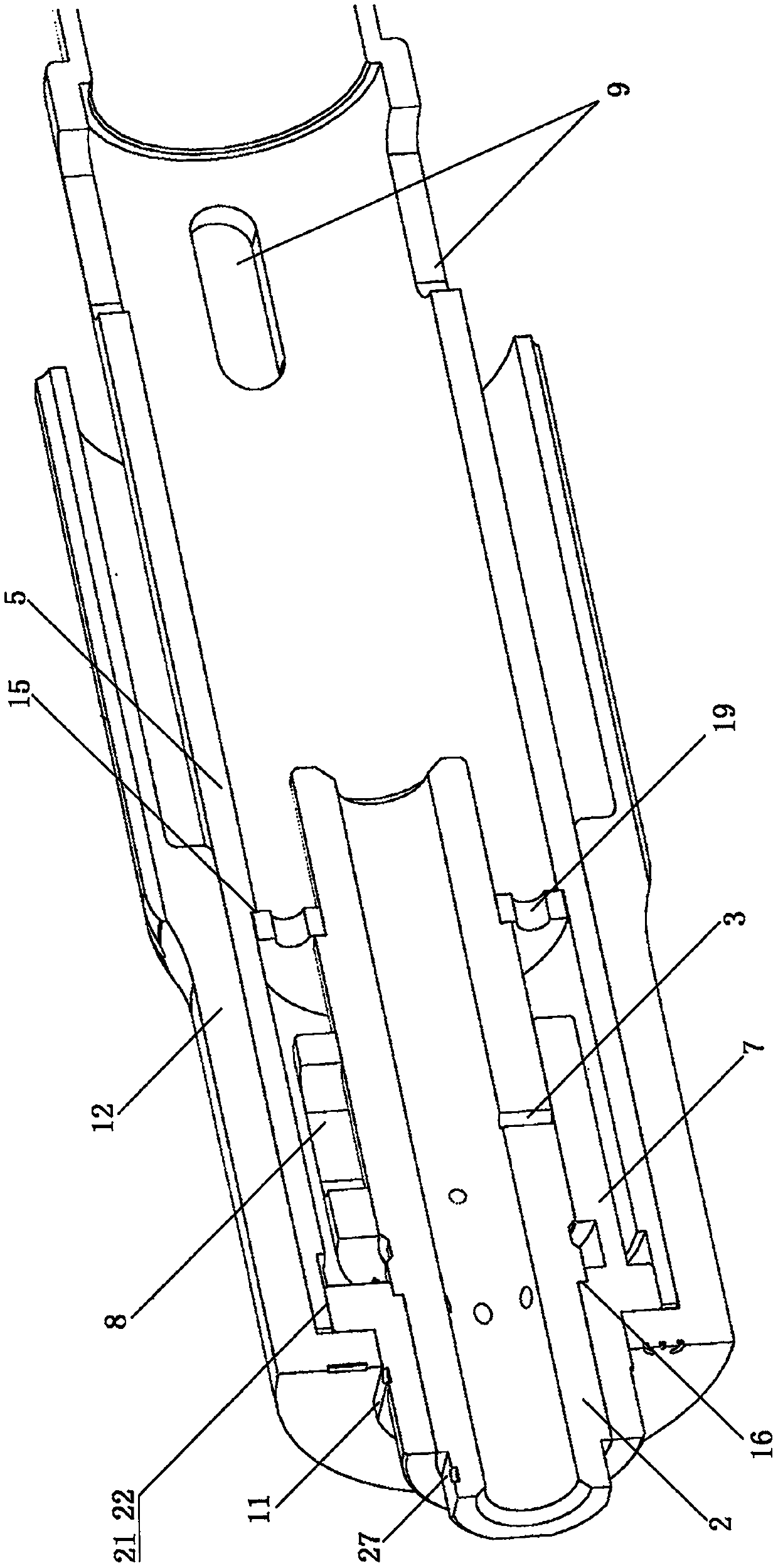

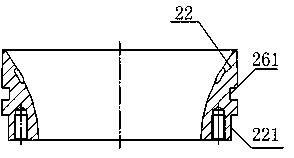

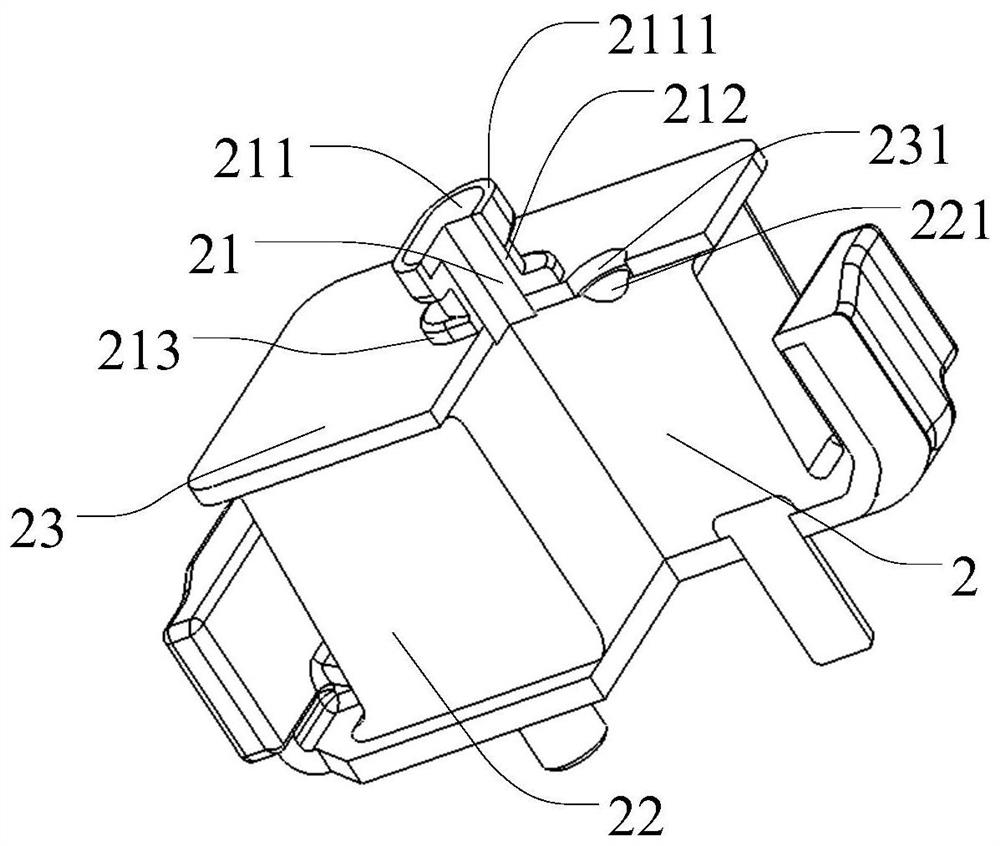

Take-up roller structure, take-up mechanism and textile equipment

InactiveCN111483879ARealize radial limitRealize axial limitFilament handlingStructural engineeringMechanical engineering

The invention relates to the technical field of textile, in particular to a take-up roller structure, a take-up mechanism and textile equipment. The take-up roller structure comprises a rotary shaft,a baffle plate, a wire roller, a resisting assembly, a pressing assembly and a regulating mechanism, wherein the baffle plate is fixed to one end of the rotary shaft; the wire roller sleeves the rotary shaft; the resisting assembly is mounted on the rotary shaft, and abuts against the inner wall of the wire roller; the pressing assembly is mounted at one end, away from the baffle plate, of the rotary shaft; the pressing assembly is matched with the baffle plate for axially limiting the wire roller; the regulating mechanism is mounted at one end of the rotary shaft and is connected to the resisting assembly and the pressing assembly; the wire roller sleeves the rotary shaft, and one end of the wire roller abuts against the baffle plate; the regulating mechanism drives the resisting assemblyand the pressing assembly to synchronously move, so that radial limiting and axial limiting of the wire roller are realized, and therefore, connecting stability between the wire roller and the rotaryshaft is ensured, and the wire roller can be effectively prevented from rotating relative to the rotary shaft.

Owner:徐州华通手套有限公司

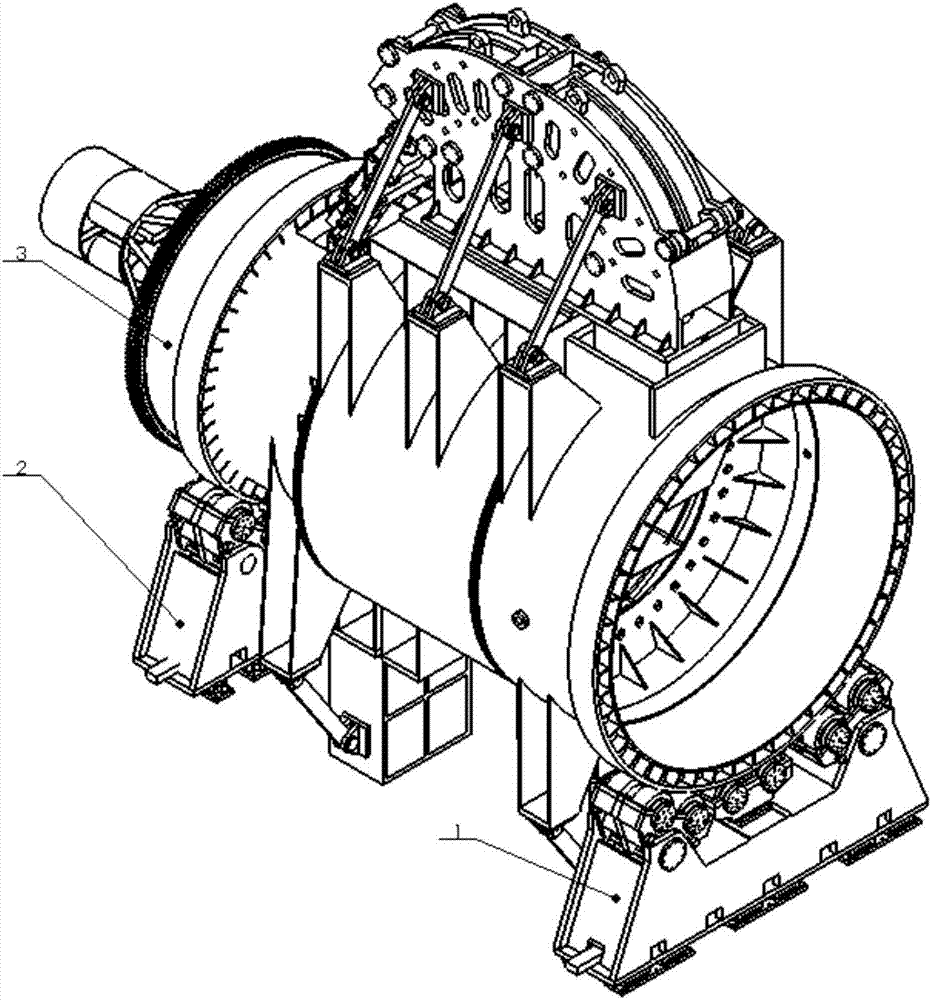

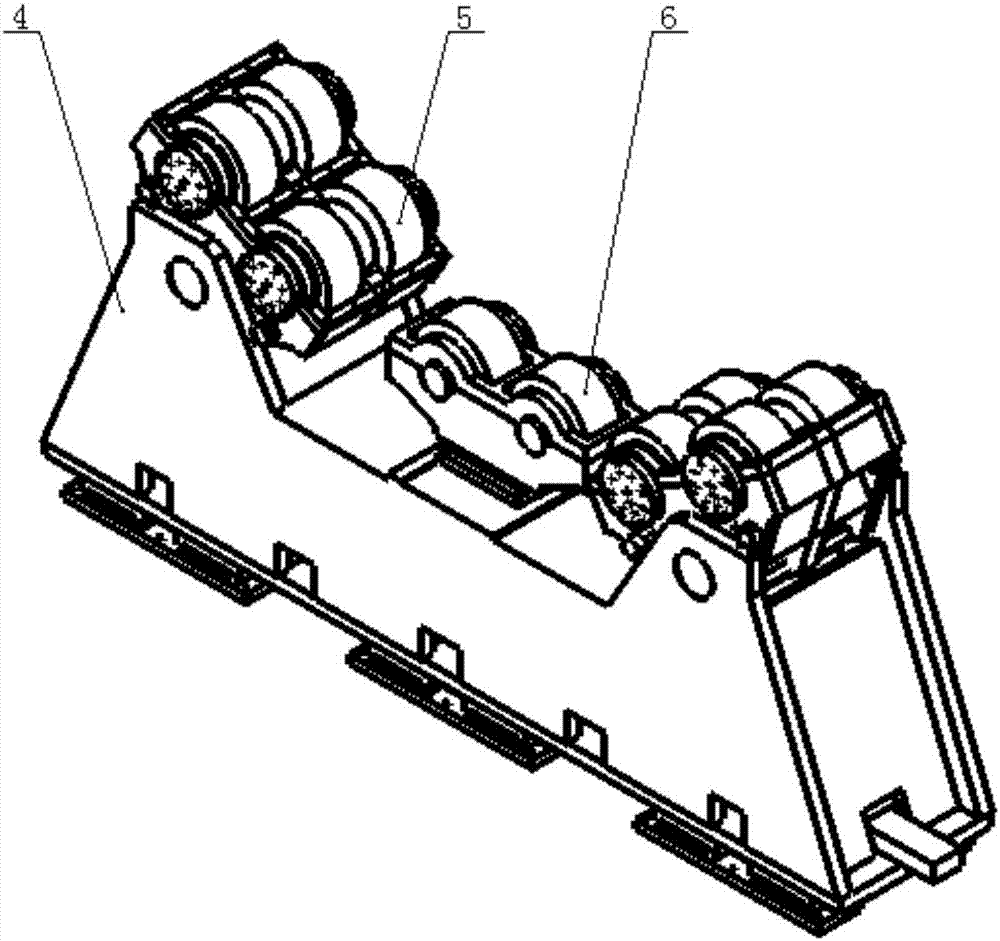

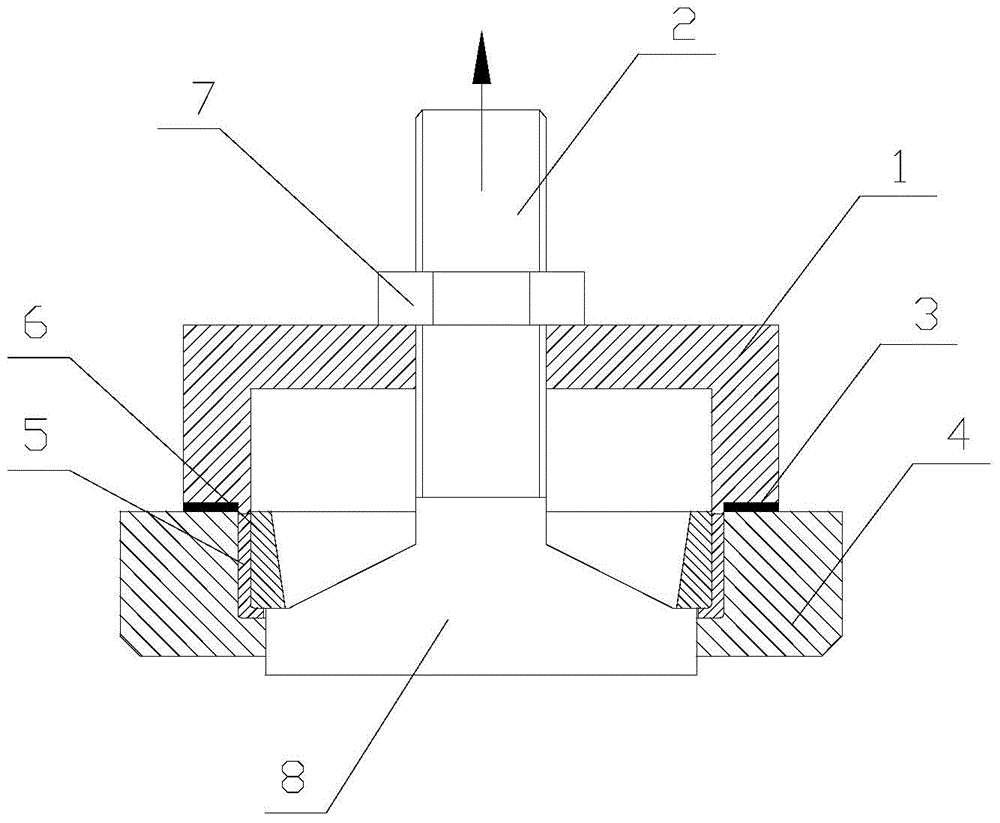

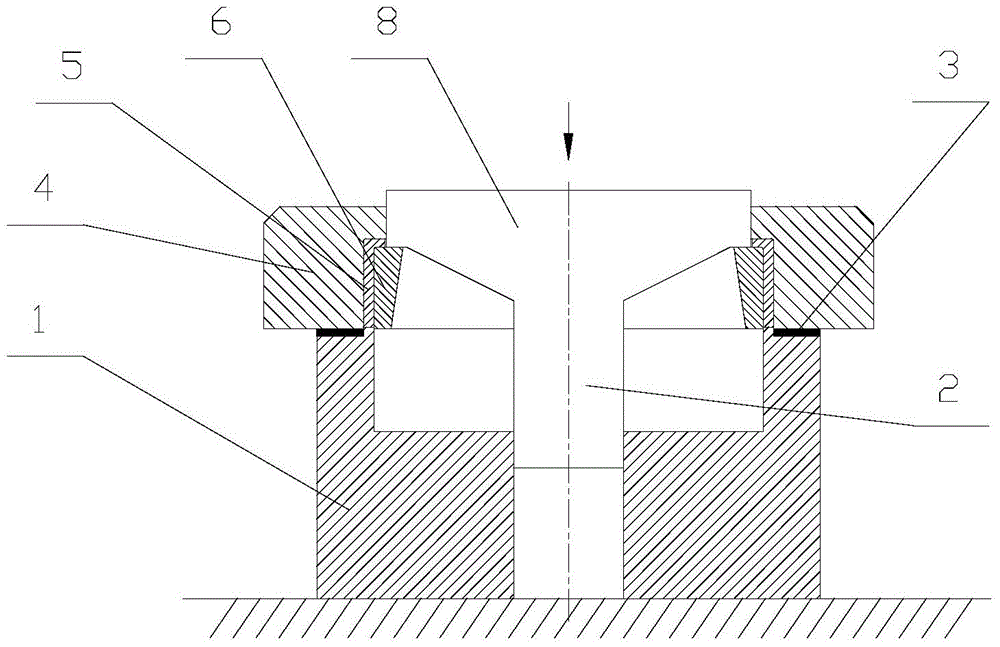

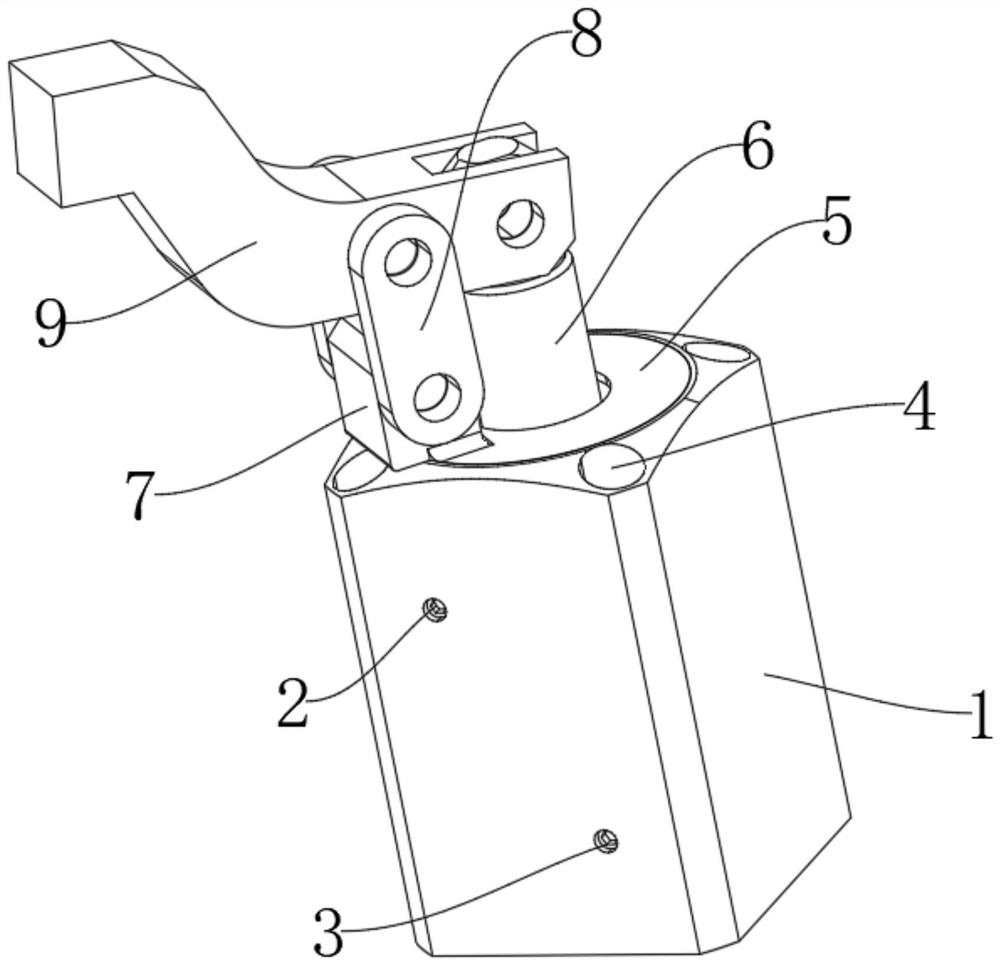

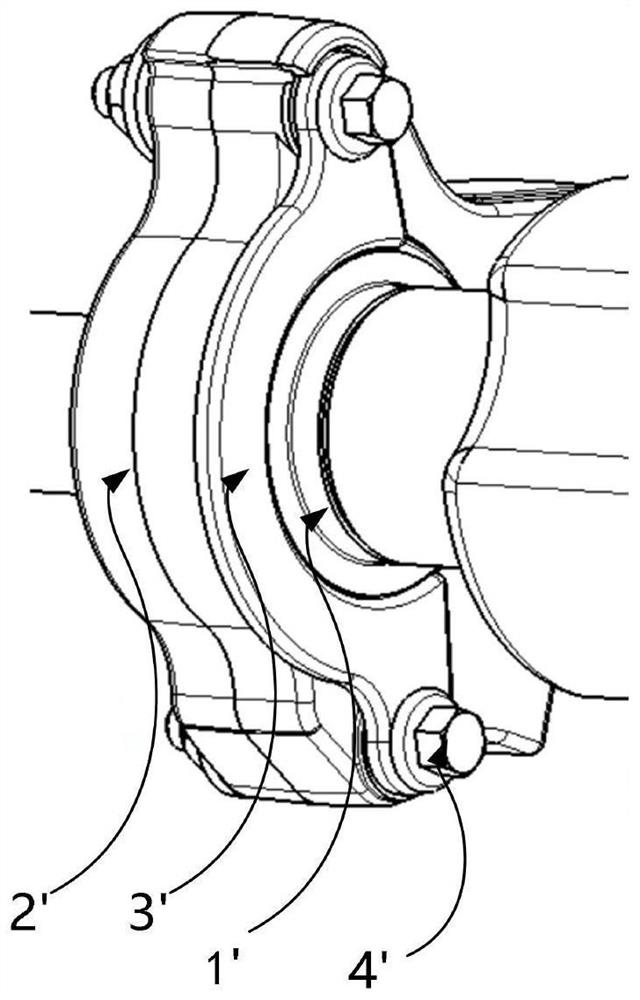

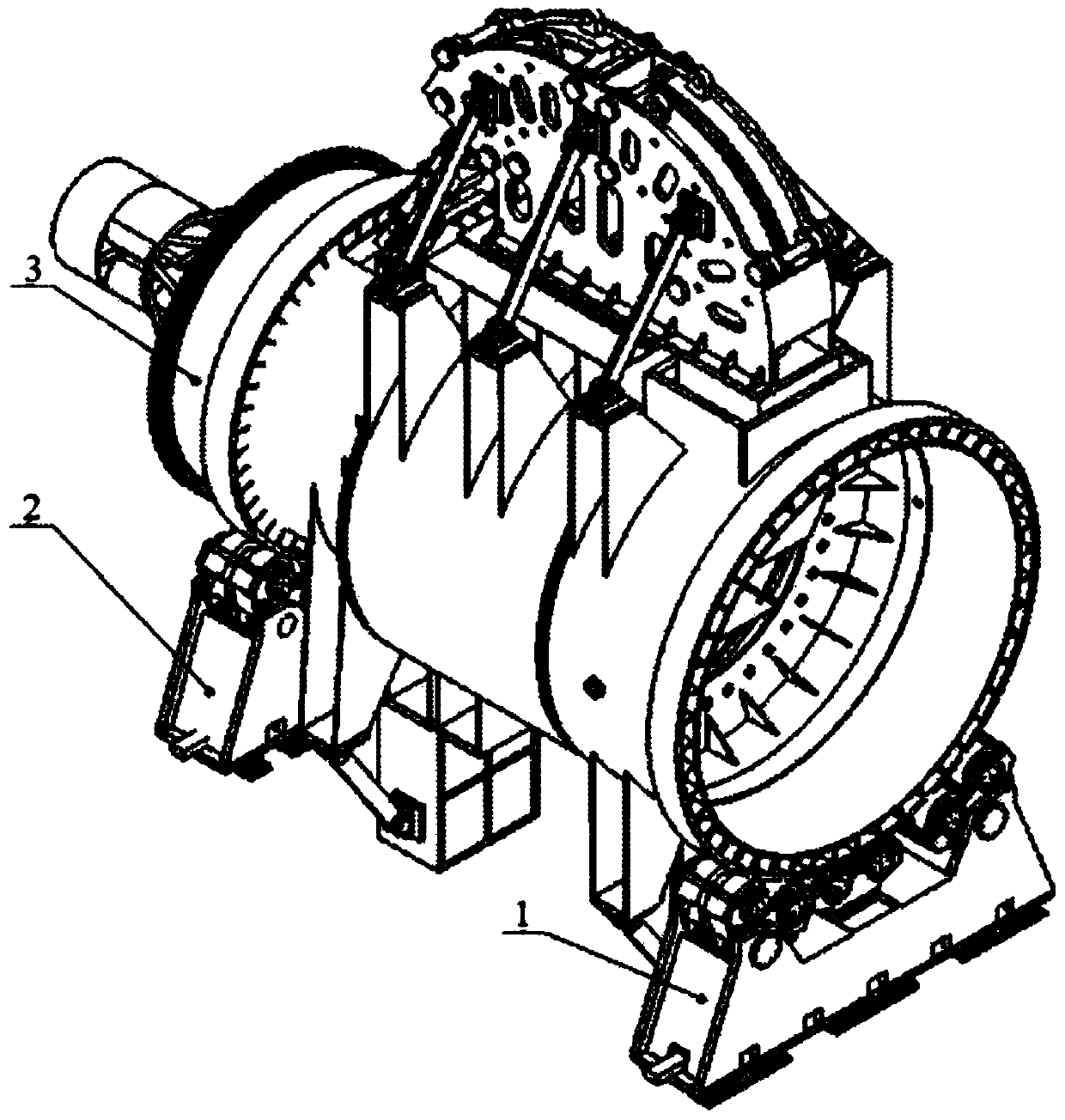

Supporting device of rolling wheel of rotary rack of radiation oncology equipment

ActiveCN107477311AReduce installation difficultyExtend your lifeMachine framesRadiation therapyEngineeringAxial force

The invention belongs to the field of radiation oncology equipment, and discloses a supporting device of rolling wheels of a rotary rack of radiation oncology equipment. The supporting device of the rolling wheels of the rotary rack of the radiation oncology equipment comprises a supporting base and a bearing wheel supporting assembly, the bearing wheel supporting assembly comprises a supporting box body and a tapered bearing wheel rolling path assembly which is arranged on the supporting box body, the tapered bearing wheel rolling path assembly comprises two sets of tapered bearing wheel supporting units, and each set of tapered bearing wheel supporting units comprises a bearing wheel shaft, a tapered bearing wheel, a bearing wheel end cover and a box body end cover. According to the supporting device of the rolling wheels of the rotary rack of the radiation oncology equipment, the mounting difficulty of the bearing wheel shafts can be lowered by utilizing the two bearing wheel shafts to support a tapered bearing shaft; meanwhile, the two tapered bearing wheels are utilized and each tapered bearing wheel is internally provided with a self-aligning bearing, and the self-aligning function can be achieved in the mounting process; in addition, axial limitation of the rotary rack can be achieved by utilizing the tapered bearing wheels, the self-aligning bearing can only bear the radial force through force transmission, the axial force is borne by a self-aligning thrust roller bearing, and accordingly the life of the self-aligning bearing can be prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Axial limiting structure of collecting ring of electromotor

InactiveCN102480193ASimple structureEasy to implementDynamo-electric machinesEngineeringConductor Coil

The invention discloses an axial limiting structure of a collecting ring of an electromotor. The axial limiting structure is arranged on an electromotor rotor assembly mainly comprising a rotor shaft, a collecting ring and an electromagnetic winding, wherein the collecting ring is sleeved at the left end of the rotor shaft; a ring groove is formed at the position of the left end surface of the collecting ring of the rotor shaft; and a circlip for a shaft is embedded in the ring groove to form the axial limiting structure of the collecting ring. The axial limiting structure disclosed by the invention has a simple structure and is simple in process and easy in realization; and the circlip for the shaft is adopted for axially limiting, so that the phenomena of loosening and falling can be avoided and the axial limiting of the collecting ring of the electromotor can be reliably realized.

Owner:TAIZHOU CITY YUANDA ELECTRIC MOTOR MFG

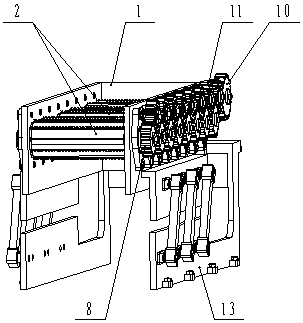

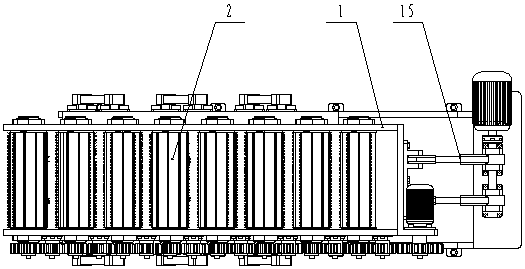

Hemp thread removal device of tobacco products

PendingCN109351586AAchieve sticky hookEfficient removal of impuritiesTobacco preparationSievingDrive wheelEngineering

The invention discloses a hemp thread removal device of tobacco products. The device comprises an impurity removal roller way arranged in a conveying groove of a vibration conveyor, an impurity removal roller is formed through combined arrangement of thread impurity removal rollers, the thread impurity removal rollers are of split type roller structures and comprise roller bodies arranged on roller shafts in a sleeving manner and each formed through abut joint of two half roller bases, multiple discharging racks made of elastic materials are evenly distributed on the roller faces of the rollerbodies in the circumference direction, the thread impurity removal rollers are arranged on the conveying groove through the corresponding roller shafts and matched bearings, transmission gears are fixedly arranged on roller shaft ends, located on the same side, of the thread impurity removal rollers, the transmission gears are in transmission connection with a drive mechanism, the drive mechanismcomprises a driving wheel and multiple driven wheels distributed on the outer wall of the conveying groove, and the driven wheels are located between two adjacent transmission gears and are in engaged connection with the transmission gears on two sides adjacent to the driven wheels. Threads such as hemp ropes and hemp browns can be subjected to efficient impurity removal and eliminating, and thedamage to the tobacco leaves can be reduced.

Owner:CHINA TOBACCO HENAN IND

Mounting method of torsion bar component and torsion bar component mounting structure

ActiveCN110254459ASimple structureDoes not affect the reliability of useBogiesBogie-underframe connectionsOccupancy rateBogie

A mounting method of a torsion bar component is characterized in that a mounting hole corresponding to the torsion bar component is machined in a framework of a bogie; the torsion bar component transversely penetrates through the mounting hole, and the torsion bar component is connected with the mounting hole in the form of interference fit; a stopper used for axially limiting the torsion bar component is arranged in the mounting hole; and the stopper is in contact with the torsion bar component in an abutting manner. According to the mounting method of the torsion bar component, as the torsion bar component is directly mounted on the framework, a supporting seat component in an anti-roll torsion bar system is eliminated, the structure of an anti-roll torsion bar component is simplified, the production cost is reduced, the use reliability of the torsion bar component is not affected in the case of guaranteeing that the supporting seat component is eliminated, the connection between the torsion bar component and the framework is easy to realize, the connecting mode is simpler, the labor intensity of mounting the torsion bar component on the framework can be effectively reduced, and moreover, the space occupancy rate of the a connecting structure between the torsion bar component and the framework is small, and the structural compactness of the connecting structure between the torsion bar component and the framework is high. The invention further provides a torsion bar component mounting structure.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

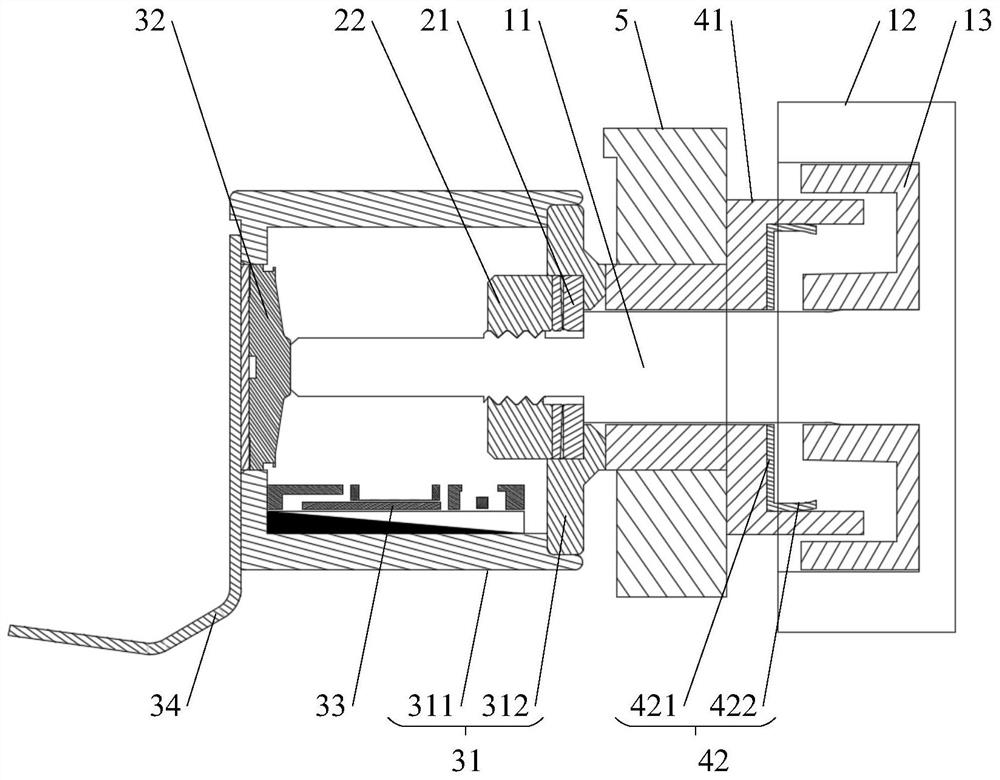

Watch crown and wrist-wearing equipment with watch crown

ActiveCN112433460AEasy to assembleReduce complexityMechanical devices for setting timeMechanical engineeringEngineering

The invention discloses a watch crown and wrist-wearing equipment with the watch crown. The watch crown comprises a key rod provided with an external thread, a body, a non-loosening nut and a second non-loosening nut, wherein the body is used for being fixedly connected with the inner side of the watchcase, and the body is provided with a first insertion hole for allowing the key rod to be inserted; the first non-loosening nut is fixedly arranged on the body; the second non-loosening nut and the first non-loosening nut are locked in a one-way mode, the second non-loosening nut is provided withan internal thread used for being connected with the external thread in a matched mode, and the screwing direction of the external thread and the internal thread is the same as the locking directionof the first non-loosening nut and the second non-loosening nut; and the second non-loosening nut can be assembled on the body in advance through the first non-loosening nut, then the key rod is installed, the second non-loosening nut does not affect assembly of the key rod, axial limiting of the key rod can be achieved, and the effect of blind installation of the key rod is achieved. And comparedwith the prior art, by using the watch crown and the wrist-wearing equipment of the invention, assembling is convenient, and the assembling complexity is reduced. The wrist-wearing equipment comprises the watch crown and has the above beneficial effects.

Owner:西安歌尔泰克电子科技有限公司

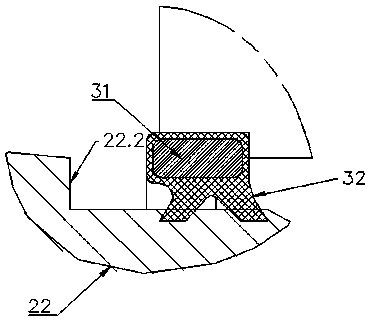

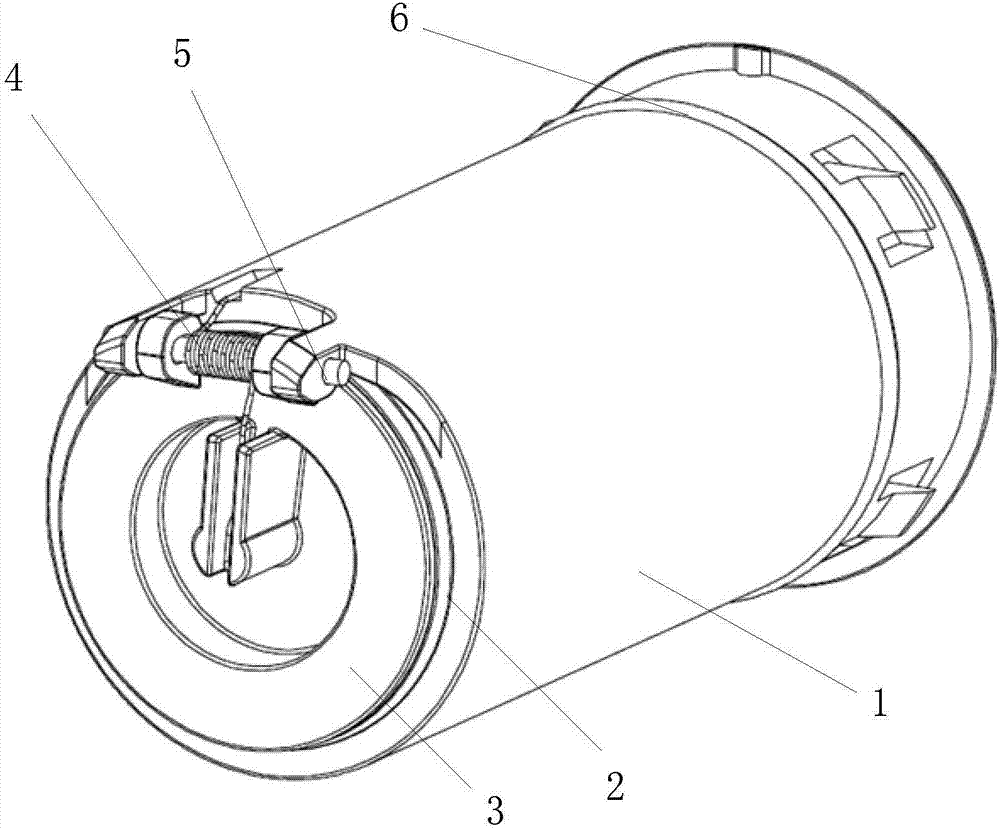

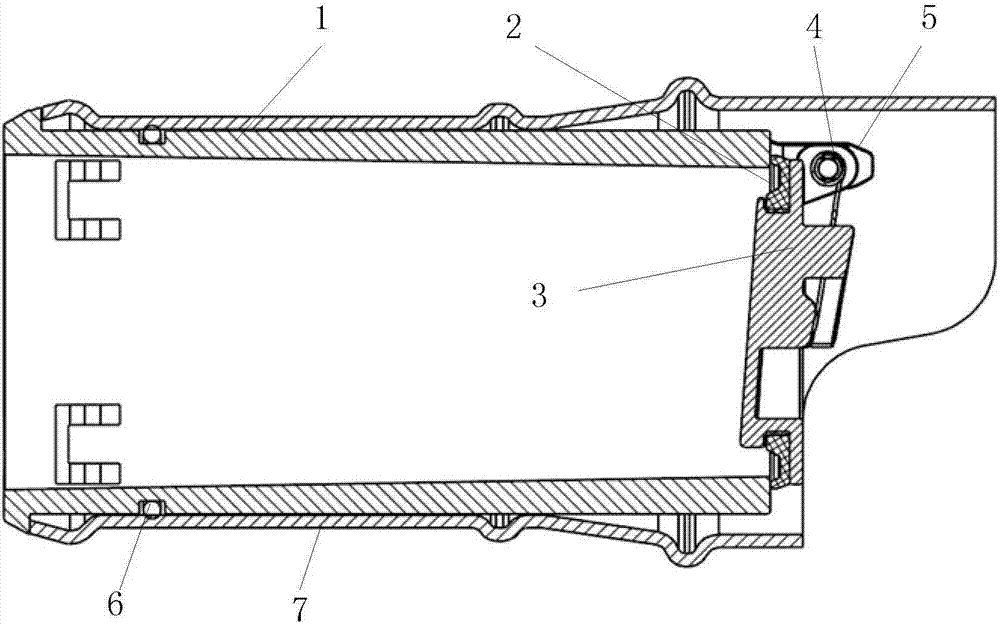

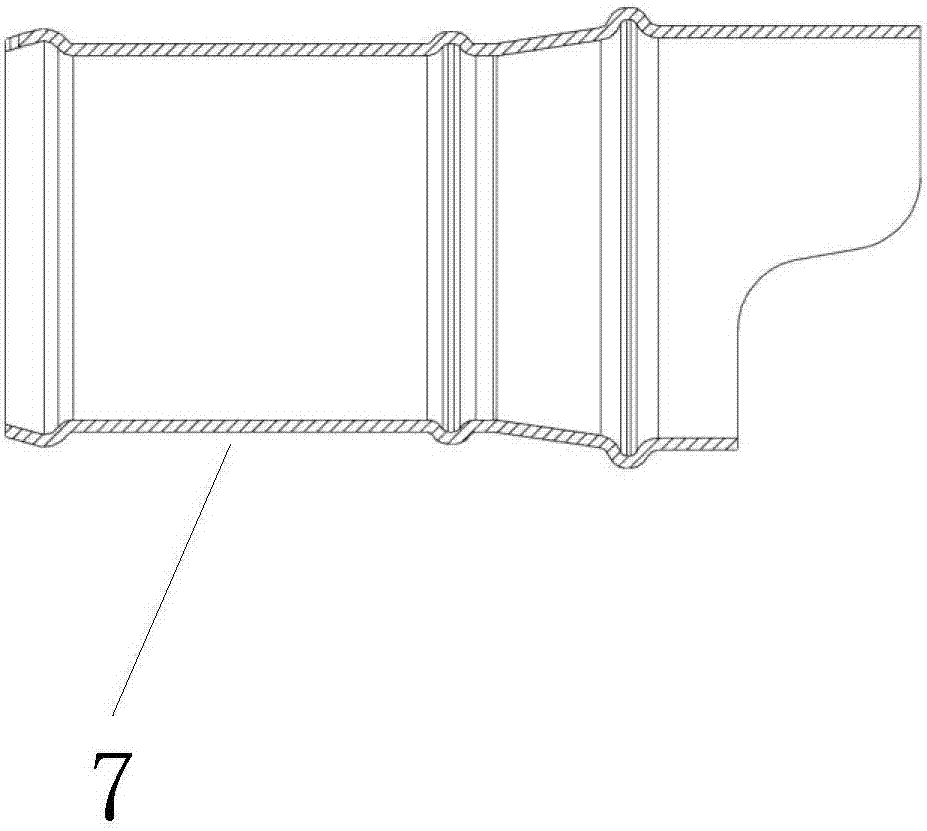

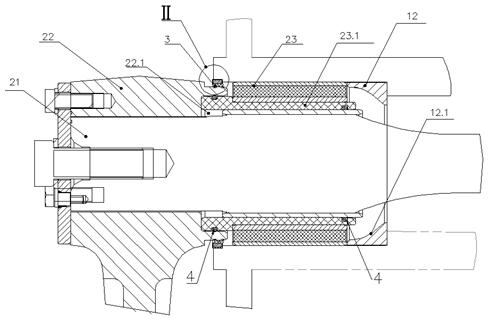

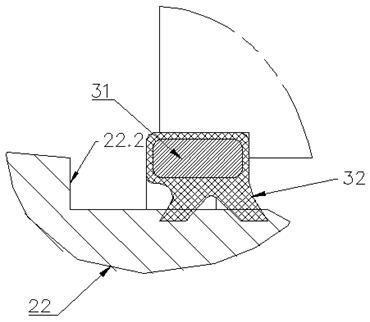

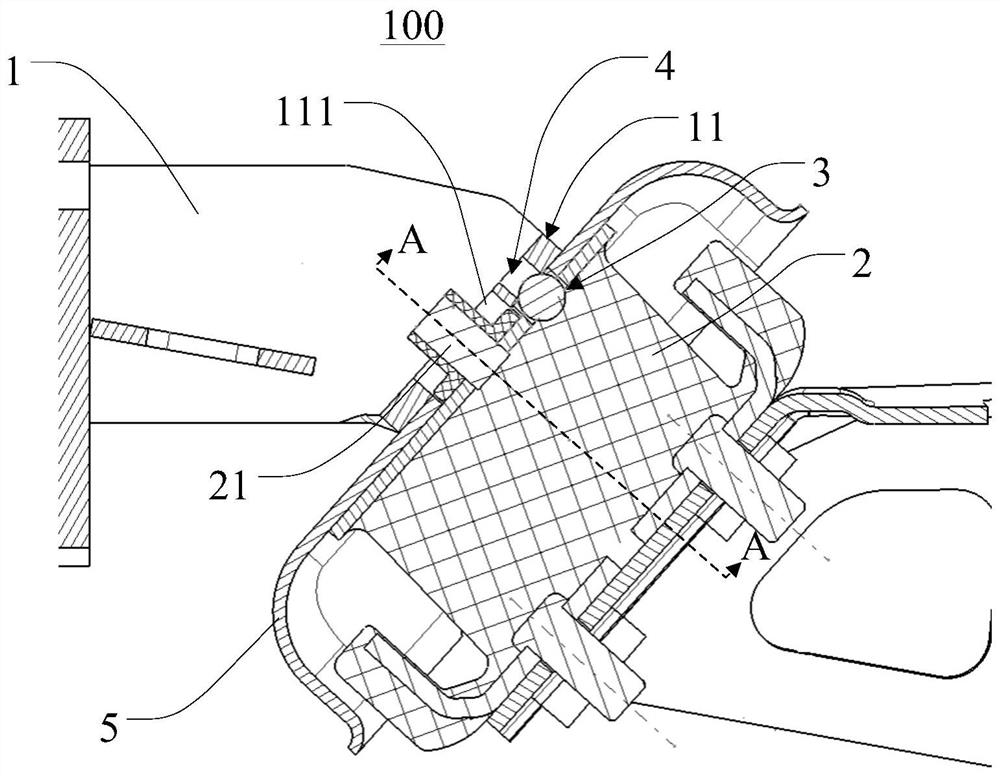

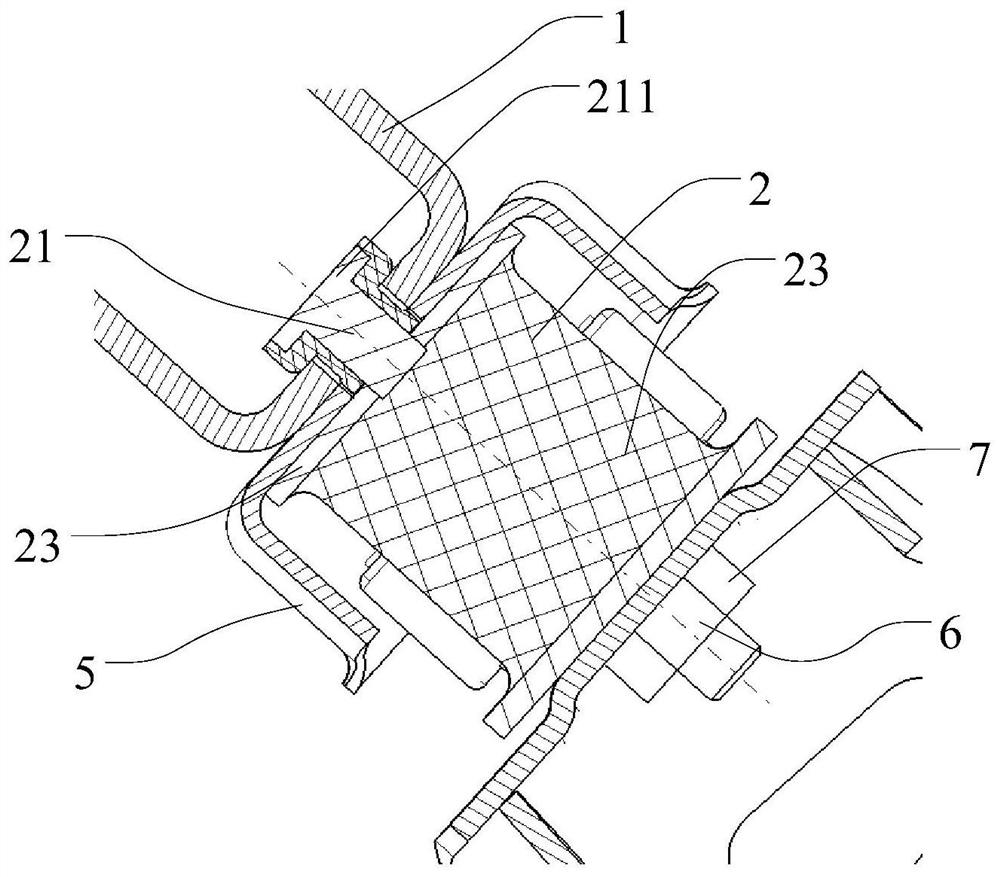

Refueling check valve

The invention discloses a refueling check valve. The refueling check valve comprises a valve body, a valve block and a rubber sealing pad, wherein the valve block is connected with the valve body through a rotary shaft pin; a spring is arranged on the rotary shaft pin; the spring is used for pre-tightening the valve block for realizing normal close of the valve; the rubber sealing pad is arrangedon the valve block in an interference fit manner and is arranged on a sealing match surface of the valve block and the valve body; a groove is formed in the outer side of the valve body; an O-shaped sealing ring is arranged in the groove for realizing sealing between the valve body and an outer side match pipe after assembly; the match pipe which is used for being matched with the valve body is provided with an extrusion bump on the outer part of the front end; a groove is formed in the match pipe; and an expansion section is arranged on the tail pipe diameter of the match pipe, so that different pipe diameters and match needs are met. By adopting the refueling check valve, rolling over of fuel can be effectively prevented; gas rolling over is prevented; rapid changing can be realized after damage; and meanwhile, the flow diameter of fuel in a pipeline is not affected after the valve block is opened.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

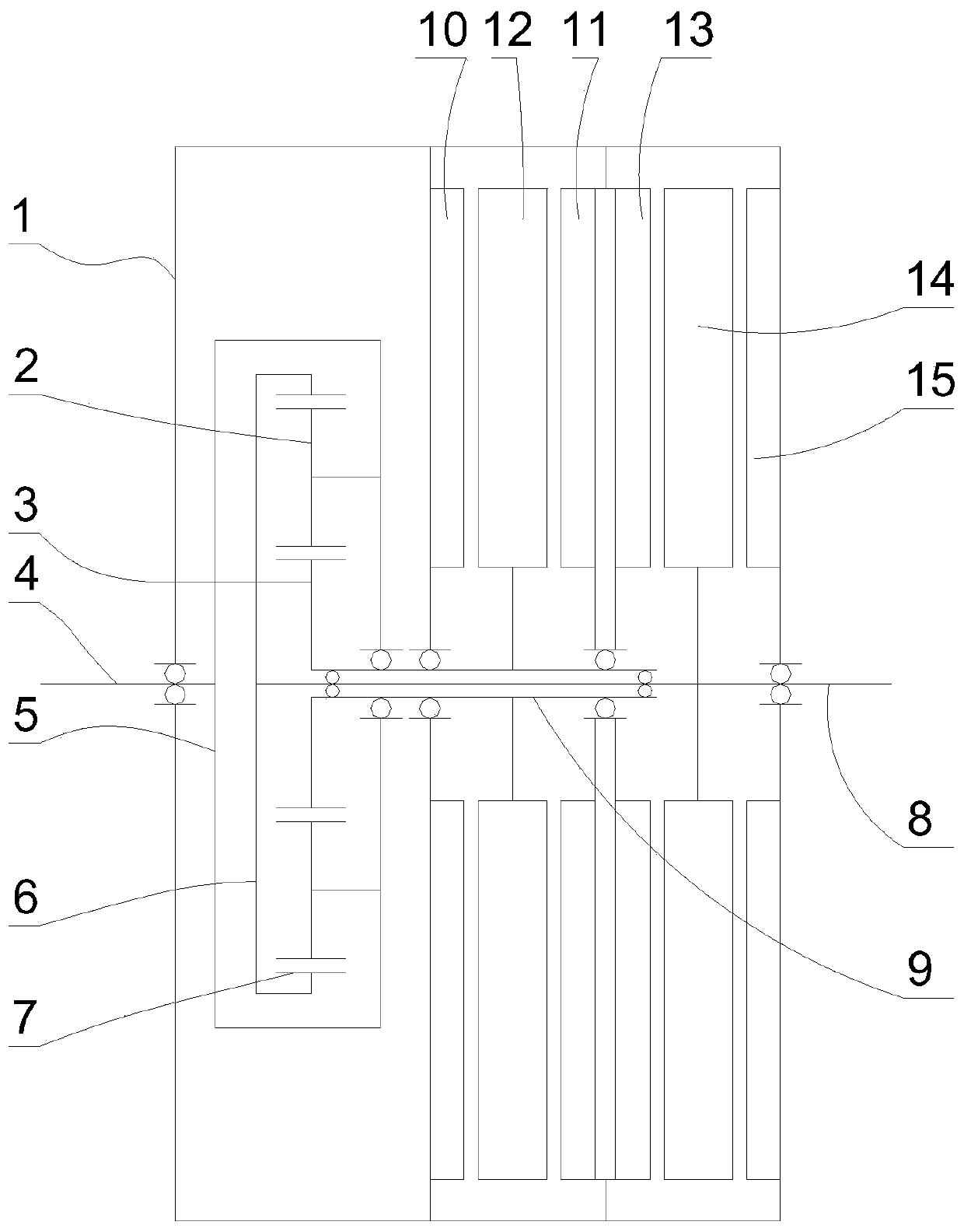

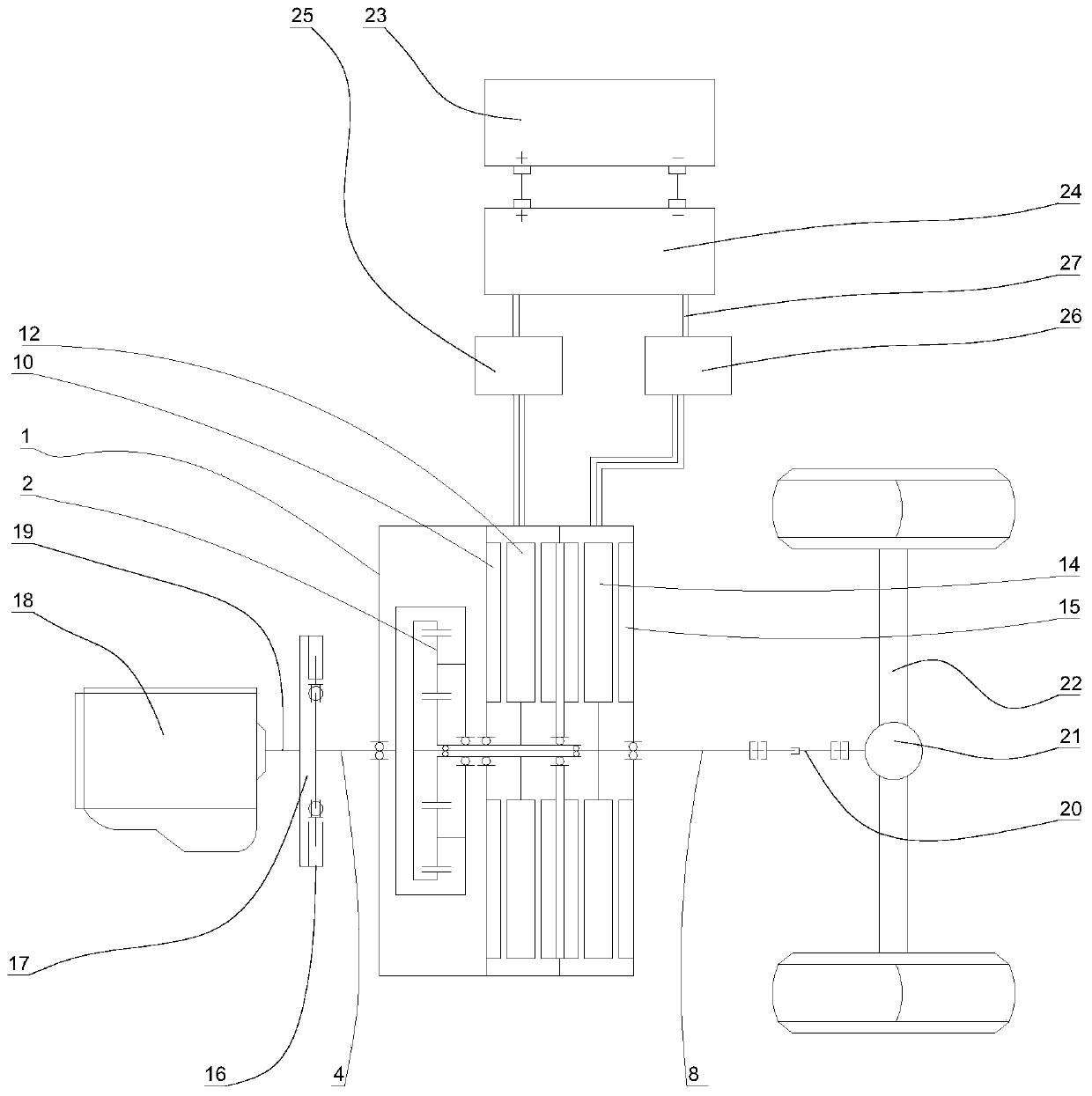

Double-disc type motor electric stepless speed change mechanical-electrical integration system

PendingCN111376698AAxial dimension shortCompact structureGas pressure propulsion mountingMagnetic circuit stationary partsElectric machineDrive motor

The invention relates to a double-disc type motor electric stepless speed change mechanical-electrical integration system. The system comprises a shell, a planet wheel, a sun wheel, an input shaft, aplanet carrier, a gear ring carrier, a gear ring, an output shaft, a hollow shaft, an ISG motor stator, an ISG motor stator, an ISG motor rotor, a main drive motor stator, a main drive motor rotor anda main drive motor stator; the ISG motor stator and the ISG motor rotor form an ISG disc type motor; the main drive motor stator and the main drive motor rotor form a main drive motor with a double-stator structure; the output shaft penetrates through the hollow shaft; supporting bearings are arranged between the front end and the rear end of the hollow shaft and the output shaft; the sun wheel,the planet wheel and the gear ring form a planet row; the ISG motor stator and the main drive motor stator are connected together and are connected with the hollow shaft through the support bearings;an ISG motor stator side shell is connected with the hollow shaft through the supporting bearing; a main drive motor stator side shell is connected with the output shaft through the supporting bearing. The system of the invention has the advantages of compact structure, high power density, high system efficiency and outstanding NVH characteristics.

Owner:南京清研海易新能源动力有限责任公司

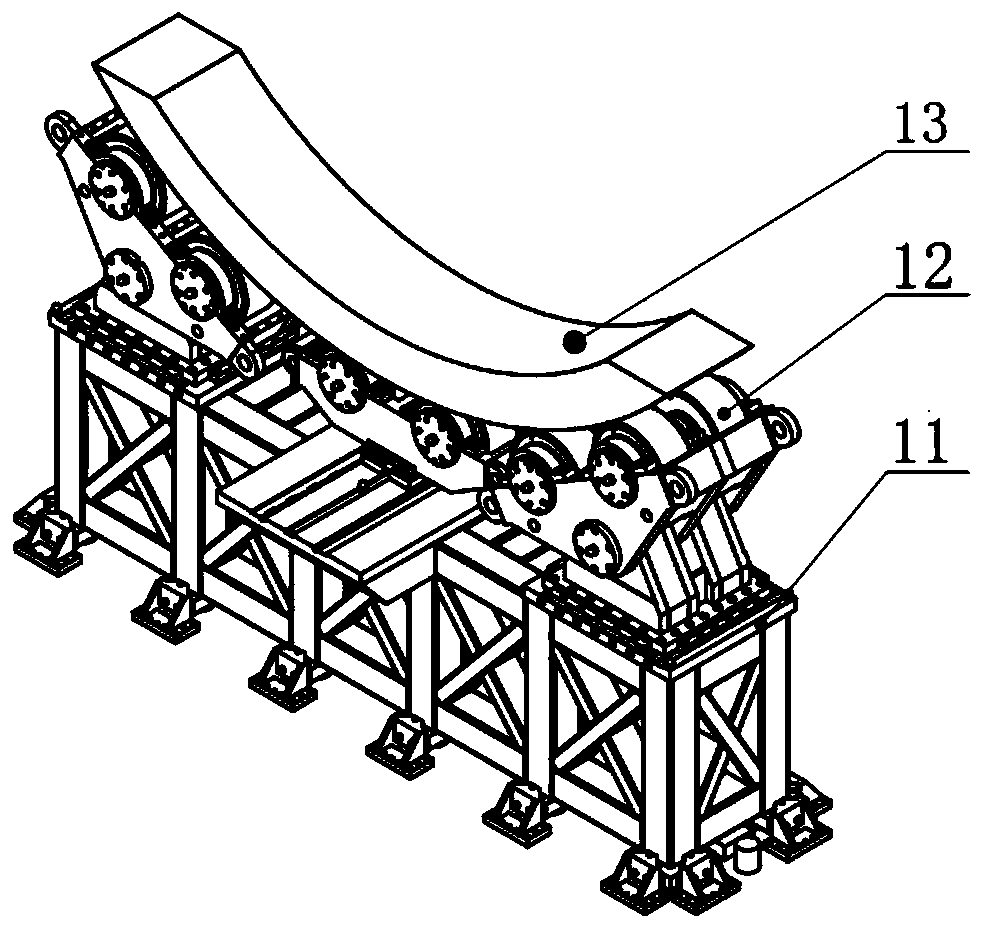

Tempering furnace material rack slideway mechanism

ActiveCN105018708AAchieve regulationSave man hoursFurnace typesHeat treatment furnacesEngineeringMachine tool

The invention provides a tempering furnace material rack slideway mechanism which comprises a support, a slideway baffle and a discharging baffle, wherein two support plates of the support are respectively and fixedly arranged on two side walls of a feeding hole of a tempering furnace machine tool, a two-way screw rod and at least one guide rod are arranged between the two support plates, and the slideway baffle comprises a first baffle and a second baffle which are parallelly arranged between the two support plates; the slideway for feeding shaft workpieces is formed between the first baffle and the second baffle, the two-way screw rod and the guide rod respectively penetrate through the slideway baffle, and the first baffle and a left screw cap arranged on the two-way screw rod are fixed together; the second baffle and a right screw cap arranged on the two-way screw rod are fixed together, the first baffle and the second baffle are respectively provided with a guide sleeve matched with a guide rod, and the discharging baffle is arranged on the tail of the feeding hole; and the upper end of the discharging baffle is fixed, and a V-shaped charging groove is formed between the lower end of the discharging baffle and the tail end of a bottom plate of the feeding hole. The axial limiting and radial positioning for shaft workpieces with different lengths are realized, the tempering furnace machine tool is high in automation degree and high in working efficiency, and the production cost of shaft workpieces is low.

Owner:SHANGHAI JINGZHI IND CO LTD

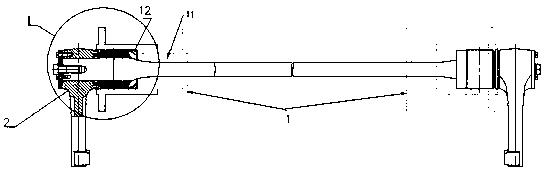

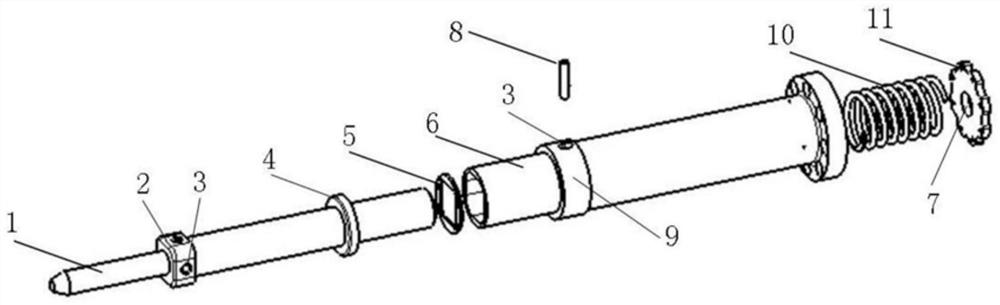

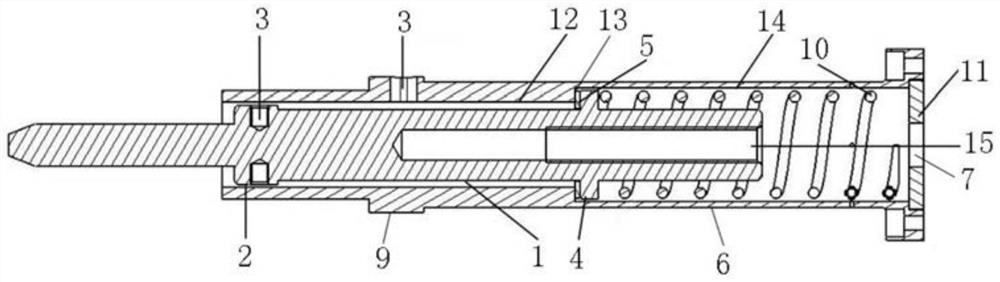

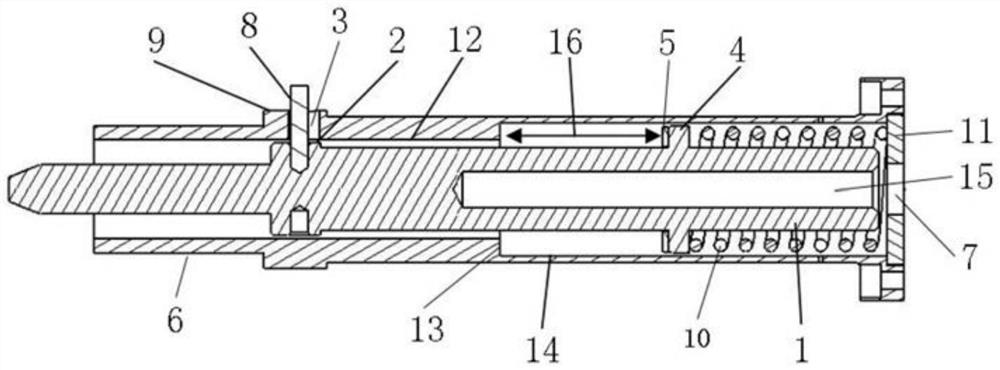

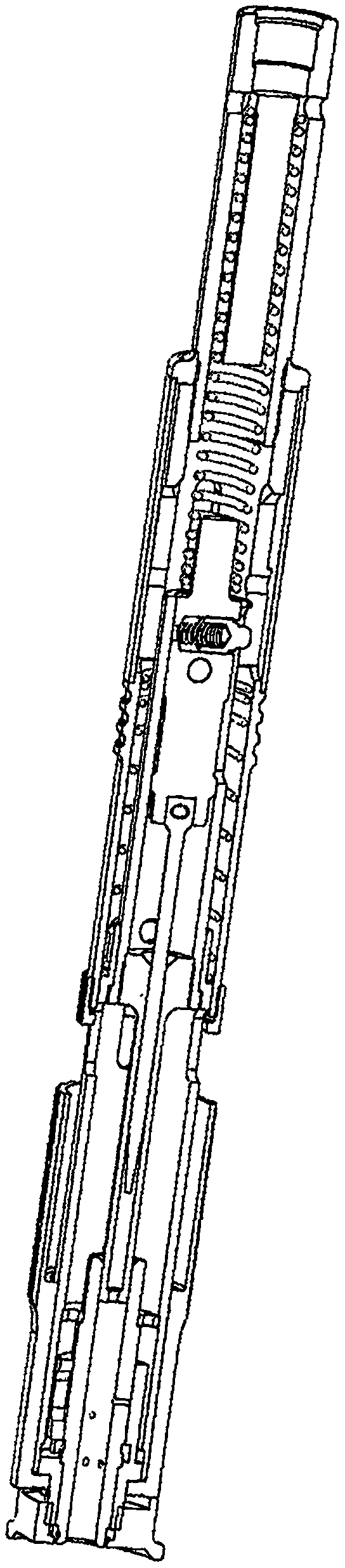

Limiting type rocket separation impulse providing device based on spring

The invention provides a limiting type rocket separation impulse providing device based on a spring. The limiting type rocket separation impulse providing device comprises a sleeve and an ejector rod located in the sleeve, one end of the ejector rod extends out of the sleeve, the outer side of the other end of the ejector rod is sleeved with the spring, and a polygonal limiting section is arranged on the outer side wall of the ejector rod. A cavity section matched with the polygonal limiting section in shape is arranged in an inner cavity of the sleeve, limiting holes capable of being matched with a positioning pin are formed in the outer side wall of the ejector rod and the side wall of the sleeve respectively, and the center distance between the limiting hole in the ejector rod and the limiting hole in the sleeve is equal to the working stroke of the spring. The device can ensure that the ejector rod only moves in the axial direction to push the separation section of the rocket along with gradual release of the compression spring, and therefore separation impulse loss is prevented.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Check valve for engine

InactiveCN101881225BRealize axial limitImprove liquidityCheck valvesEngine controllersStructural deformationEngineering

The invention provides a check valve for controlling air current to flow in one direction on an engine, which consists of an upper shell, a lower shell, a membrane and a support sheet. The support sheet and the membrane are matched with a positioning boss of the upper shell through a mounting hole and are matched with a positioning hole of the lower shell to realize axial limitation of the membrane through the positioning boss of the upper shell. Gas acts upon the membrane from an air inlet of the upper shell to an air pore on the support sheet, the membrane carries out structure deformation under the action of the air current to reserve a gap with the upper shell, and the air current passes through an air outlet of the lower shell to flow out through the gap to realize the flowing actionof positive air current of the check valve. When the gas flows reversely, the membrane cannot deform due to the action of the air current, the reversed air current is stopped by the matched sealing action of the membrane and the upper shell, and the membrane has favorable sealing performance on the reversed air current. The check valve has the advantages of simple structure composition, easy assembly, light weight and small volume, can ensure that the air current is smooth when the air current positively flows, and has favorable airtightness when the air current reversely flows, thereby the requirements on related performance are satisfied.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

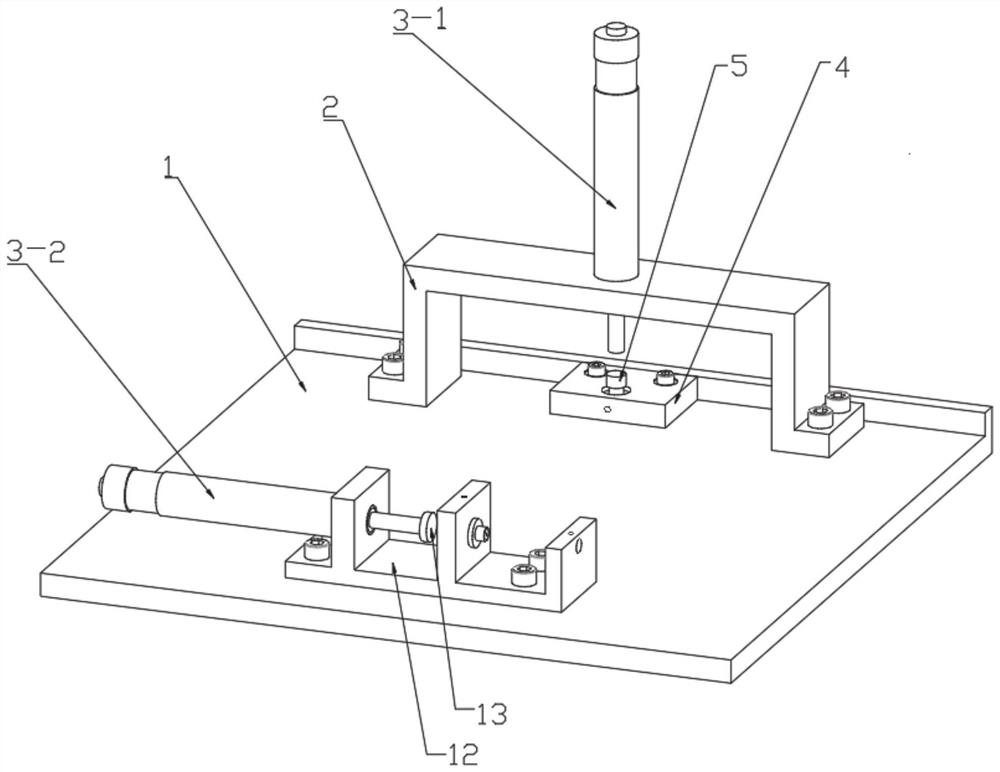

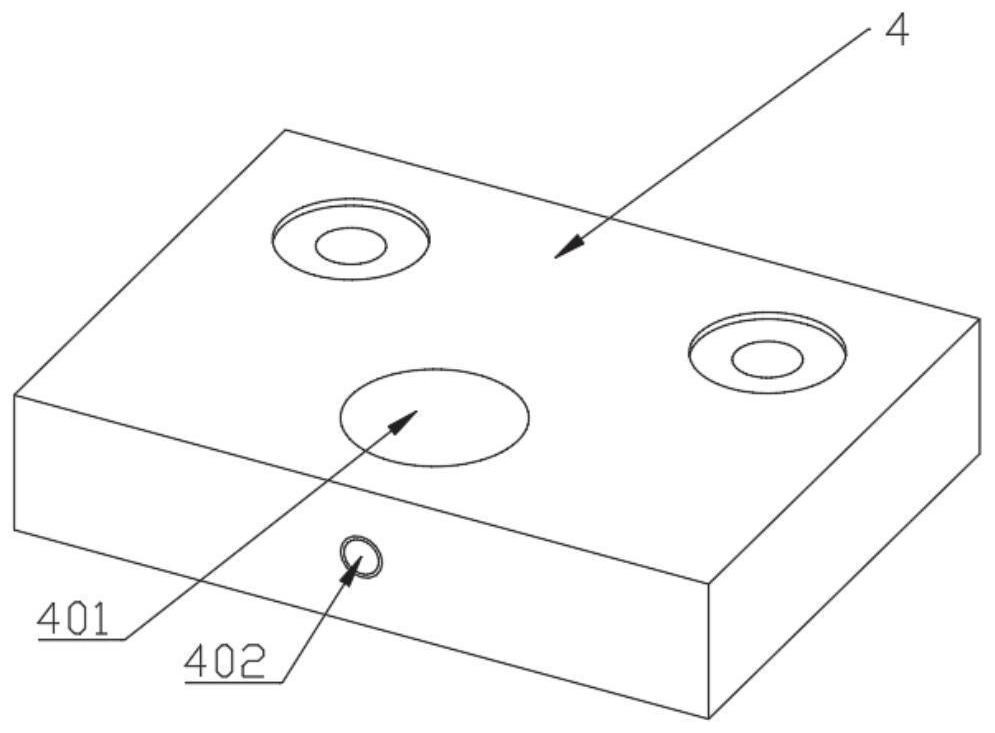

Assembly device of single-pole-plate capacitance sensor and assembly method

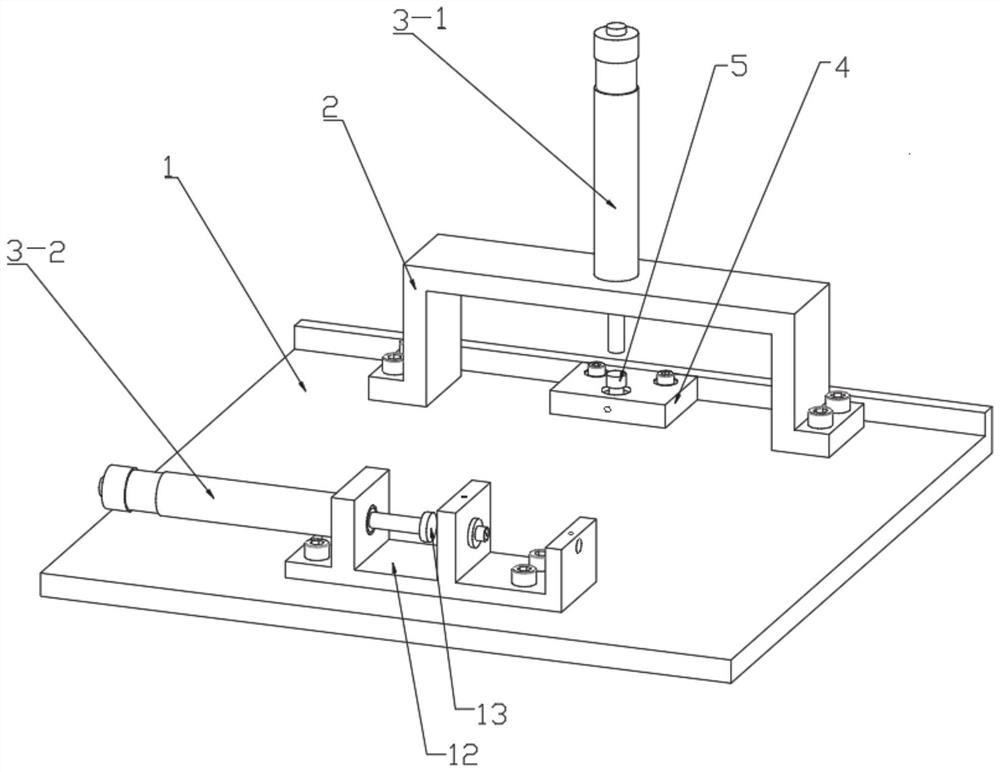

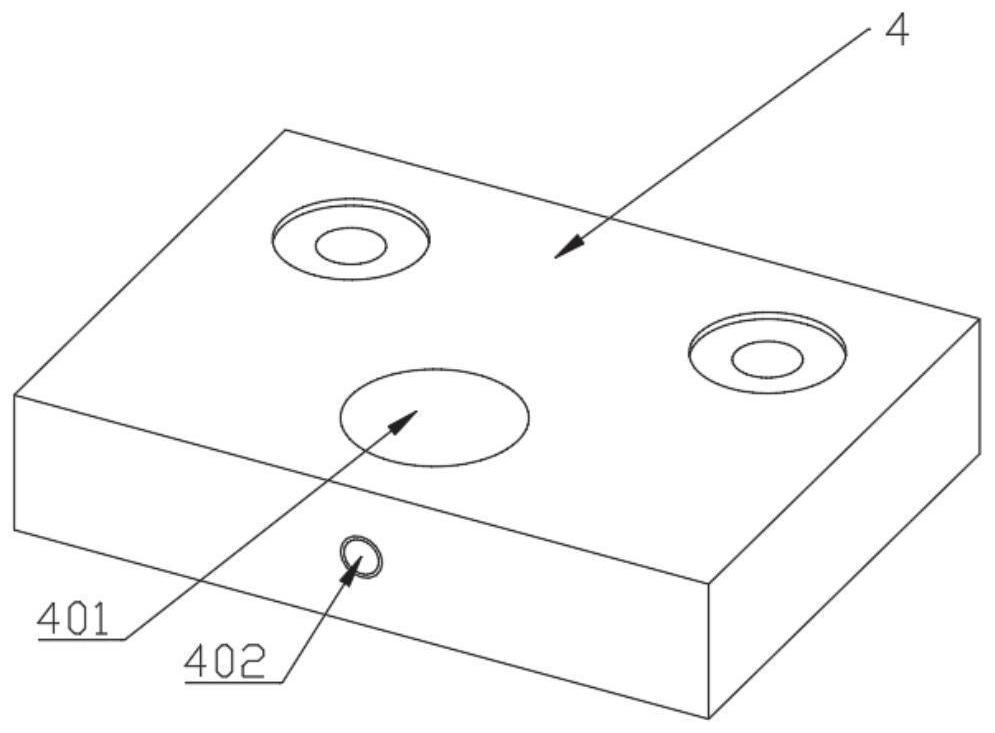

ActiveCN112959050AAchieve insulationRealize the shielding effectMaterial gluingMetal working apparatusMechanical engineeringCapacitance transducer

The invention belongs to the field of capacitance sensor assembly, and provides an assembly device of a single-pole plate capacitance sensor and an assembly method. The assembly device comprises a base plate, a sensor fixing table, a portal frame, a first micrometer head, a correction block, a flexible ring and a flexible disc. The sensor fixing table and the portal frame are both mounted on the base plate. The sensor fixing table is arranged below the portal frame. The correction block is arranged on a sensor to be assembled, and the first micrometer head is arranged on the portal frame and is opposite to the correction block. The two sides of the flexible disc are connected with the correction block and a measuring electrode of the sensor separately, so that longitudinal flexible assembly of the measuring electrode is achieved. The two sides of the flexible ring are connected with the correction block and an equipotential ring of the sensor separately, so that longitudinal flexible assembly of the equipotential ring is achieved. The first micrometer head is used for applying pressure to the correction block through longitudinal flexible pre-tightening, so that the measuring electrode of the sensor, the equipotential ring and a shielding ring are transversely limited and coaxially assembled, the bottom surfaces of the three are on the same horizontal plane, so that the flatness of the surface of the sensor is ensured.

Owner:SHANDONG UNIV

Bearing dismantling device

InactiveCN104308803AGuaranteed not to moveRealize axial limitMetal-working hand toolsMechanical engineering

Owner:HARBIN DONGAN ENGINE GRP

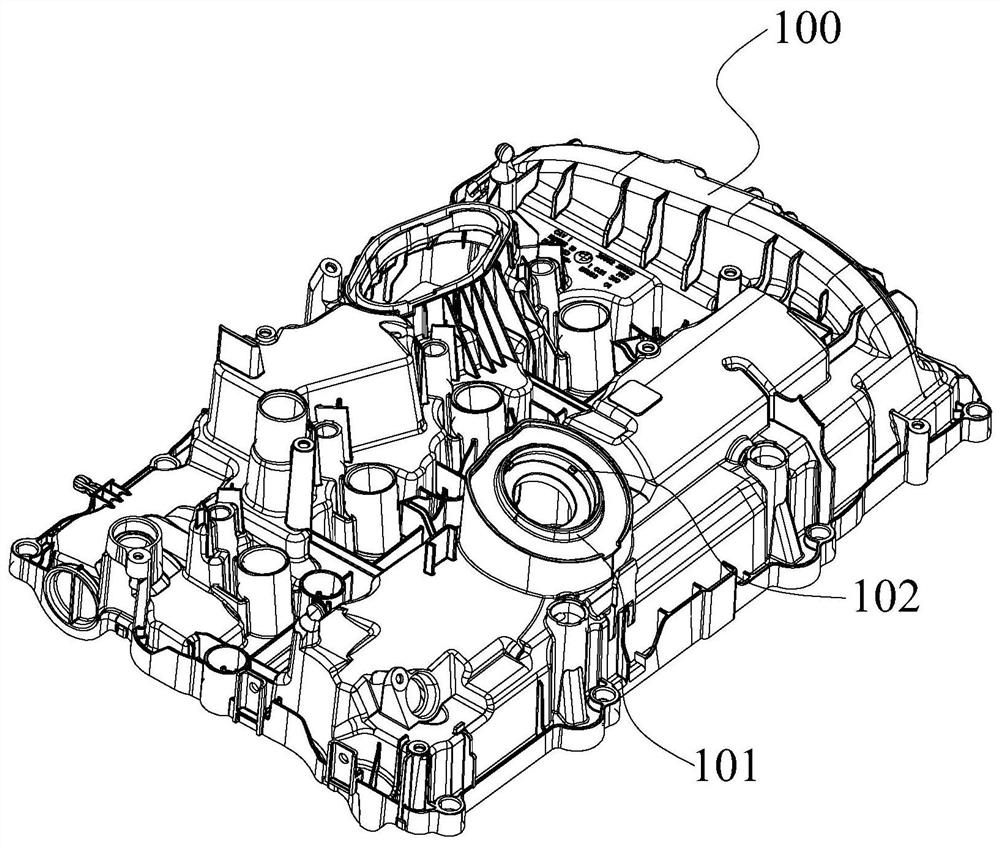

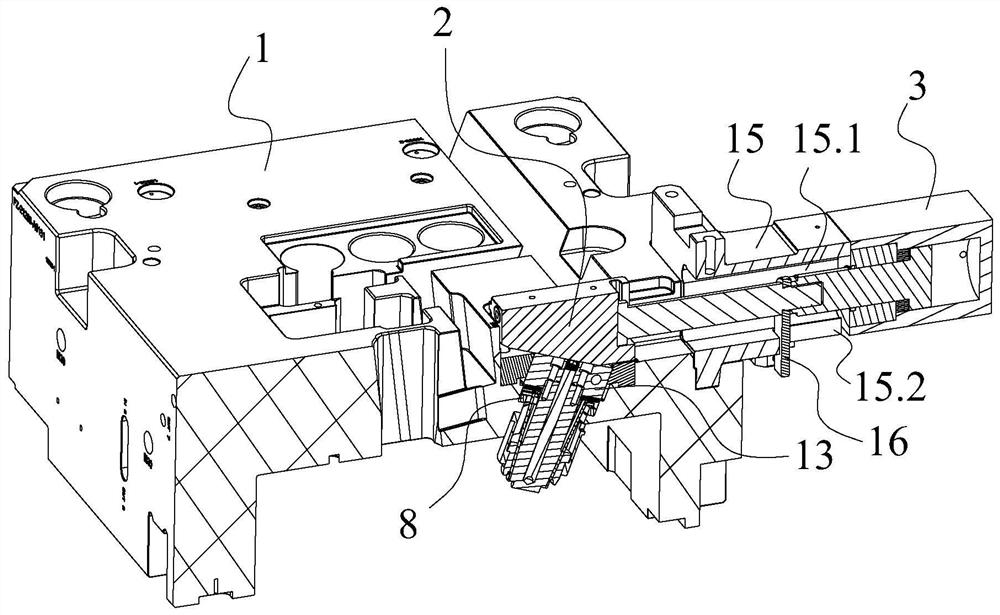

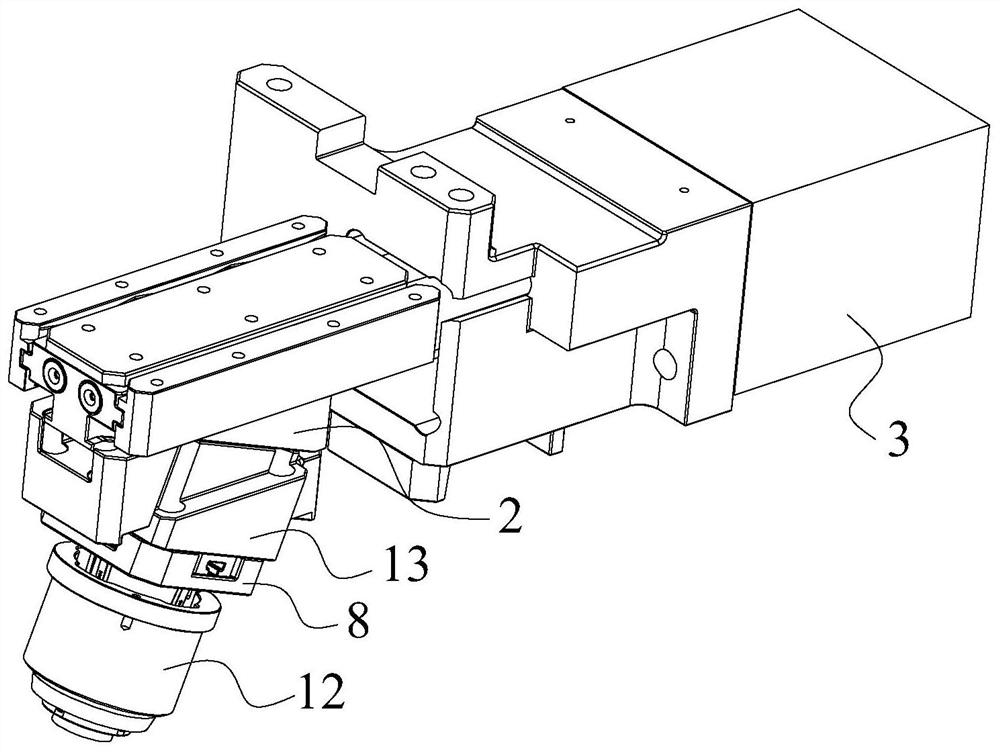

Demoulding mechanism for engine cylinder cover plate

PendingCN114311560AImprove stabilityStability does not affectDomestic articlesEngineeringStructural engineering

The invention provides an engine cylinder cover plate demolding mechanism which comprises a mold frame, a sliding block, an inclined drawing rod and a driving cylinder are arranged on the mold frame, the sliding block is in sliding fit with the mold frame, and the sliding block is in linkage fit with the inclined drawing rod. The sliding block drives the first core pulling block on the inclined pulling rod to be demolded and separated from the inner wall of an outwards-protruding inclined sleeve on the engine steel cover plate; and an inclined pulling assembly is arranged on the inclined pulling rod in a sliding mode, a second core pulling block is arranged on the inclined pulling assembly, and when the inclined pulling rod slides in a core pulling mode in the direction away from the inclined sleeve, the inclined pulling assembly moves inwards in the radial direction of the inclined pulling rod, so that demolding separation of the second core pulling block and an inverted buckle on the inner wall of the inclined sleeve is achieved. The engine cylinder cover plate demolding mechanism is simple in structure, and inclined hole demolding and inverted buckle demolding of the inner wall of an inclined hole can be conducted at the same time through one driving structure.

Owner:NINGBO FANGZHENG TOOL

External force adjusting and automatic residue discharging type axial powder actuated tool

PendingCN109968286ARealize axial limitAchieve free spinsNailing toolsExplosive forcePowder-actuated tool

The invention relates to an external force adjusting type and automatic residue discharging type axial powder actuated tool. The external force adjusting and automatic residue discharging type axial powder actuated tool is characterized in that a pressure relief through hole is formed in a nail pipe, an outer sleeve, a main sleeve and a force adjusting sleeve are involved, wherein a residue discharging channel is formed in the force adjusting sleeve, and silencing holes of the nail pipe communicate with a residue discharging heat dissipation hole in the outer sleeve; and when a reset spring iscompressed, the main sleeve can seal the residue discharging heat dissipation hole. According to the powder actuated tool, the nail pipe can freely rotate under external operation, and the most suitable explosive force can be obtained, meanwhile, when a reset action is carried out, functions of residue discharging and heat dissipation are realized as well, so that heat is timely dissipated, the residue debris can be discharged at any time, a residue discharging maintaining process is omitted, and residue discharging difficulty is reduced; more importantly, the temperature of parts can be effectively reduced, and serious potential safety hazards are avoided; and in addition, due to the arrangement of an anti-rotation sleeve, relative rotation between the nail pipe and the force adjusting sleeve can be effectively realized, marking is assisted, and namely the purpose of conveniently and accurately adjusting force can be achieved.

Owner:宜宾市南溪区鑫盛技术开发有限公司

Lever type oil cylinder capable of steering by 360 degrees

PendingCN114151413ARealize axial limitLow rotational resistanceFluid-pressure actuatorsOil canEngineering

The lever type oil cylinder capable of steering by 360 degrees comprises a cylinder body and a rotary sealing cylinder cover seat, a guide hole is formed in the middle of the cylinder body, a bottom plug is arranged at the bottom end of the guide hole, a piston is arranged in the guide hole, a piston rod is arranged at the top of the piston, and the rotary sealing cylinder cover seat is arranged on the piston rod. And the top end of the piston rod penetrates through the top of the guide hole. The movable clamping balls are injected into the two semispherical clamping holes formed between the rotary sealing cylinder cover seat and the cylinder body, axial limiting of the rotary sealing cylinder cover seat is achieved, lubricating oil can be injected into the semispherical clamping holes, the clamping balls can provide guiding for rotation of the rotary sealing cylinder cover seat, the guiding effect is equal to the effect of a bearing, and the sealing effect of the rotary sealing cylinder cover seat is improved. The rotating resistance of the rotary sealing cylinder cover seat can be greatly reduced, the rotary sealing cylinder cover seat can rotate more flexibly and reliably, the requirement for locking at different angles is met, and the rotary sealing cylinder cover seat is flexible and changeable and more flexible to use.

Owner:克里斯顿工业科技(东莞市)有限公司

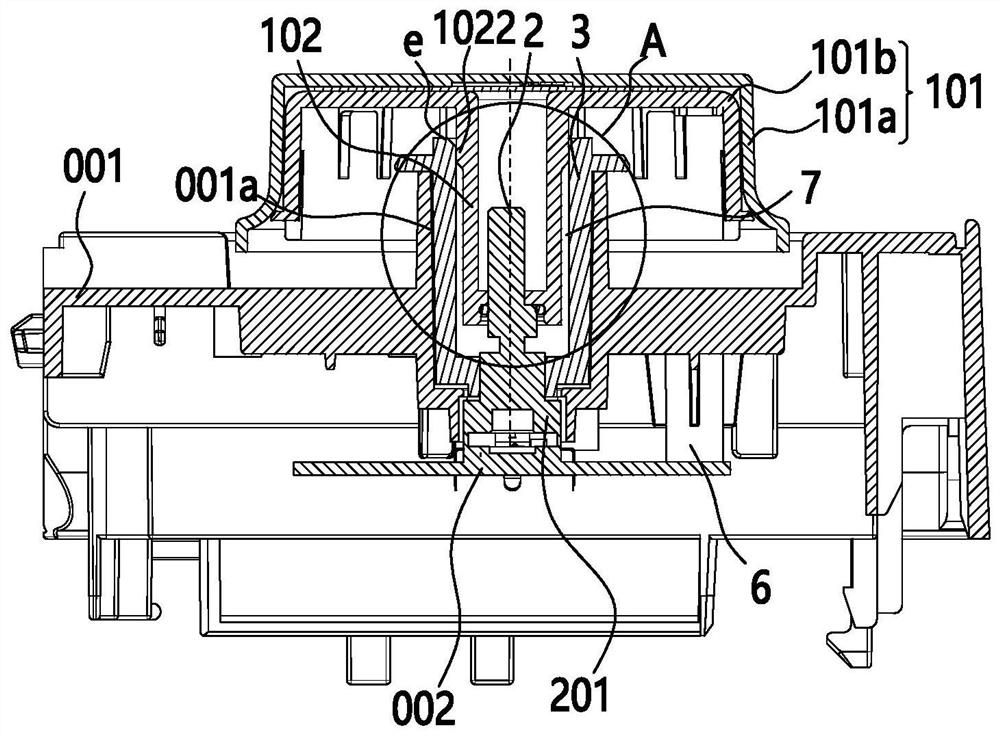

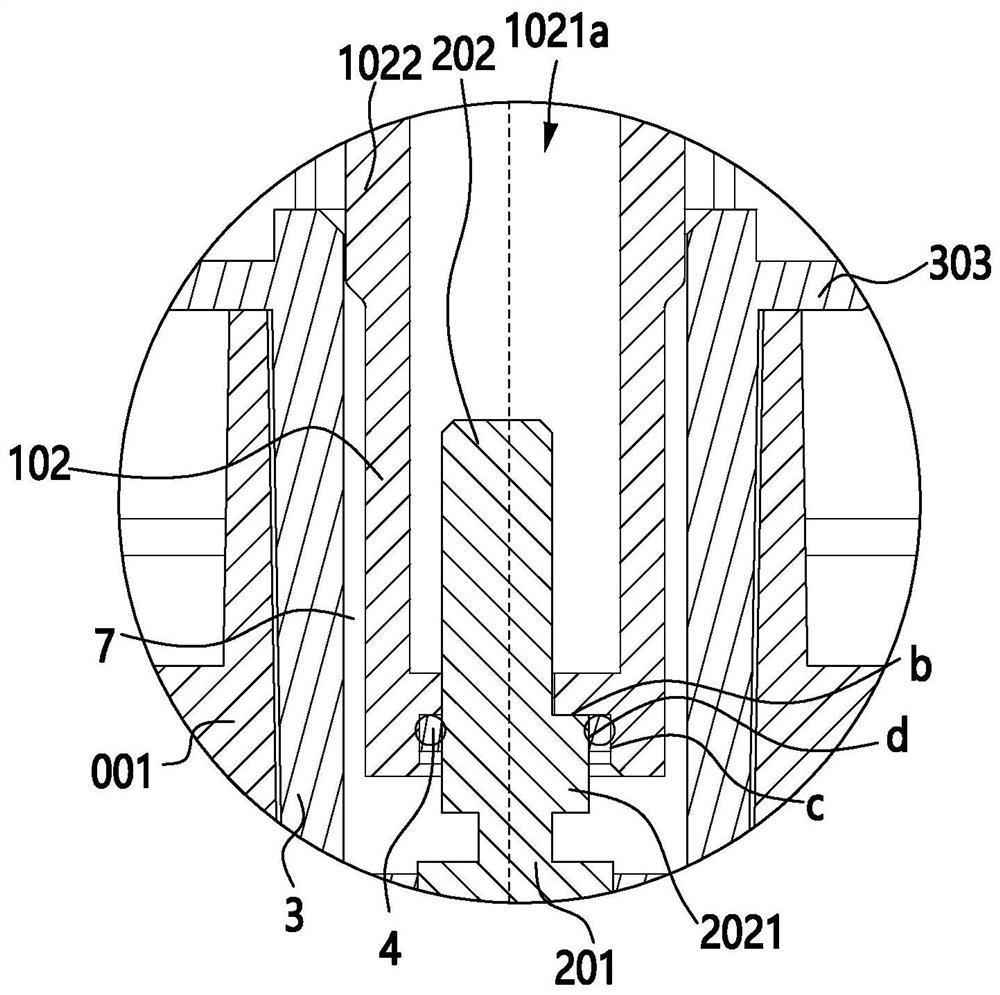

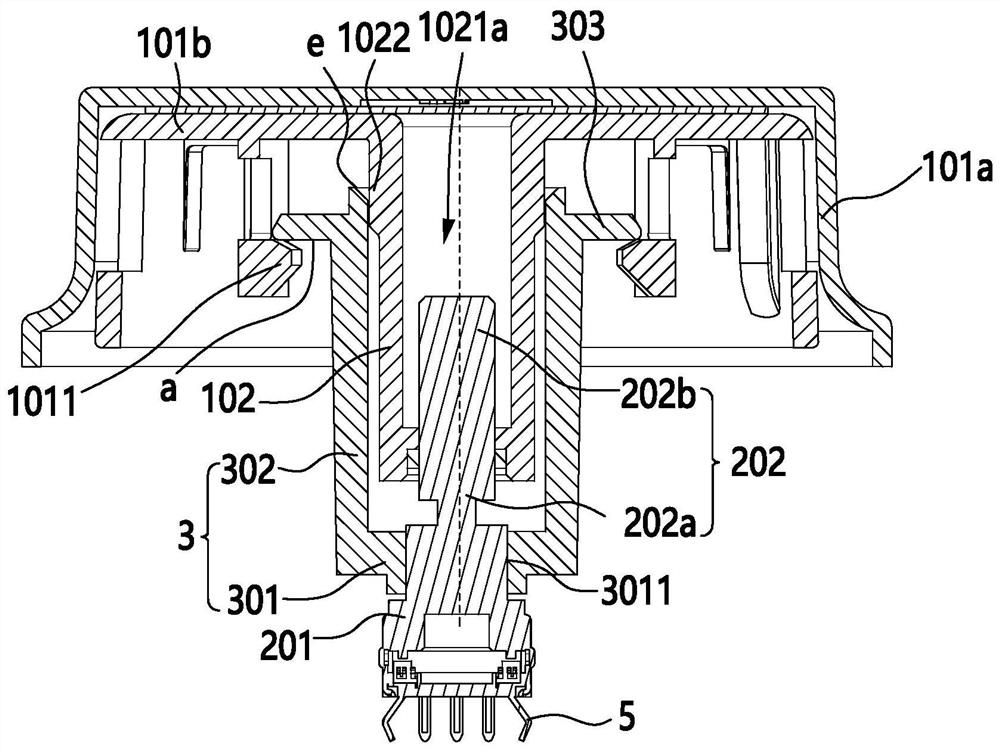

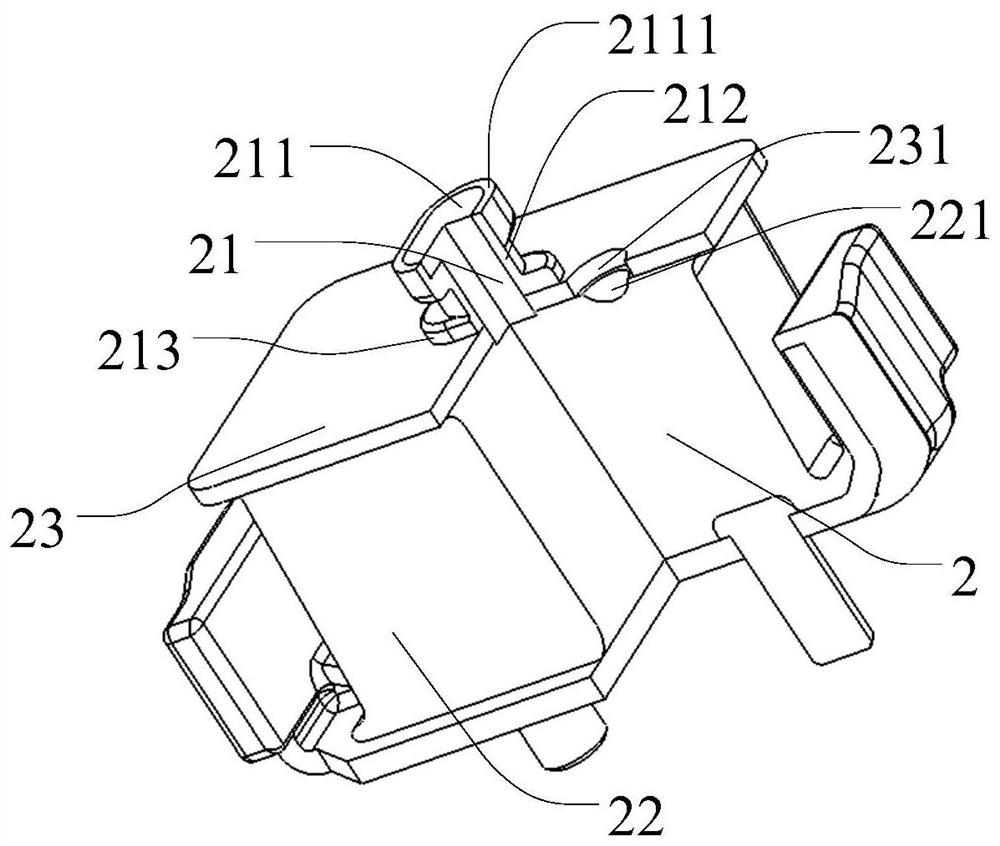

Knob operation assembly and household appliance

The invention discloses a knob operation assembly and a household electrical appliance, and belongs to the technical field of household electrical appliances. The knob operation assembly comprises an operation rotary knob; an encoder which is provided with a base and a rotating shaft connected to the base, wherein the rotating shaft is driven by the operation knob to synchronously act, and the base responds to the action of the rotating shaft to generate a corresponding electrical signal; a limiting member which is connected with the base and used for radially limiting the operation knob, wherein the encoder indirectly and radially limits the operation knob through the limiting member, the limiting member is connected to the base of the encoder to form an assembly, and the limiting member and the base can keep good coaxiality; moreover, the fit tolerance between the limiting piece and the operation knob is not limited by the assembly tolerance of other parts, so the fit tolerance between the limiting piece and the operation knob can be reduced as much as possible on the premise of not influencing the action of the operation knob, the shaking feeling of the operation knob is reduced, and the operation experience is improved.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

Installation method of torsion bar assembly, installation structure of torsion bar assembly

ActiveCN110254459BSimple structureReduce manufacturing costBogiesBogie-underframe connectionsBogieInterference fit

The installation method of the torsion bar assembly is characterized in that the installation hole corresponding to the torsion bar assembly is processed on the frame of the bogie, the torsion bar assembly is crossed in the installation hole, and the torsion bar assembly and the installation hole are connected by interference fit A stopper for axially limiting the torsion bar assembly is arranged in the installation hole, and the stopper is in close contact with the torsion bar assembly. The present invention installs the torsion bar assembly directly on the frame, saves the supporting seat assembly in the anti-rolling torsion bar system, simplifies the structure of the anti-rolling torsion bar assembly, reduces its production cost, and ensures that the support seat assembly is omitted The use reliability of the torsion bar assembly is not affected, the connection between the torsion bar assembly and the frame is easy to realize, and the connection method is simpler, which not only can effectively reduce the labor intensity of installing the torsion bar assembly on the frame, but also the torsion bar assembly and the frame The space occupation rate of the connecting structure is small, and the structure is highly compact. The invention also provides a torsion bar assembly installation structure.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

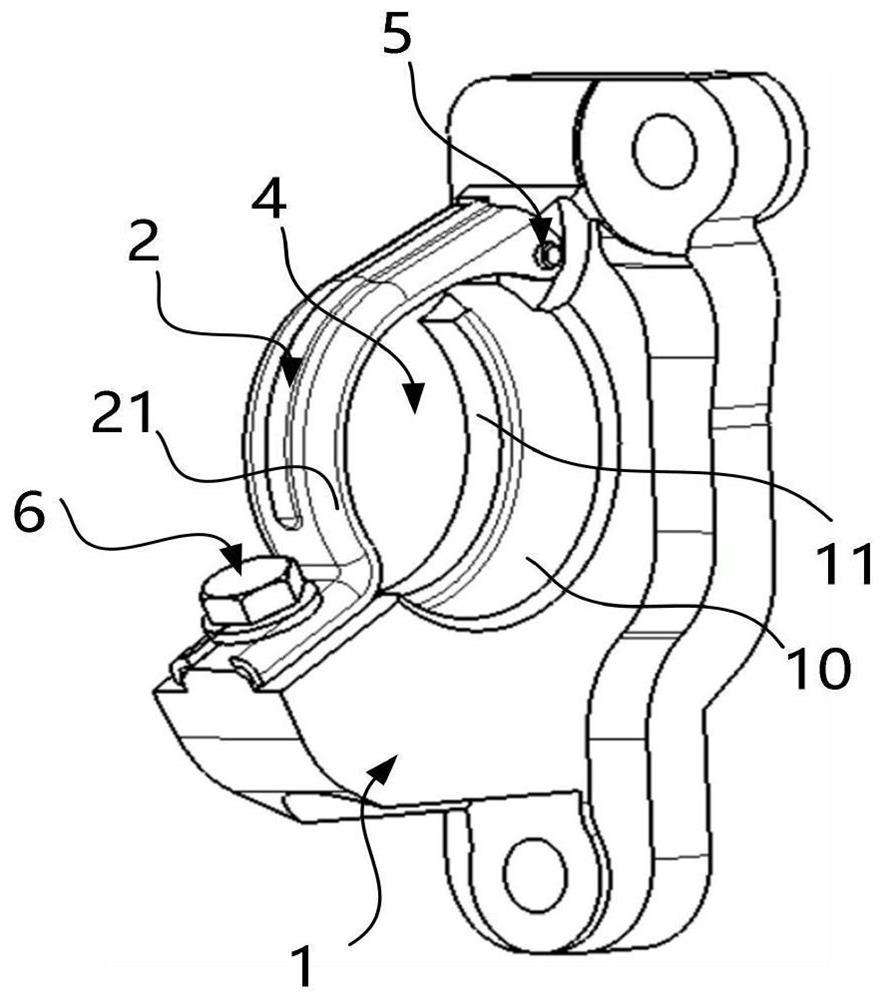

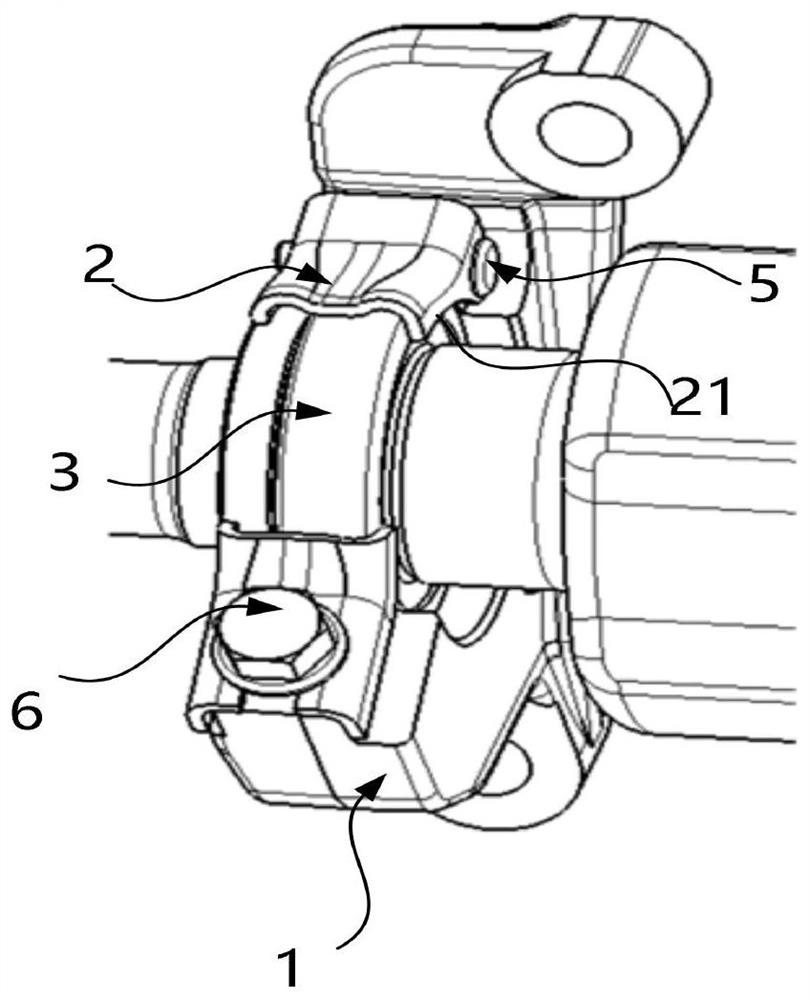

connection structure

InactiveCN112124061BRealize axial limitSmall assembly space requirementJet propulsion mountingInternal combustion mountingVehicle frameEngineering

The invention discloses a connection structure and relates to the technical field of connection accessories. The connection structure is used to connect the front support of the engine with the vehicle frame. The connection structure includes: the front support has a mounting part, and an elongated hole is formed through the mounting part; The frame is connected, and the other end is protruded with a protruding post, and the side wall of the protruding post away from the end of the connecting seat protrudes with a first protruding block, and the protruding post penetrates the elongated hole, and the The first protrusion cooperates with the edge of the elongated hole to axially limit the protrusion. The invention does not need to use bolts, reduces the requirement for assembly space, has a simple structure, and solves the problem that the connecting seat and the nuts supported in front of the engine cannot be assembled and tightened, which affects the assembly efficiency and assembly quality. In addition, in the connection structure proposed by the present invention, when the protrusion is matched with the elongated hole, it is not easy to loosen under complex road conditions and has strong stability.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A crown and a wrist-worn device having the same

ActiveCN112433460BPosition unchangedTo achieve a fixed connectionMechanical devices for setting timeKey pressingEngineering

The invention discloses a crown and a wrist-worn device with the crown. The crown comprises: a button rod provided with an external thread; The first jack for rod insertion; the first captive nut fixed on the body; the second captive nut that is unidirectionally locked with the first captive nut, and the second captive nut is provided for connecting with the outer The internal threads of the thread fit connection, the screwing direction of the external threads and the internal threads are the same as the locking directions of the first captive nut and the second captive nut. The second captive nut can be pre-assembled on the body through the first captive nut, and then the key rod is installed. The existence of the second captive nut does not affect the assembly of the key rod, and can realize the axial direction of the key rod The position is limited to achieve the effect of blindly installing the key rod. Compared with the prior art, the assembly is convenient and the complexity of assembly is reduced. The wrist-worn device includes the above-mentioned crown and has the above-mentioned beneficial effects.

Owner:西安歌尔泰克电子科技有限公司

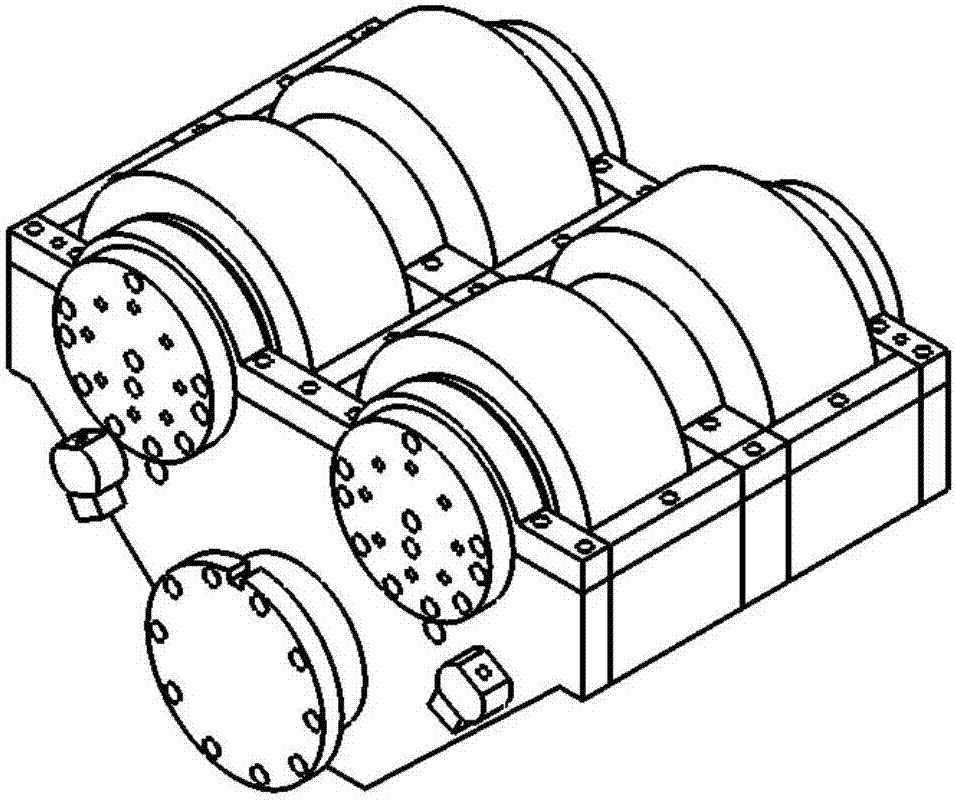

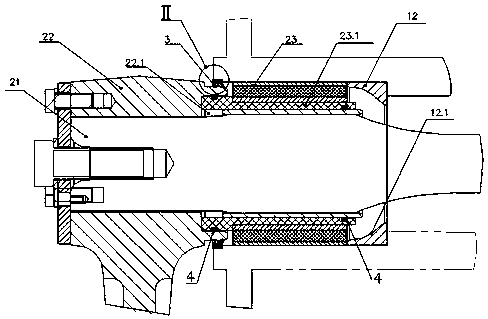

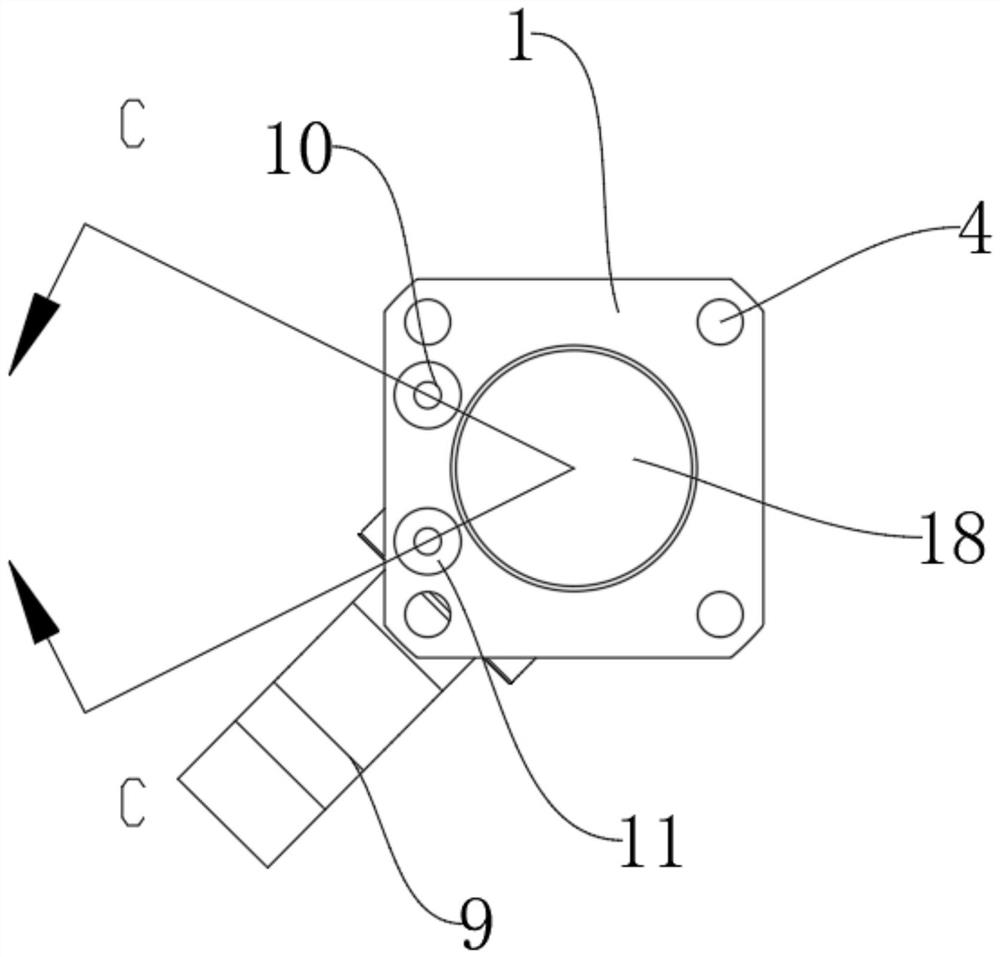

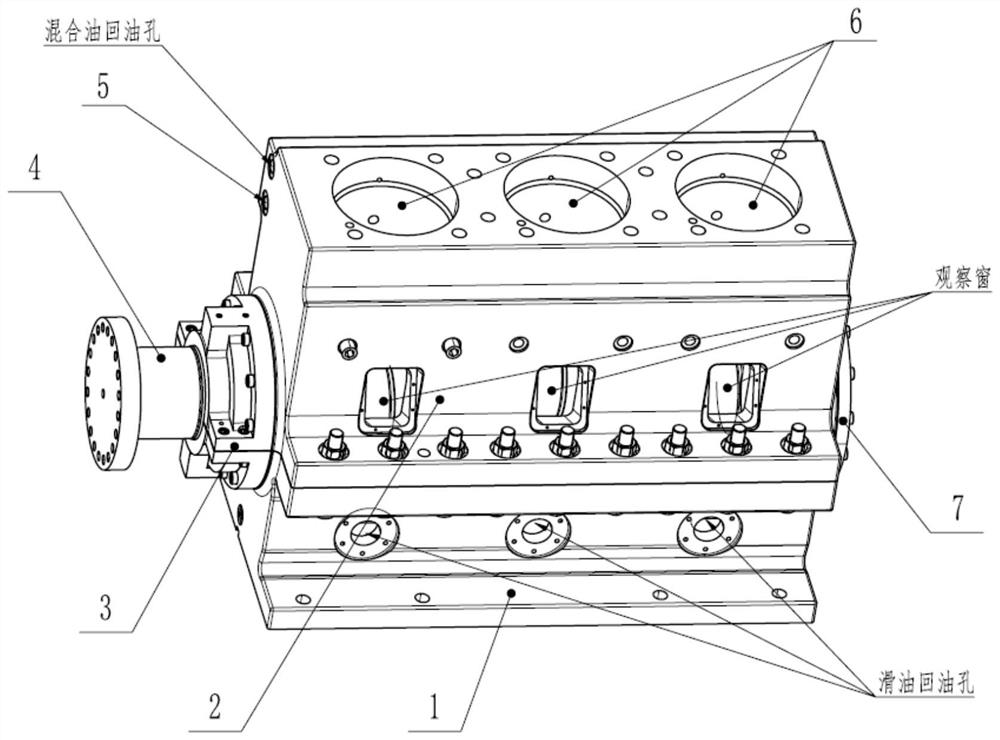

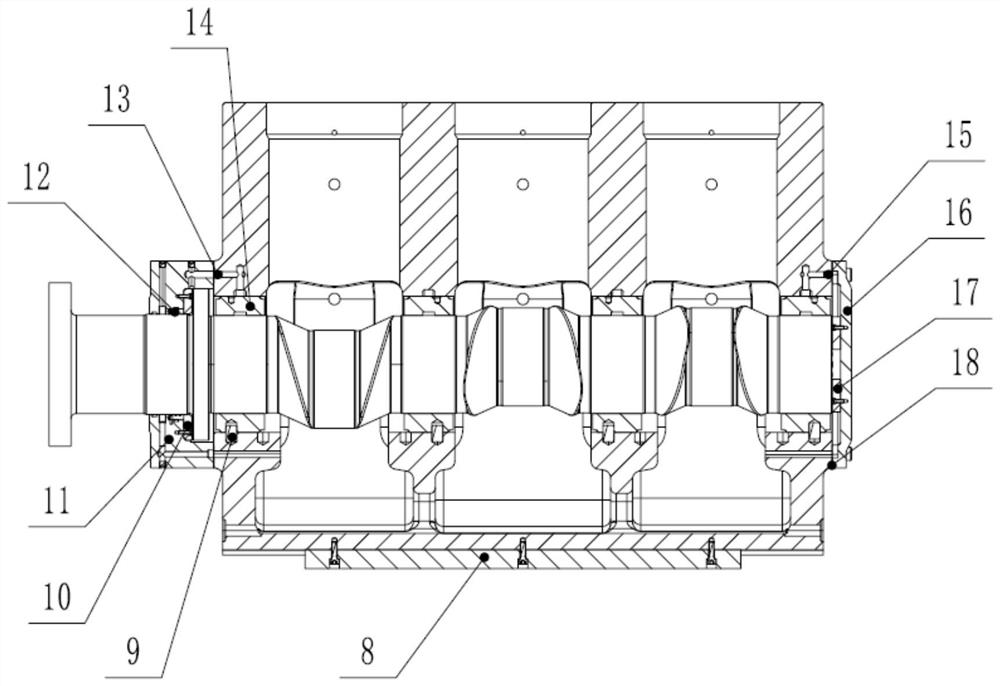

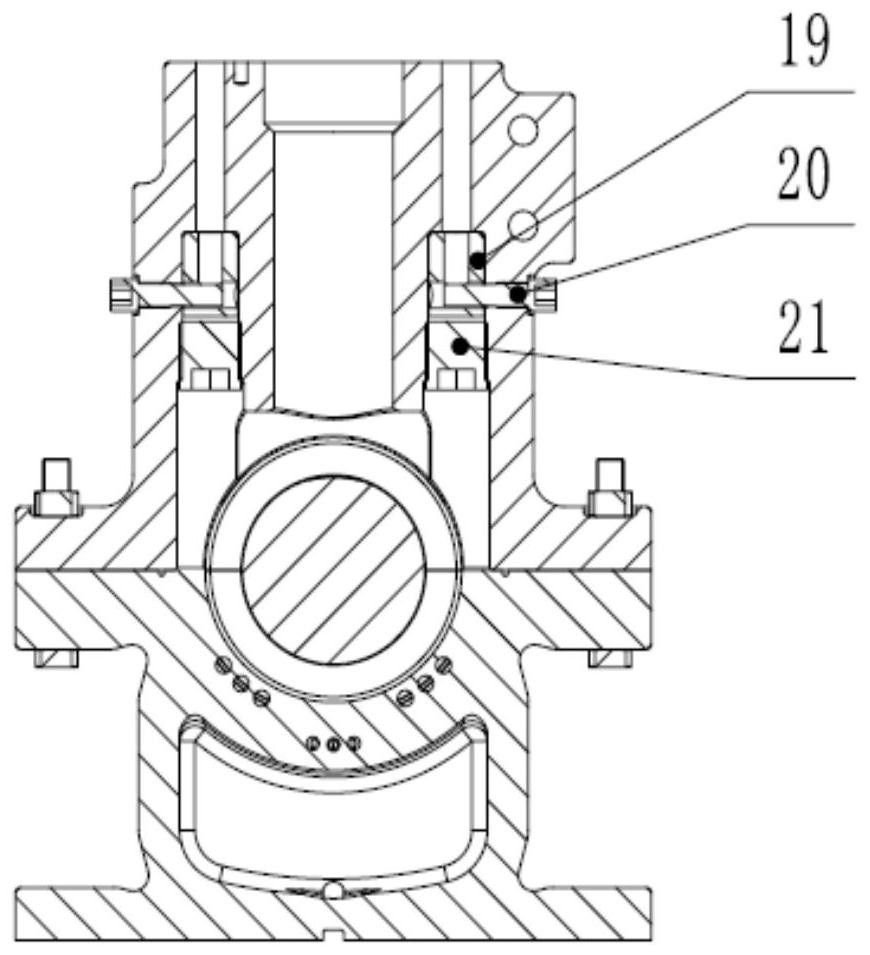

Large high-pressure oil pump cam box assembly

PendingCN114198229AOvercome the problems of large volume and difficulty in integral castingSolve castingMachines/enginesFuel injecting pumpsBall bearingSlider bearing

A large high-pressure oil pump cam box assembly comprises a lower box body, an upper box body, a cam shaft, a left end cover assembly, a right end cover assembly, a bearing bush assembly and the like. The box body adopts a split design, and a high-pressure oil pump mounting hole is formed in the upper box body and is used for mounting a high-pressure oil pump; a reverse thread bushing is arranged and is used for fastening the high-pressure oil pump; throttling plug screws are designed at the left end and the right end and used for controlling the amount of lubricating oil flowing into the left thrust plate and the right thrust plate. A lubricating oil channel is arranged in the box body and is used for lubricating the high-pressure oil pump, the bearing assembly, the left thrust plate and the right thrust plate; the oil tank is provided with a mixed oil return channel and is used for collecting mixed oil of the high-pressure oil pump and leading the mixed oil to the oil tank; the cam shaft supporting part adopts a sliding bearing instead of a ball bearing. Axial limiting of the cam shaft is achieved through the left thrust plate and the right thrust plate. A mechanical sealing ring is designed in the left end cover assembly and used for axial sealing of lubricating oil. The cam box assembly can meet the requirements of large oil supply amount and large load of an existing low-speed machine single-body type high-pressure oil pump on the cam box assembly.

Owner:CHONGQING HONGJIANG MACHINERY

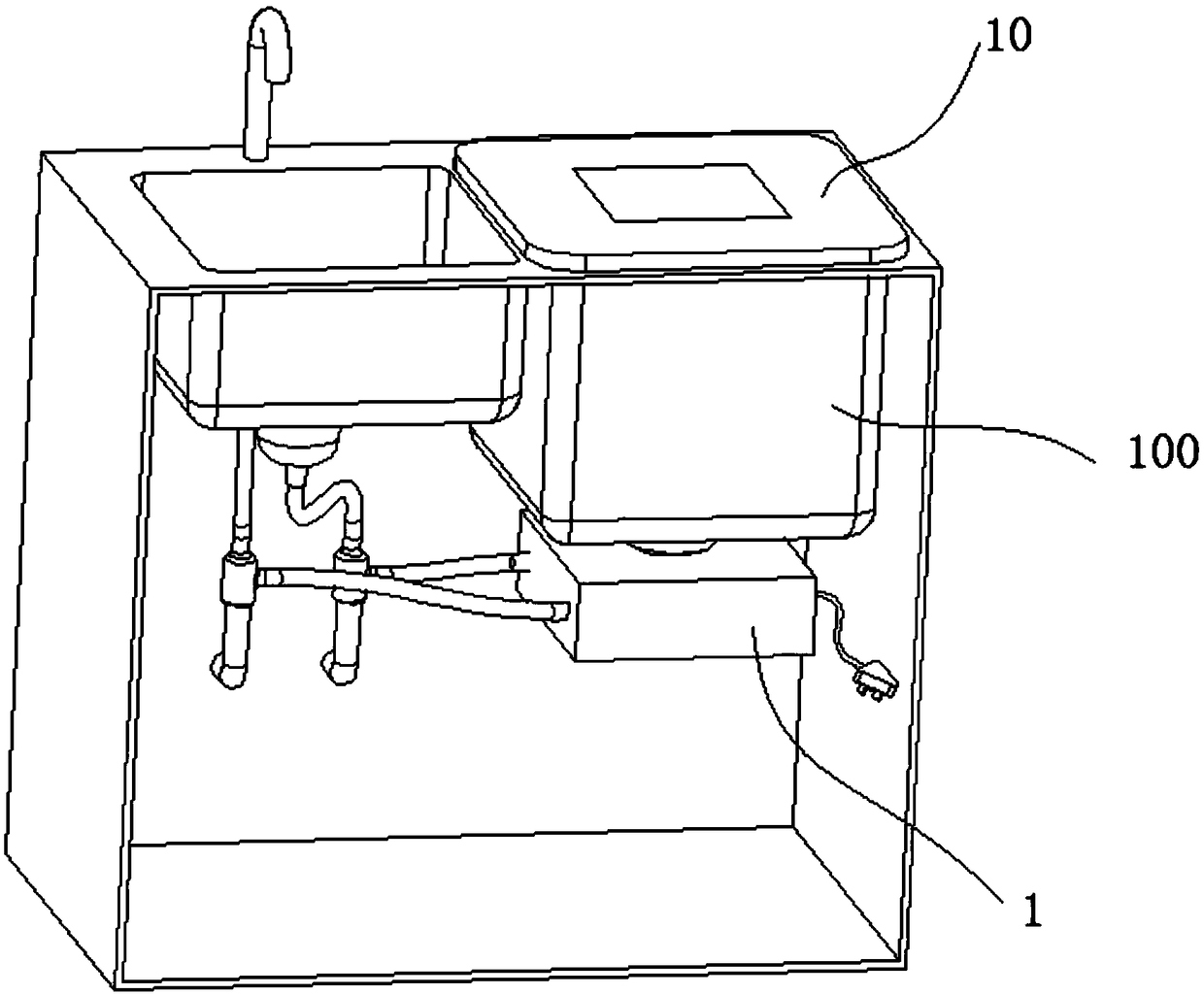

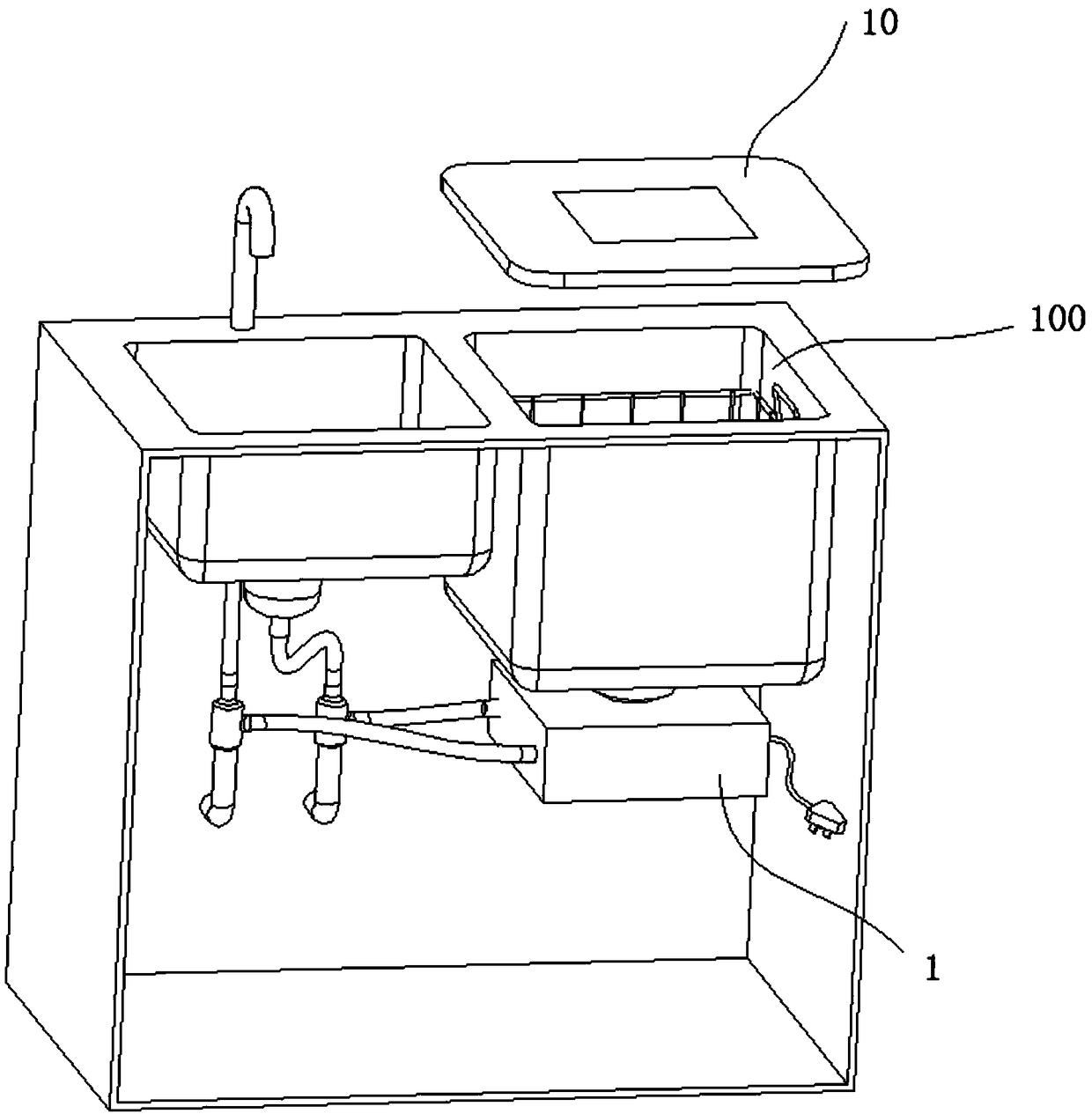

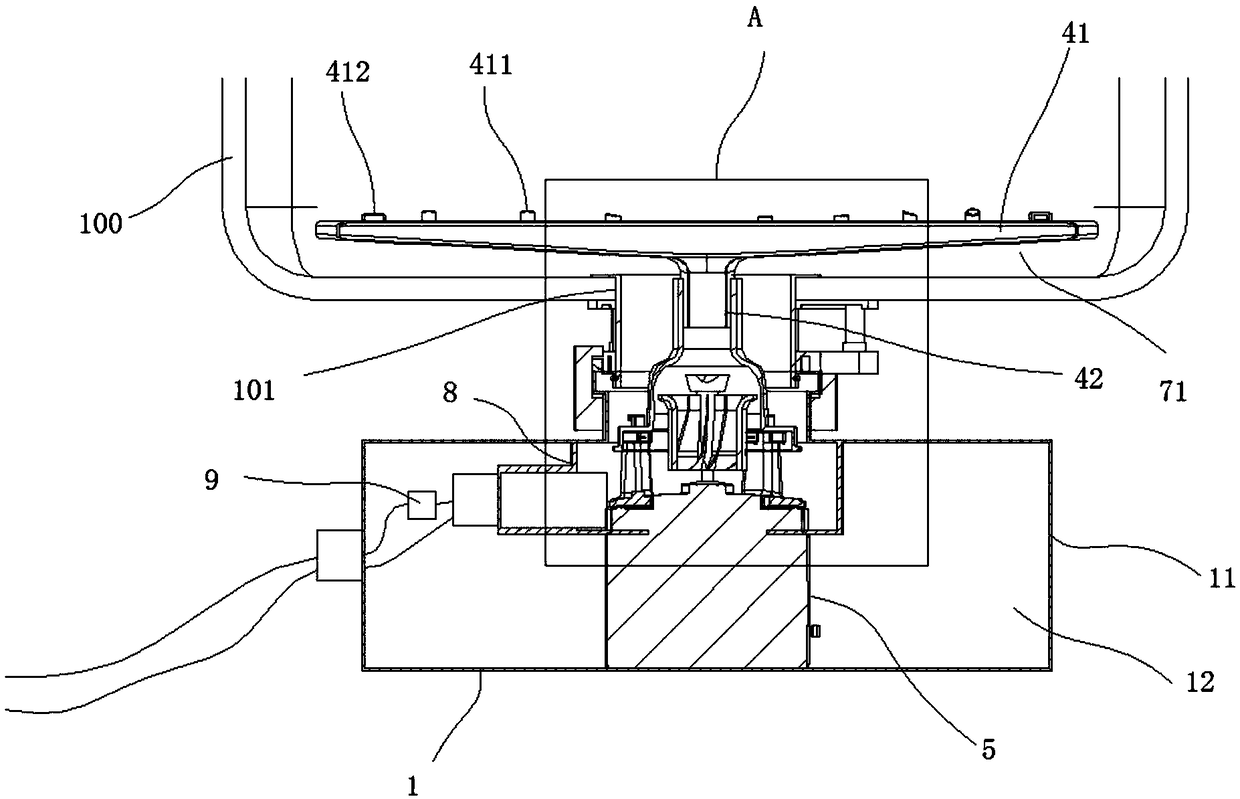

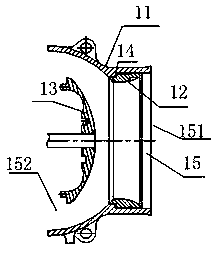

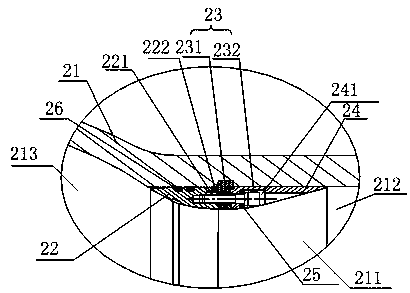

Cleaning equipment

PendingCN108937791AEffective exhaustionInstall instantTableware washing/rinsing machine detailsCleaning equipmentWater sourceWaste management

Owner:GREE ELECTRIC APPLIANCES INC

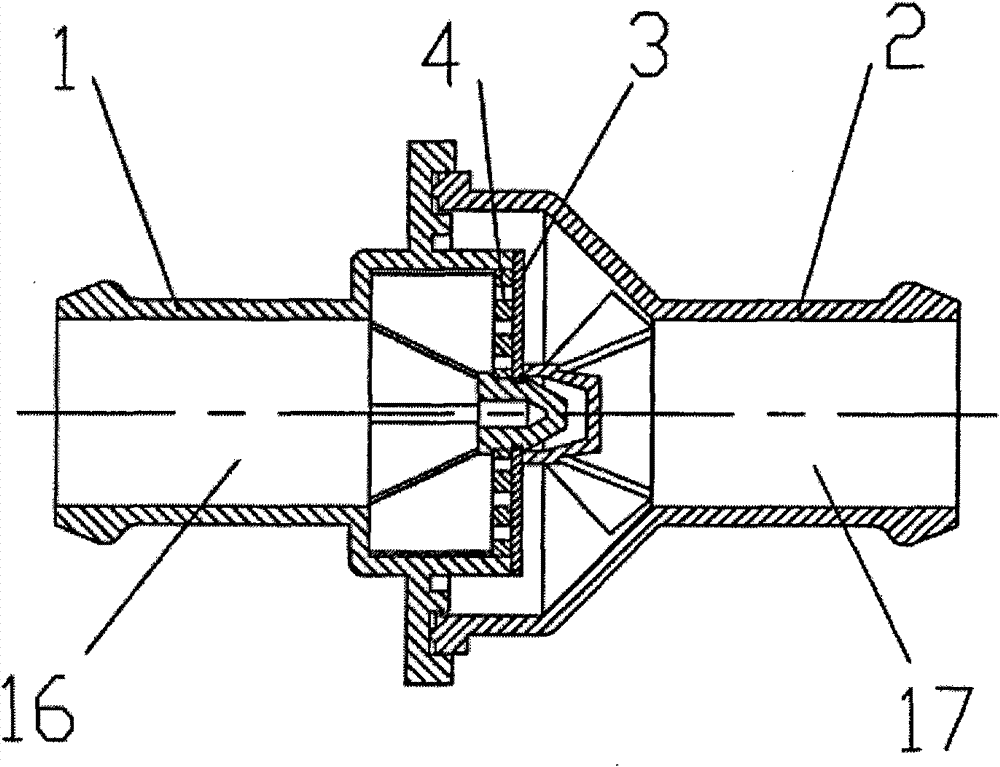

The connection structure of the valve seat and the valve body of the check valve

ActiveCN103603981BEasy to implement manufacturingEasy to assemble and disassembleEngine sealsCheck valvesCheck valveValve seat

The invention relates to a connecting structure of a valve seat and a valve body of a check valve. The connecting structure comprises a valve body, a valve seat and a fixing structure. The valve seat is arranged on the inner wall of the valve body and is tightly connected with the valve body, the fixing structure is used for fixing the valve seat on the valve body and comprises a locating part and a fastener, the locating part is axially arranged opposite to the valve body in a locating manner, and the fastener is used for fixedly connecting the locating part and the valve seat. The valve body is fixed on the valve seat via the locating part and the fastener; with the fixing structure, dismounting between the valve body and the valve seat is easy to realize and the fixing structure is stable in connection; the parts above is easy to be manufactured by manufacturers.

Owner:NEWAY VALVE SUZHOU

Limiting device of driving half axle bearing

ActiveCN113682089ALimit radial movementAchieve supportAxle unitsRolling resistance optimizationStructural engineeringControl theory

Owner:DONGFENG MOTOR GRP

Positioning assembly for heart stent metal mold processing machine tool

The present invention discloses a positioning assembly for a heart stent metal mold processing machine tool. The positioning assembly comprises a base disc, a driving pair and a vertical frame which are fixedly arranged above the base disc, and the base disc is rotationally connected with a first horizontal transmission gear disc, a second horizontal transmission gear disc and an intermittent gear through a rotating shaft; a first gear transmission roller and a second gear transmission roller are arranged above the base disc, an eccentric rod is fixedly arranged on the side face of the vertical transmission gear disc, and a transmission rod is connected between the eccentric rod and the connecting rod in a transmission manner. According to the present invention,by adopting a circulating up-and-down extrusion forming structure, the annular extrusion teeth drive a mold circular ring in an annular groove to bend, and by adopting a clearance transmission rotating structure, the annular extrusion teeth conduct extrusion forming on the mold circular ring, and meanwhile by adopting a co-power linkage transmission structure, the mold circular ring is extruded and formed to be of an uneven structure after being subjected to linkage transmission, and meanwhile, convenience is brought to disassembly and material taking after being formed at a lantern ring.

Owner:黄国强

An assembly device and assembly method for a unipolar plate capacitive sensor

ActiveCN112959050BAchieve insulationRealize the shielding effectMaterial gluingMetal working apparatusMechanical engineeringCapacitance transducer

The invention belongs to the field of capacitance sensor assembly and provides an assembly device and method for a single-plate capacitance sensor. Wherein, the assembly device includes a base plate, a sensor fixing table, a gantry frame, a first differential head, a correction block, a flexible ring and a flexible disk; the sensor fixing table and the gantry frame are both installed on the base plate; the sensor fixing table is arranged on Below the gantry frame; the correction block is arranged on the sensor to be assembled, the first differential head is installed on the gantry frame and set opposite to the correction block; the two sides of the flexible disk are respectively connected to the correction block and the measuring pole of the sensor, To realize the longitudinal flexible assembly of the measuring pole; the two sides of the flexible ring are respectively connected with the calibration block and the equipotential ring of the sensor to realize the longitudinal flexible assembly of the equipotential ring; Tightly apply pressure to the calibration block so that the sensor measuring pole, the equipotential ring and the shielding ring are assembled coaxially and the bottom surfaces of the three are on the same level, so as to ensure the smoothness of the sensor surface.

Owner:SHANDONG UNIV

Connecting structure

ActiveCN112124061ARealize axial limitSmall assembly space requirementJet propulsion mountingInternal combustion mountingVehicle frameRoad condition

The invention discloses a connecting structure, and relates to the technical field of connecting accessories. The connecting structure is used for connecting an engine front support with a vehicle frame, and comprises the following components: a front support and a connecting seat; the front support is provided with an installation part; a long hole is formed in the installation part in a penetrating manner; one end of the connecting seat is used for being connected with the vehicle frame; a protruding column is arranged at the other end of the connecting seat in a protruding mode; a first protruding block is arranged on the side wall at the end, away from the connecting seat, of the protruding column in a protruding mode; the protruding column is arranged in the long hole in a penetratingmode; and the first protruding block is matched with the hole edge of the long hole so as to axially limit the protruding column. Bolts are not needed, the requirement for assembling space is lowered, the structure is simple, and the problems that a connecting seat and a nut of an engine front support cannot be assembled and screwed, and the assembling efficiency and assembling quality are affected are solved. Besides, according to the connecting structure, when the protruding block is matched with the long hole, loosening is not easily caused under complex road conditions, and the stabilityis high.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

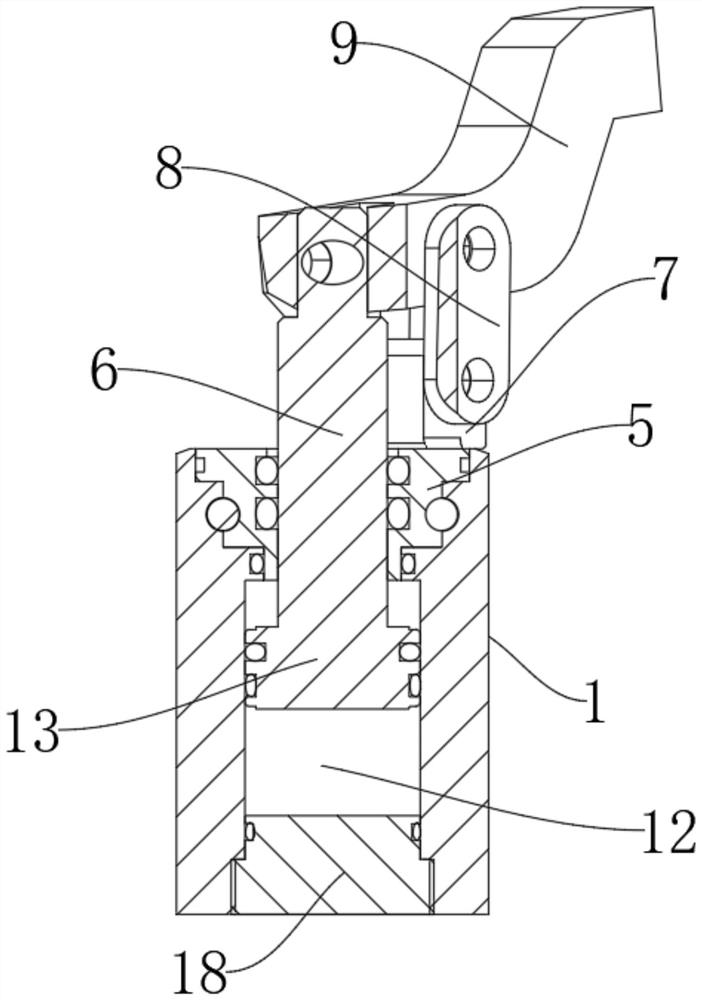

Radiotherapy device rotating machine frame support eccentric type adjustment device

ActiveCN109865208AImprove reliabilityImprove securityX-ray/gamma-ray/particle-irradiation therapyMechanical engineeringSelf alignment

The present invention belongs to the technical field of radiotherapy devices and also discloses a radiotherapy device rotating machine frame support eccentric type adjustment device. The radiotherapydevice rotating machine frame support eccentric type adjustment device comprises a front end support device and a rear end support device, the front end support device and the rear end support deviceboth comprise a supporting base seat and a riding wheel support component, the riding wheel support component comprises a support box body and a riding wheel roller path component, the riding wheel roller path component comprises two sets of riding wheel support units, riding wheels in the front end support device are tapered riding wheels, the rear end support device uses cylindrical riding wheels, and riding wheel shafts are all eccentric shafts. The device has a certain self-alignment function, also can realize own axial limit, can perform fine adjustment in a vertical direction after initial installation, and thus reduces errors of rotation center vertical directions of the front and rear end support devices, so that the support devices have relatively high reliability and safety, andthe adjustment device is high in adjustment precision.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com