Double-disc type motor electric stepless speed change mechanical-electrical integration system

A technology of electric motor and stepless speed change, applied in the field of auto parts, can solve the problems of low power density, poor NVH characteristics, large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

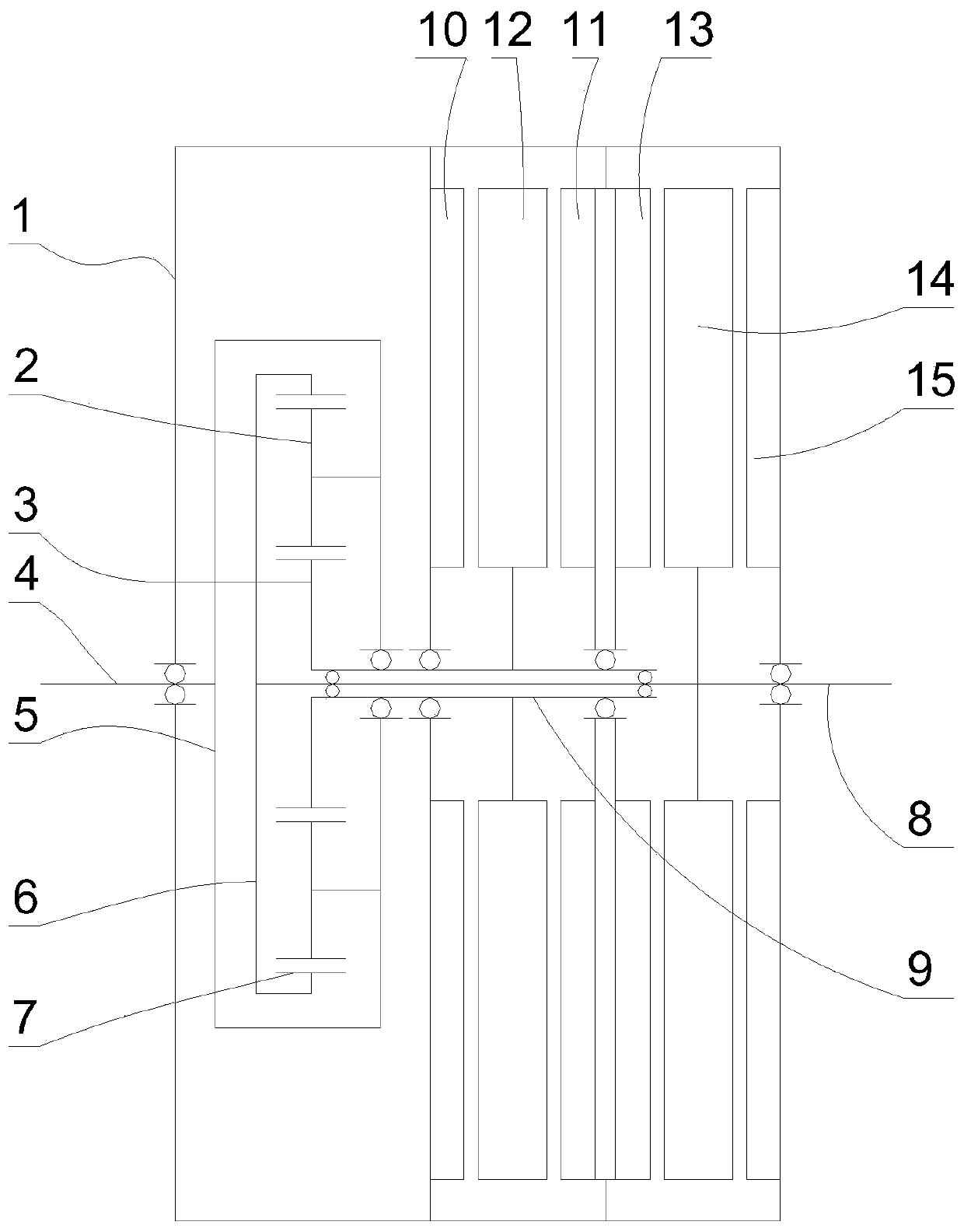

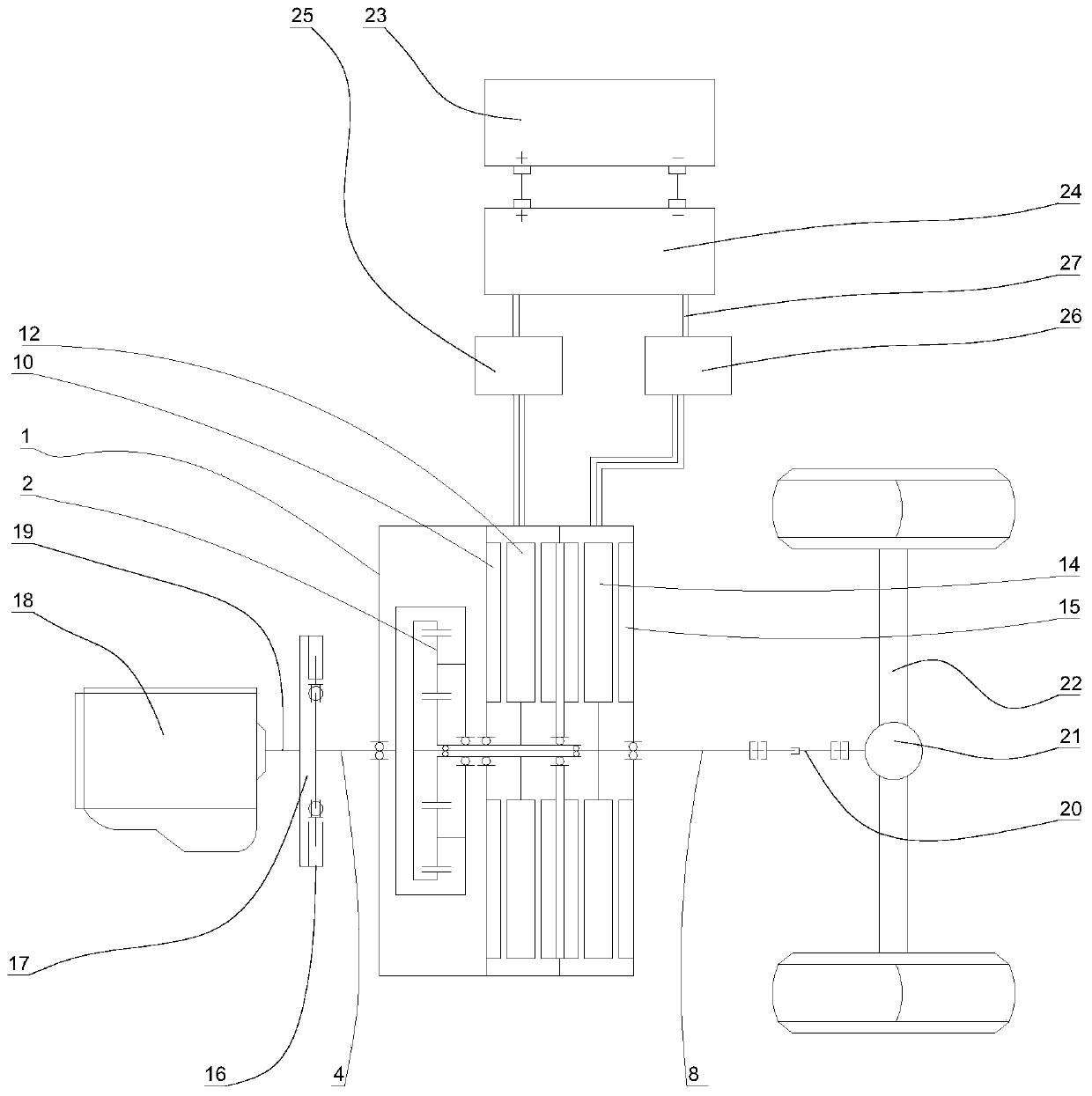

[0044] Such as Figure 1-Figure 2 As shown, a double-disk motor electric stepless variable speed electromechanical integration system includes a housing 1, a planetary gear 2, a sun gear 3, an input shaft 4, a planetary carrier 5, a ring gear carrier 6, a ring gear 7, an output shaft 8, Hollow shaft 9, ISG motor stator one 10, ISG motor stator two 11, ISG motor rotor 12, main drive motor stator one 13, main drive motor rotor 14 and main drive motor stator two 15.

[0045] ISG motor stator 1 10, ISG motor stator 2 11 and ISG motor rotor 12 form an ISG disc motor with double stator structure. ISG motor stator one 10 and ISG motor stator two 11 include but are not limited to stator windings, stator cores, and cooling channels.

[0046] The distance between ISG motor stator 10 and ISG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com