Knob operation assembly and household appliance

A technology of knobs and components, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of increasing the design gap, shaking of the knob operation components, and not effectively solving the shaking of the matching parts of the knob structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

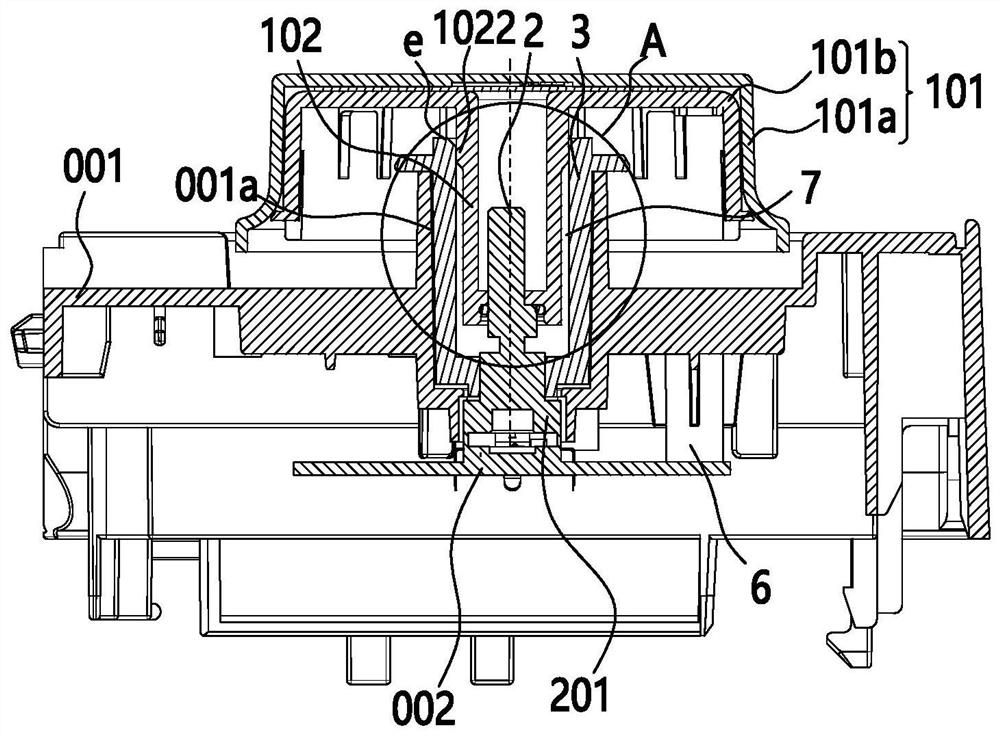

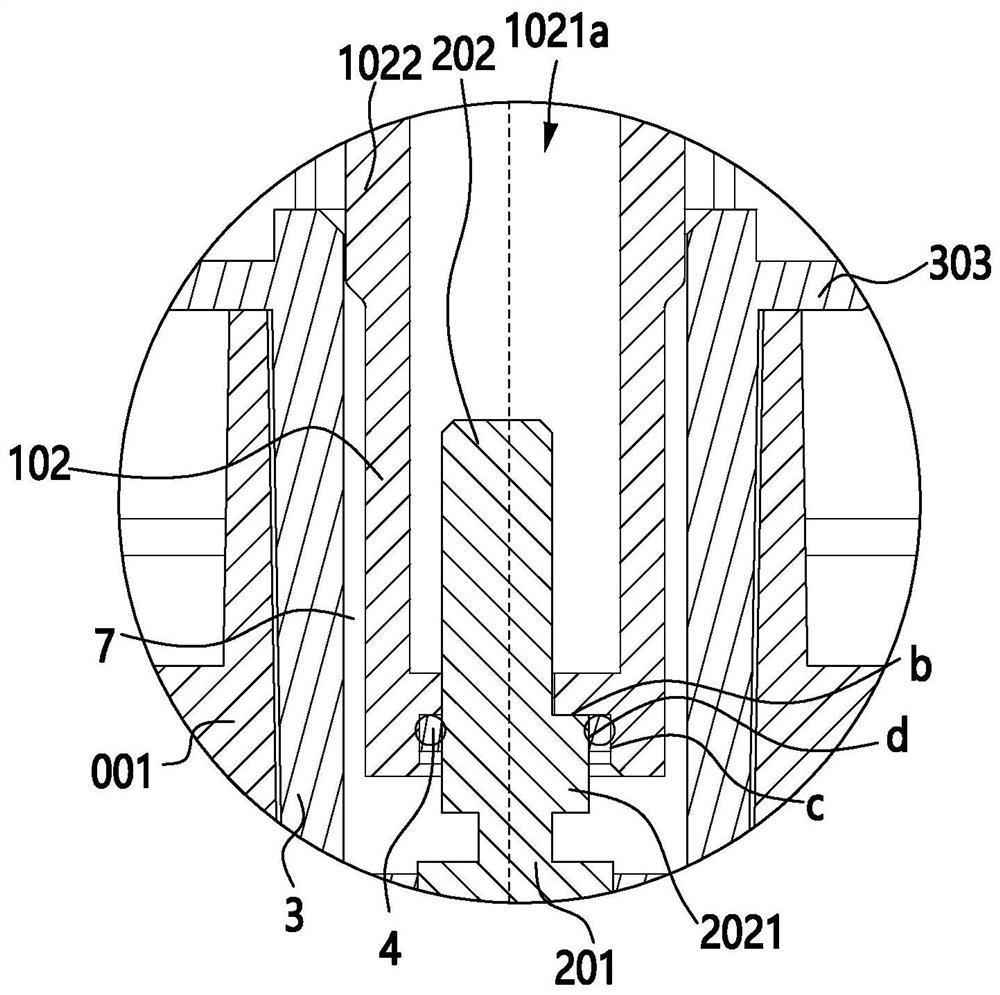

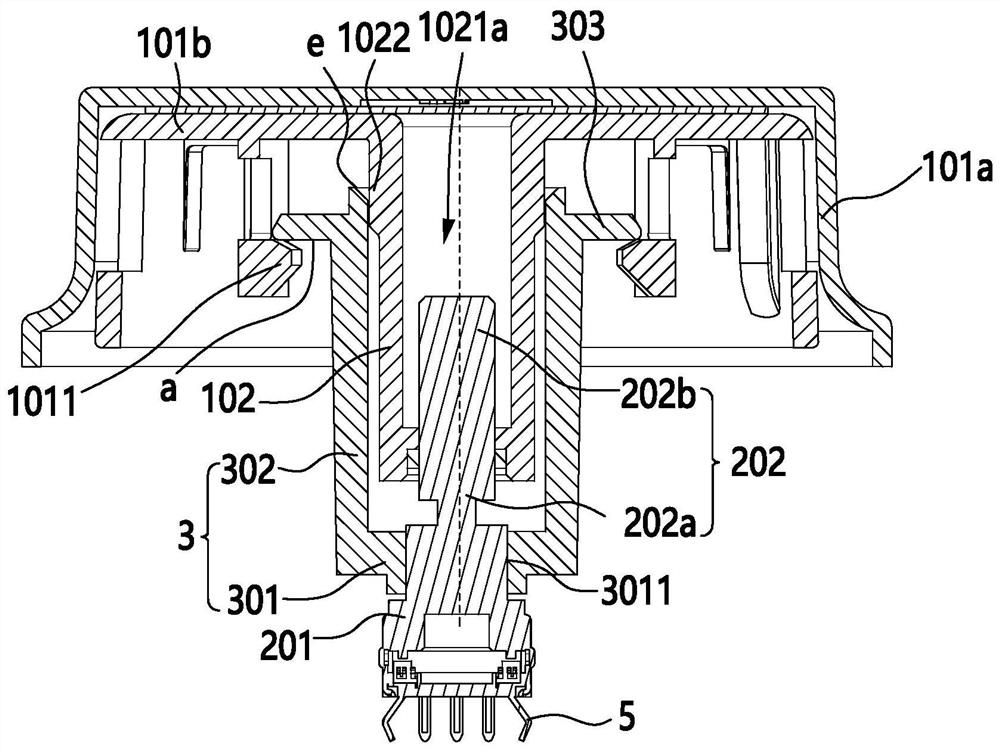

[0054] like Figure 1 to Figure 5 As shown, the knob operates components, including:

[0055] operating knob 1; and

[0056] The encoder 2 has a base 201 and a rotating shaft 202 connected to the base 201, the operation knob 1 drives the rotating shaft 202 to act synchronously, and the base 201 generates a corresponding electrical signal in response to the action of the rotating shaft 202; and,

[0057] The limiting member 3 connected with the base 201 is used for radially limiting the operating knob 1 .

[0058] Based on the problem that the encoder knob shakes due to the cumulative tolerance problem in the prior art, the solution proposed by the present invention is to connect the limit member 3 for the radial limit operation knob 1 to the base 201 of the encoder 2, in other words , the encoder indirectly radially limits the operating knob 1 through the limiter 3, since the limiter 3 is connected to the base 201 of the encoder 2 to form an assembly, and the fit tolerance b...

Embodiment 2

[0076] like figure 1 with Figure 5 As shown, the household appliance includes an operation panel 001 on which the knob operation assembly in the first embodiment is installed.

[0077] Specifically, such as figure 1 As shown, the operation panel 001 is provided with an assembly hole 001a for installing the rotating shaft 202 and the stopper 3, the operation knob 1 is located on the outside of the operation panel 001, and the inside of the operation panel 001 is provided with a circuit board 002 electrically connected to the base 201 .

[0078] With the above structure, when assembling, such as Figure 5 As shown, the base 201 of the encoder 2 is first installed on the circuit board 002 through the pin 5, and then the rotating shaft 202 of the encoder 2 is inserted into the assembly hole 001a of the operation panel 001, and the circuit board 002 and the operation panel 001 pass through The screw 6 is fixedly connected by means of penetration, etc., and then the limiter 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com