Patents

Literature

30results about How to "Wide torque range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

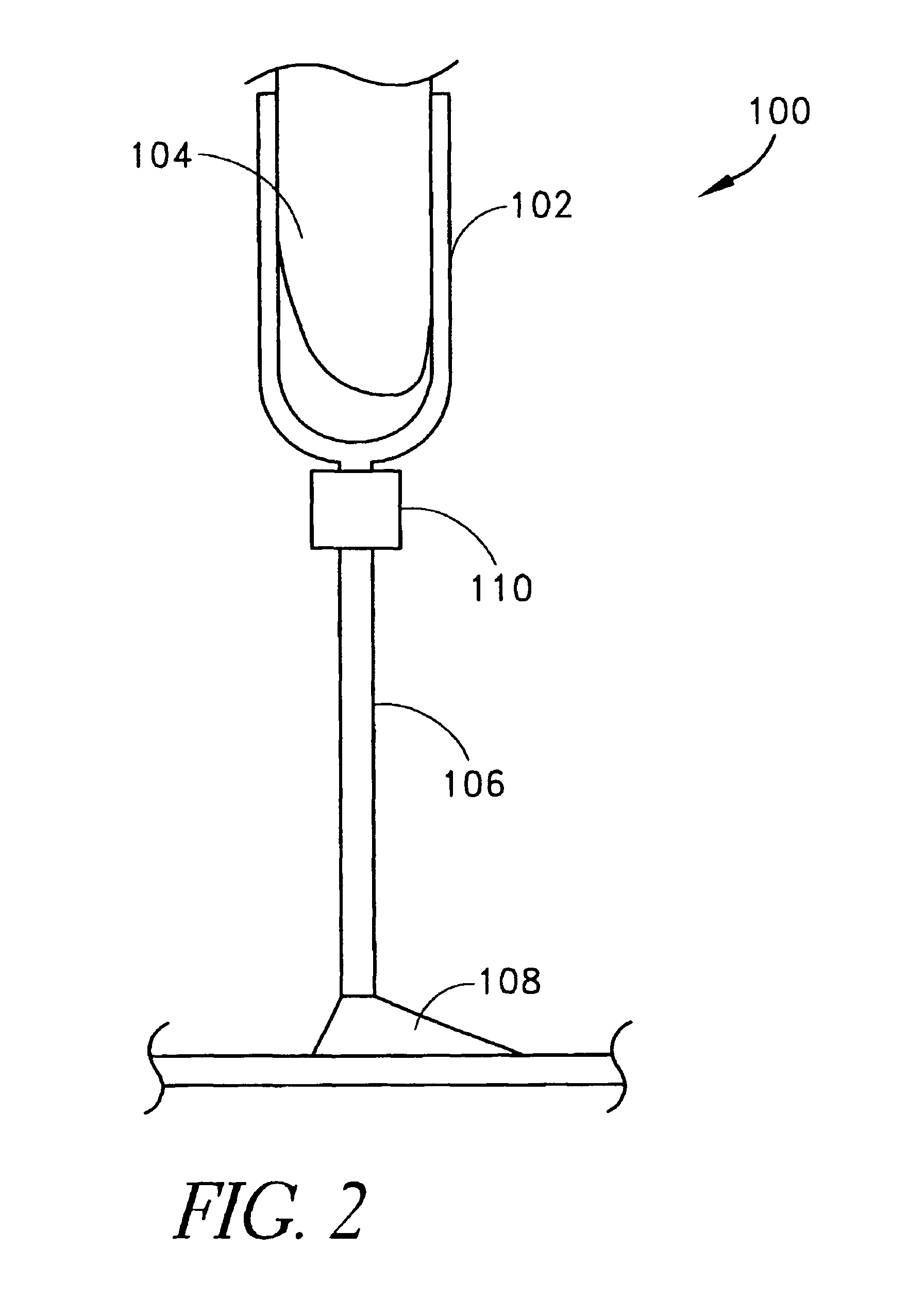

Electronically controlled prosthetic knee

InactiveUS6764520B2Improve efficiencyImprove practicalitySpringsNon-rotating vibration suppressionLow speedMagnetorheological fluid

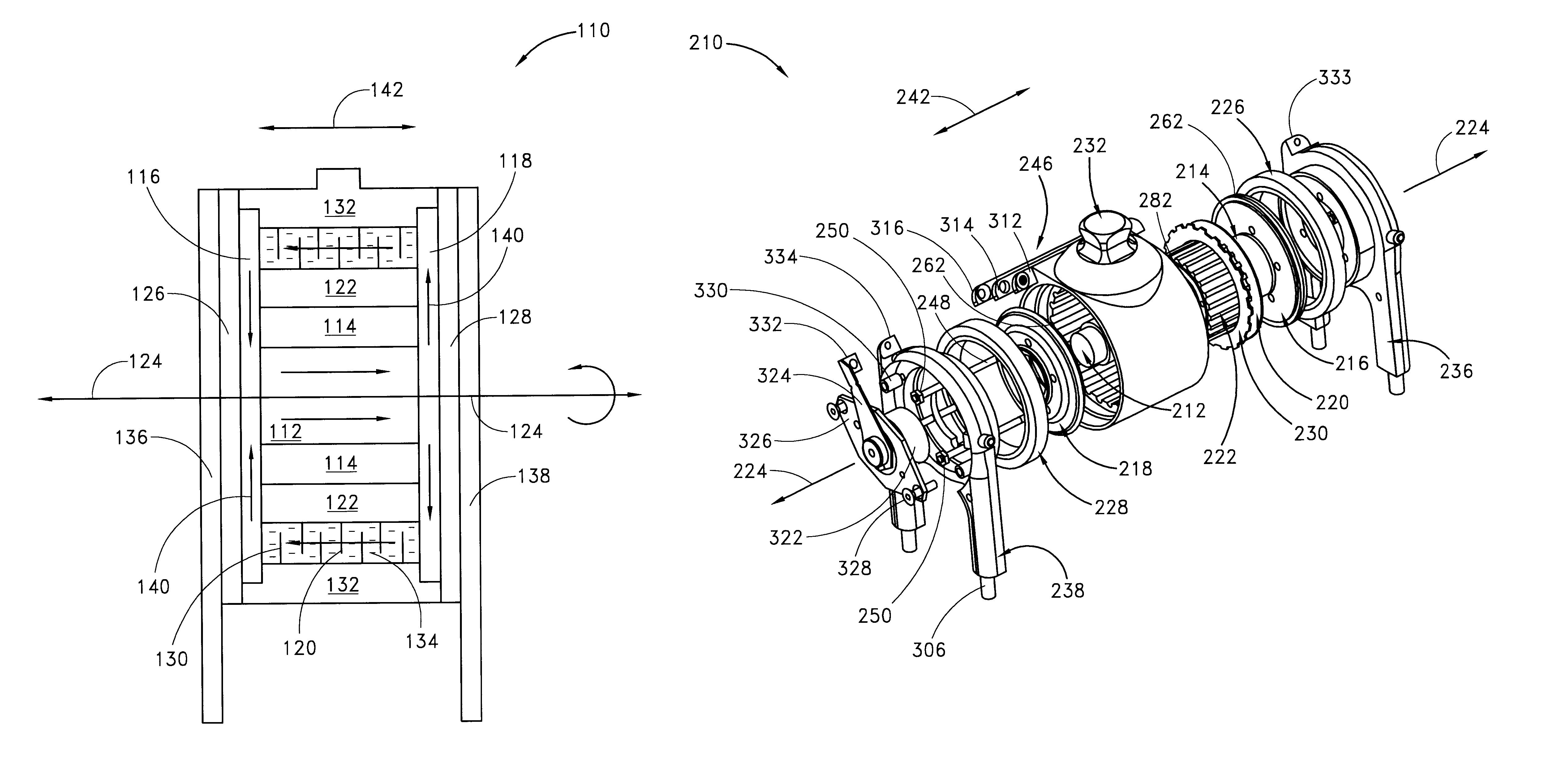

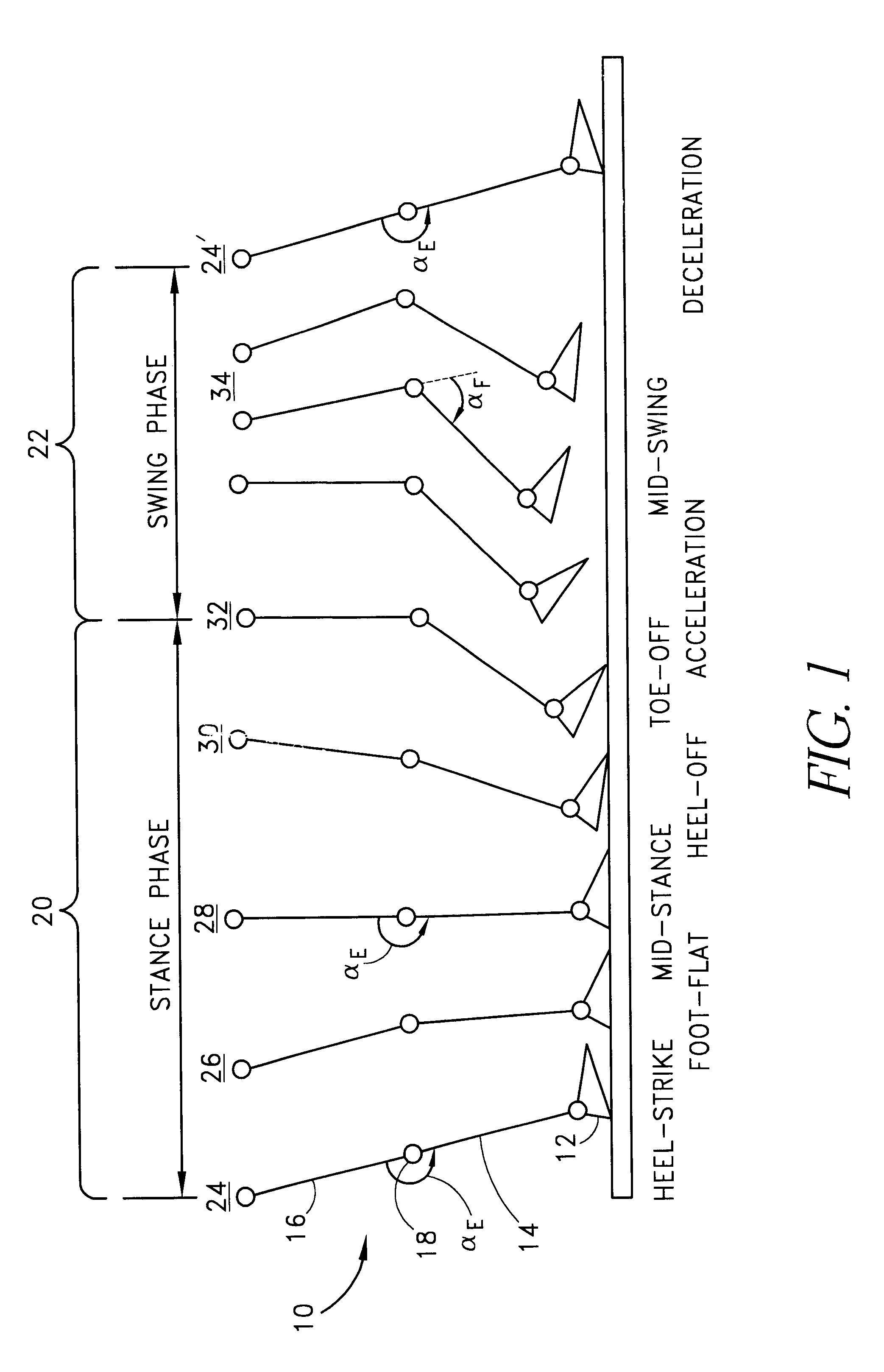

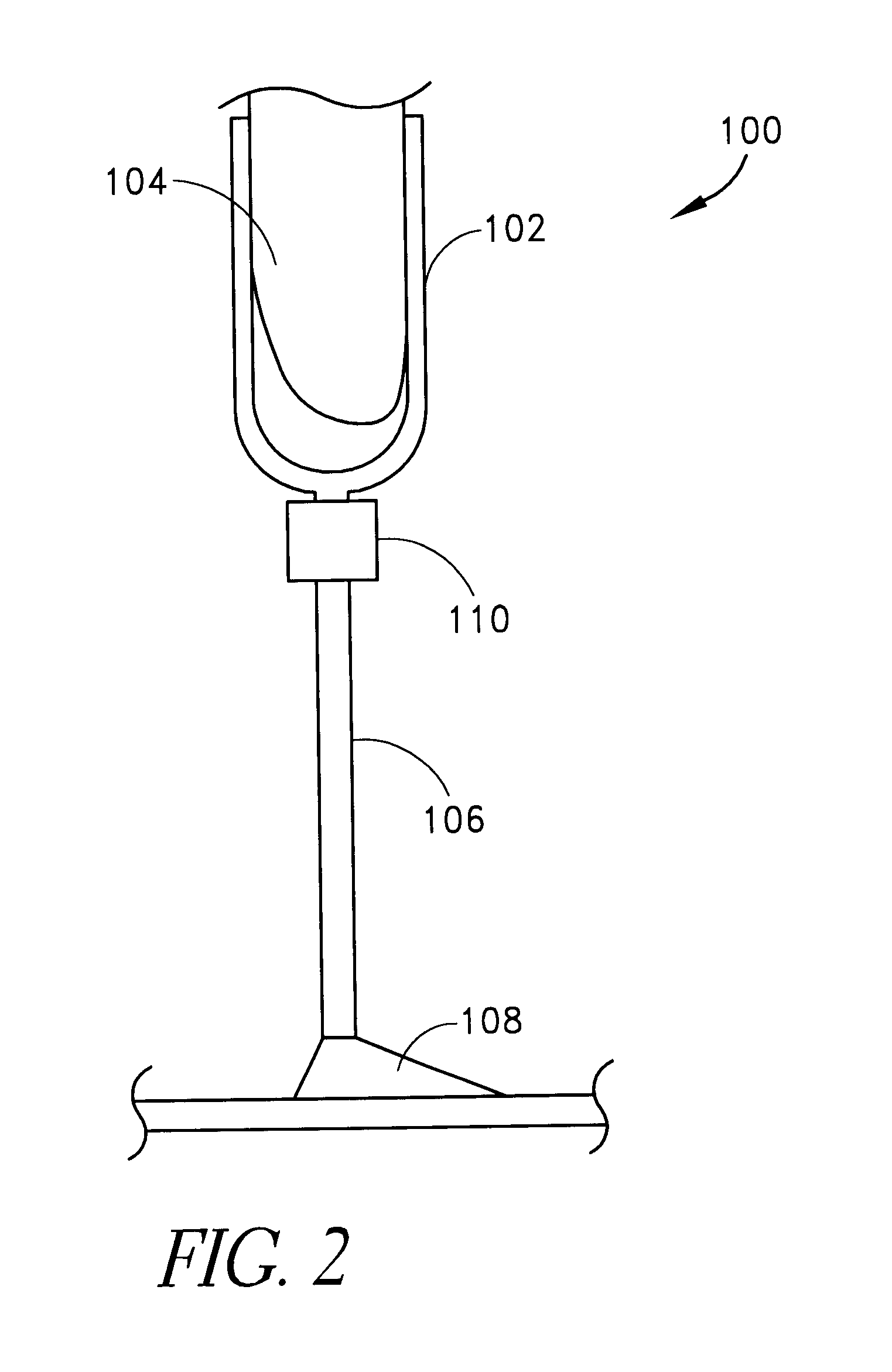

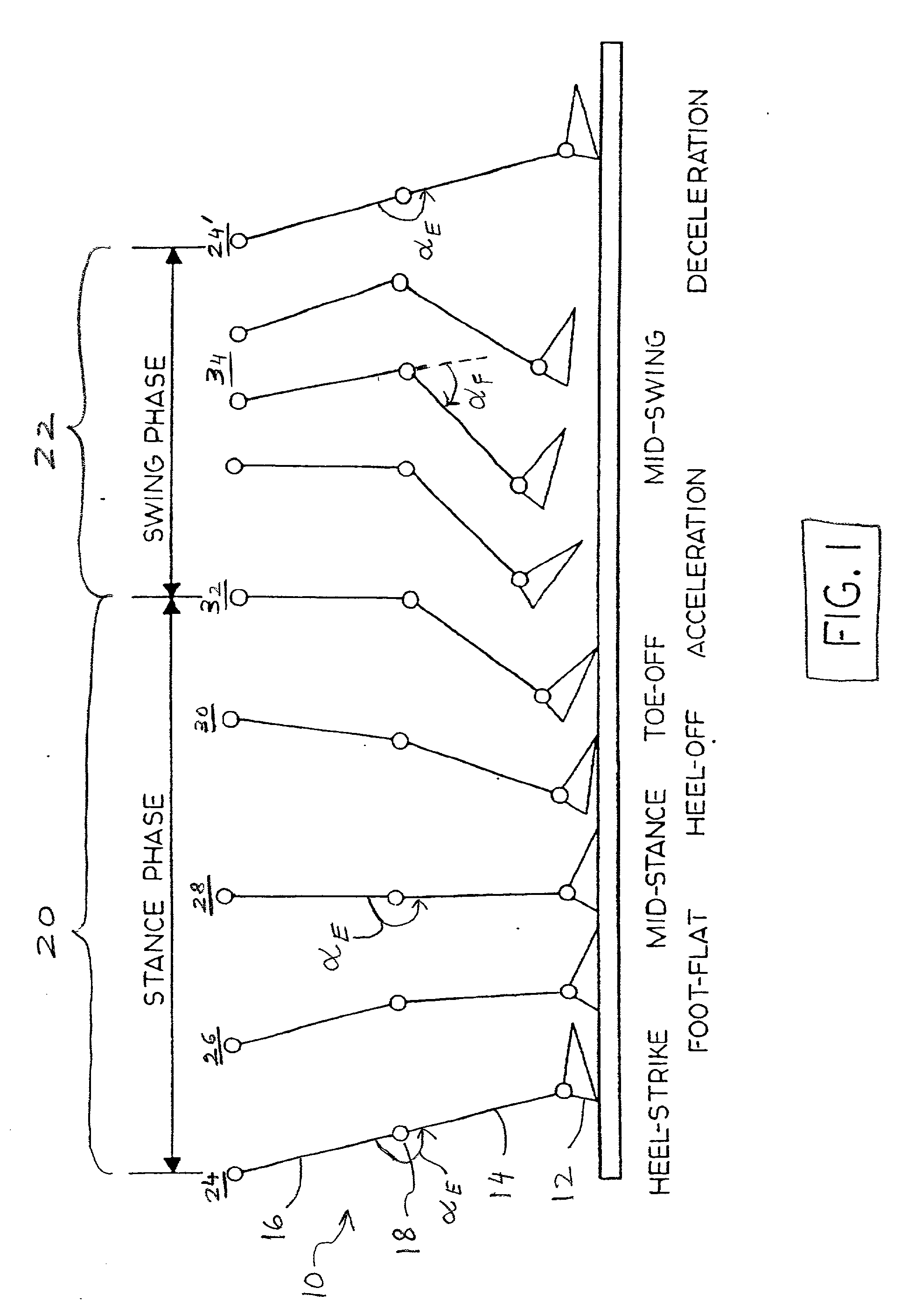

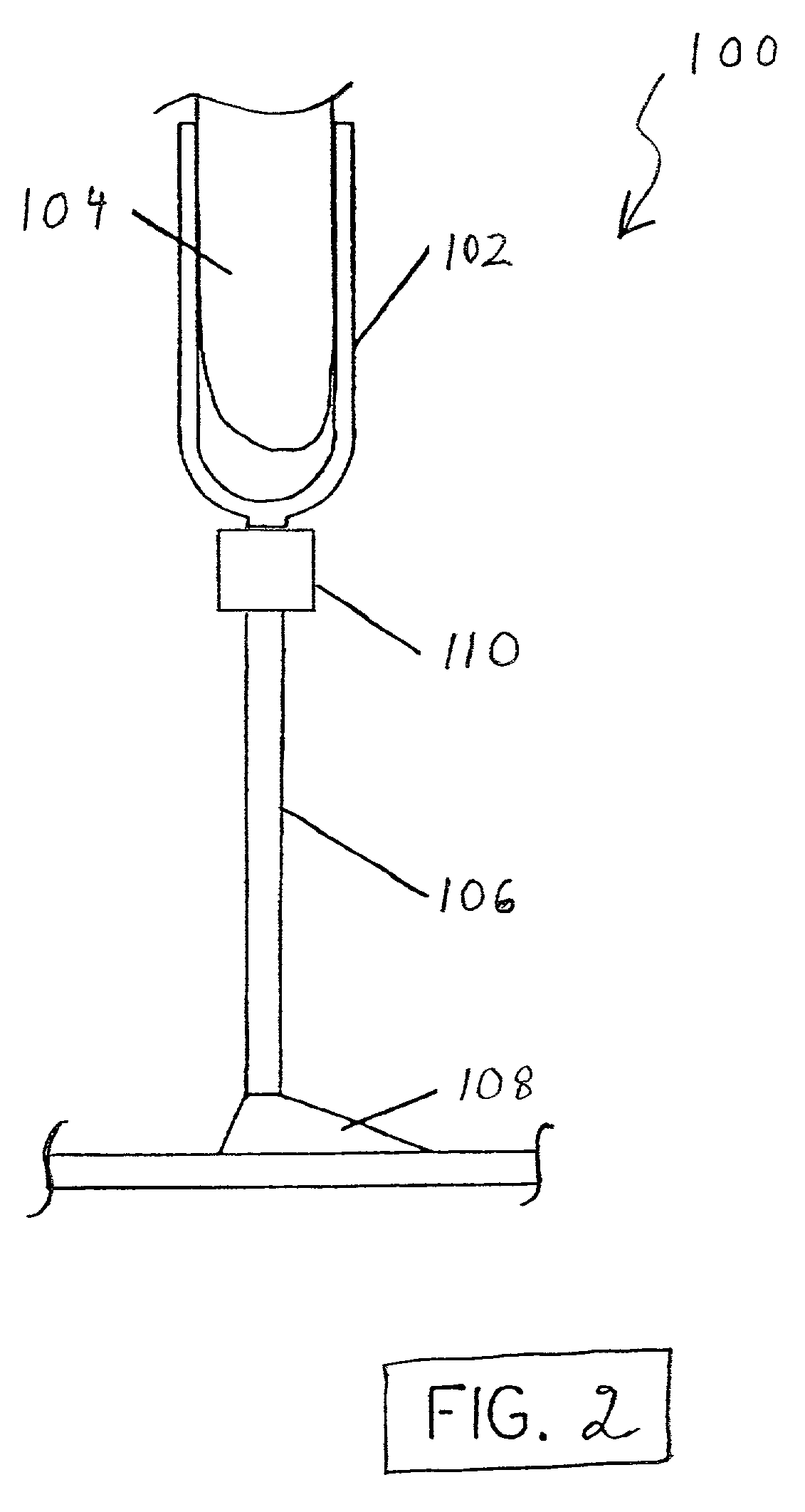

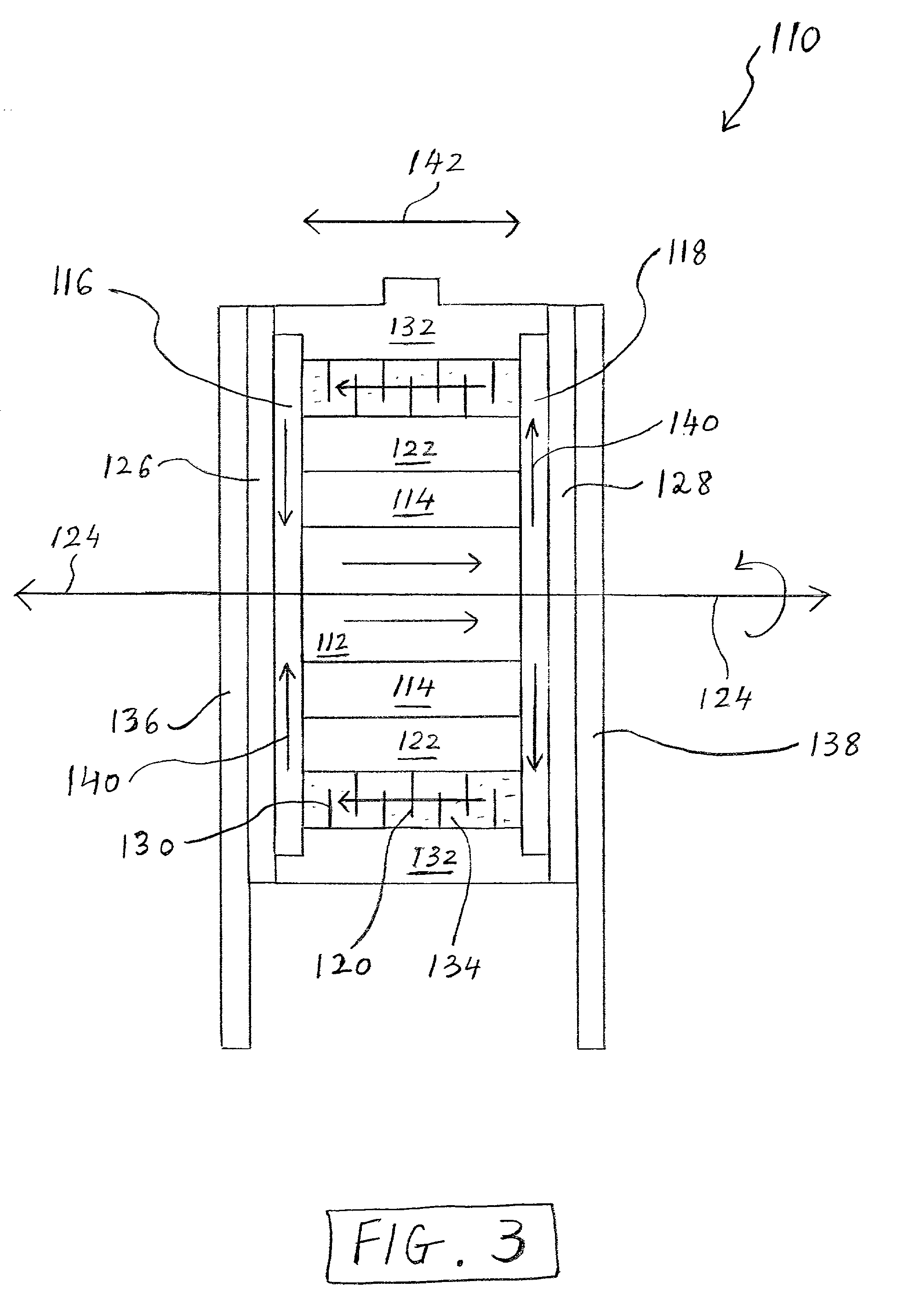

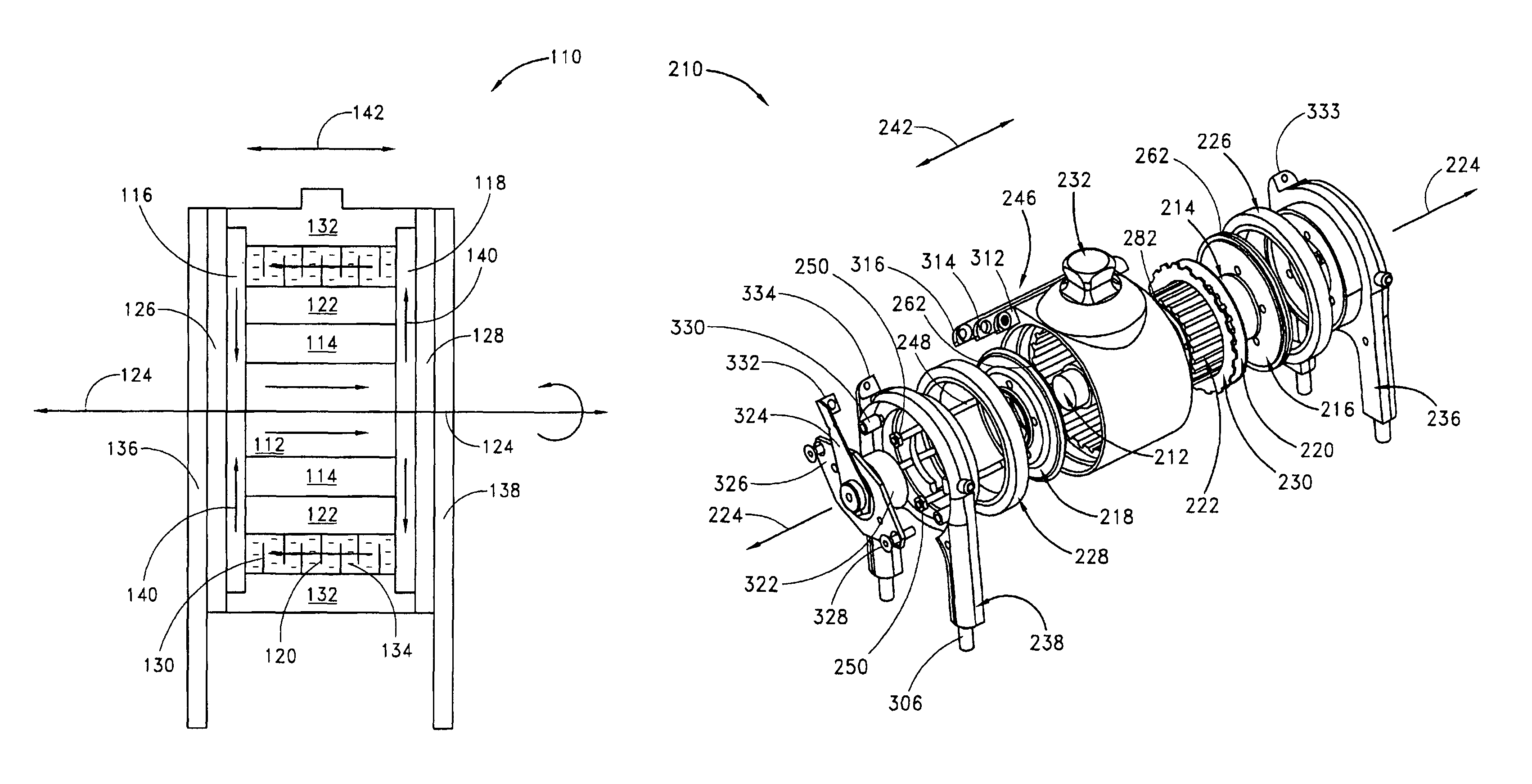

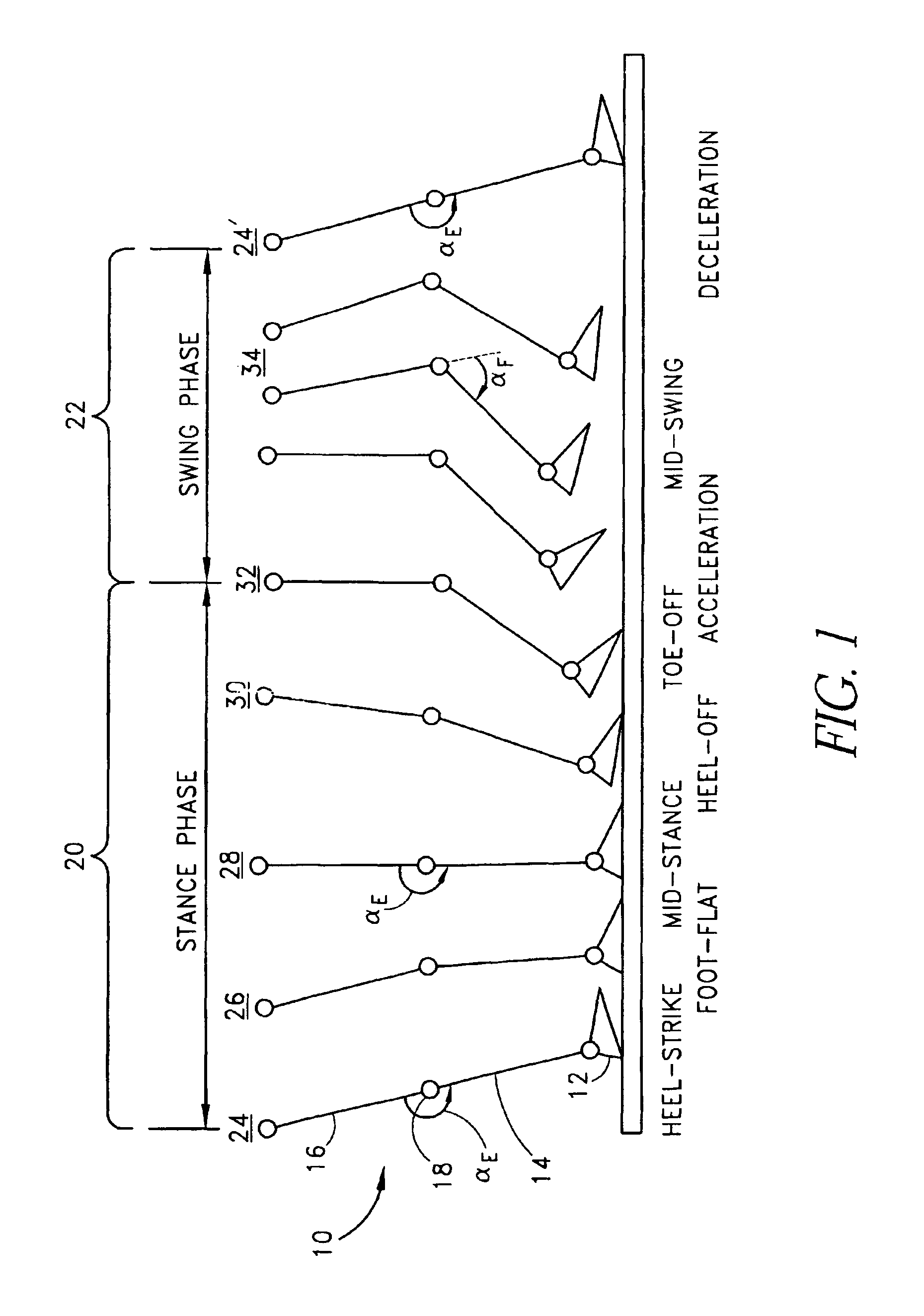

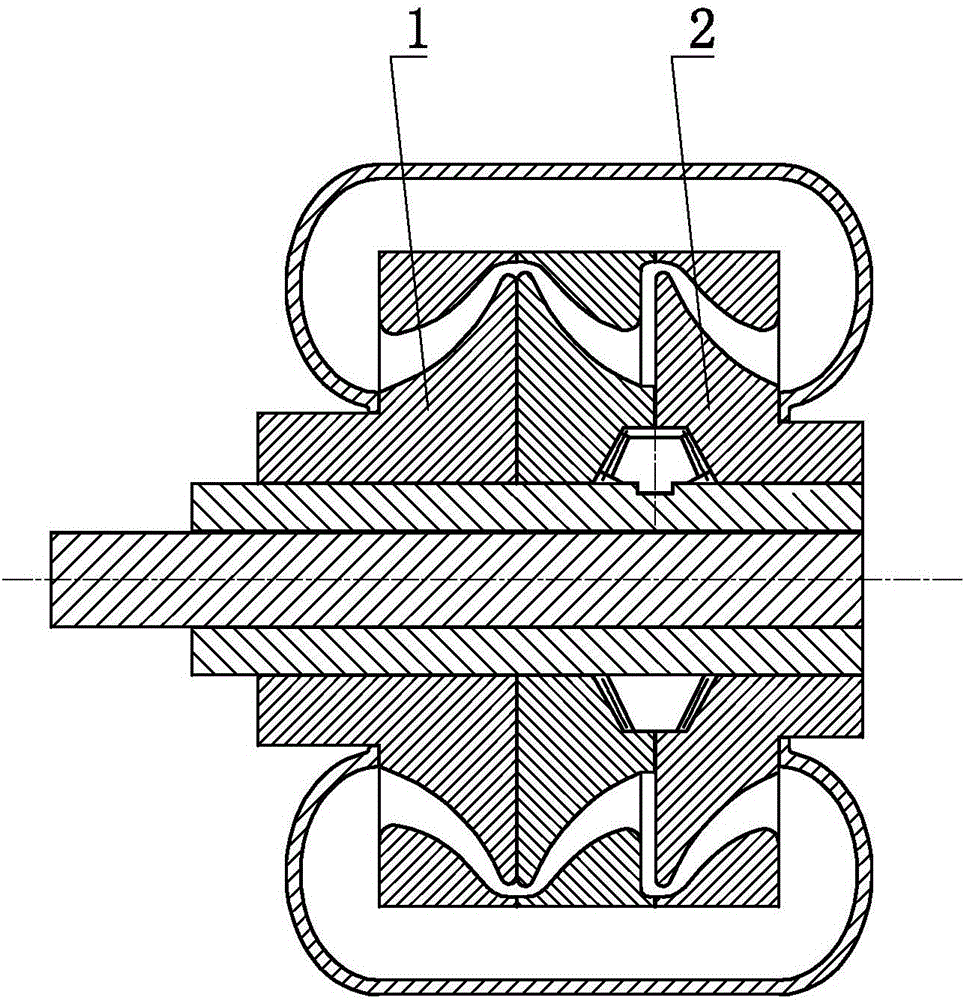

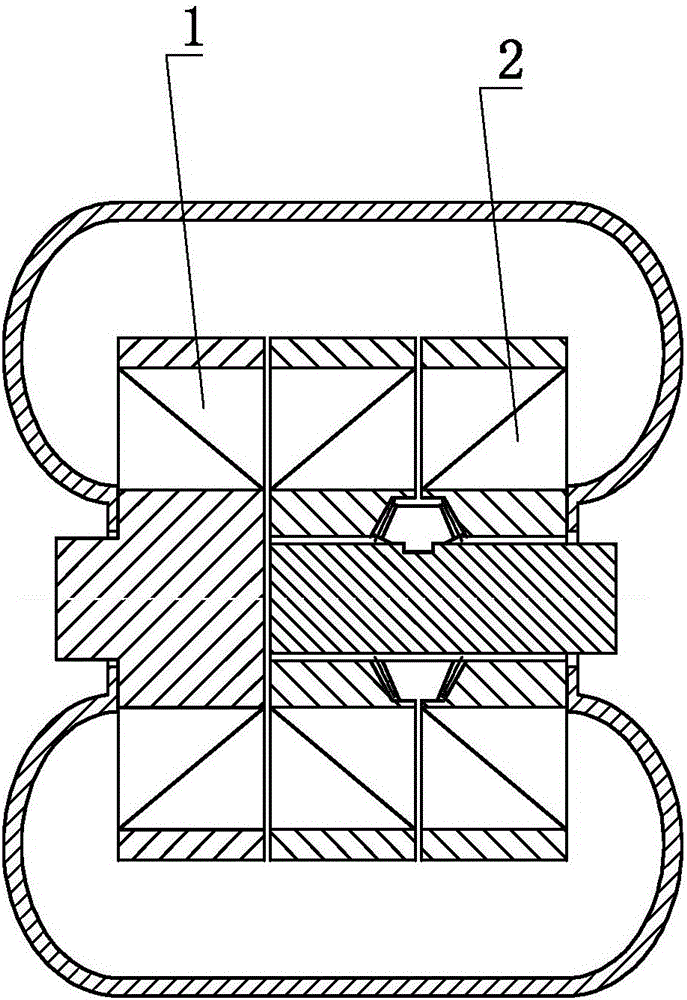

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

Electronically controlled prosthetic knee

InactiveUS20010029400A1Move and/or adapt comfortably and safelyImprove efficiencySpringsNon-rotating vibration suppressionFriction torqueMagnetorheological fluid

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

Electronically controlled prosthetic knee

InactiveUSRE42903E1Negligible changeNegligible pressureSpringsNon-rotating vibration suppressionMagnetorheological fluidControl theory

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the “shear mode” there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed—eliminating the need for a transmission—and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a “hybrid” braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

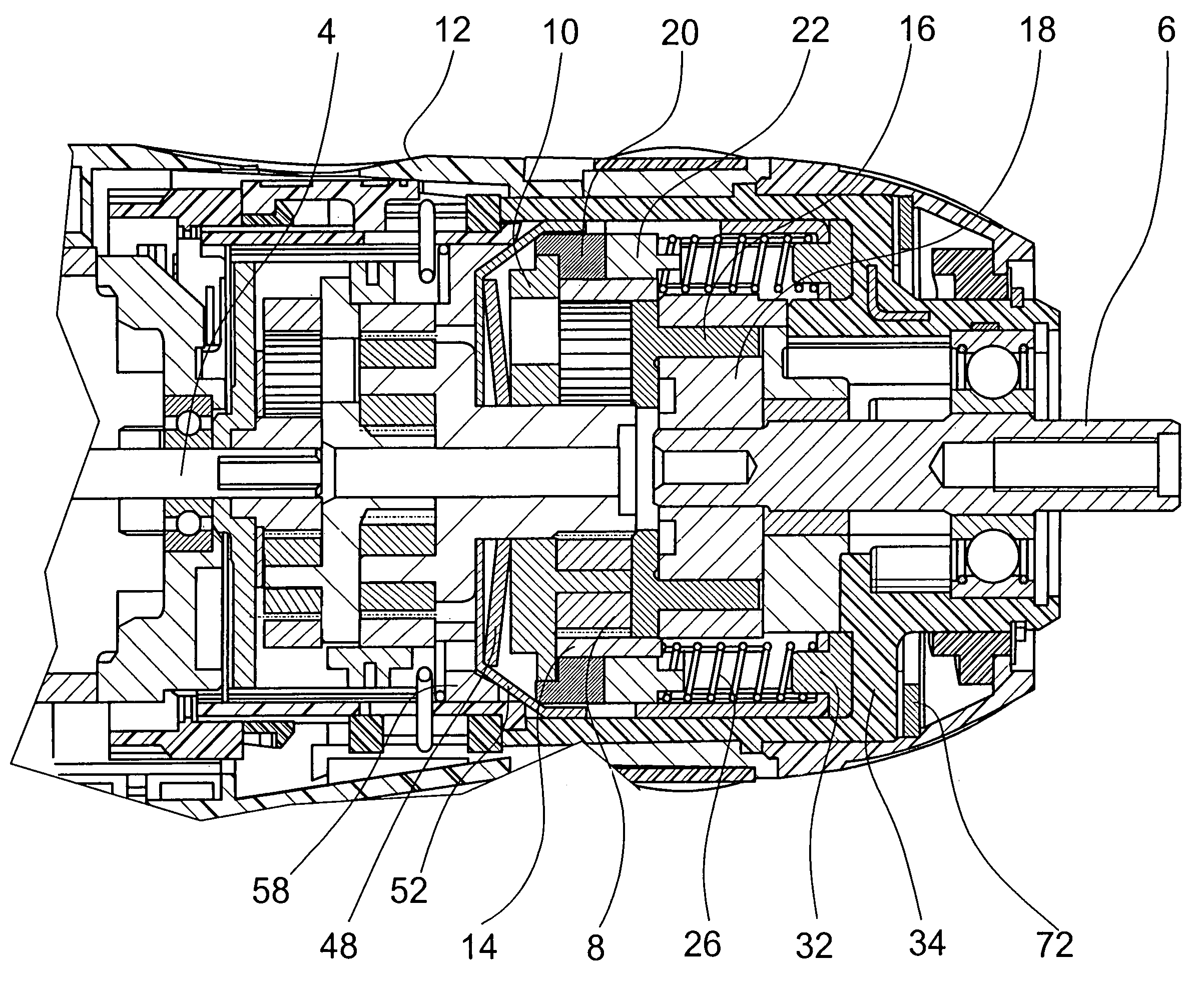

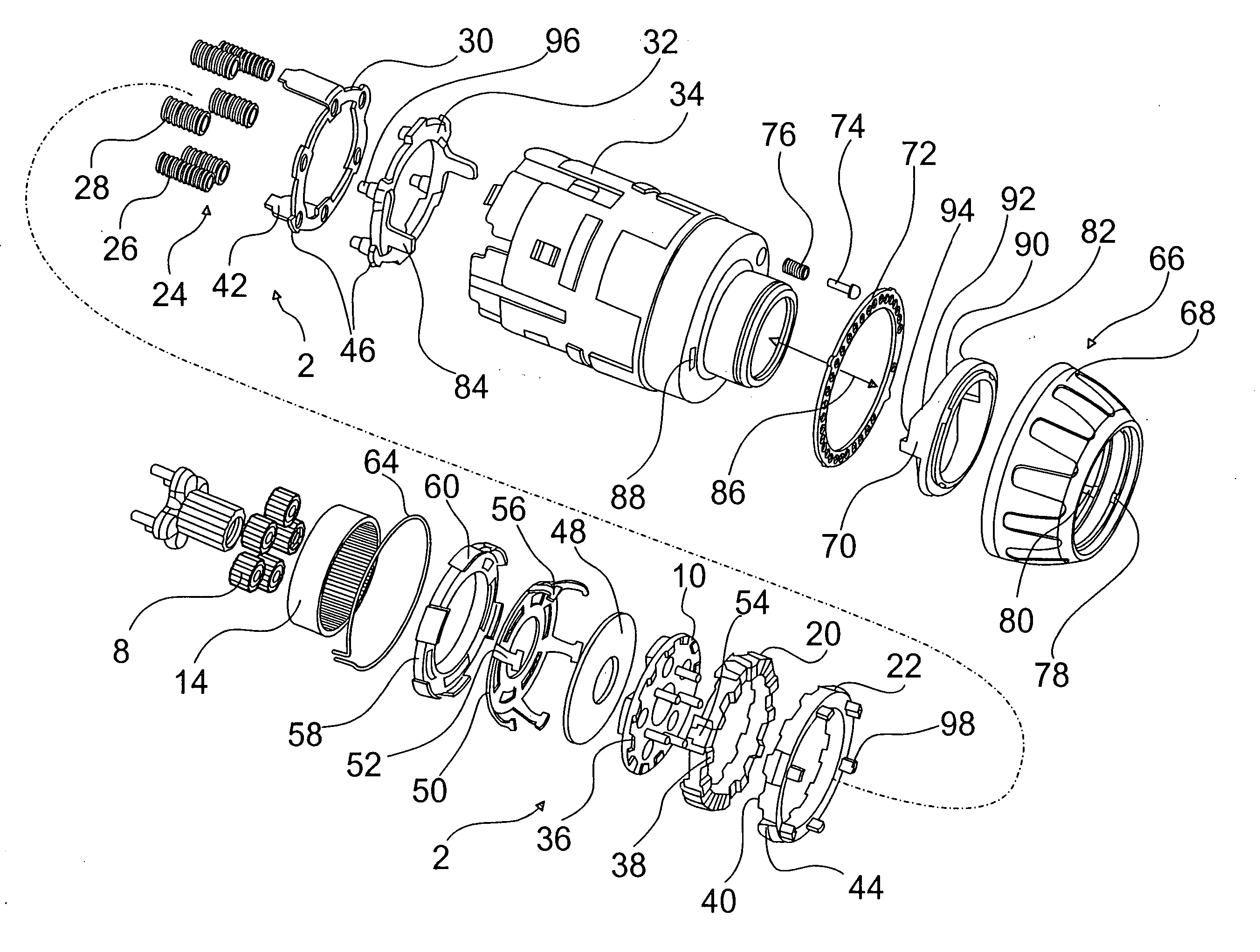

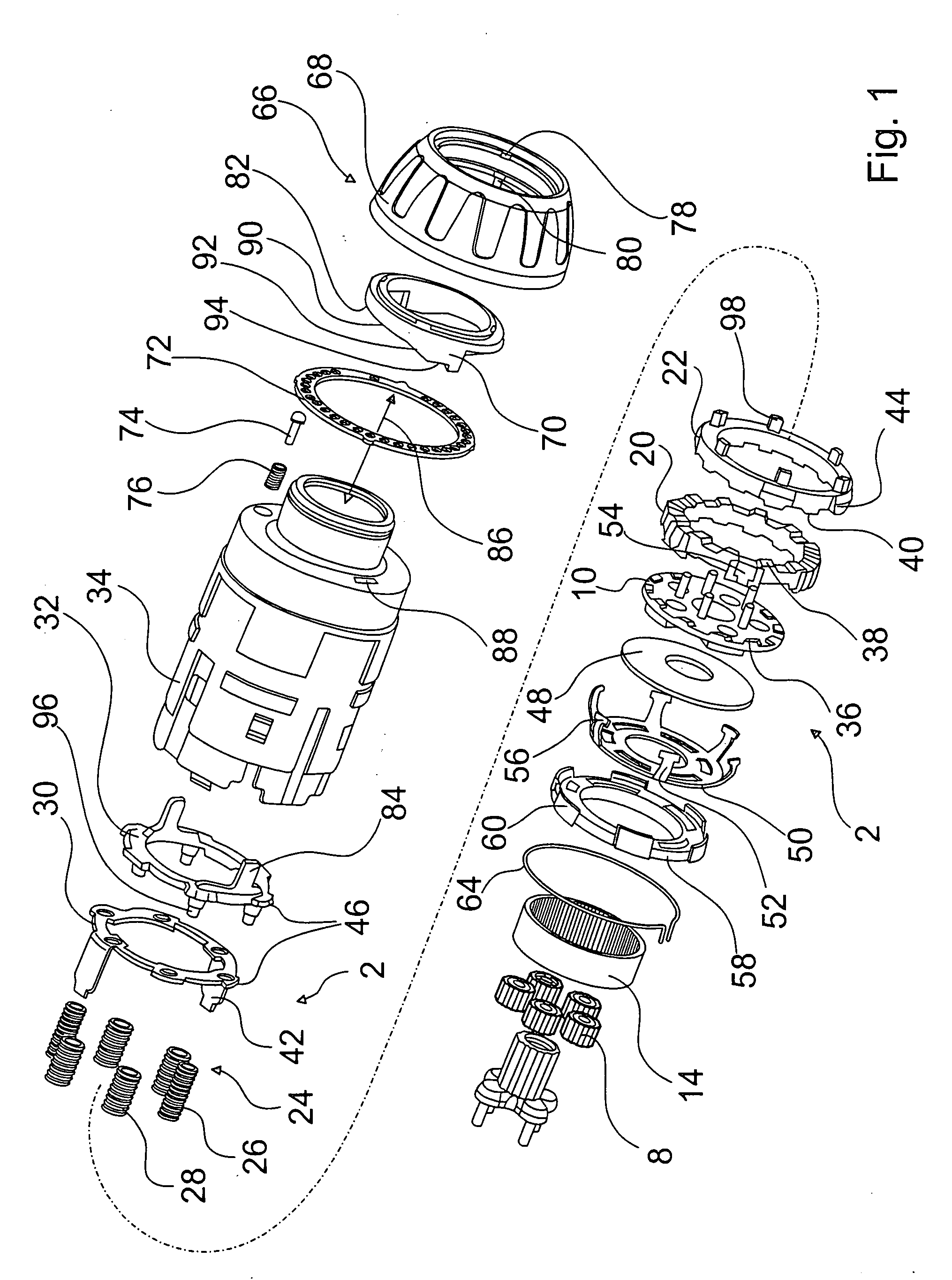

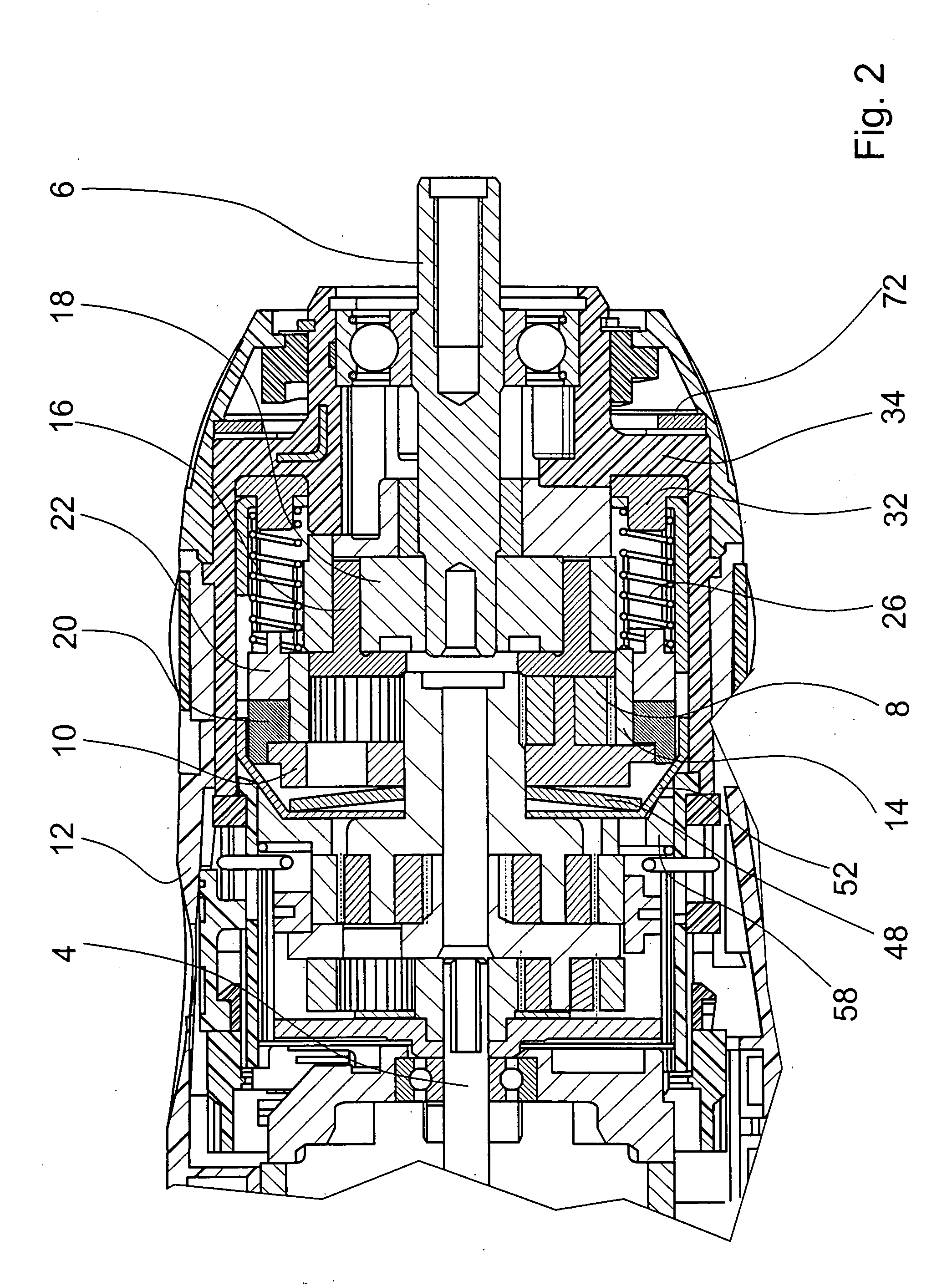

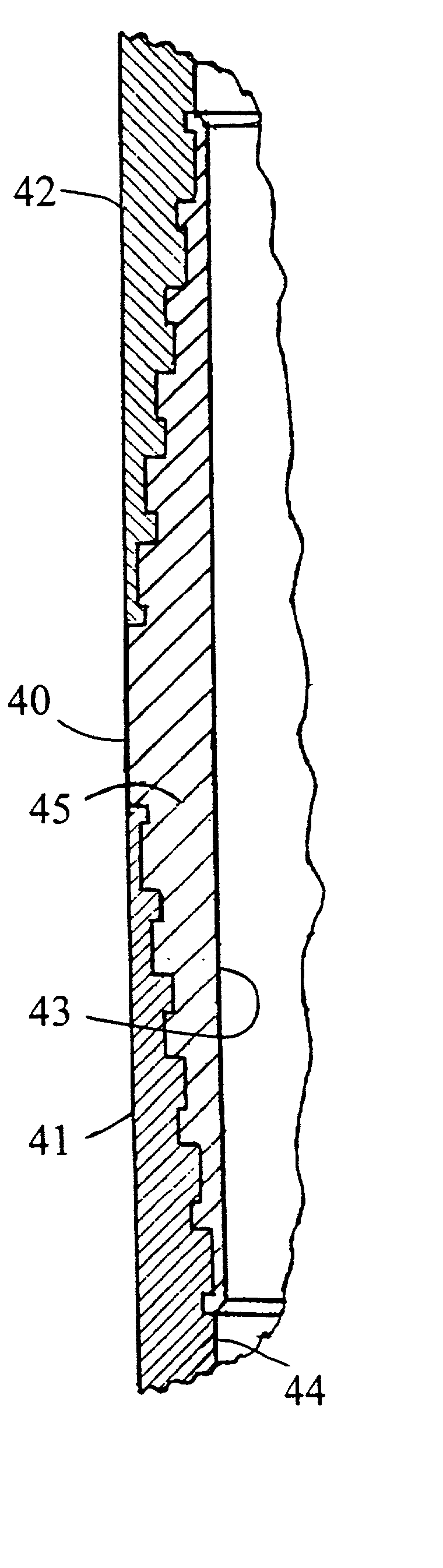

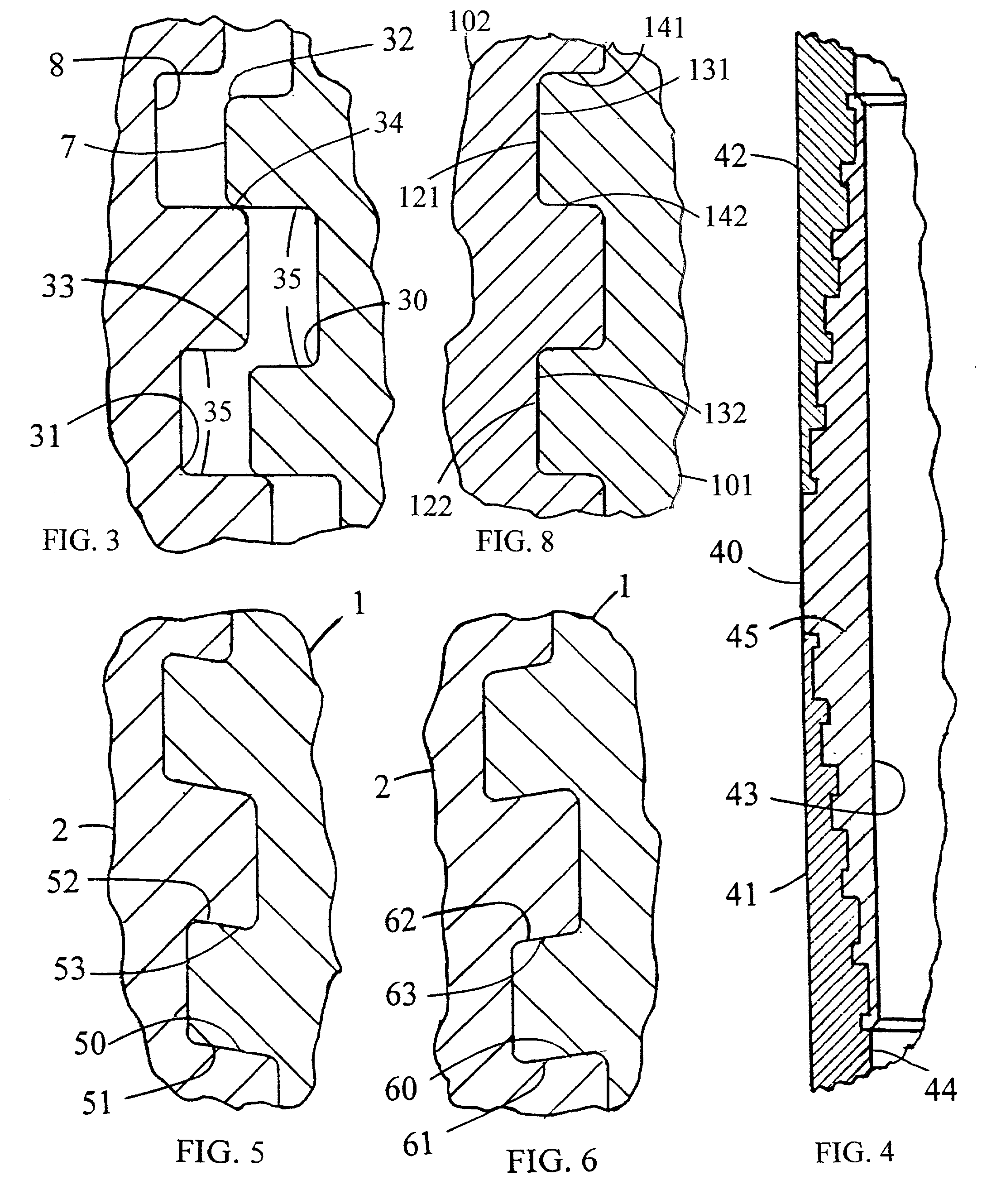

Hand-held power tool with a torque-limiting unit

InactiveUS7455123B2Easy to set upWide torque rangeMechanical actuated clutchesSlip couplingMaximum torqueHand held

A hand-held power tool has a motor output shaft, a tool driver, and a torque-limiting unit with which a maximum torque transferred from the motor output shaft to the tool driver is adjustable by an operator, the torque-limiting unit including a spring system, the spring system including differently-acting spring elements.

Owner:ROBERT BOSCH GMBH

Hand-held power tool with a torque-limiting unit

InactiveUS20060118380A1The method is simple and reliableImprove uniformityMechanical actuated clutchesSlip couplingMaximum torqueHand held

A hand-held power tool has a motor output shaft, a tool driver, and a torque-limiting unit with which a maximum torque transferred from the motor output shaft to the tool driver is adjustable by an operator, the torque-limiting unit including a spring system, the spring system including differently-acting spring elements.

Owner:ROBERT BOSCH GMBH

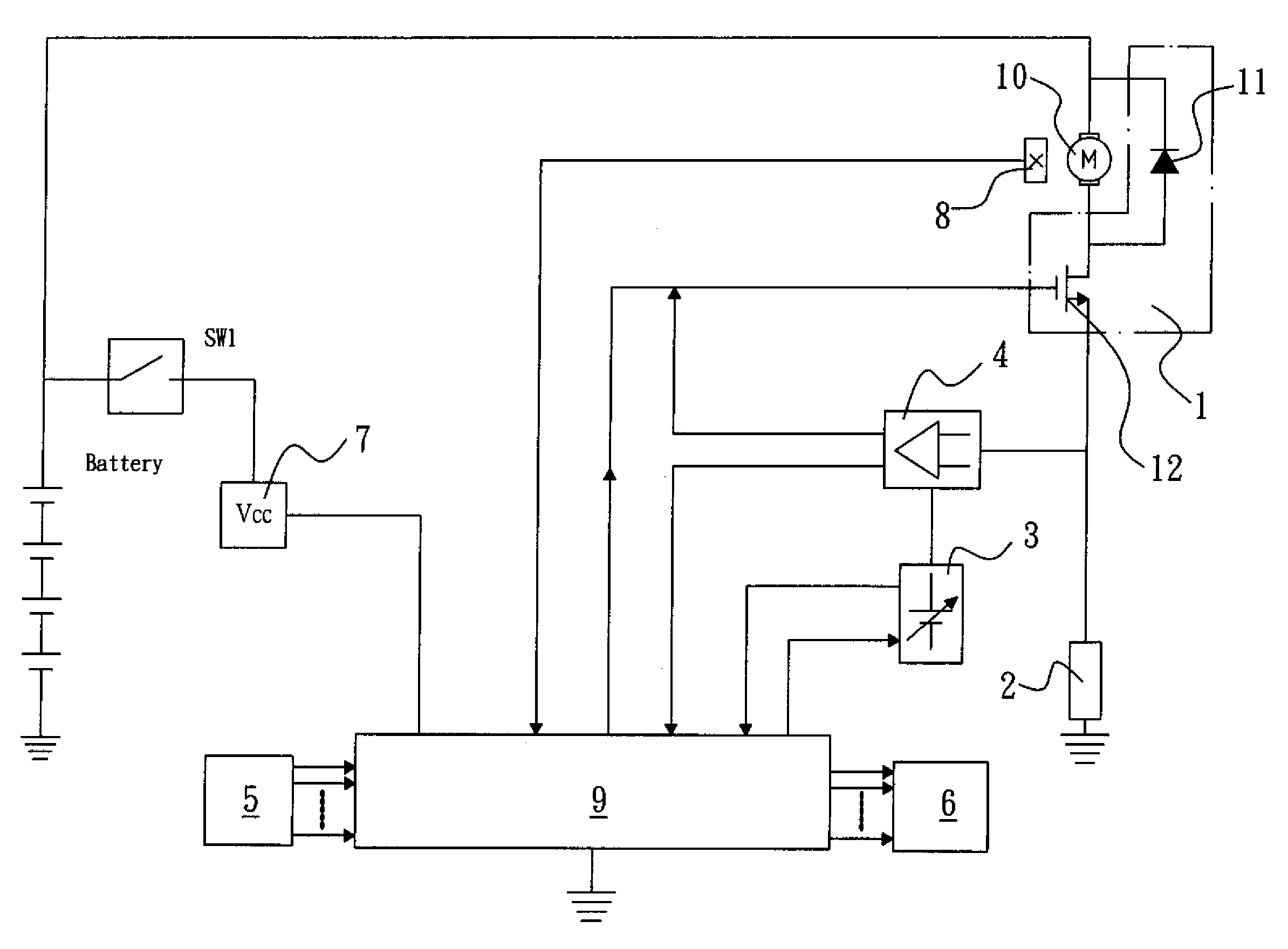

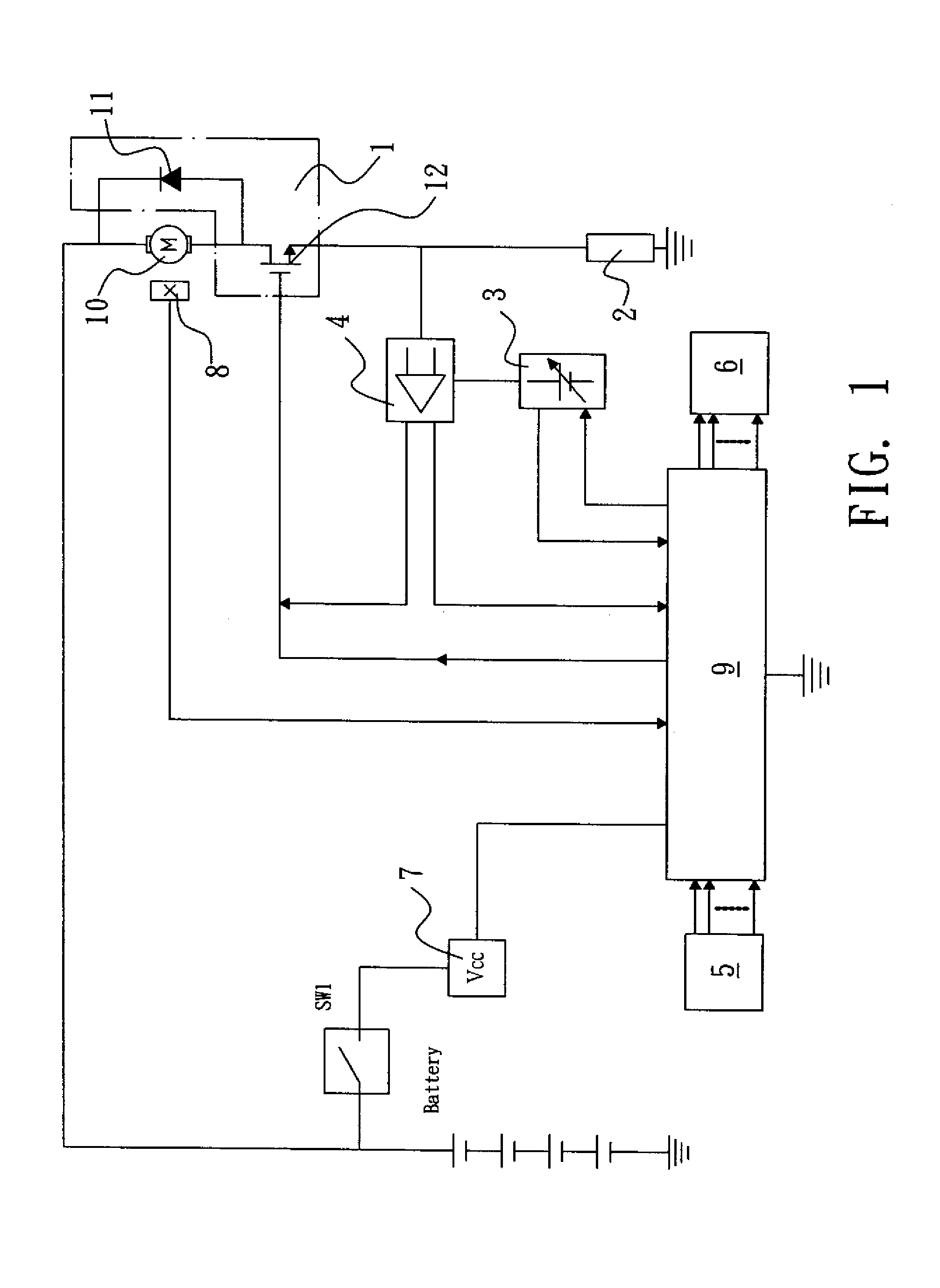

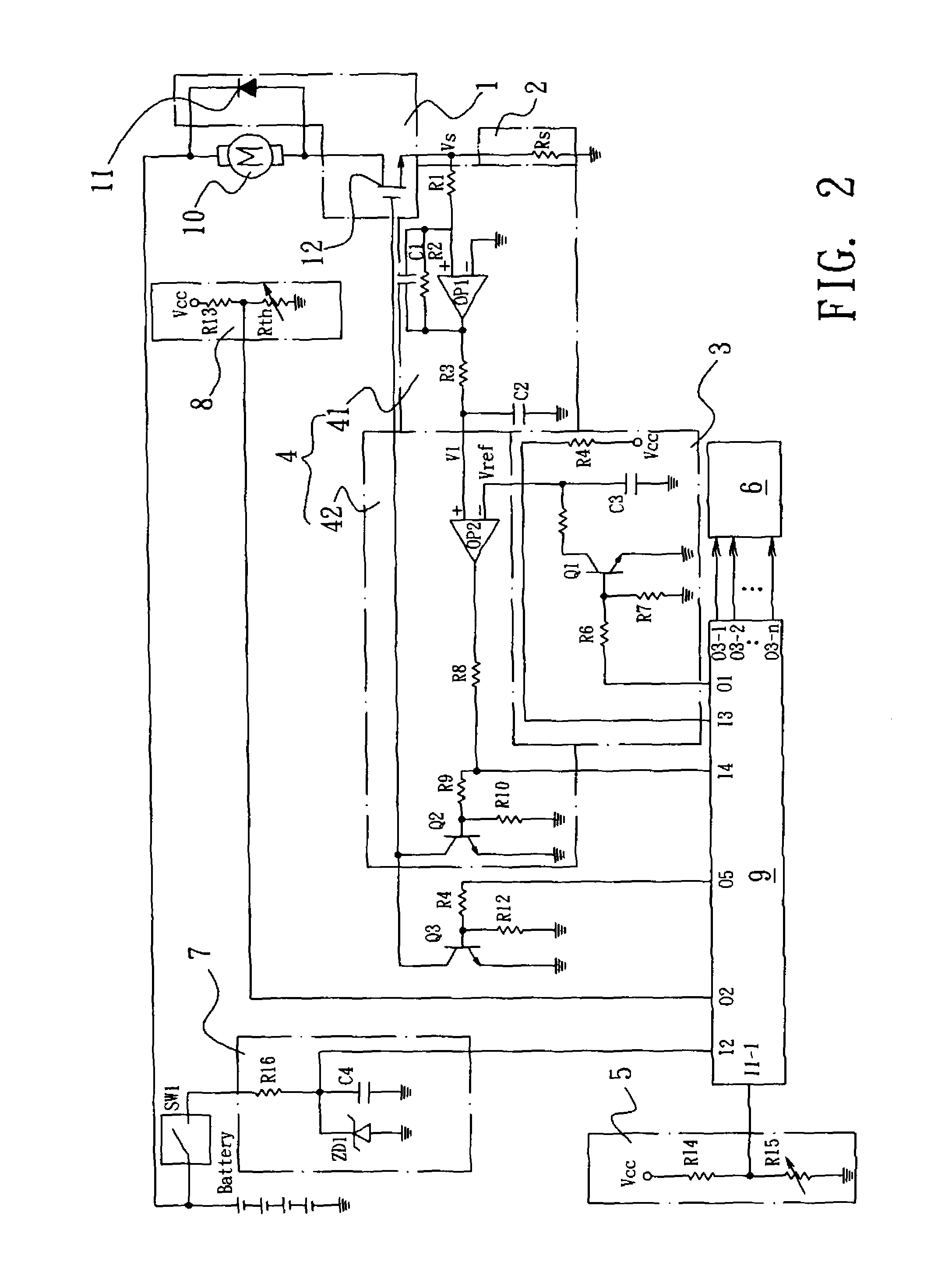

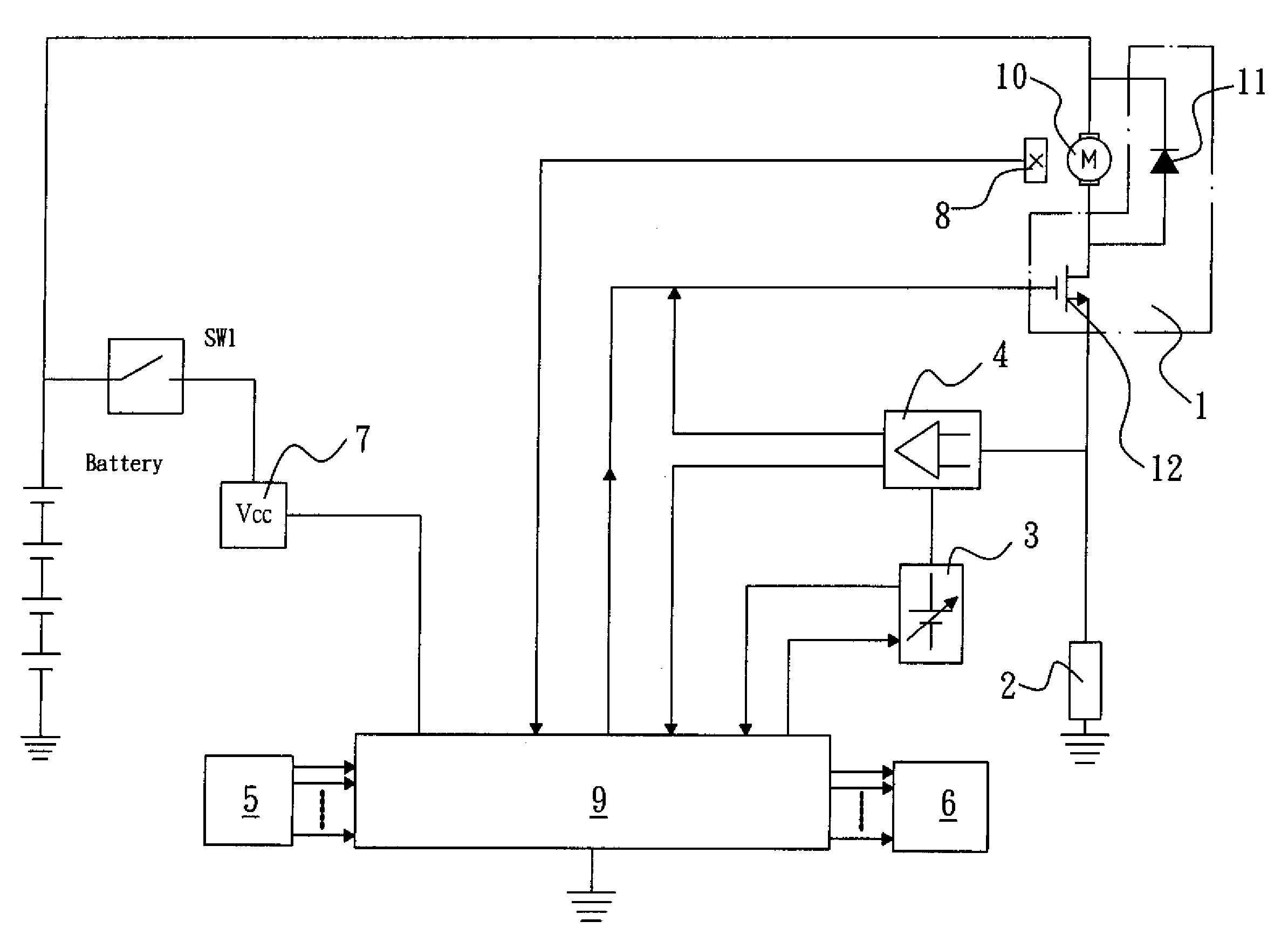

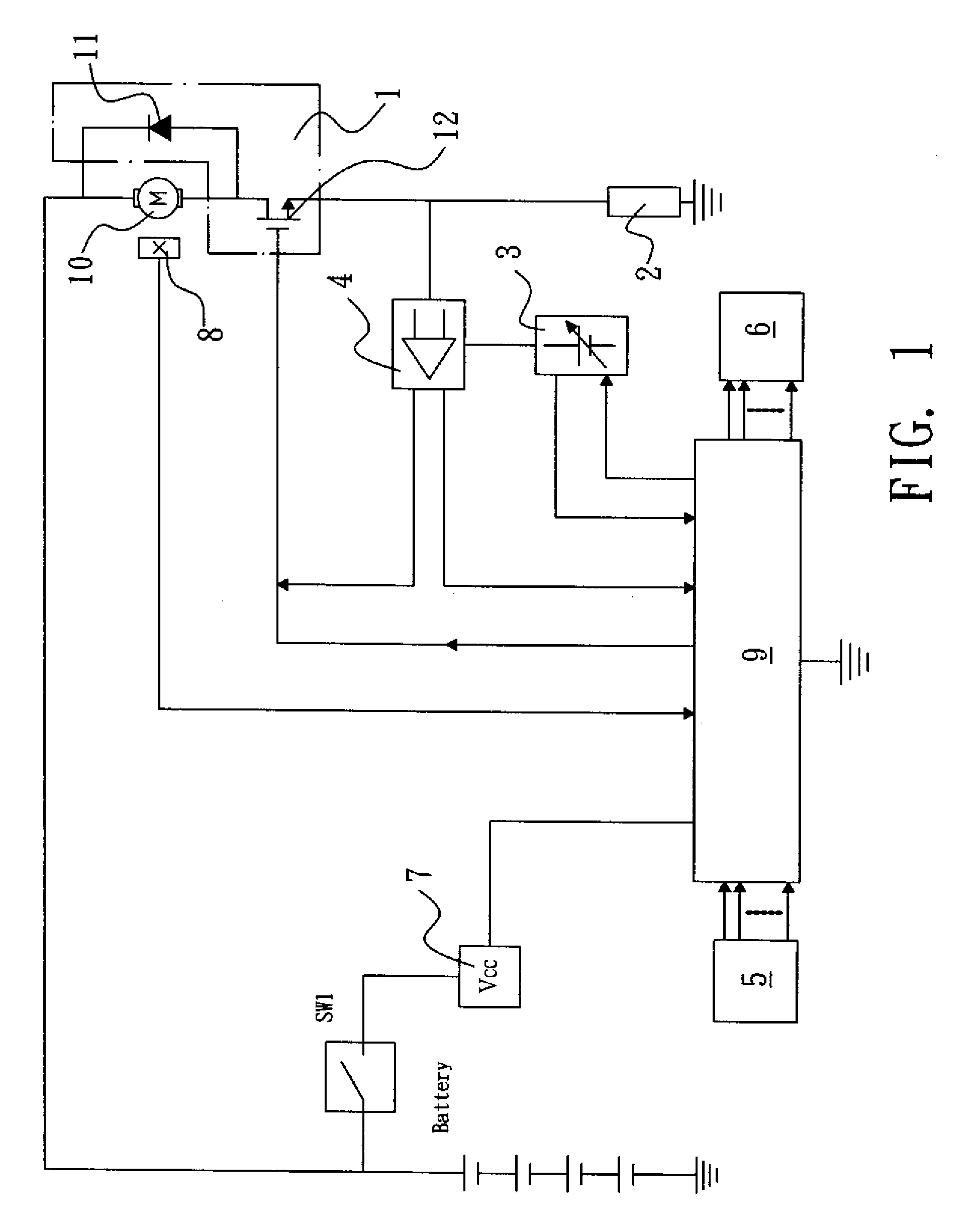

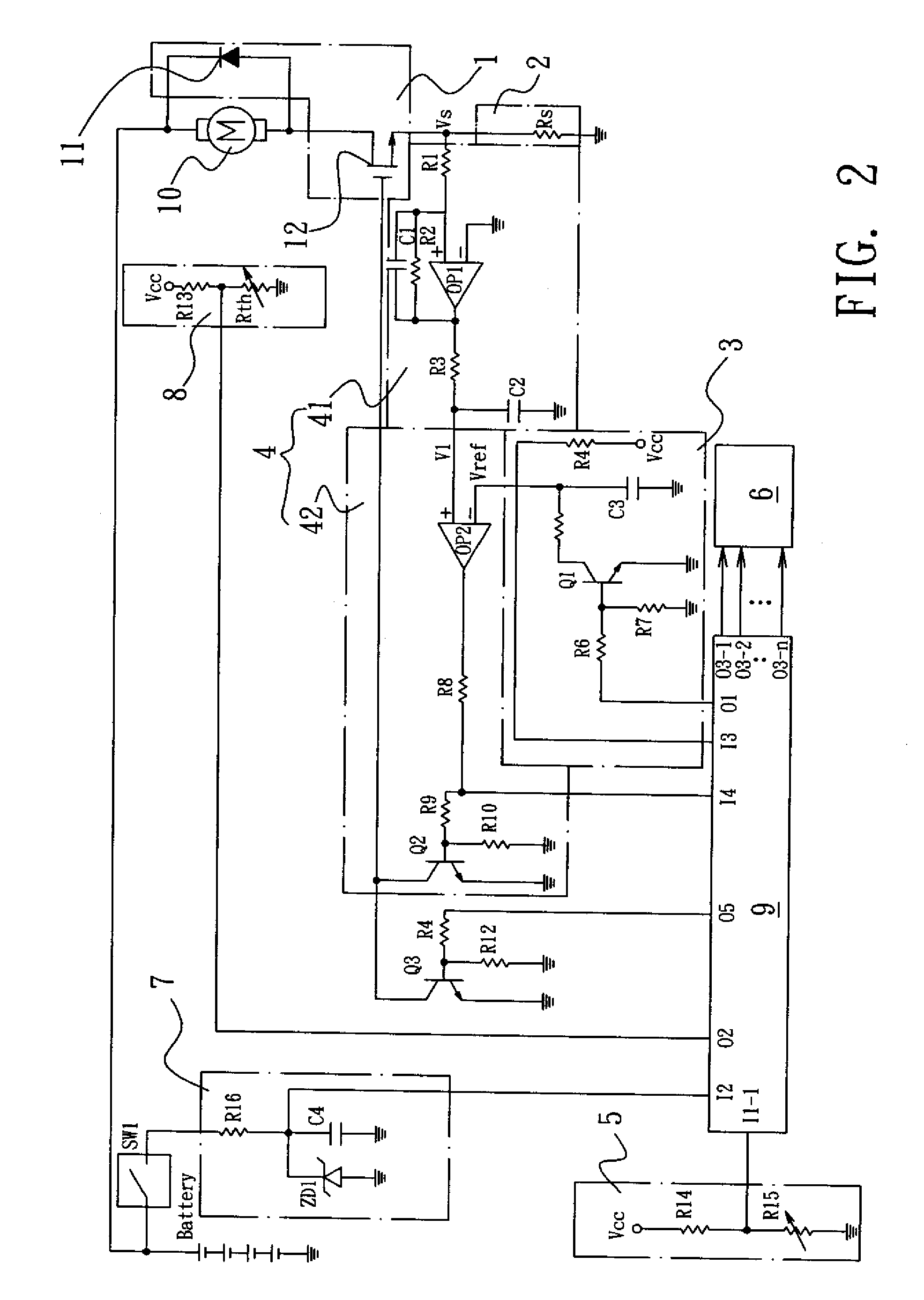

Torque control circuit for impact tool

InactiveUS7839112B2Less degree of tighteningSave powerDC motor speed/torque controlSimulator controlMotor driveElectric machine

A torque control circuit includes a motor driving circuit, a motor operating current detection circuit, a reference voltage generation circuit, a maximum motor current setting circuit, a torque setting circuit, an information output circuit, a regulated-voltage power supply circuit, a motor operating temperature detection circuit, and a control circuit. The control circuit includes an integrated circuit to carry out functions of reading information detection sources, processing, and instruction for execution of torque control and output terminals of the reference voltage generation circuit, the maximum motor current setting circuit, the motor operating temperature detection circuit, and the motor impedance torque setting circuit are respectively connected to corresponding input terminals of the integrated circuit to carry out desired control of torque supplied to the impact tool.

Owner:MOBILETRON ELECTRONICS

Open type wedgethread connection

InactiveUS20020074799A1Highly resistant to handling damageMinimize impactSleeve/socket jointsDrilling rodsThreaded pipeHigh pressure

An open wedgethread is disclosed that has an included angle measured in the gap between the stab flank and the load flank to be not less than zero, so as to prevent premature wedging between mating flanks before the position of full makeup is reached, as does occur between trapped wedgethreads wherein the included angle is less than zero. The invention may be used for pipe threads large or small, as a flush joint, with collars, screwed into plates or it may even be used to reversibly connect such as solid posts to base members where a wide makeup torque range is desired. This Open wedgethread, as opposed to trapped wedgethreads, provides a threaded pipe connection that: is more cost-effective; can seal high pressure gas; can provide selectively a connection strength as high as the pipe strength; assures easy makeup to the desired position of full makeup within a wide torque range; may have a torque strength as high as the pipe torque strength; is easier to manufacture; is easier to gage; and is less subject to handling damage.

Owner:RAMOS BEVERLY WATTS

Torque control circuit for impact tool

InactiveUS20090302798A1Reduce output voltageTorque set range narrowDC motor speed/torque controlSimulator controlOperating temperatureIntegrated circuit

A torque control circuit includes a motor driving circuit, a motor operating current detection circuit, a reference voltage generation circuit, a maximum motor current setting circuit, a torque setting circuit, an information output circuit, a regulated-voltage power supply circuit, a motor operating temperature detection circuit, and a control circuit. The control circuit includes an integrated circuit to carry out functions of reading information detection sources, processing, and instruction for execution of torque control and output terminals of the reference voltage generation circuit, the maximum motor current setting circuit, the motor operating temperature detection circuit, and the motor impedance torque setting circuit are respectively connected to corresponding input terminals of the integrated circuit to carry out desired control of torque supplied to the impact tool.

Owner:MOBILETRON ELECTRONICS

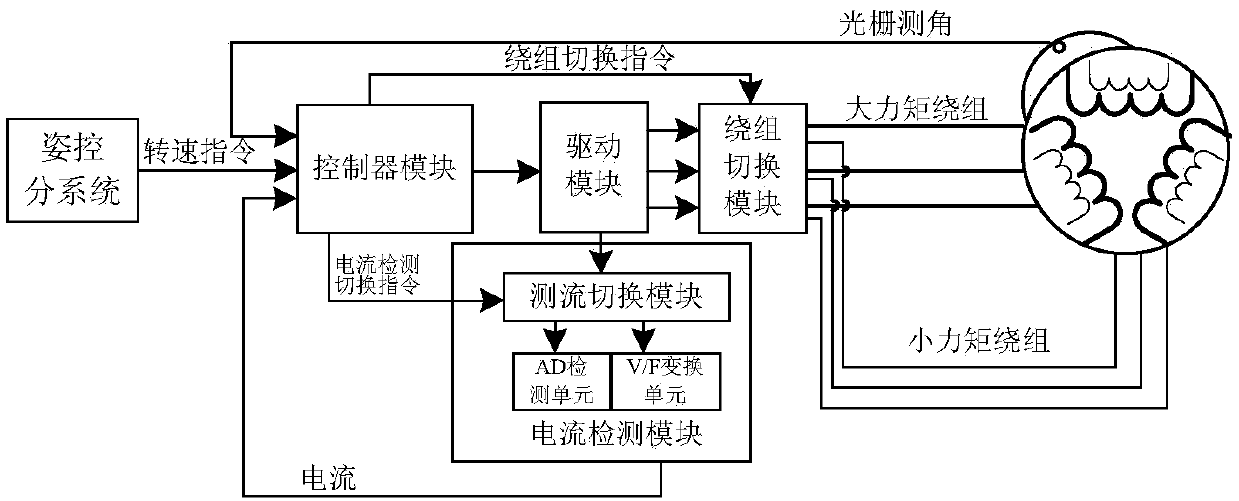

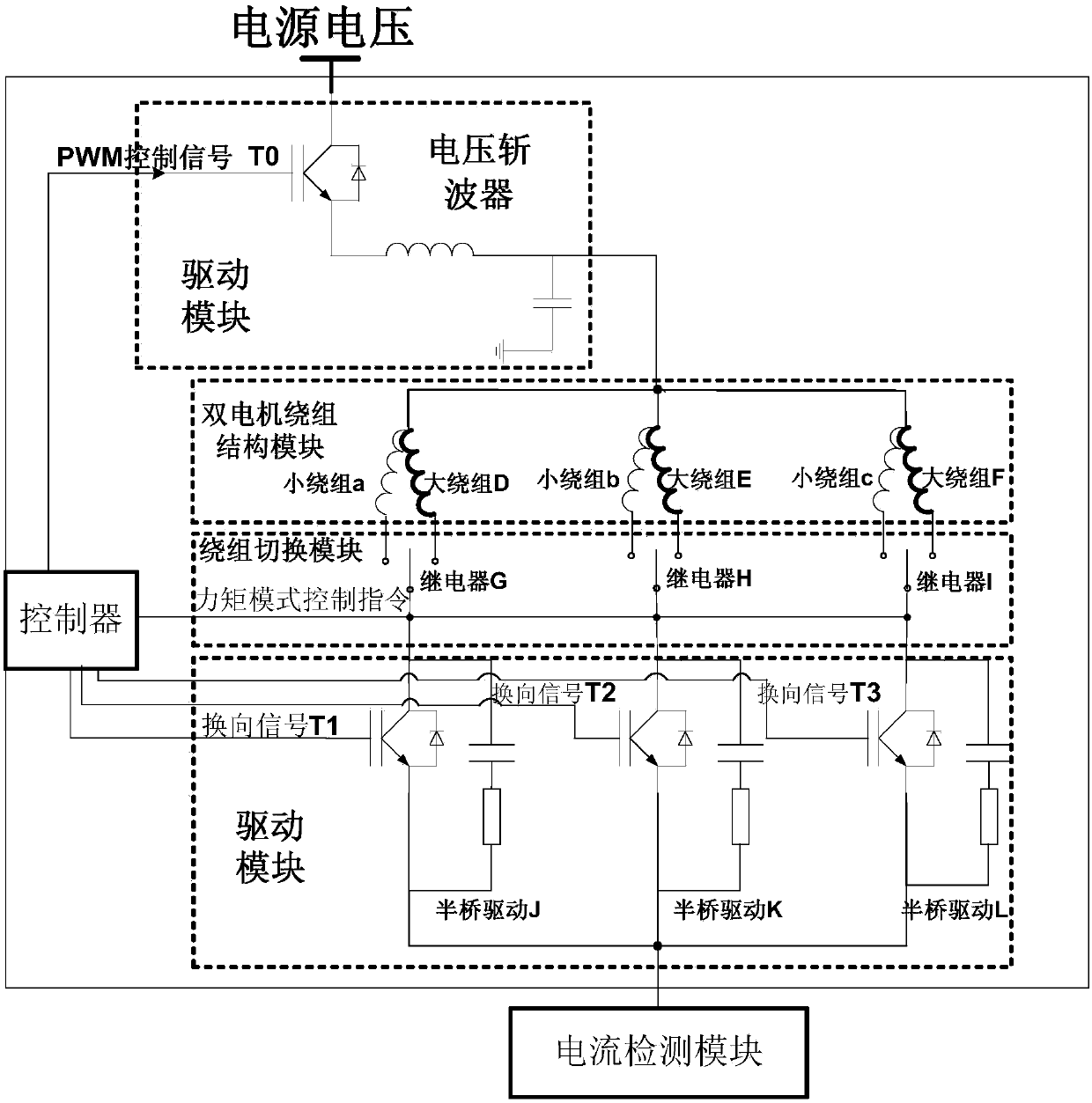

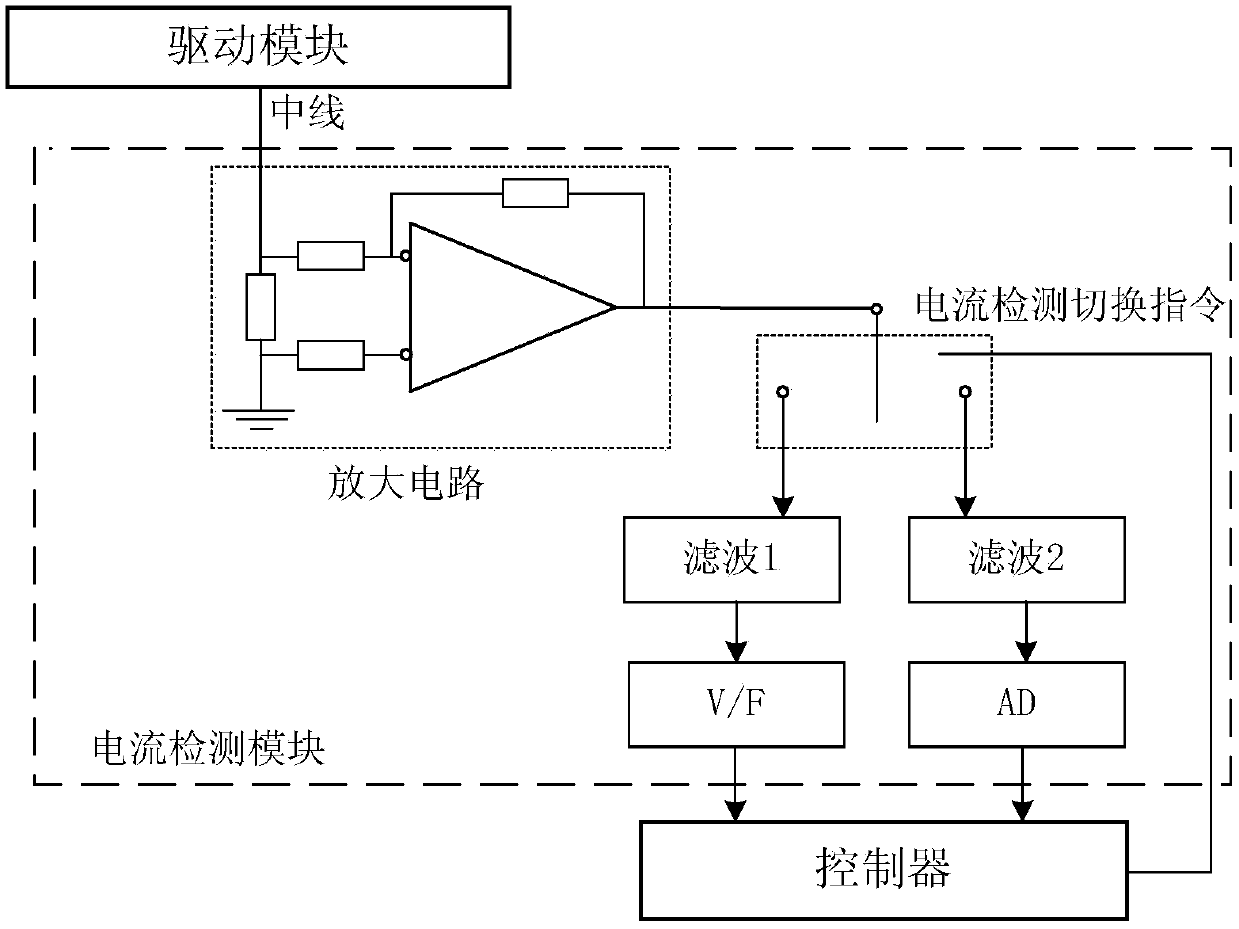

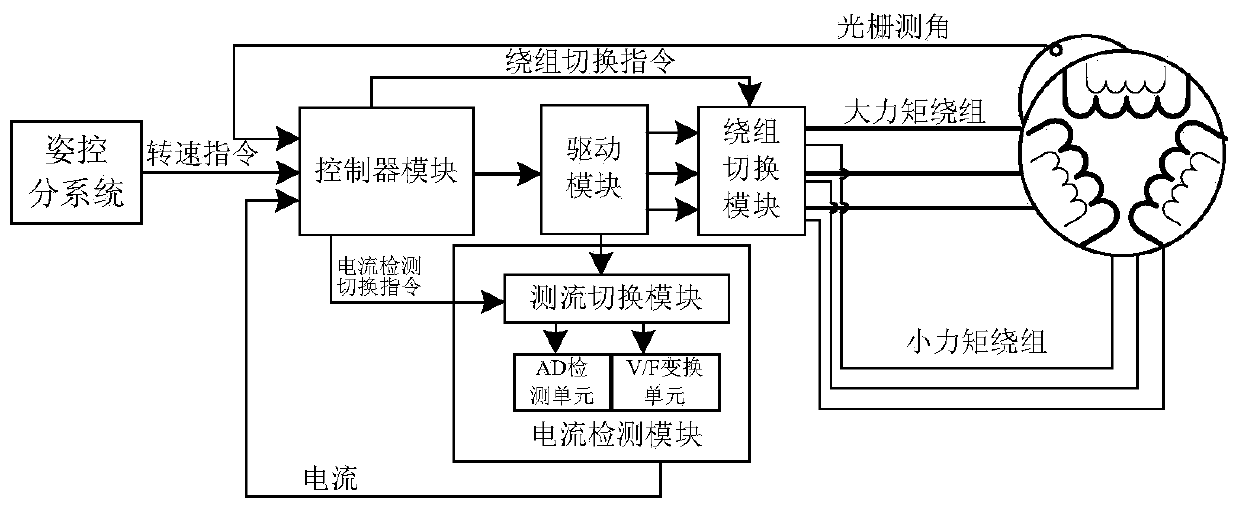

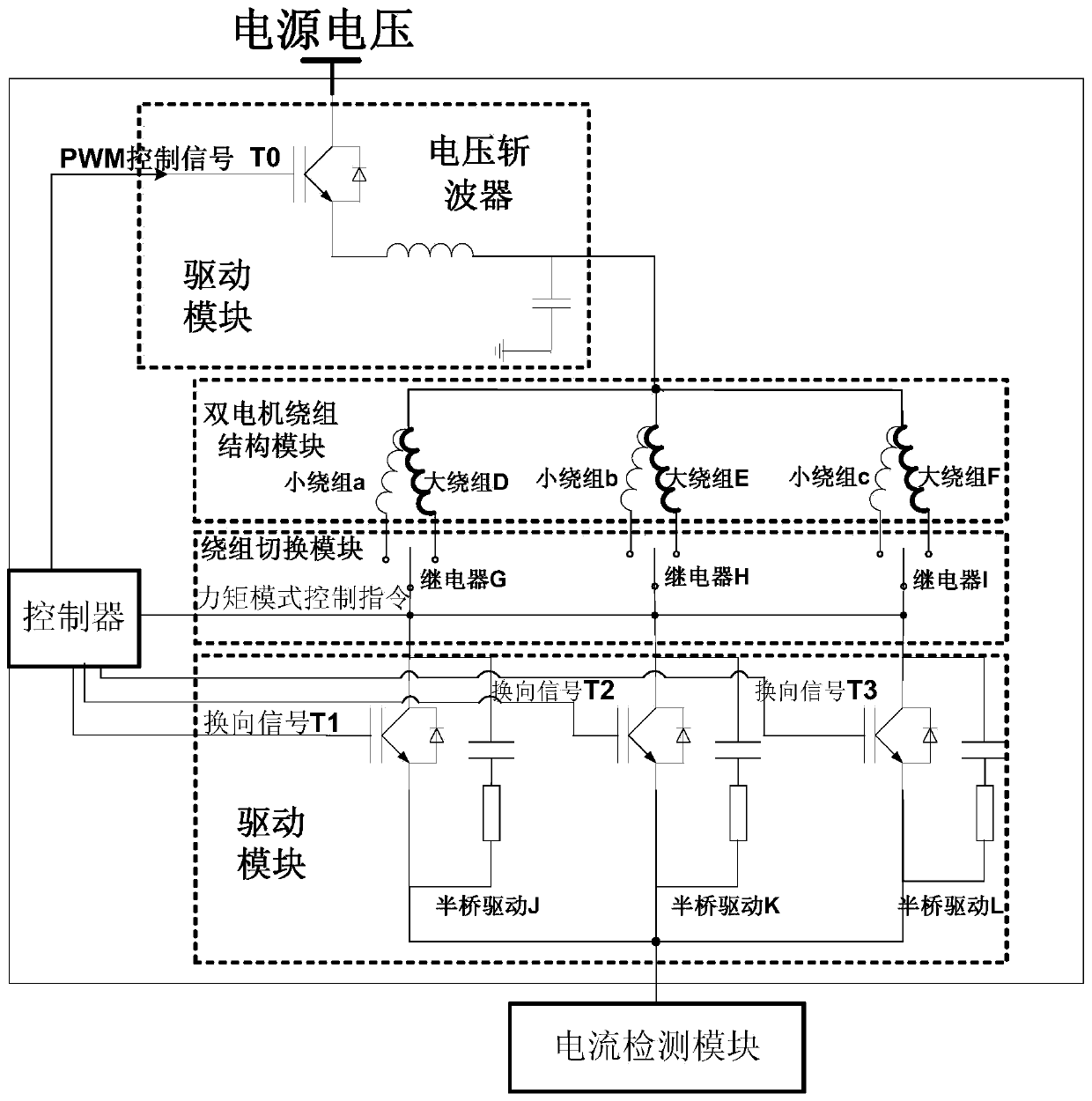

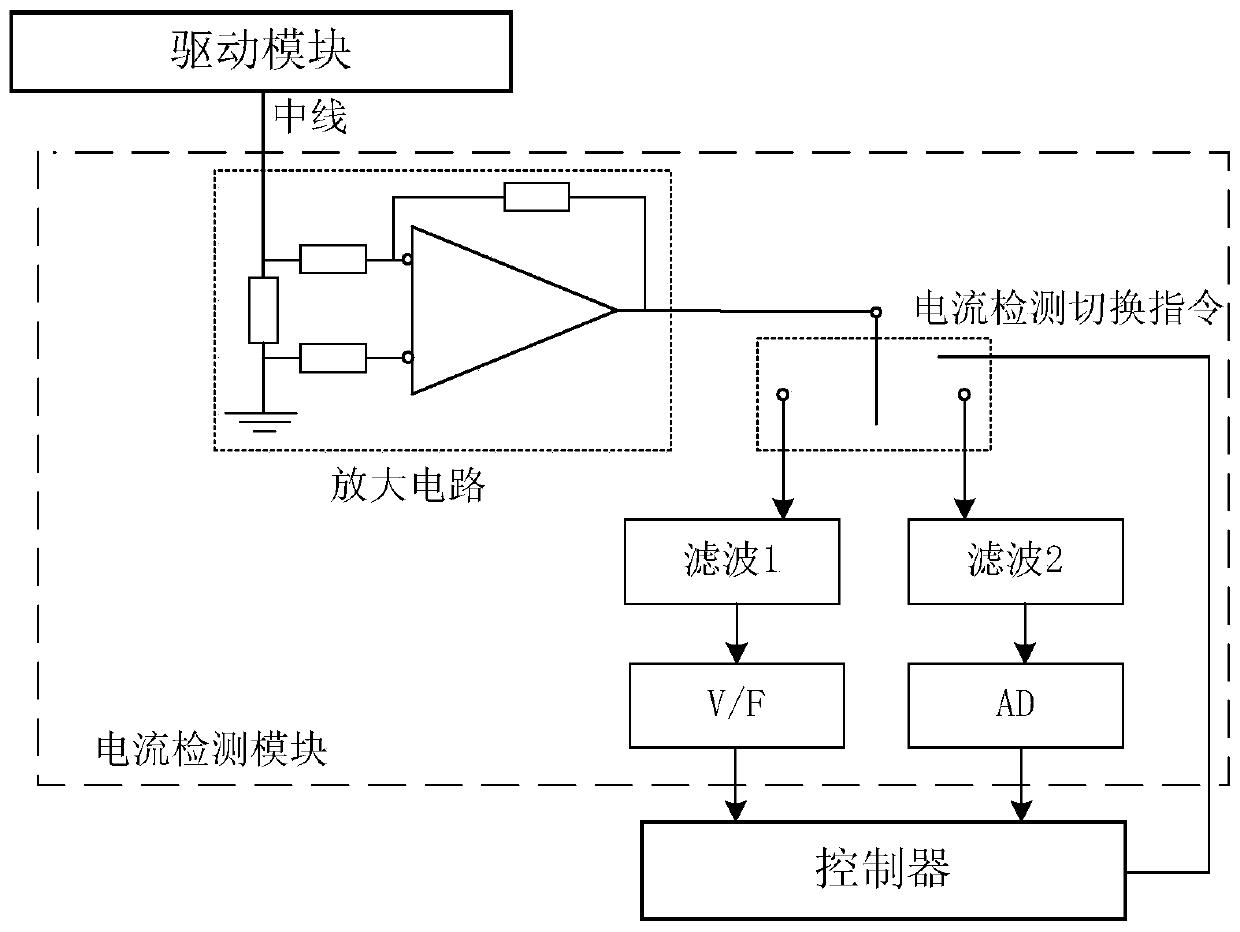

CMG low-speed framework rapid wide torque range and high-precision driving control system

ActiveCN107707172AHigh precision torqueWide torque rangeElectronic commutation motor controlAC motor controlLow speedControl system

A CMG low-speed framework rapid wide torque range and high-precision driving control system employs a dual-winding motor mode, one mode can provide a large moment, and the other one can provide a high-precision moment, two motors can perform free switching according to an operating condition, and therefore, the CMG low-speed framework rapid wide torque range and high-precision driving control system has a wide torque range and a high-precision moment output capability, and can satisfy maneuverability demands for multi-task realization for the future and demands of a super quick high-performance satellite platform capable of imaging with moving.

Owner:BEIJING INST OF CONTROL ENG

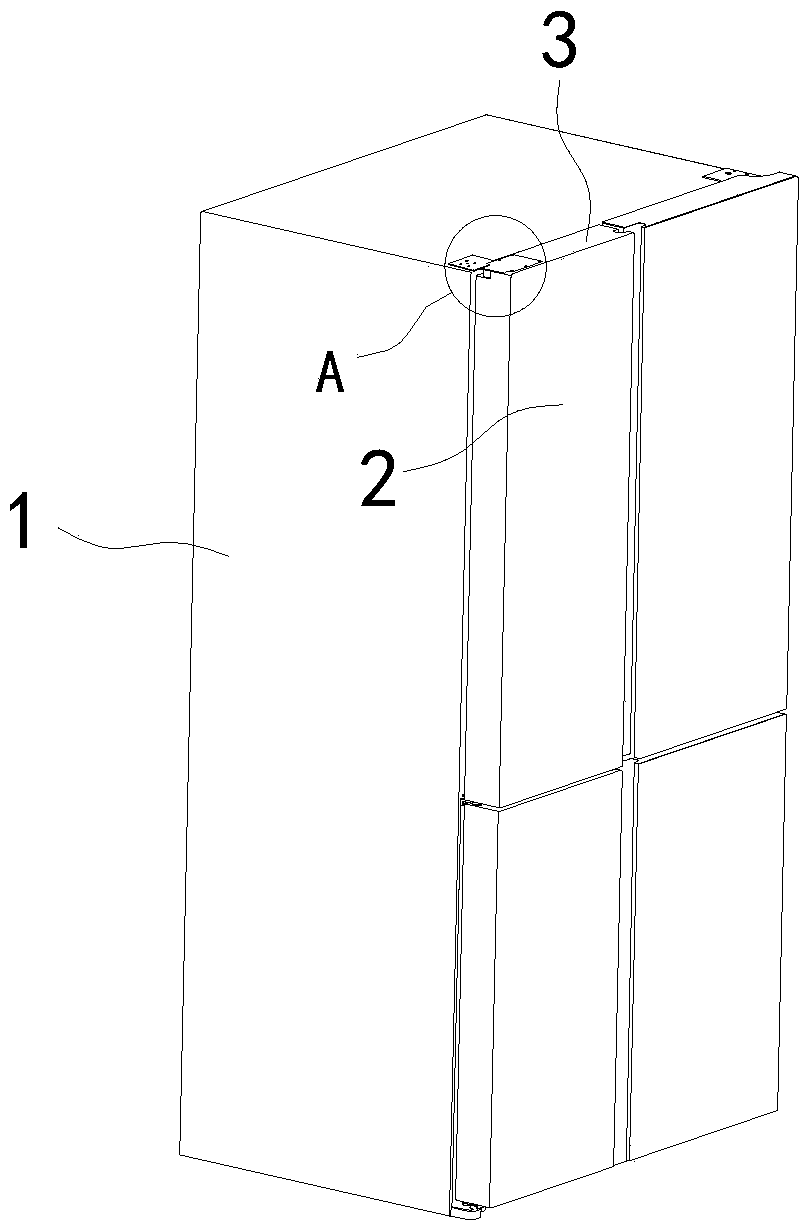

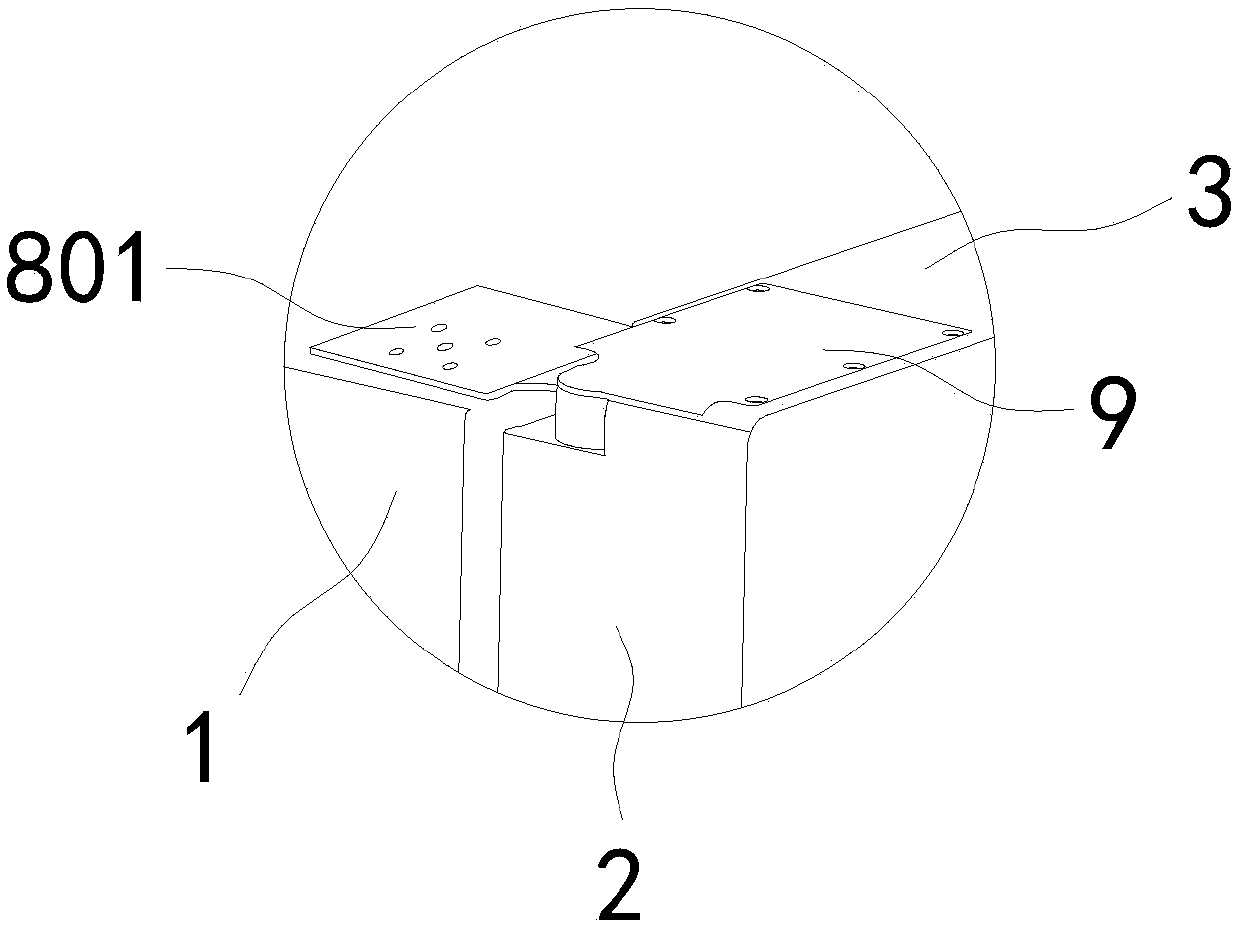

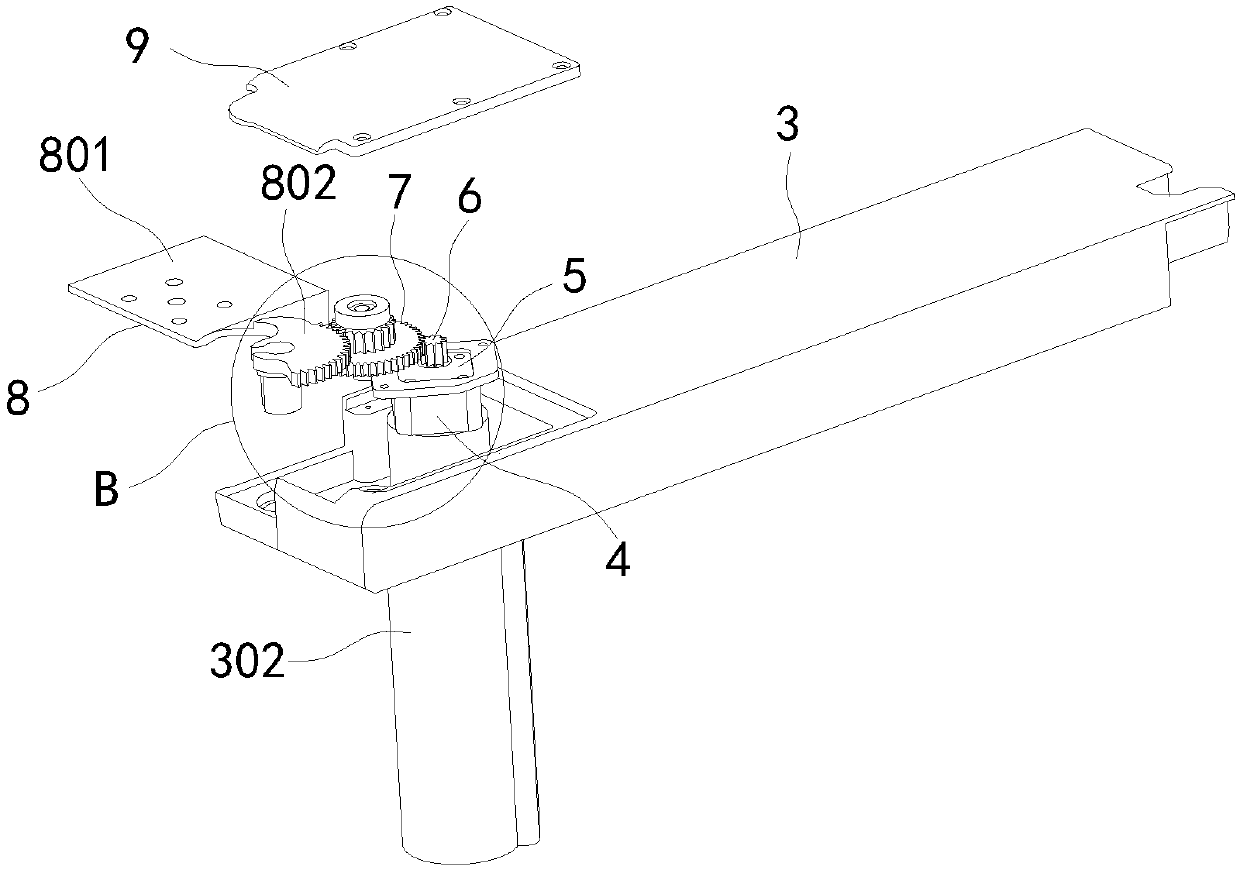

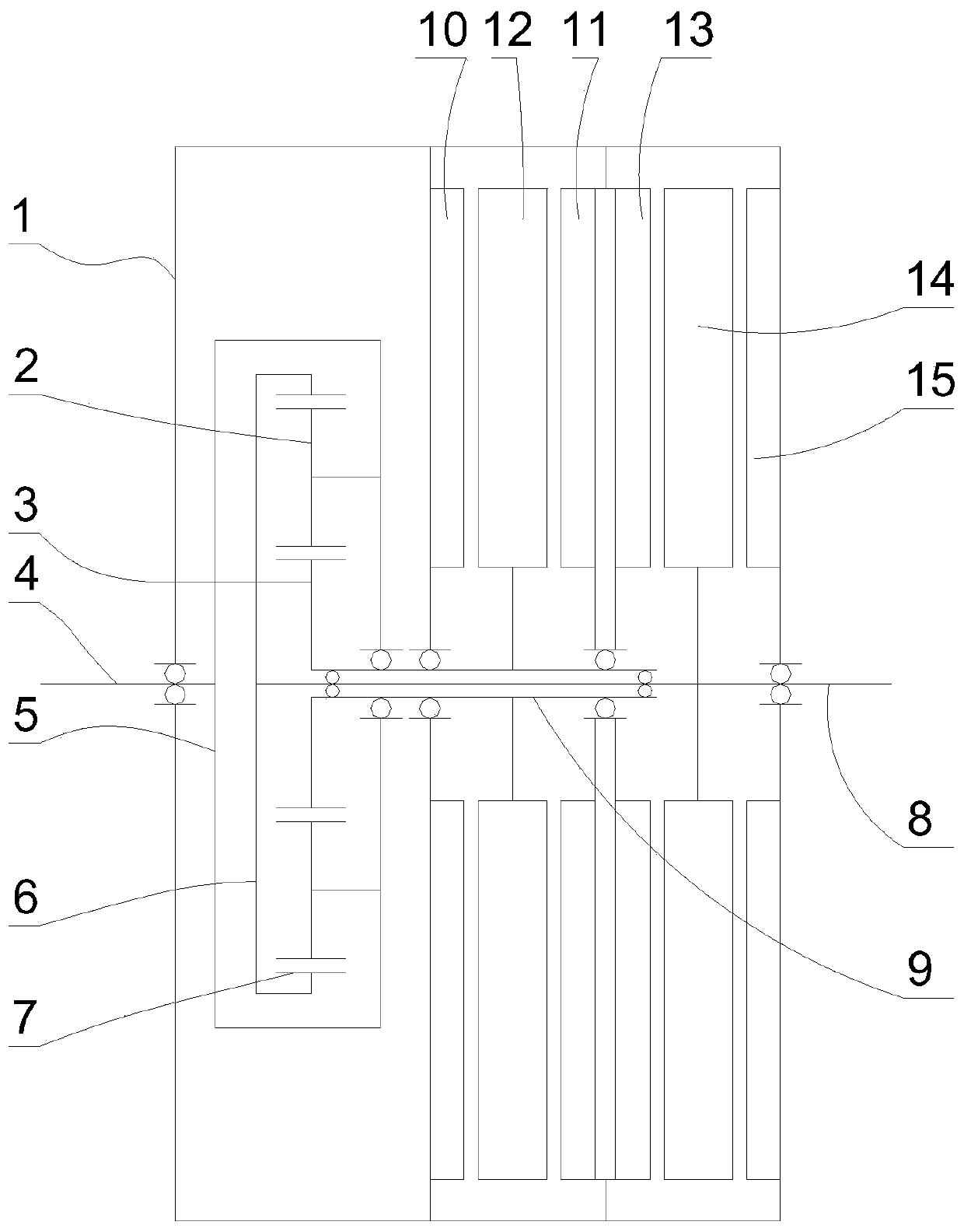

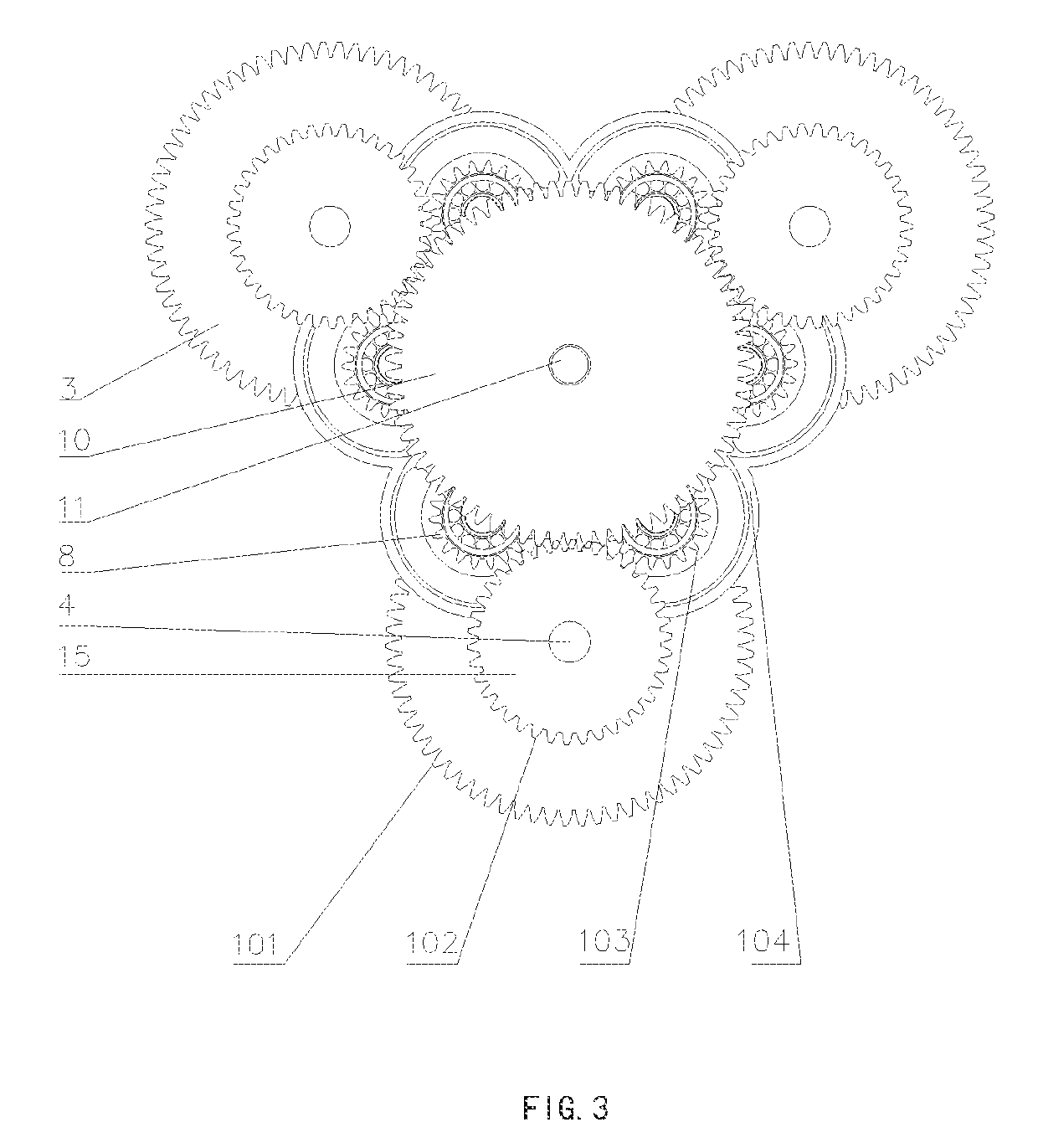

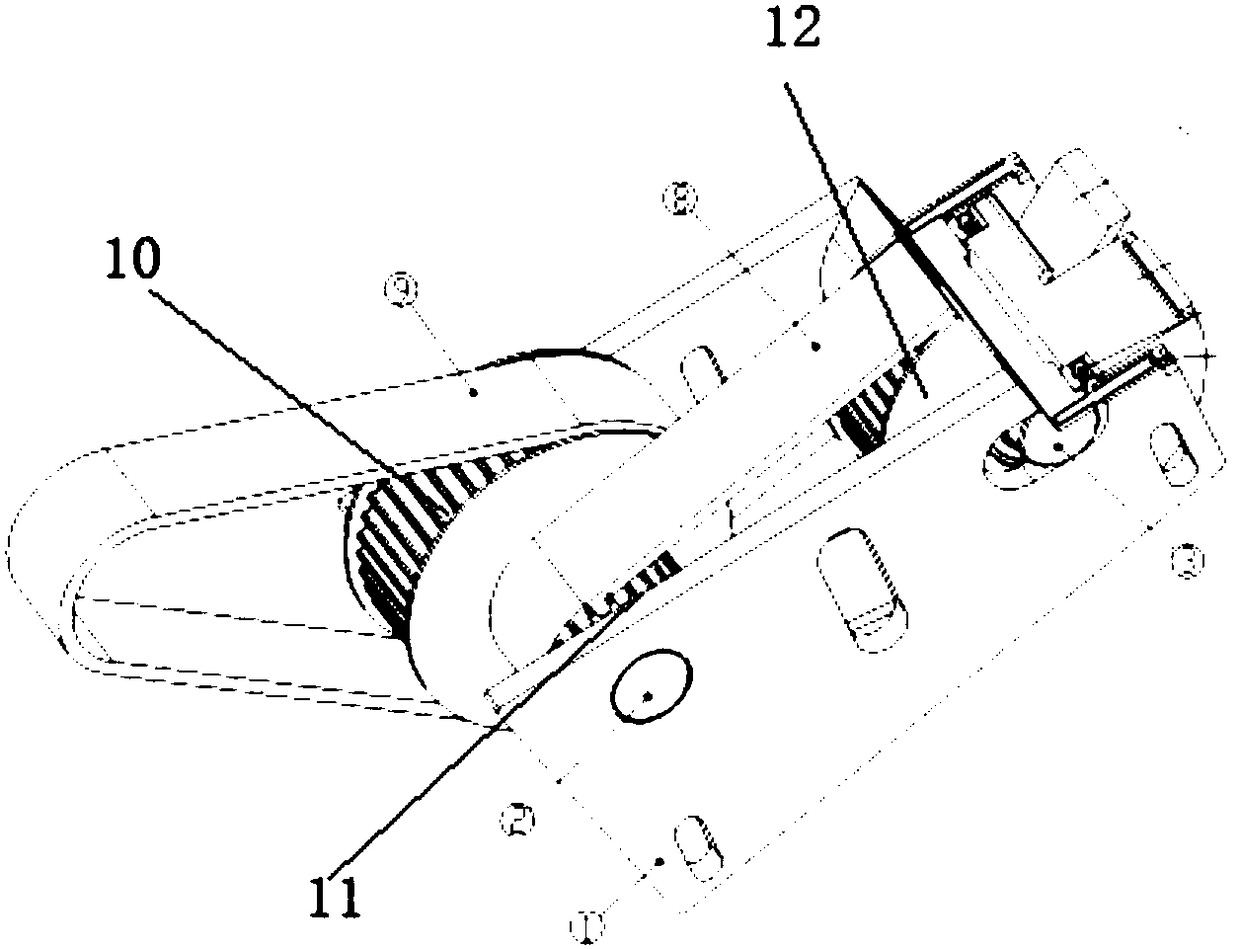

Transmission device for automatic door opening and closing of refrigerator and control system thereof

PendingCN108679913AImprove practicalitySmooth transmissionDomestic cooling apparatusLighting and heating apparatusGear driveIcebox

The invention discloses a transmission device for automatic door opening and closing of a refrigerator and a control system thereof and relates to the field of intelligent refrigerators. The transmission device comprises a refrigerator body. A refrigerator door body is hinged to the refrigerator body. An upper decorating strip is installed on the top face of the refrigerator door body. A groove isformed in the upper surface of the end portion, close to the connecting portion of the refrigerator body and the refrigerator door body, of the upper decorating strip. A motor box communicating withthe groove is fixed to the lower surface of the upper decorating strip. A motor is fixedly installed in the motor box. The motor is connected with a first gear through an electromagnetic clutch. The first gear is in transmission connection with a hinge gear through a planet gear part. The planet gear part comprises a second gear, a third gear and a rotating shaft. According to the transmission device, power is supplied through the electromagnetic clutch, the motor works to enable the first gear and the planet gear part to transmit, then the planet gear part and the hinge gear are driven to transmit, finally the refrigerator door body is opened, the hands of people are liberated, and intelligence and practicality of the refrigerator are improved.

Owner:CHANGHONG MEILING CO LTD

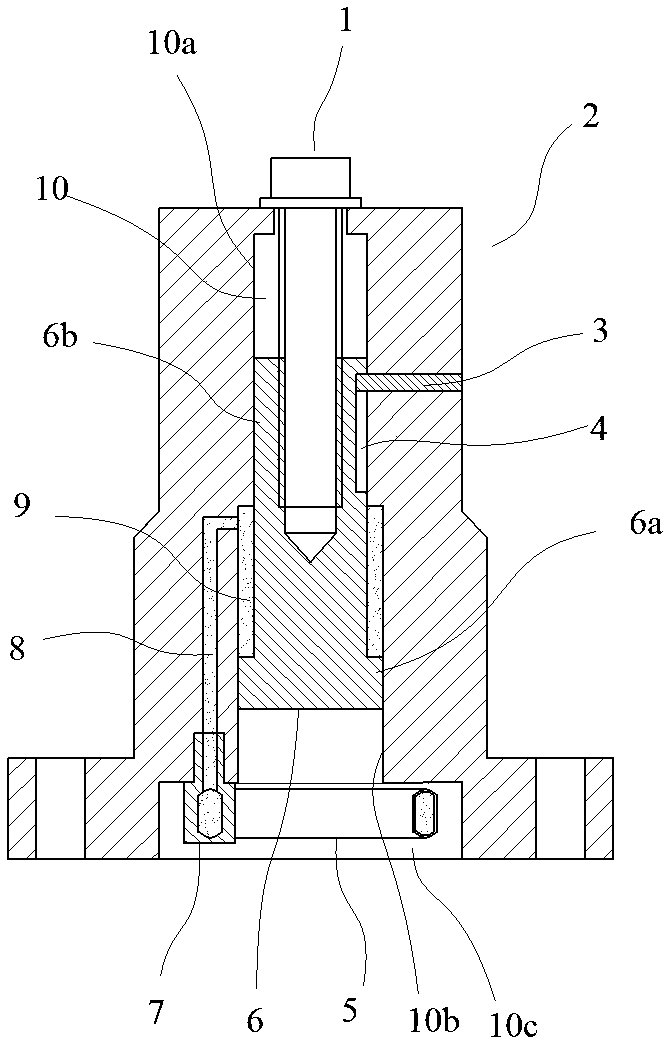

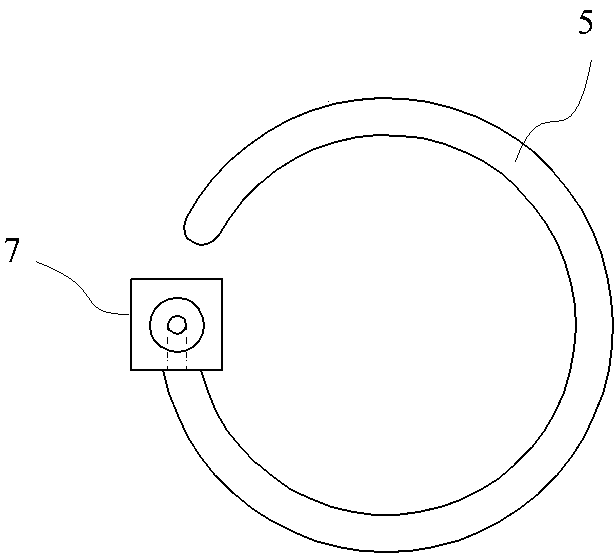

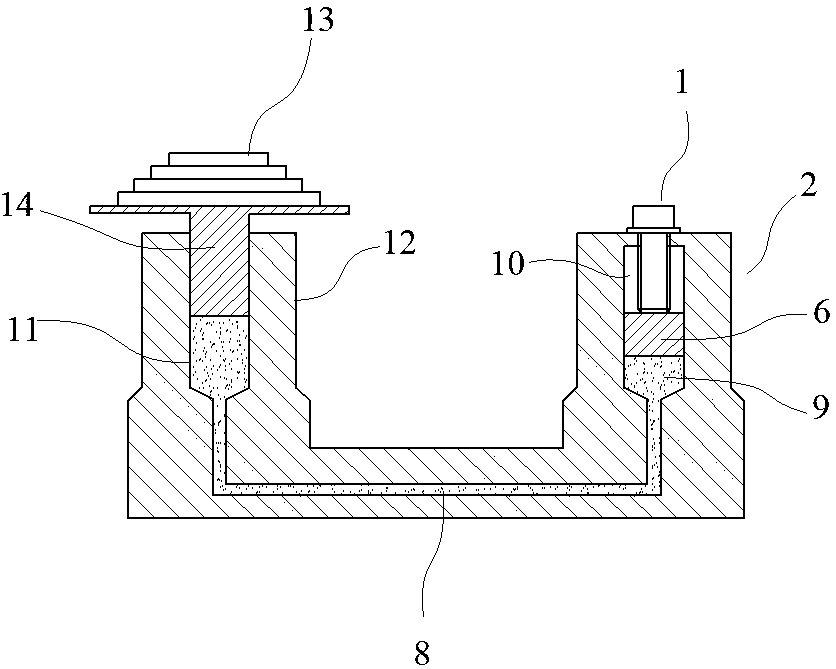

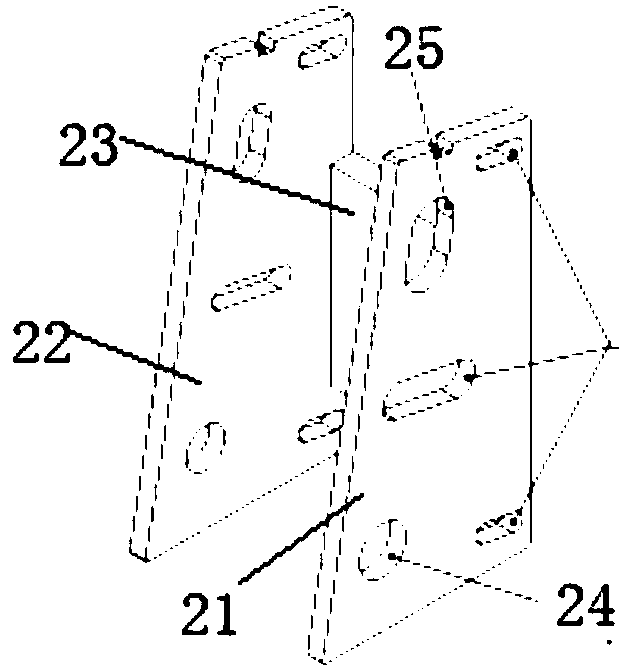

A bolt simulator structure

InactiveCN105716773BReduce false positive rateExpand the scope of workMachine part testingMeasurement of torque/twisting force while tighteningEngineeringBolt connection

The invention discloses a bolt simulator structure comprising a pedestal and a transmission bolt. The pedestal is provided with a vertical inner hole, in which is disposed a piston capable of carrying out relative sliding motion. A sealed oil pressure chamber can be formed between the piston and the inner hole. The transmission bolt is used to act on the upper end of the piston to drive the piston to move axially. The pedestal is provided with an oil channel communicated with the oil pressure chamber, and the oil channel is connected with a counter-force device, which is used to provide the counter force for the oil pressure chamber. A torque spanner sleeve is connected with the transmission bolt of the simulator. The object of the invention is to provide the bolt simulator structure capable of providing wide torque range and reducing configuration quantity.

Owner:HUNAN LUOYOU ENGINE PARTS

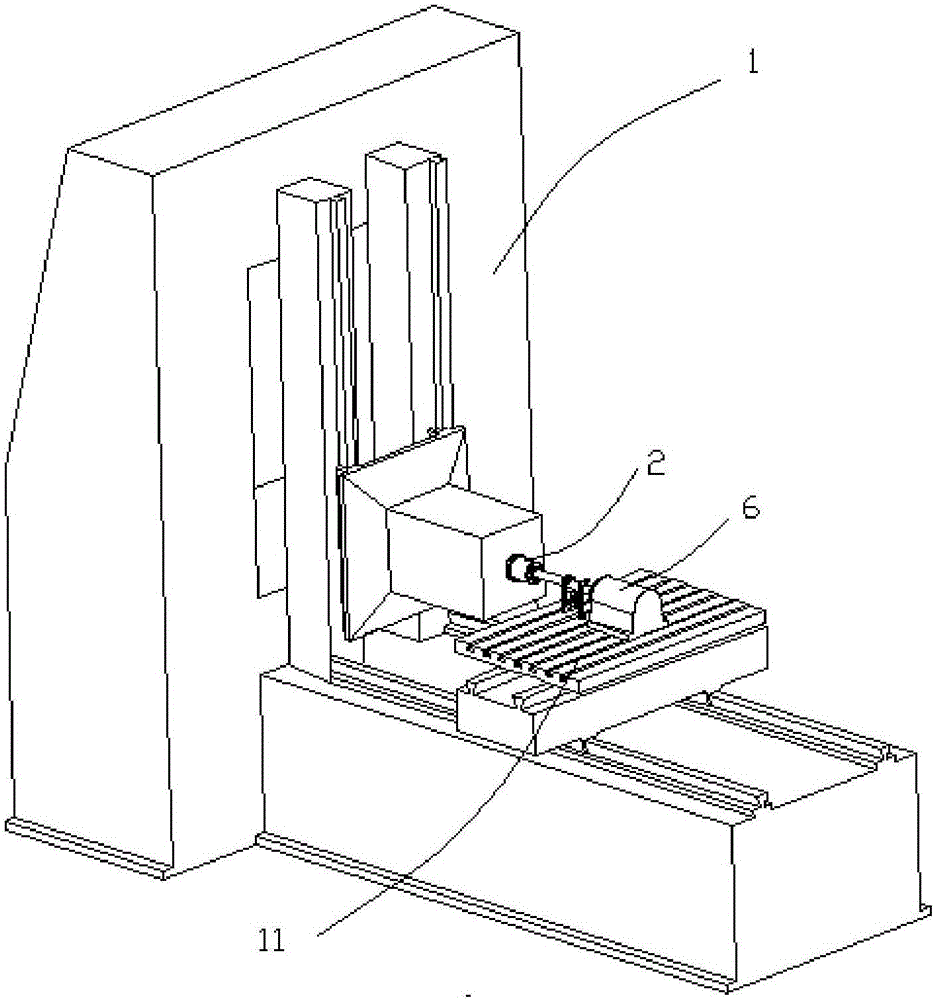

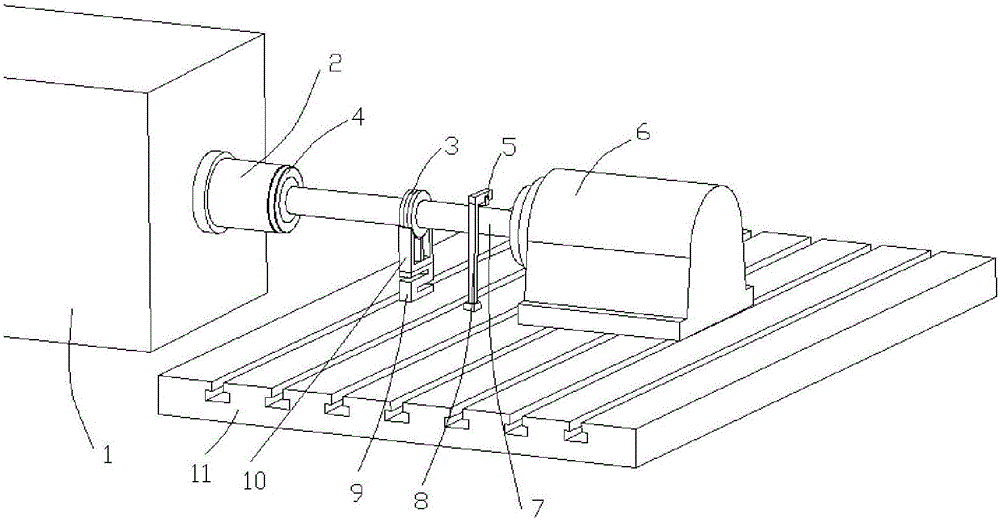

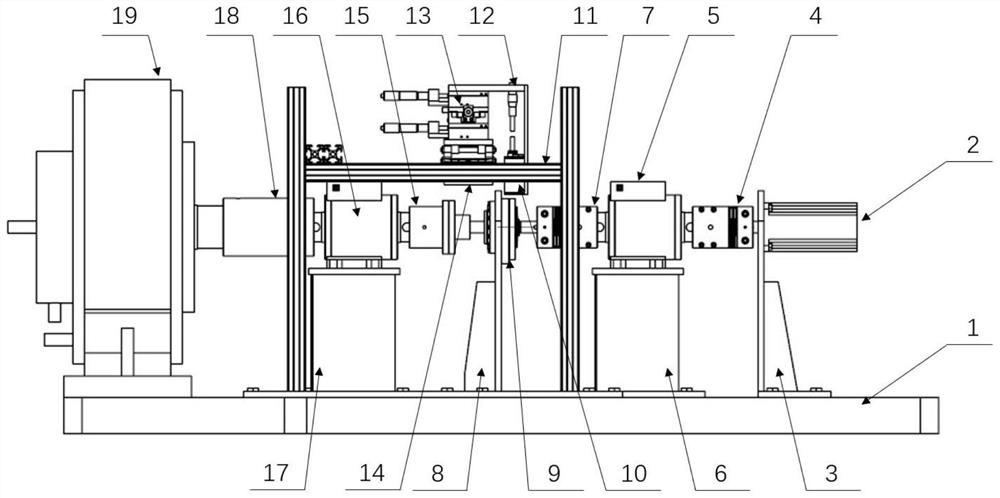

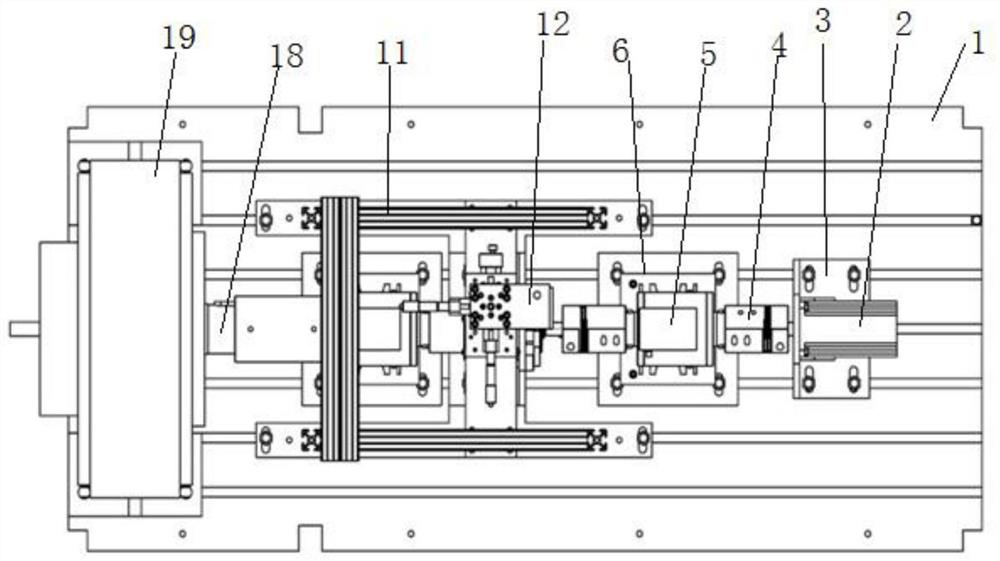

Bending composite loader, testing device and system for main shaft of machine tool

InactiveCN106679959AImprove accuracyImprove securityMachine part testingElasticity measurementContact modeEngineering

The invention provides a bending composite loader, testing device and system for a main shaft of a machine tool. The composite loader includes a main shaft of a machine tool, a torque loader, a radial loader and a test rod, wherein the torque loader includes a torsional force loading part and a torsional force induction part; the radial loader includes a radial force loading part; one end of the test rod is connected with the main shaft of a machine tool, and the other end of the test rod is connected with the torsional force induction part; the torsional force loading part generates torsional force, and the torsional force is loaded to the test rod through the torsional force induction part in a non-contact mode; and the radial force loading part generates radial force, and the radial force is loaded to the test rod in a non-contact mode. By loading torsional force and radial force to the test rod in a non-contact mode and simulating the practical condition of the main shaft for a machine tool during the operating process, the bending composite loader, testing device and system for a main shaft of a machine tool can avoid influencing the final deflection of the operating main shaft during the contact type force loading process, and can avoid crashing and rubbing the test rod, thus improving the safety of the test.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

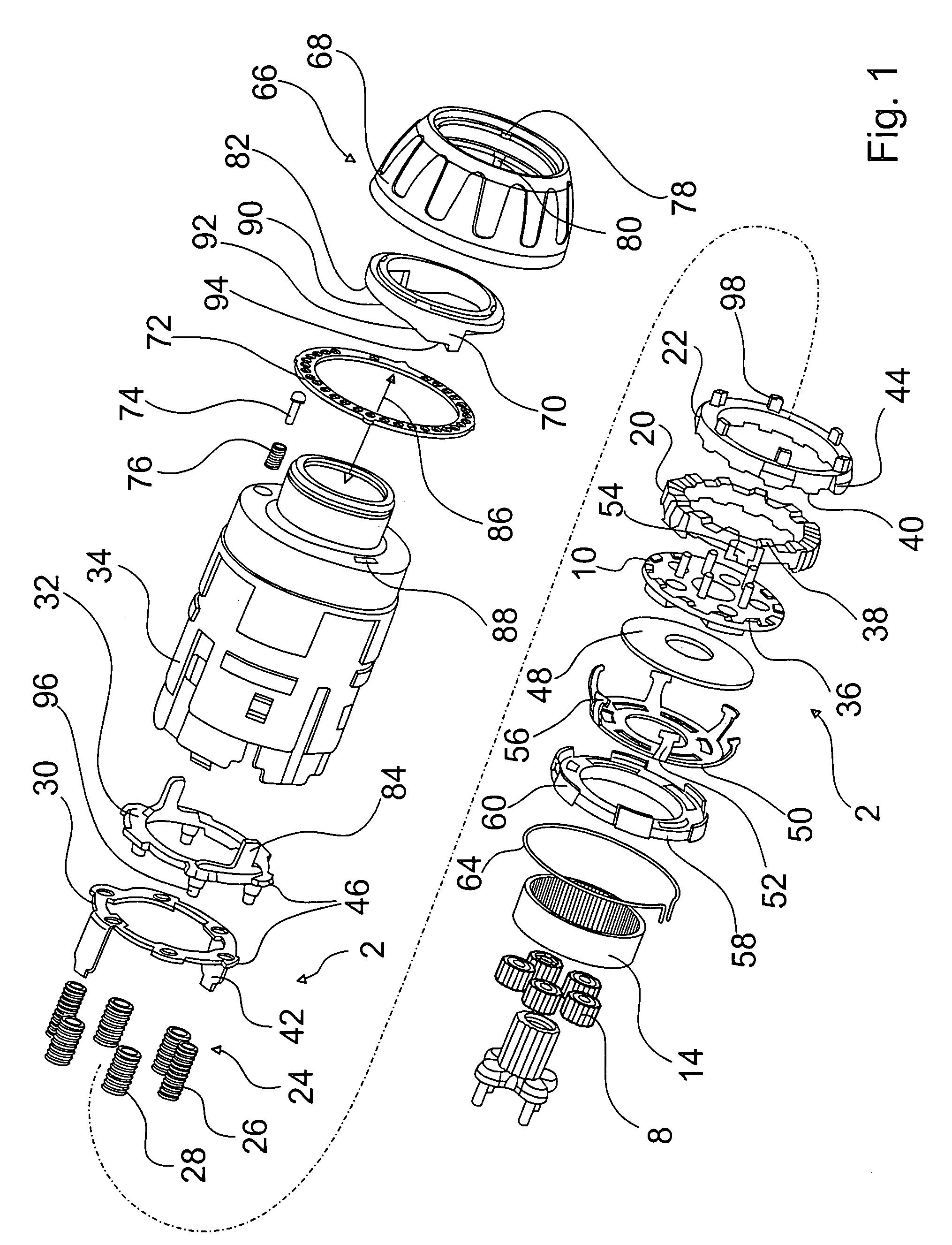

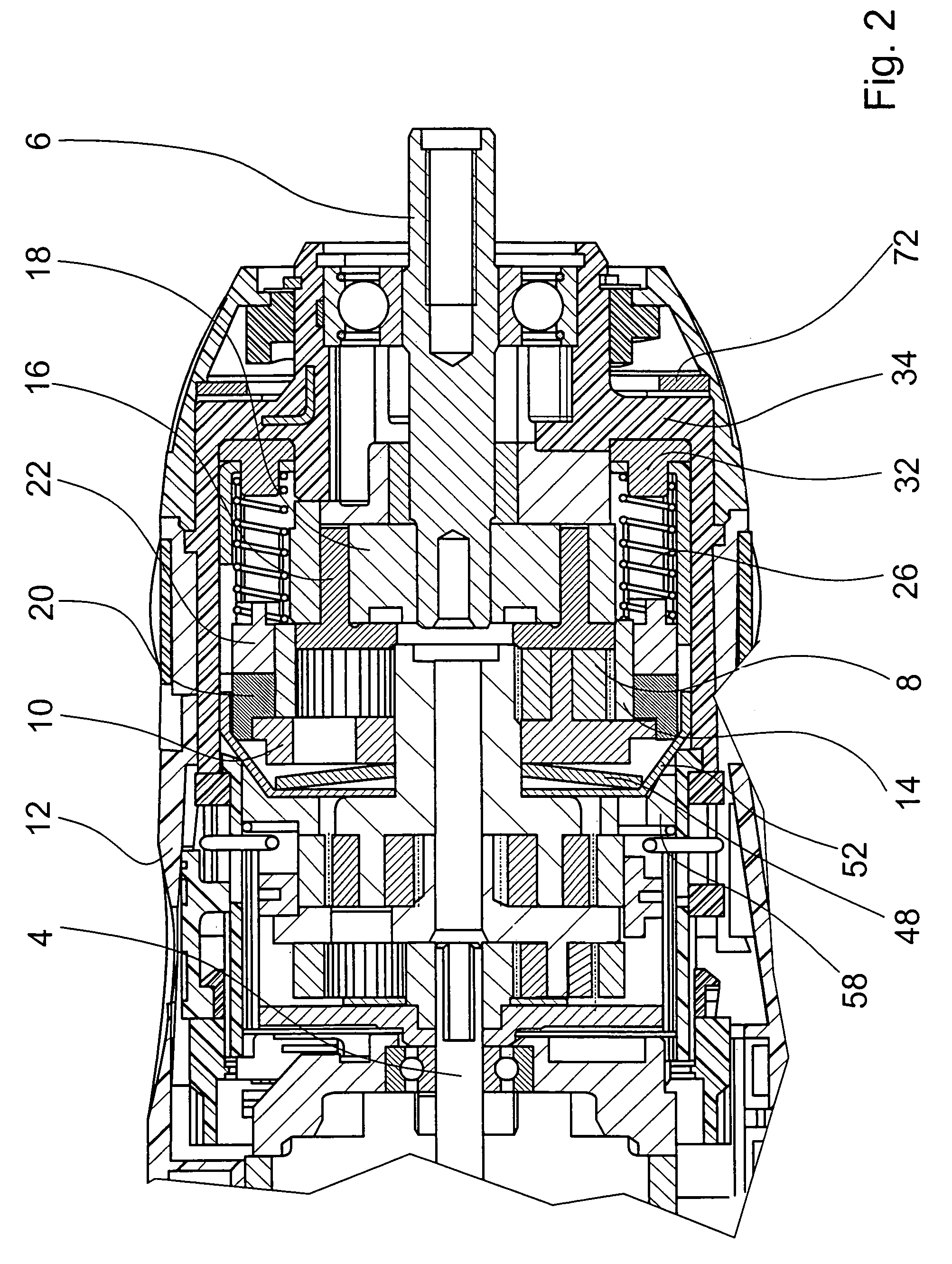

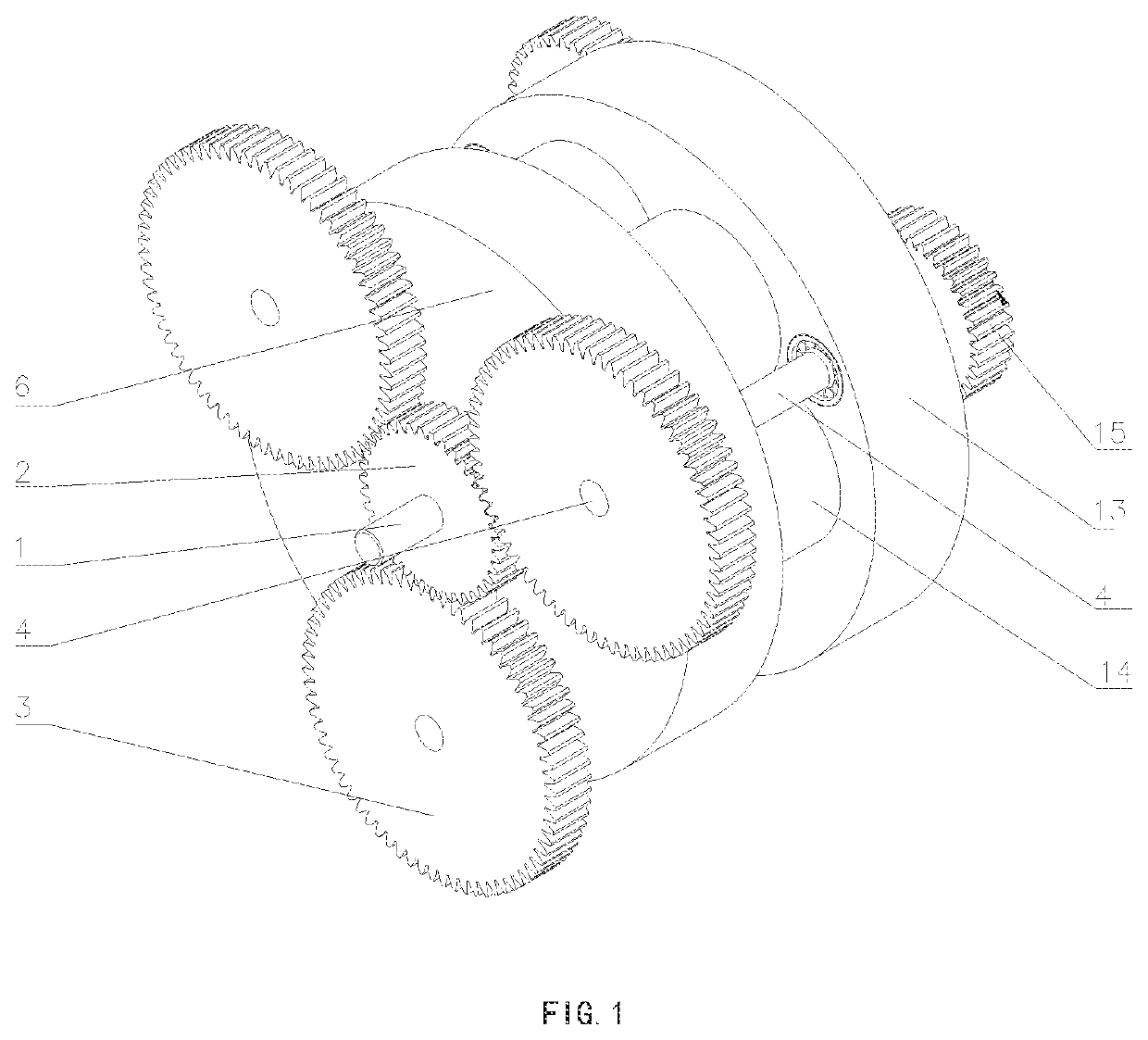

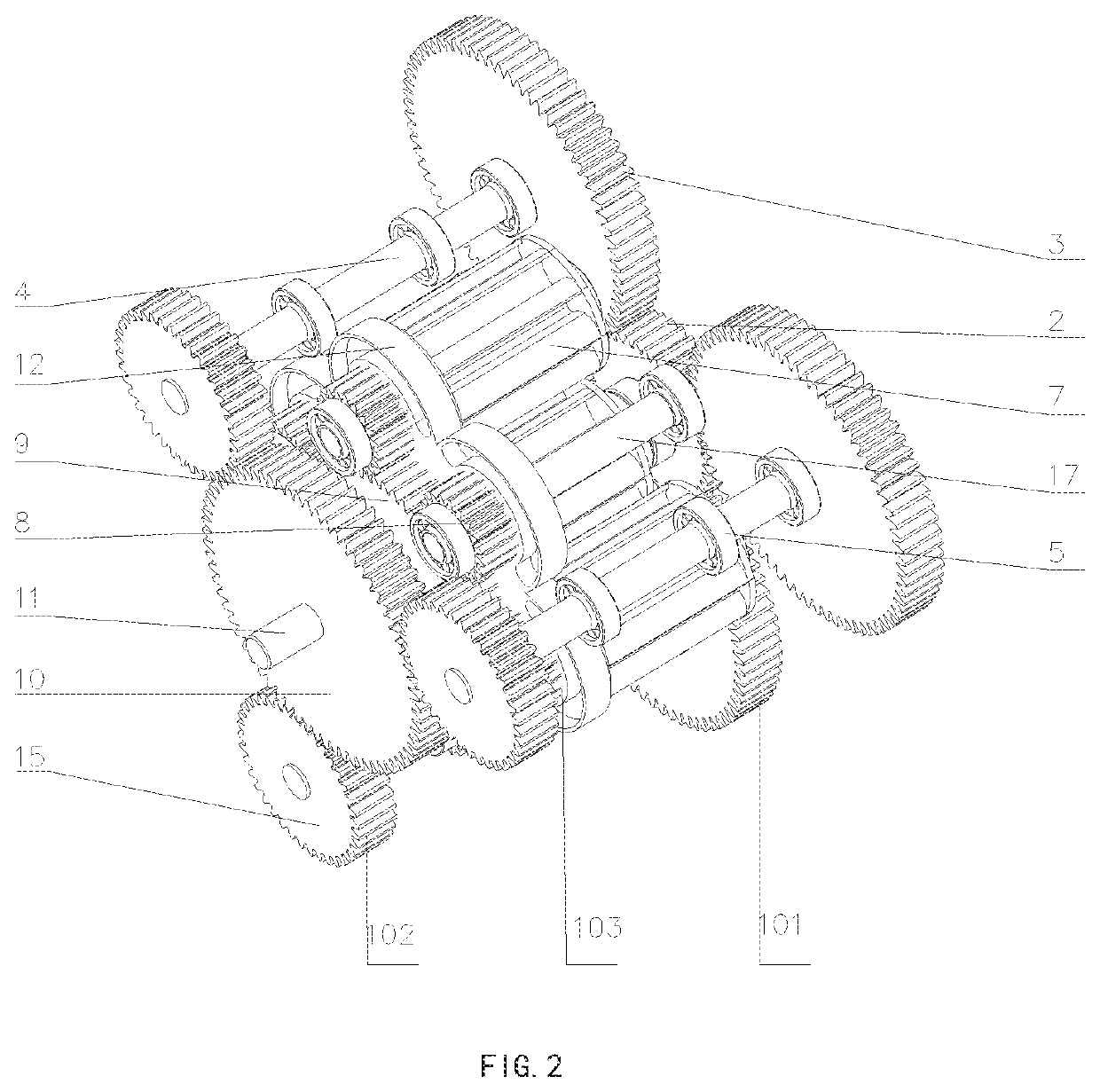

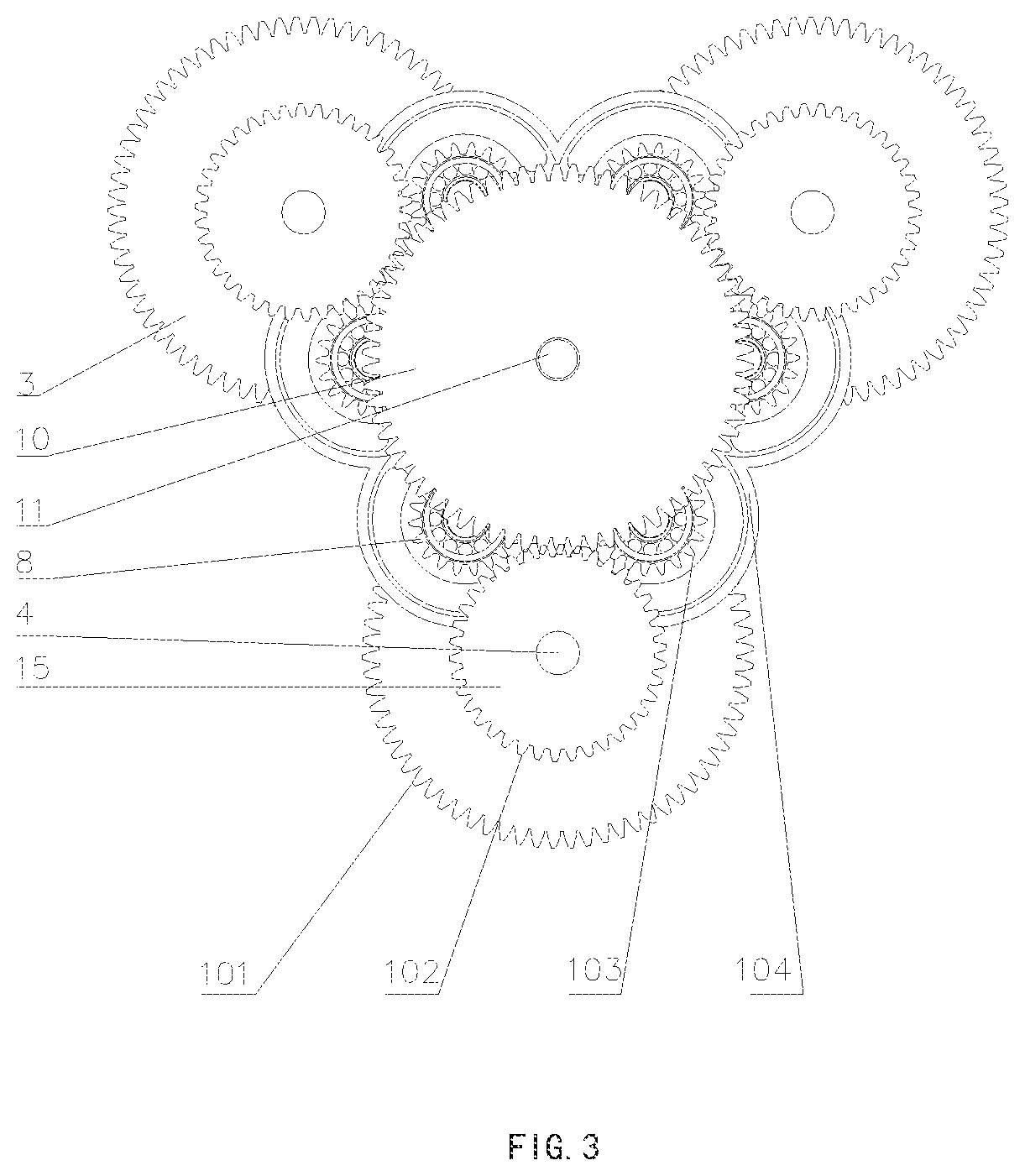

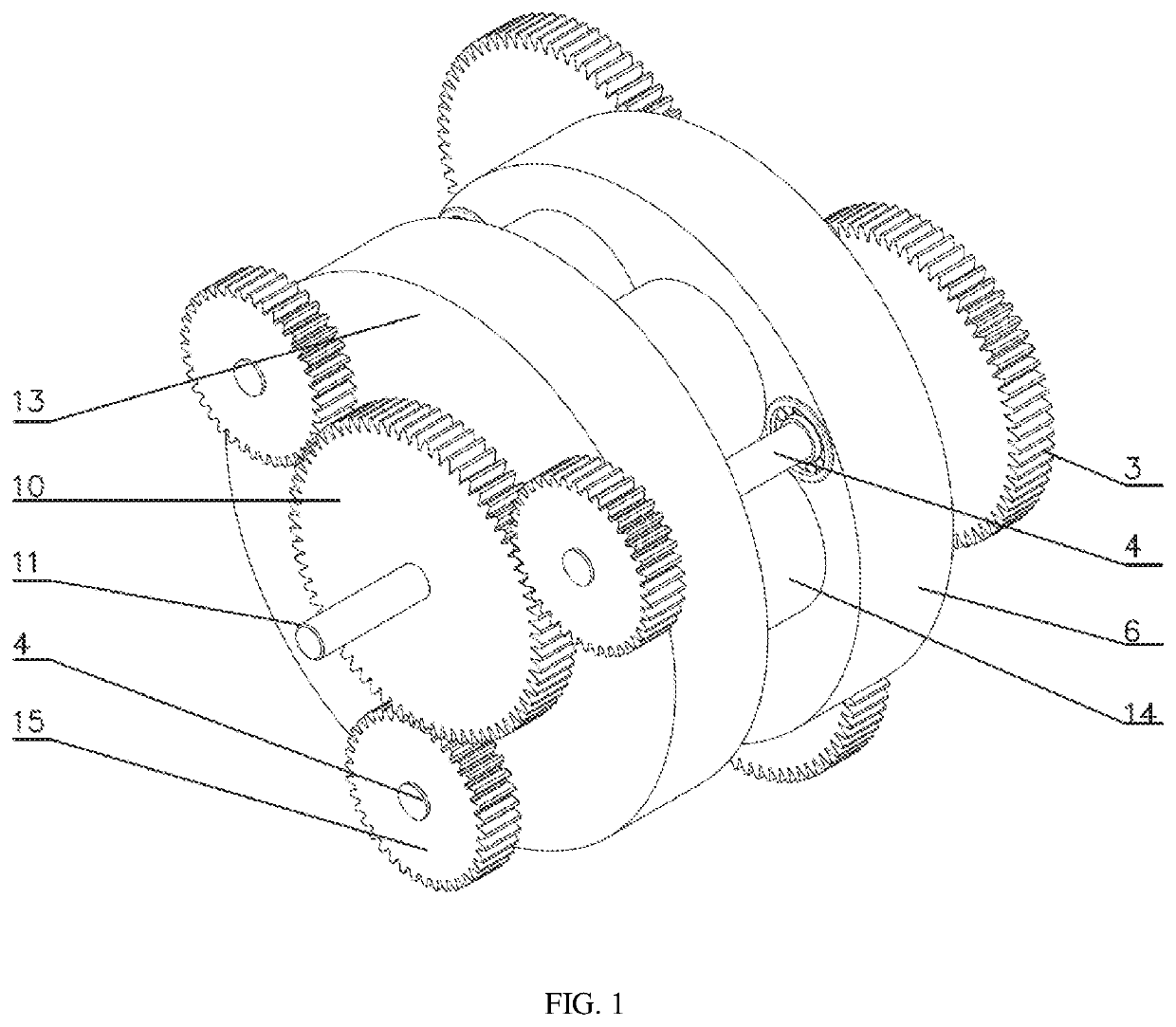

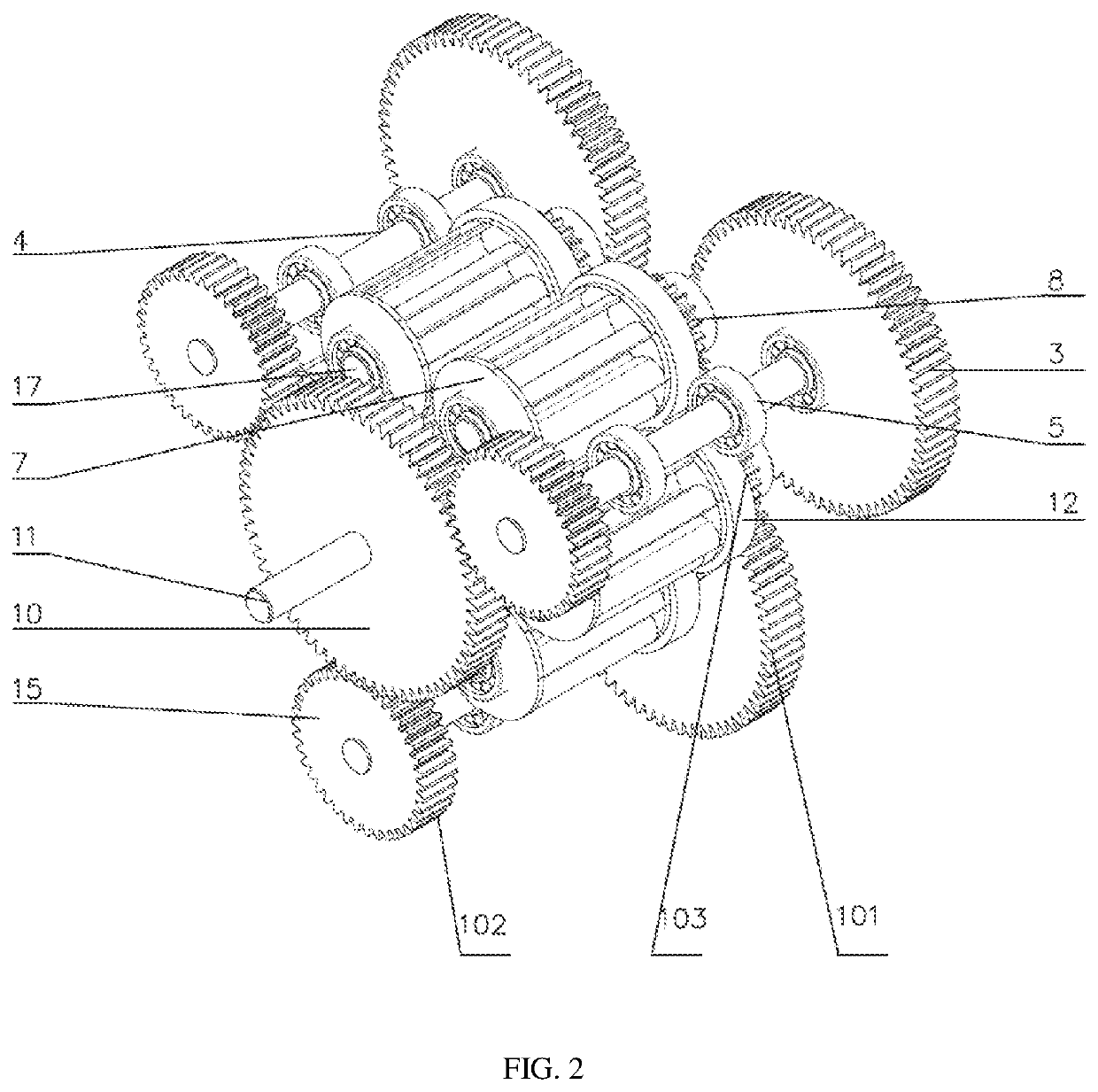

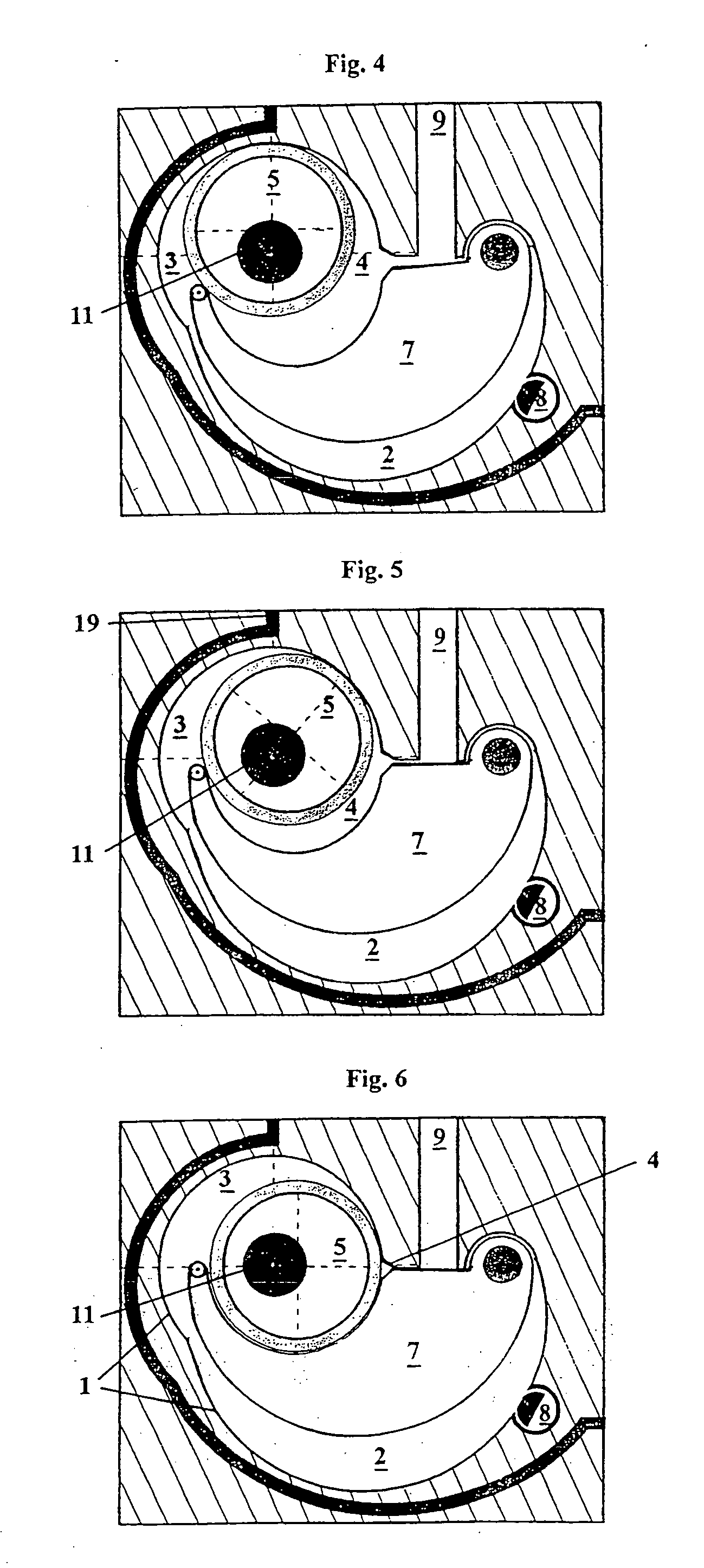

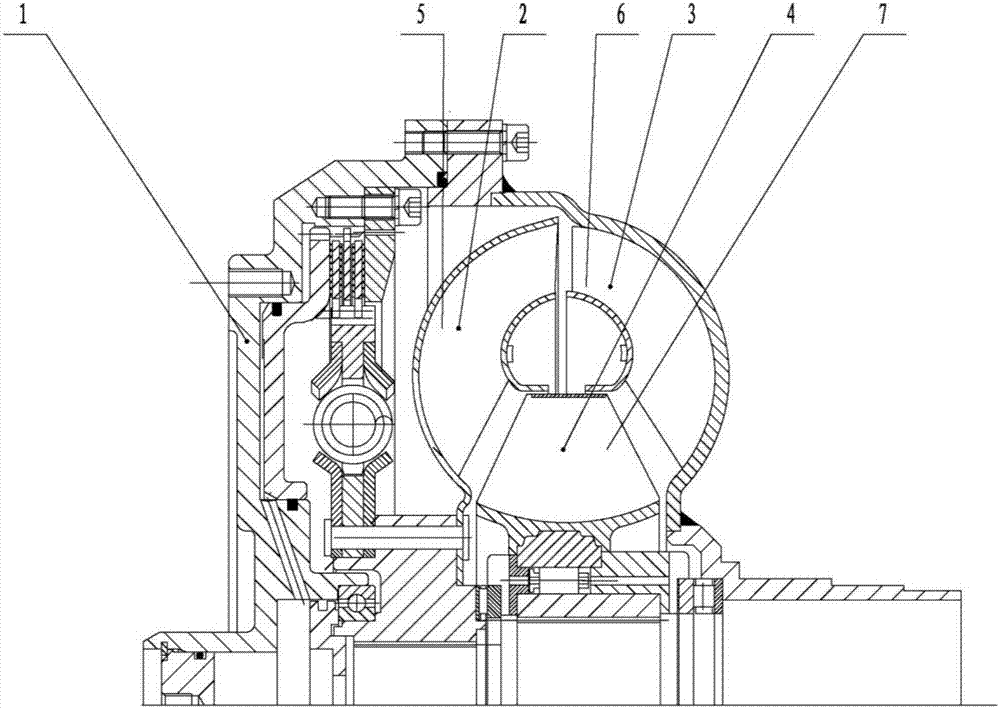

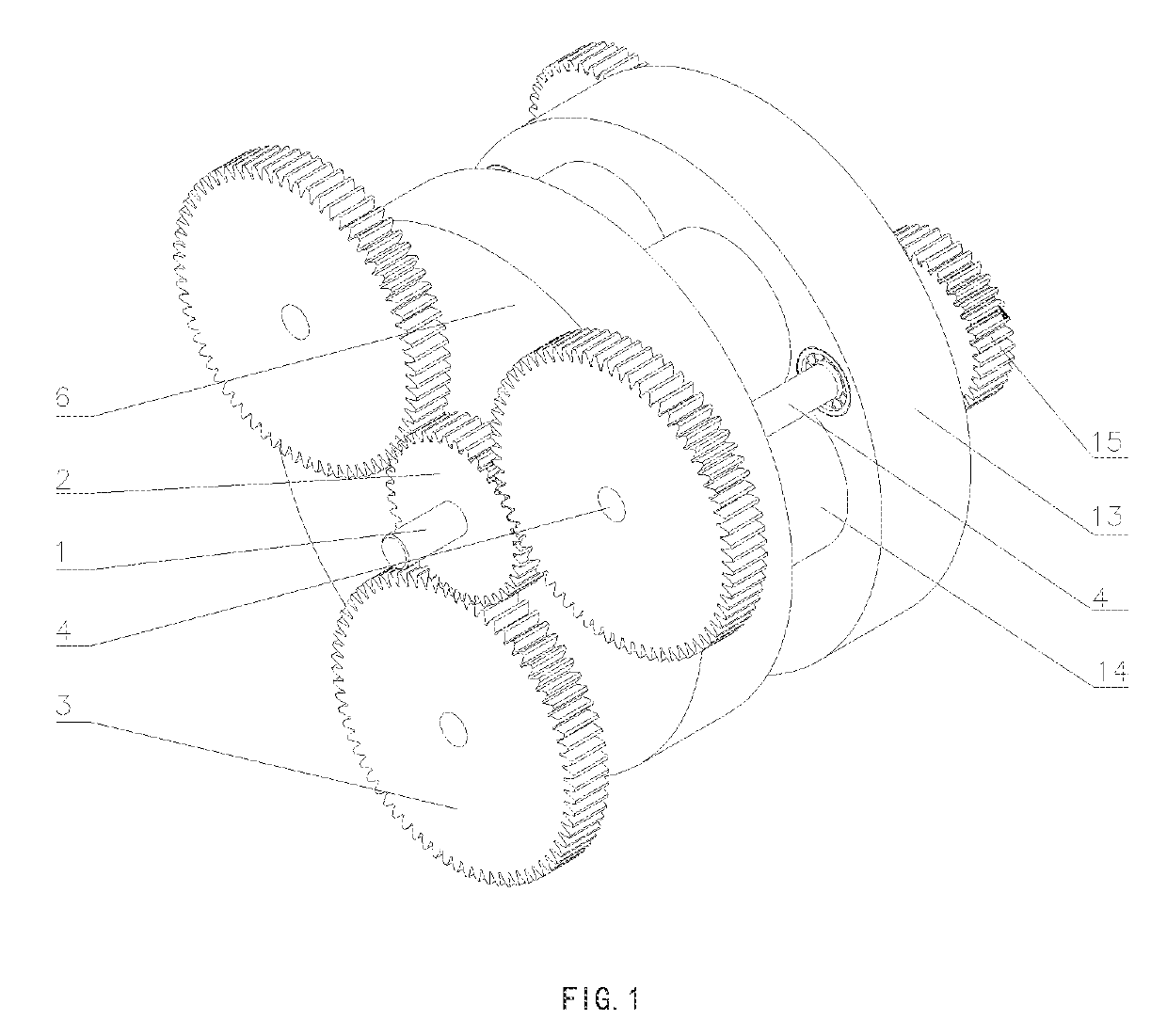

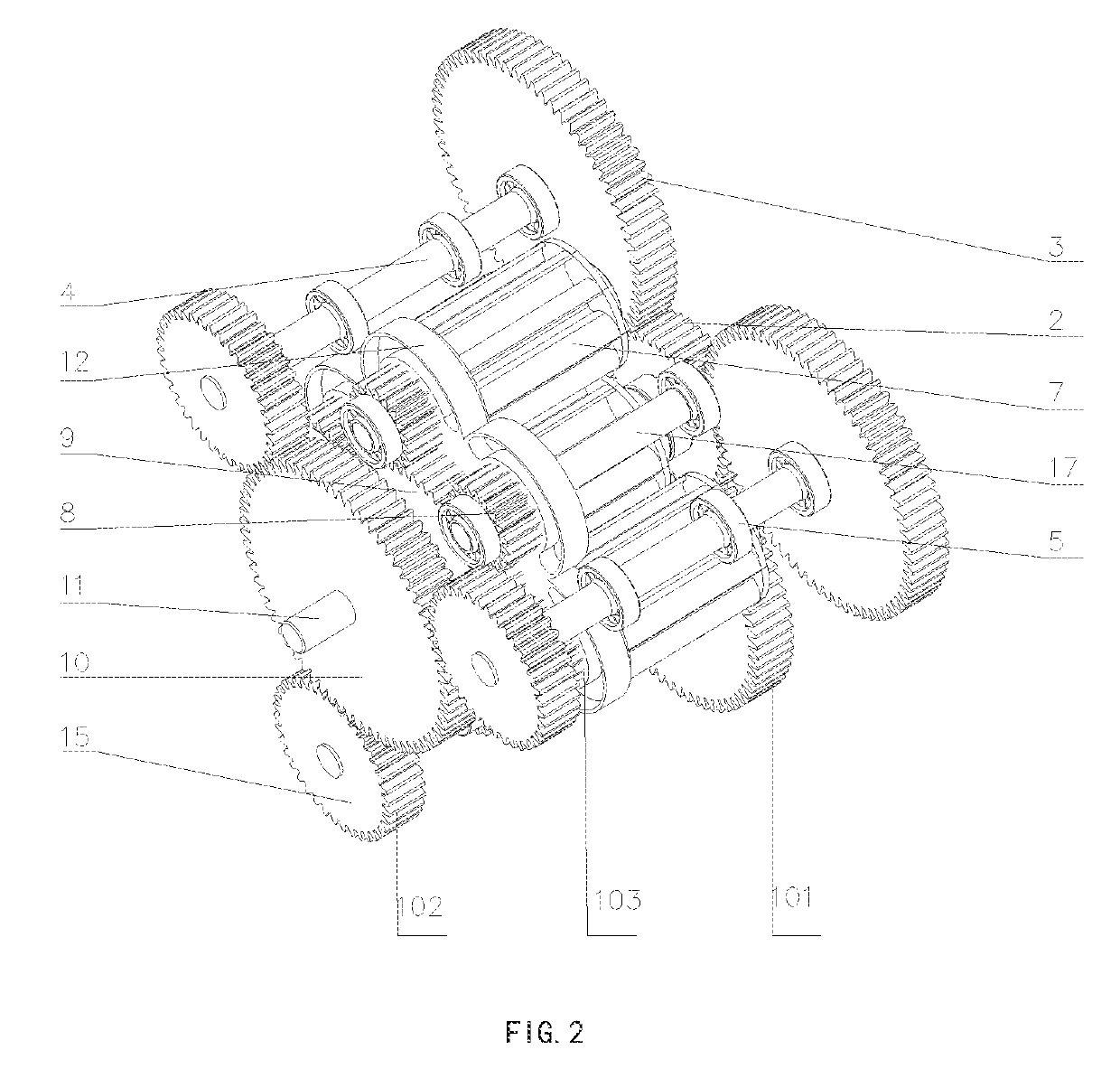

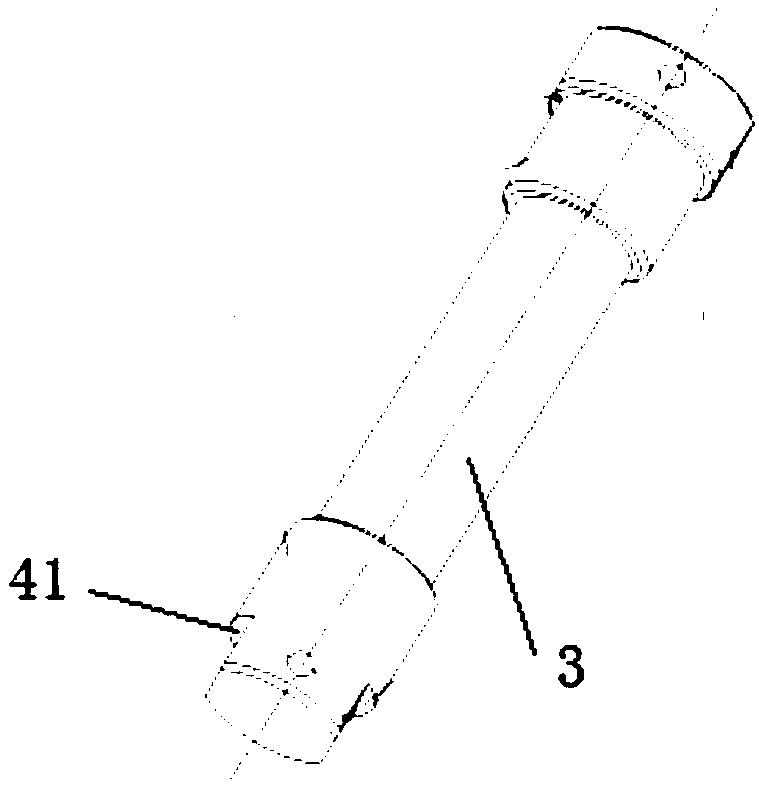

Continuously variable transmission

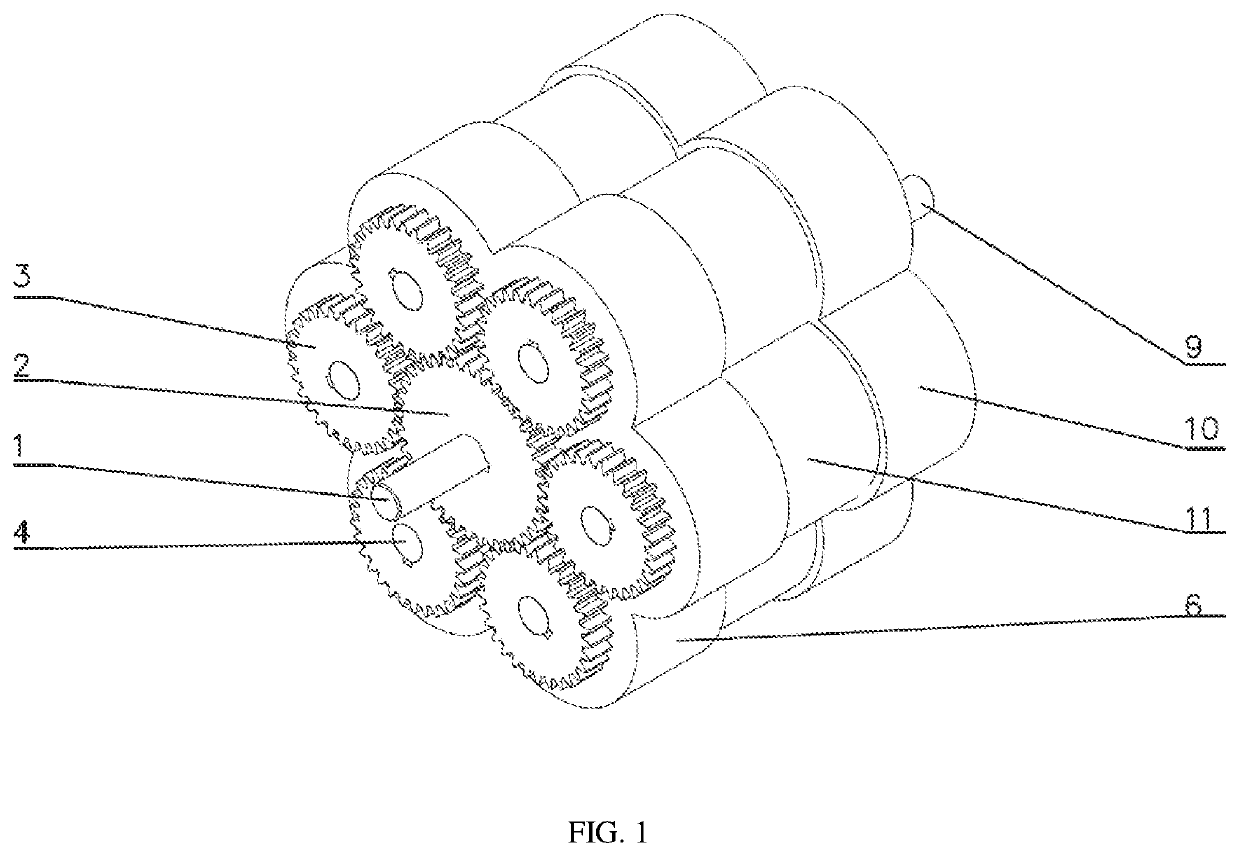

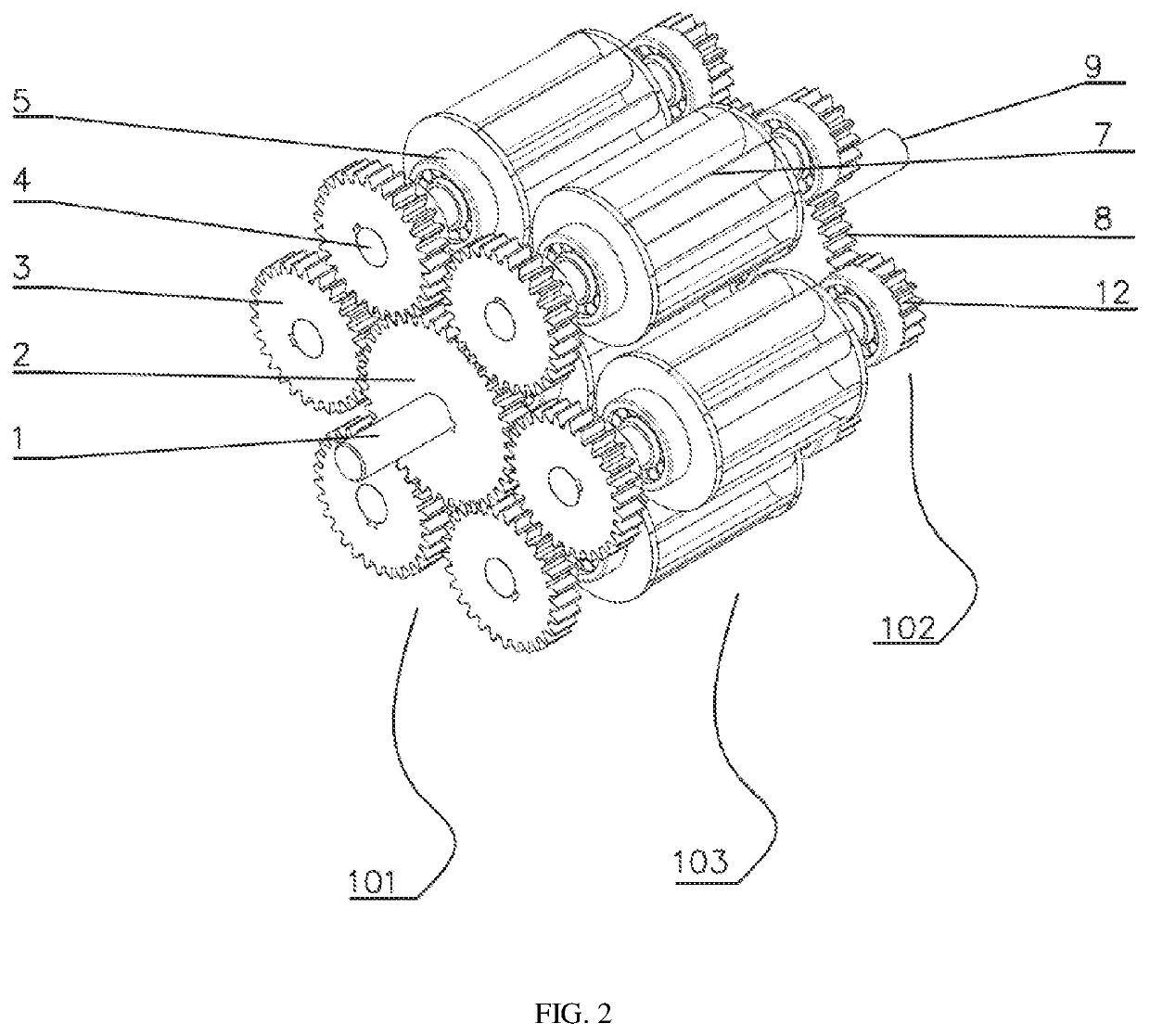

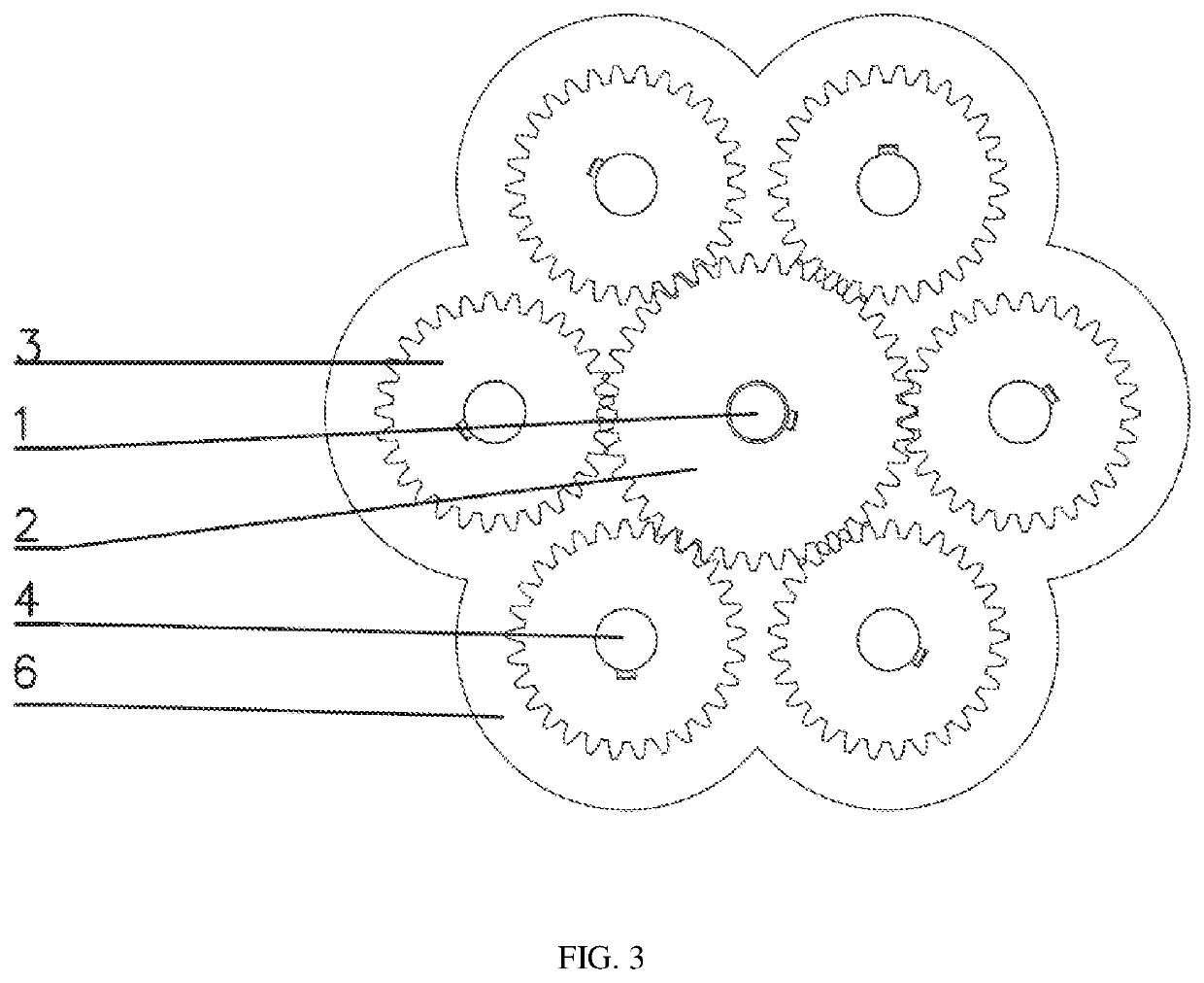

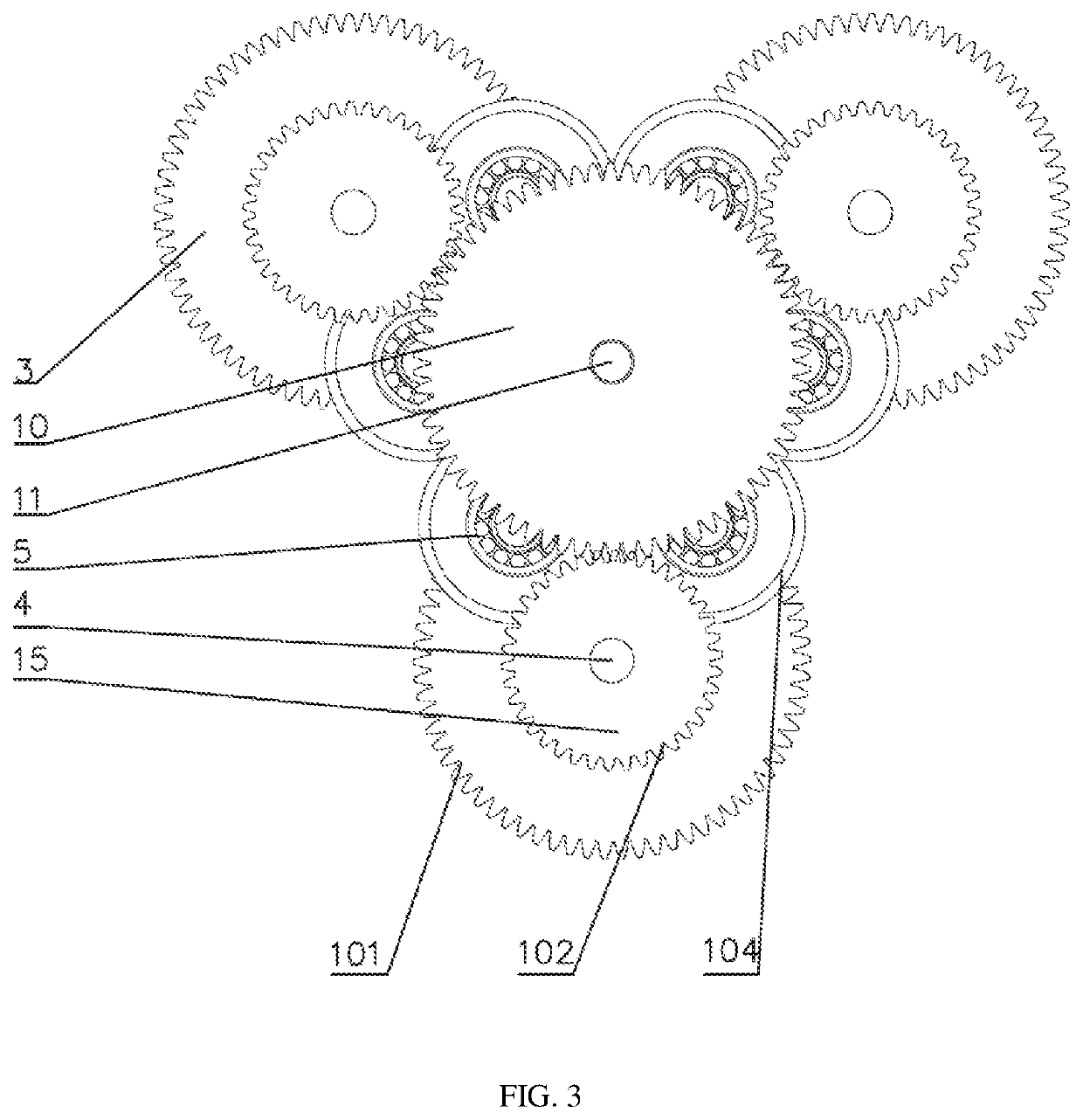

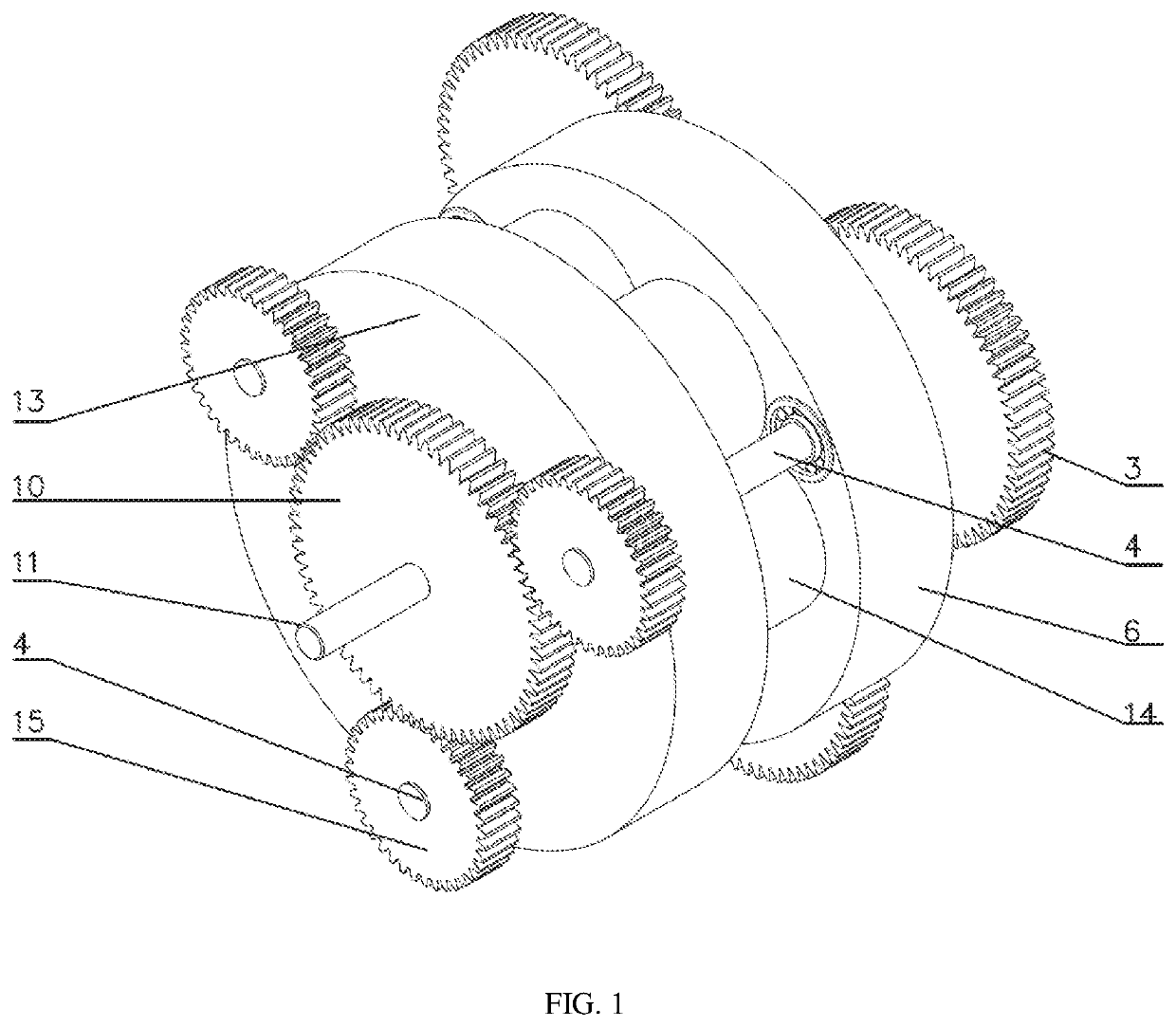

Provided is a continuously variable transmission capable of solving a technical problem of a complex structure comprising three planetary gear sets including a planetary gear set at an input end, a planetary gear set at an output end and a bucket wheel-based planetary gear set. The continuously variable transmission comprises a planetary gear set (101) at an input end and a planetary gear set (102) at an output end. A planetary carrier (103) having a cavity is provided between the planetary gear set (101) at the input end and the planetary gear set (102) at the output end. The planetary carrier (103) comprises an input end cover (6) and an output end cover (10). The input end cover (6) is connected to an inner side of the planetary gear set (101) at the input end. The output end cover (10) is connected to an inner side of the planetary gear set (102) at the output end. A bucket-wheel housing (11) having a cavity is fixed between the input end cover (6) and the output end cover (10). A bucket-wheel (7) is fixed to a planetary gear connecting shaft (4) located inside the bucket-wheel housing (11).

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

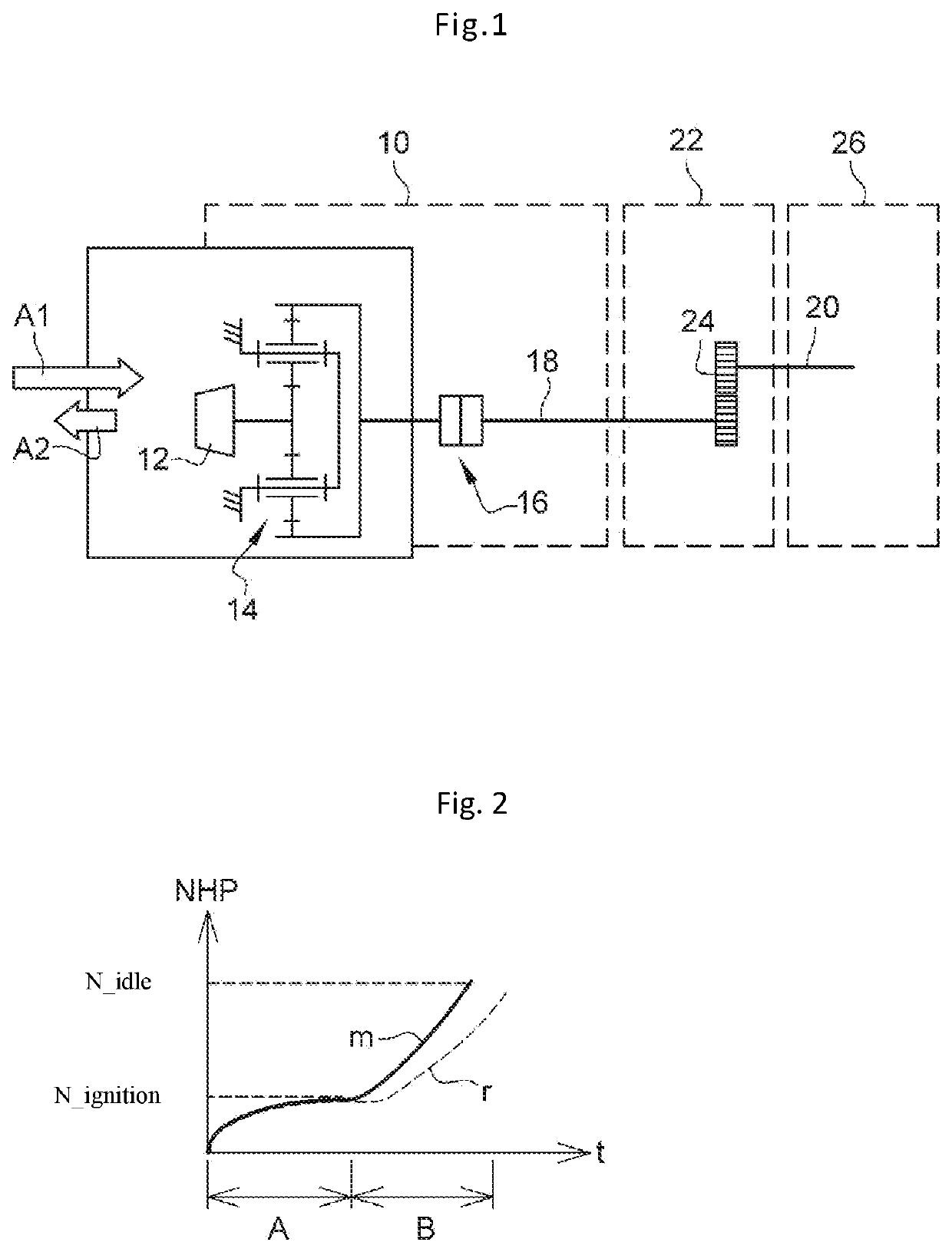

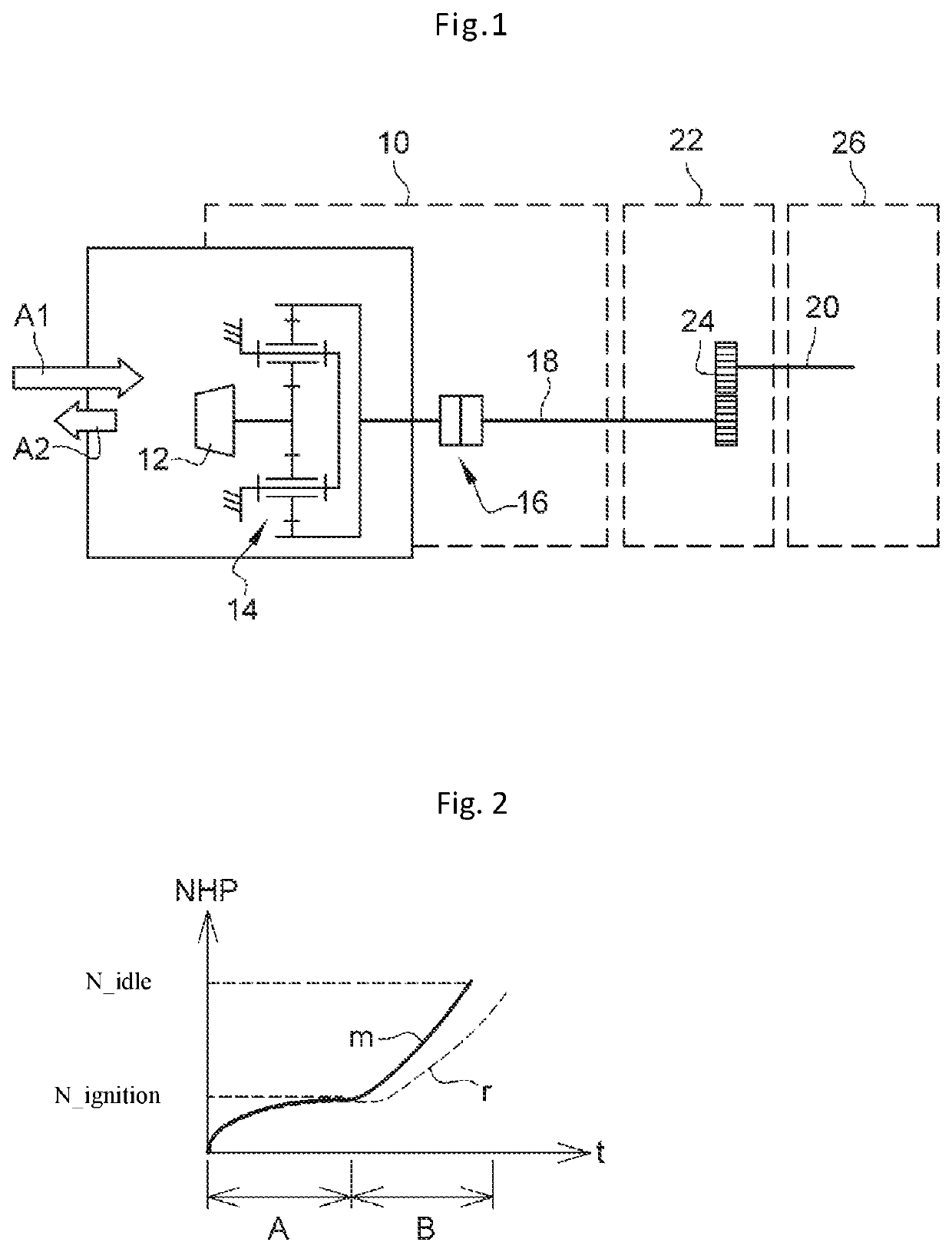

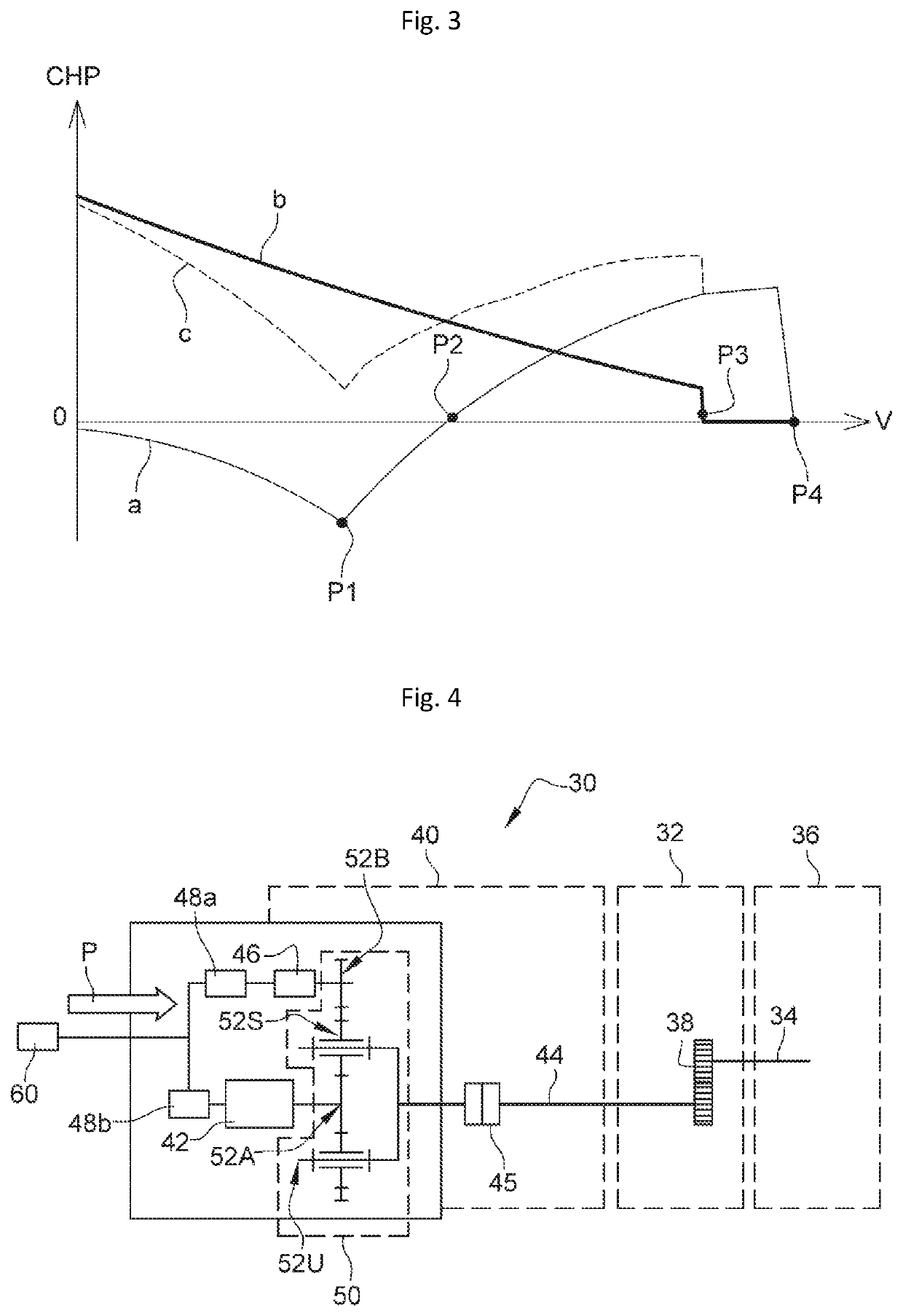

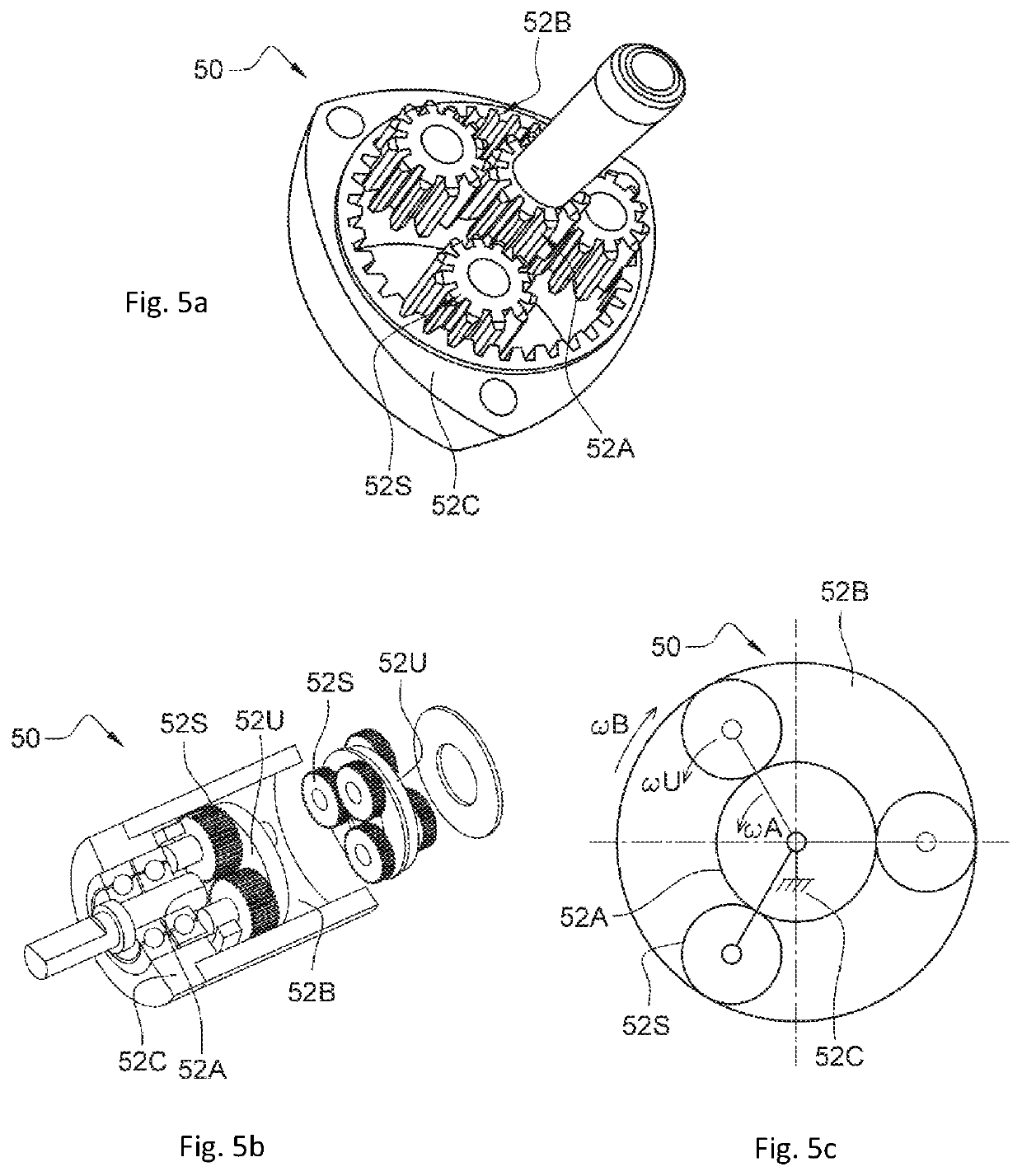

Power distribution device between an electric starter and an electric machine towards a shaft of a turbomachine

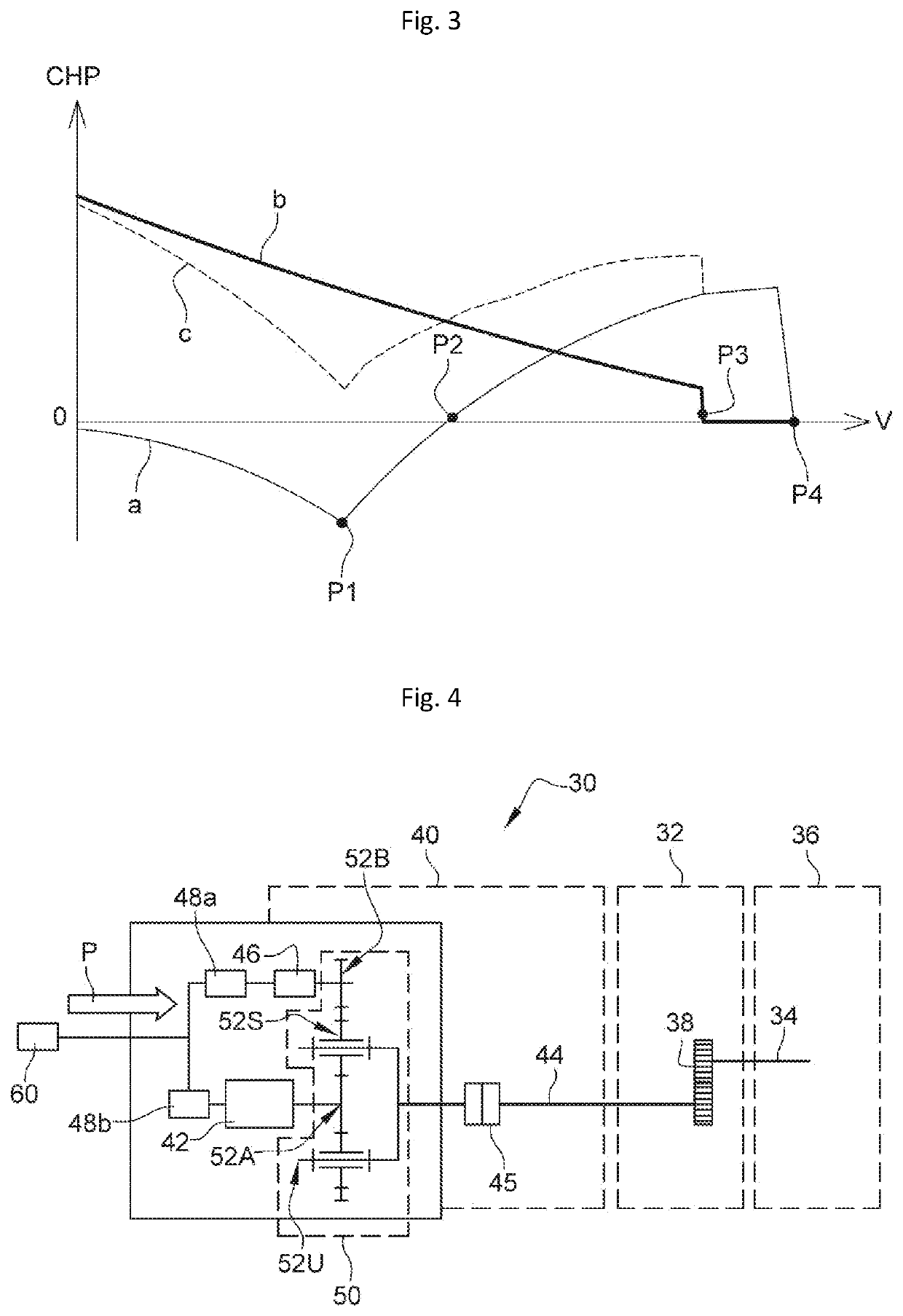

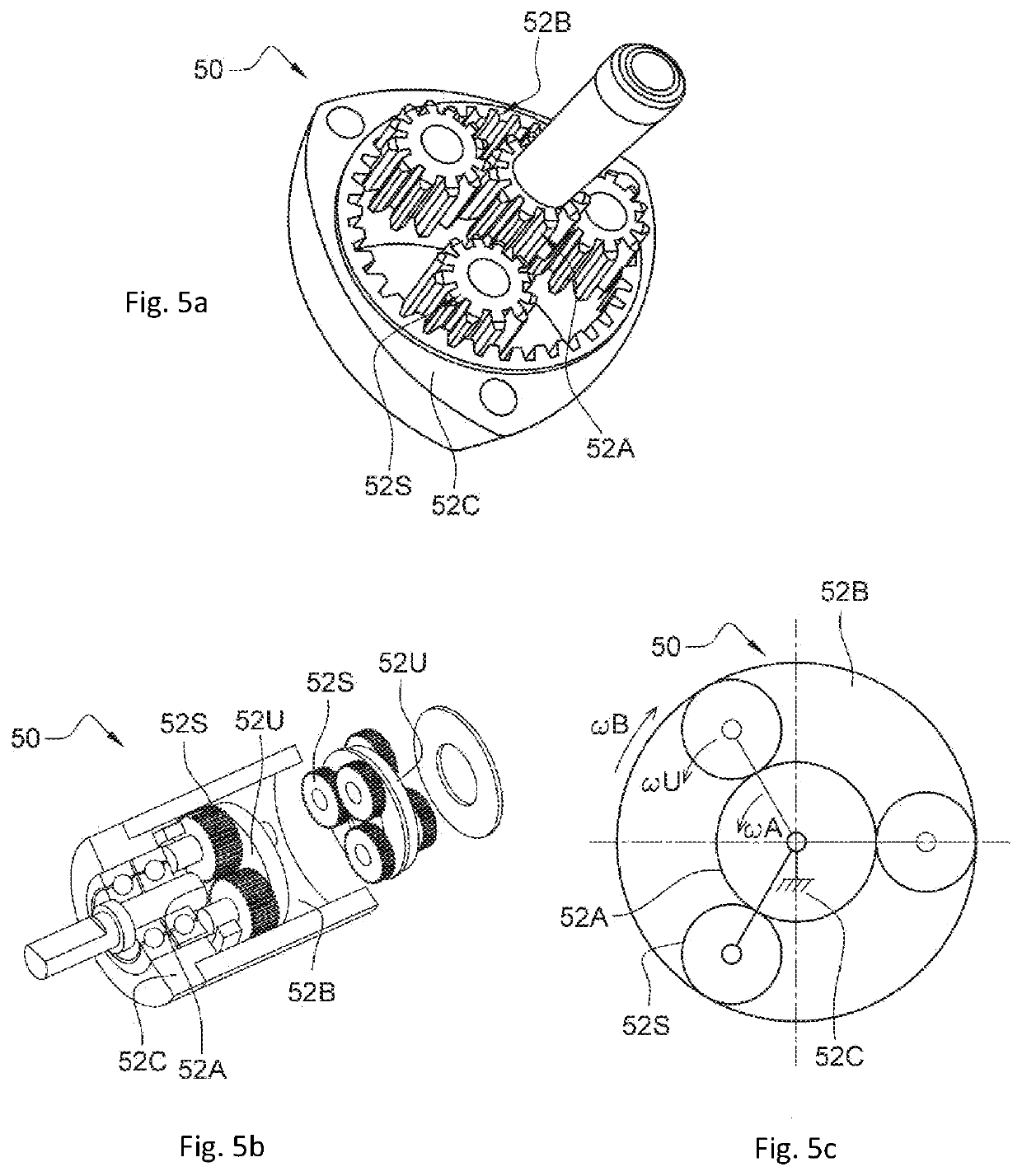

ActiveUS20210025334A1Wide torque rangeIncrease torqueEngine fuctionsEfficient propulsion technologiesElectric machineReduction drive

A power distribution device between an electric starter of a turbomachine and an electric machine toward a shaft of the turbomachine, including the electric starter, the electric machine, and a controller for controlling the electric machine. An epicyclic train reducer includes a first element intended to be coupled to the shaft, a second element coupled to the electric starter, and a third element intended to be rotated by the electric machine. The controller is configured to rotate the third of the three elements so as to obtain two bearings of reduction ratios of the speeds between the first of said three elements and the second of the three elements. The controller is configured to drive the torque of the third of the three elements in accordance with a determined output torque.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Continuously variable transmission

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

Double-disc type motor electric stepless speed change mechanical-electrical integration system

PendingCN111376698AAxial dimension shortCompact structureGas pressure propulsion mountingMagnetic circuit stationary partsElectric machineDrive motor

The invention relates to a double-disc type motor electric stepless speed change mechanical-electrical integration system. The system comprises a shell, a planet wheel, a sun wheel, an input shaft, aplanet carrier, a gear ring carrier, a gear ring, an output shaft, a hollow shaft, an ISG motor stator, an ISG motor stator, an ISG motor rotor, a main drive motor stator, a main drive motor rotor anda main drive motor stator; the ISG motor stator and the ISG motor rotor form an ISG disc type motor; the main drive motor stator and the main drive motor rotor form a main drive motor with a double-stator structure; the output shaft penetrates through the hollow shaft; supporting bearings are arranged between the front end and the rear end of the hollow shaft and the output shaft; the sun wheel,the planet wheel and the gear ring form a planet row; the ISG motor stator and the main drive motor stator are connected together and are connected with the hollow shaft through the support bearings;an ISG motor stator side shell is connected with the hollow shaft through the supporting bearing; a main drive motor stator side shell is connected with the output shaft through the supporting bearing. The system of the invention has the advantages of compact structure, high power density, high system efficiency and outstanding NVH characteristics.

Owner:南京清研海易新能源动力有限责任公司

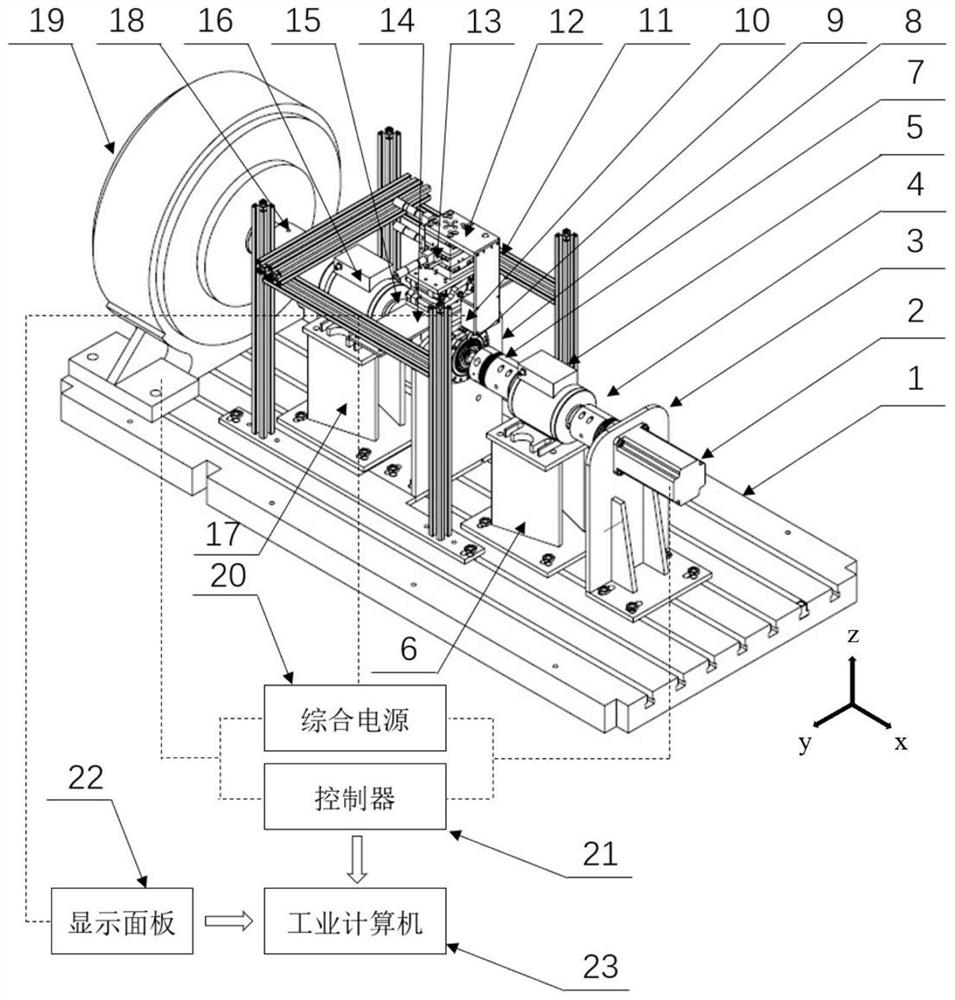

Device and method for measuring radial deformation of flexible gear teeth of harmonic reducer

PendingCN113587833AReliable measurement resultsImprove accuracyUsing optical meansPhysicsShape design

The invention discloses a device and method for measuring radial deformation of flexible gear teeth of a harmonic reducer; a harmonic reducer rigid gear is processed to form an observation notch, and a laser displacement sensor is used for respectively measuring the radial deformation of flexible gear teeth at different positions along the central axis direction of the harmonic reducer during meshing movement of the harmonic reducer. According to the invention, the real radial deformation during meshing movement of a flexible gear can be measured, real and effective guidance parameters are provided for design and modification of the tooth shape of the rigid gear, improvement of the tooth shape design precision of the harmonic reducer rigid gear is facilitated, and the problem of partial interference between the flexible gear and the rigid gear of the harmonic reducer is solved. The method is of great significance in designing and optimizing the tooth shape of the rigid gear of the harmonic reducer.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Continuously variable transmission

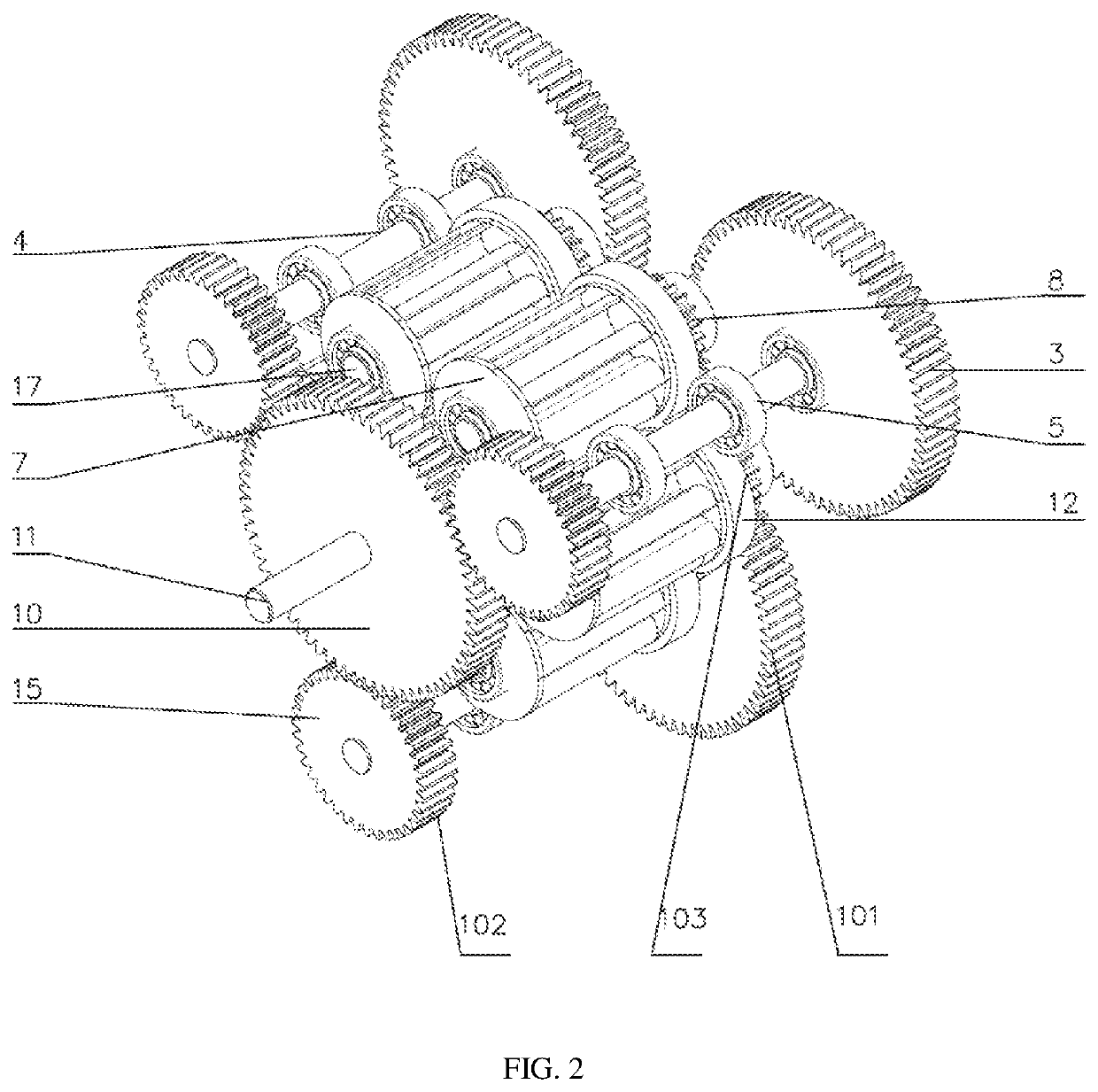

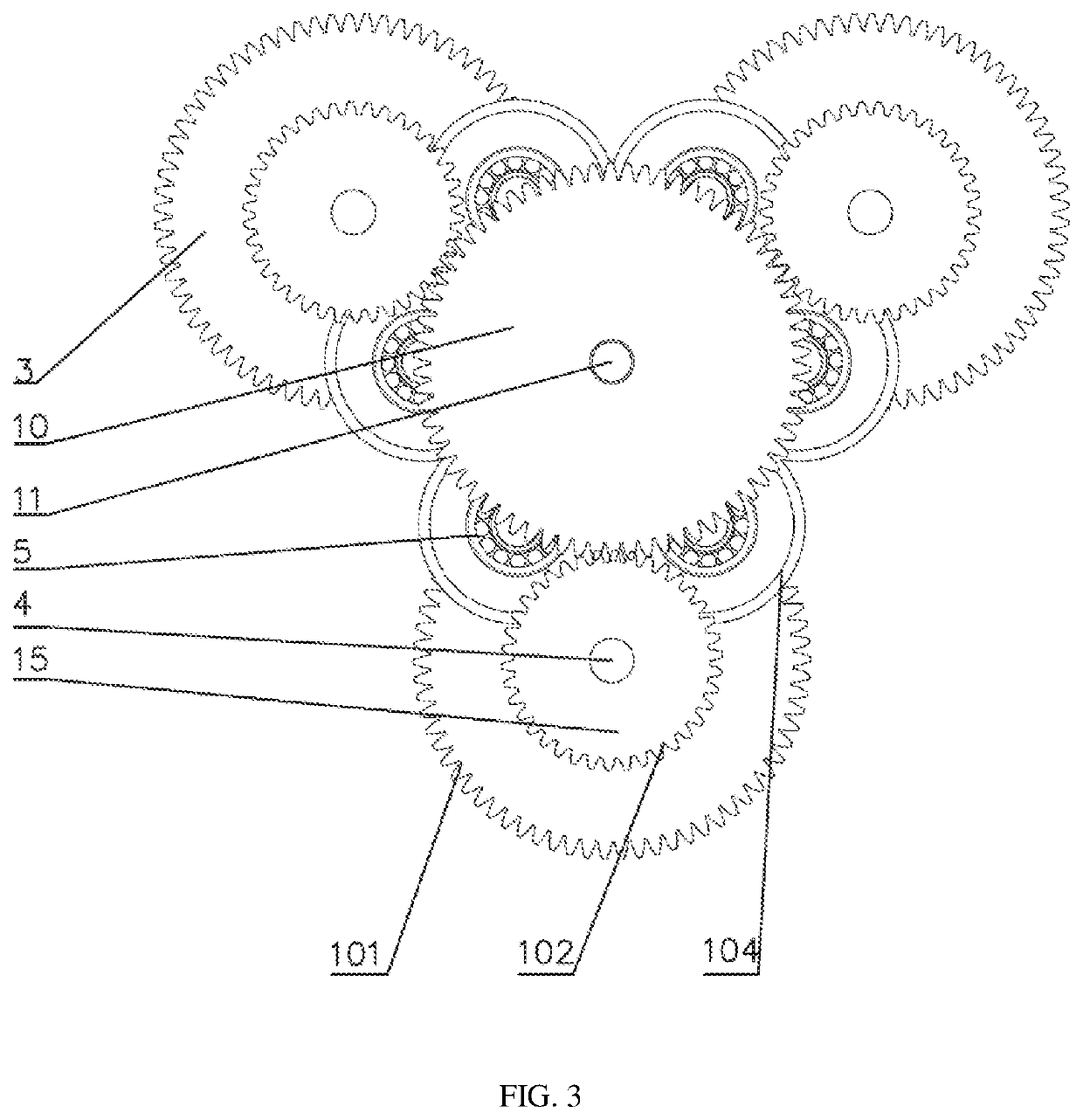

ActiveUS20190383376A1Wide torque rangeTransmission elementsFluid gearingsControl theoryPower density

Provided is a continuously variable transmission capable of solving a technical problem in which upon activation of a continuously variable transmission, speed increase in vaned-wheel power density is low and unable to meet the requirement for rapidly increasing output torque. The present continuously variable transmission comprises a planetary gear set (101) at an input end and a planetary gear set (102) at an output end. A planetary carrier (104) having a cavity is provided between the planetary gear set (101) at the input end and the planetary gear set (102) at the output end. The planetary carrier (104) comprises an input end cover (6) and an output end cover (13). A vaned-wheel housing (14) having a cavity is fixed between the input end cover (6) and the output end cover (13). An inner side of the planetary gear set (101) at the input end is connected to the input end cover (6). An inner side of the planetary gear set (102) at the output end is connected to the output end cover (13). A vaned-wheel-based planetary gear set (103) is provided at one internal side of the vaned-wheel housing (14).

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

A CMG low-speed frame fast wide torque range, high-precision drive control system

ActiveCN107707172BHigh precision torqueWide torque rangeElectronic commutation motor controlAC motor controlControl systemSatellite

A CMG low-speed framework rapid wide torque range and high-precision driving control system employs a dual-winding motor mode, one mode can provide a large moment, and the other one can provide a high-precision moment, two motors can perform free switching according to an operating condition, and therefore, the CMG low-speed framework rapid wide torque range and high-precision driving control system has a wide torque range and a high-precision moment output capability, and can satisfy maneuverability demands for multi-task realization for the future and demands of a super quick high-performance satellite platform capable of imaging with moving.

Owner:BEIJING INST OF CONTROL ENG

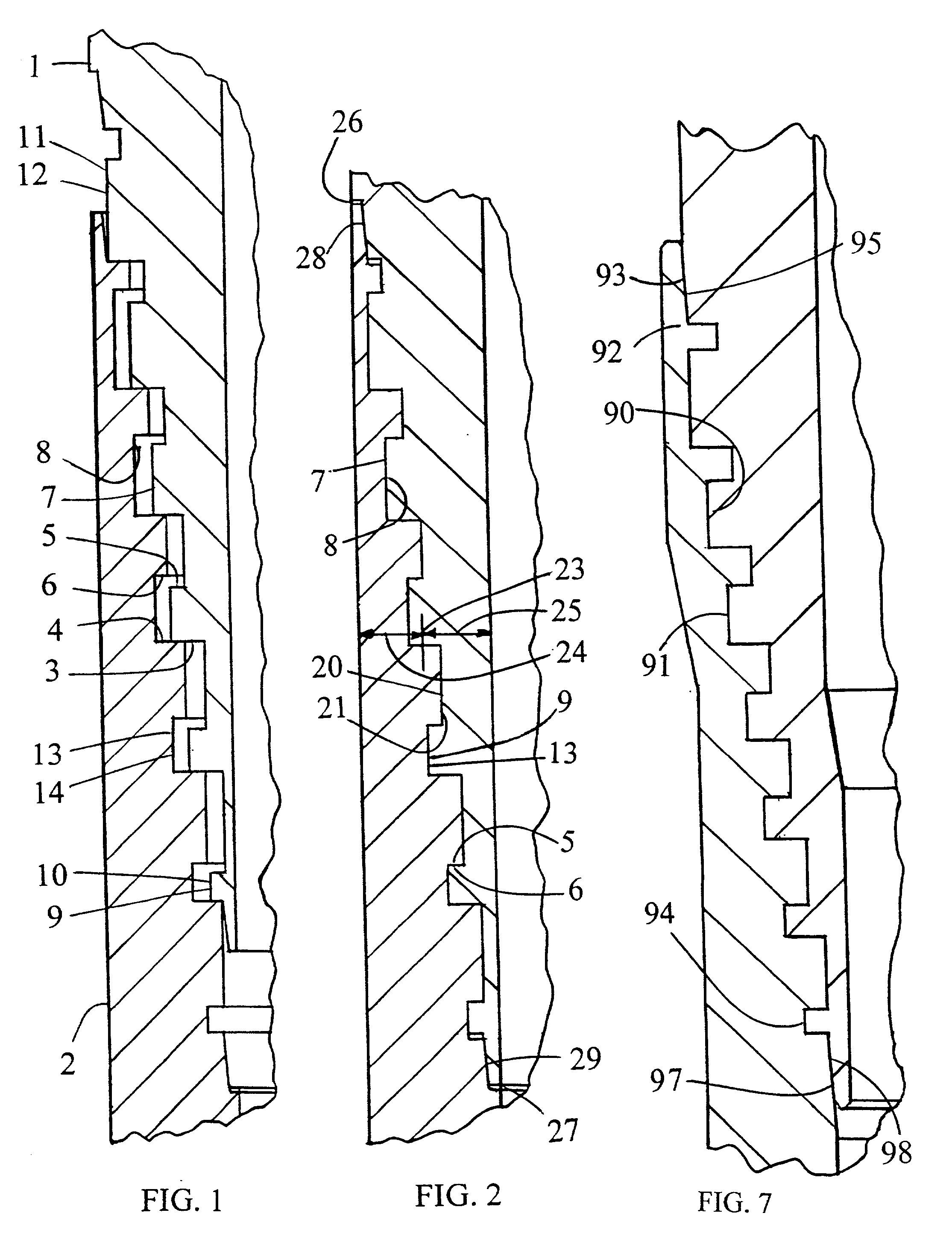

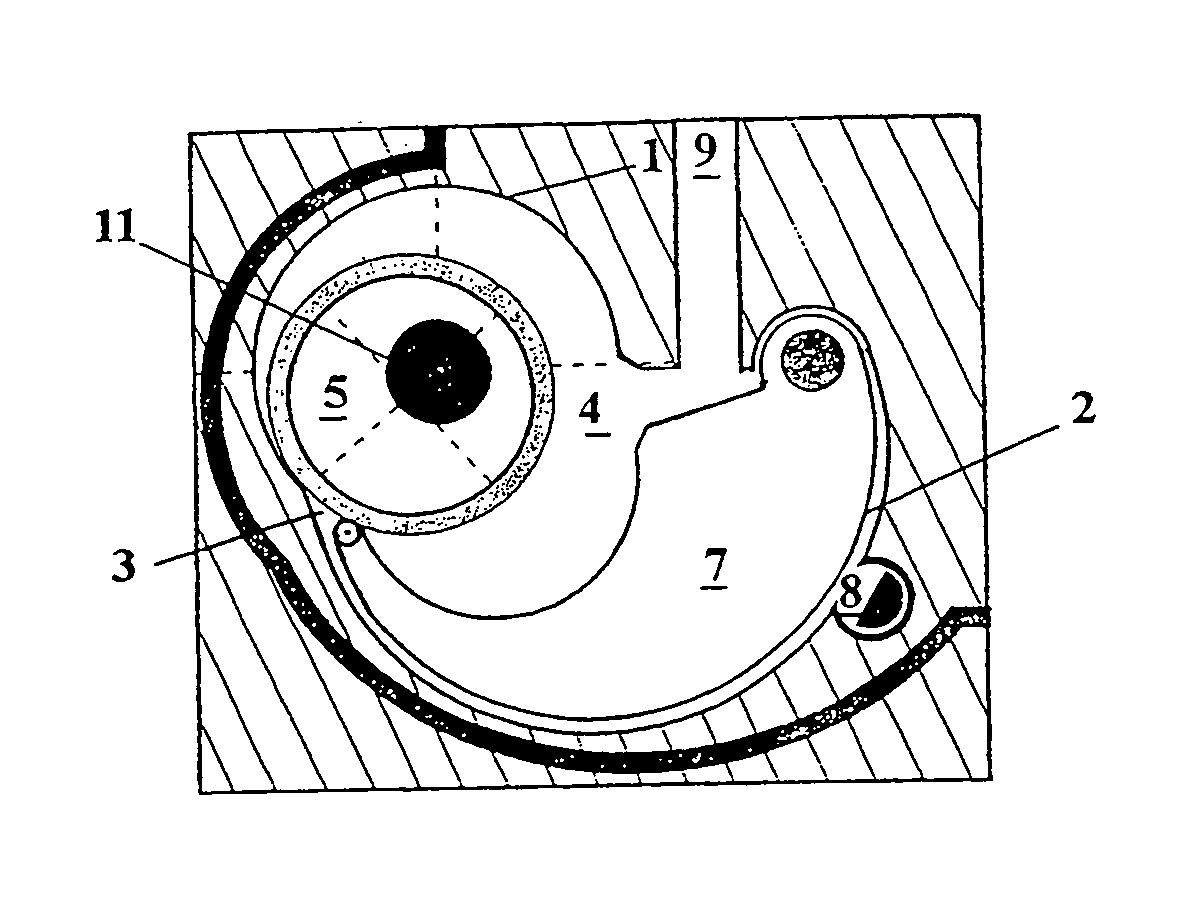

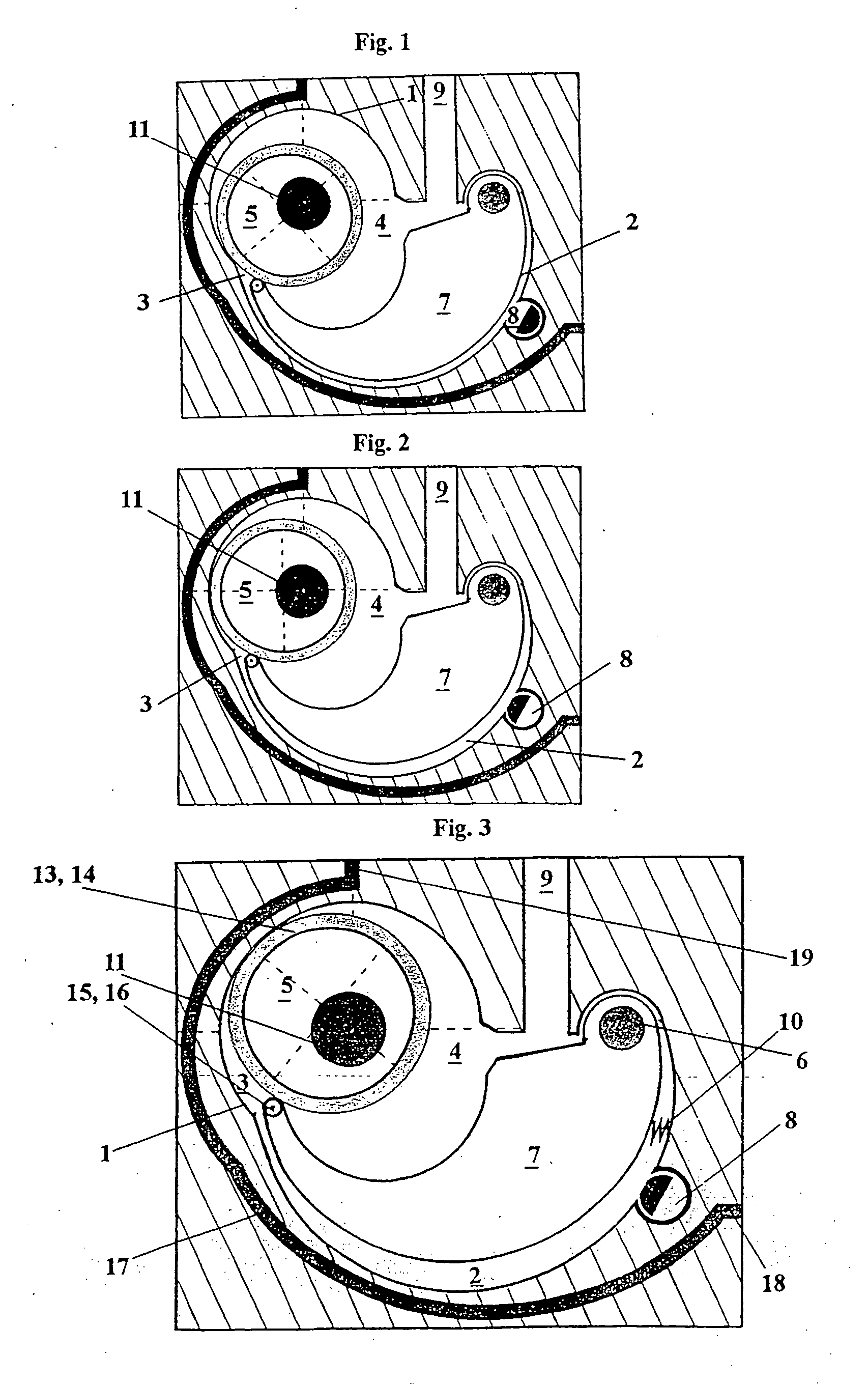

Lever-mechanism motor or pump

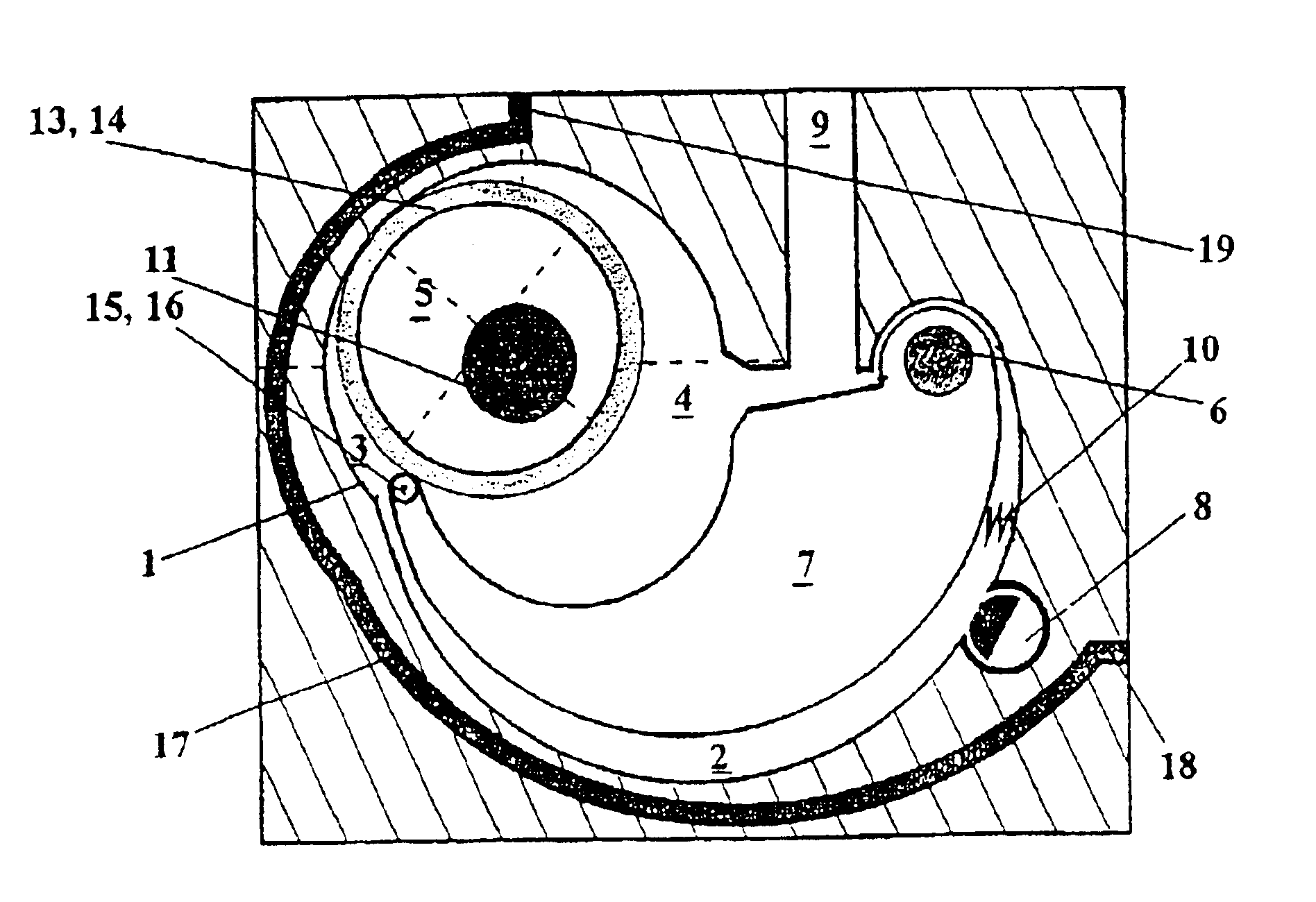

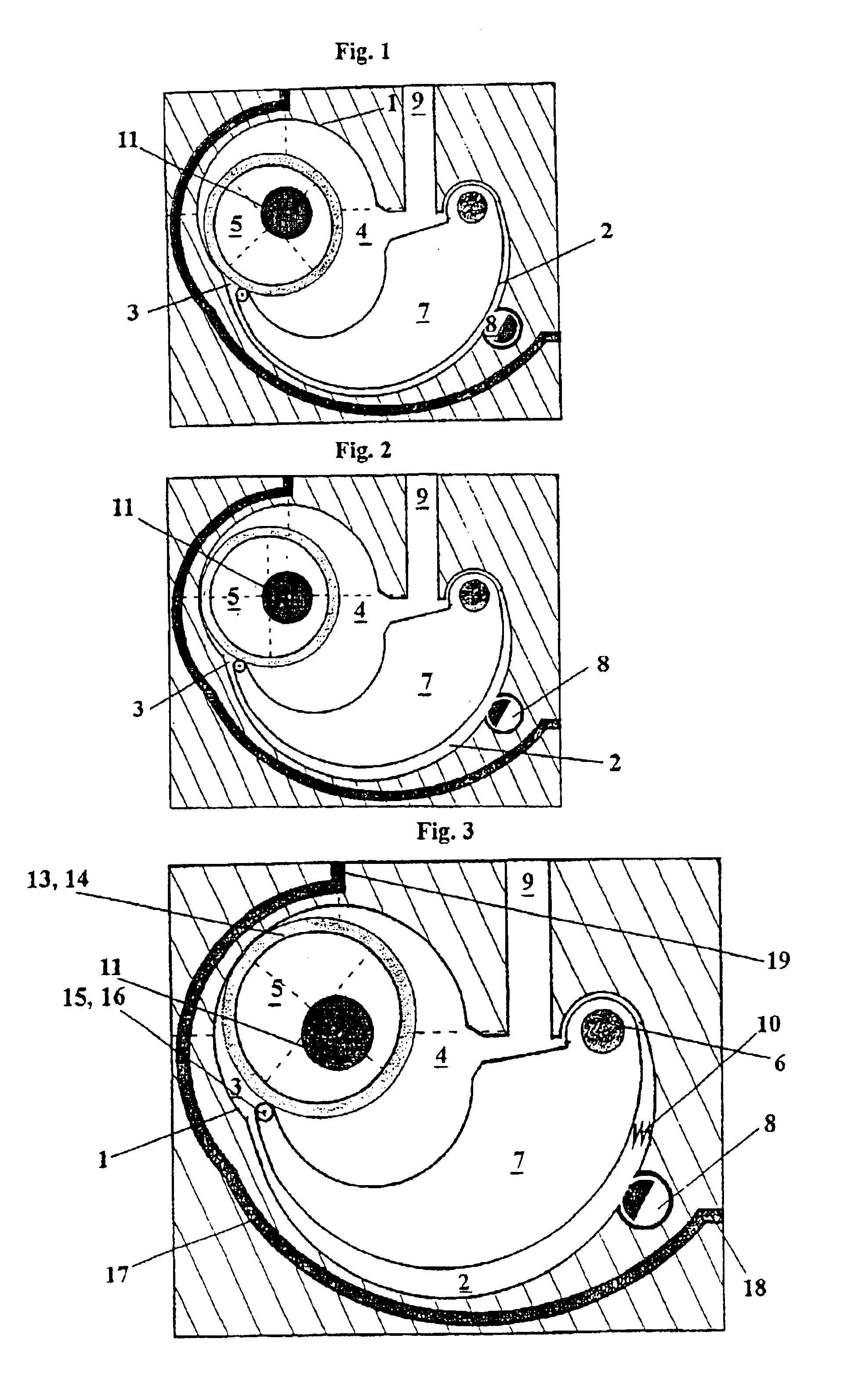

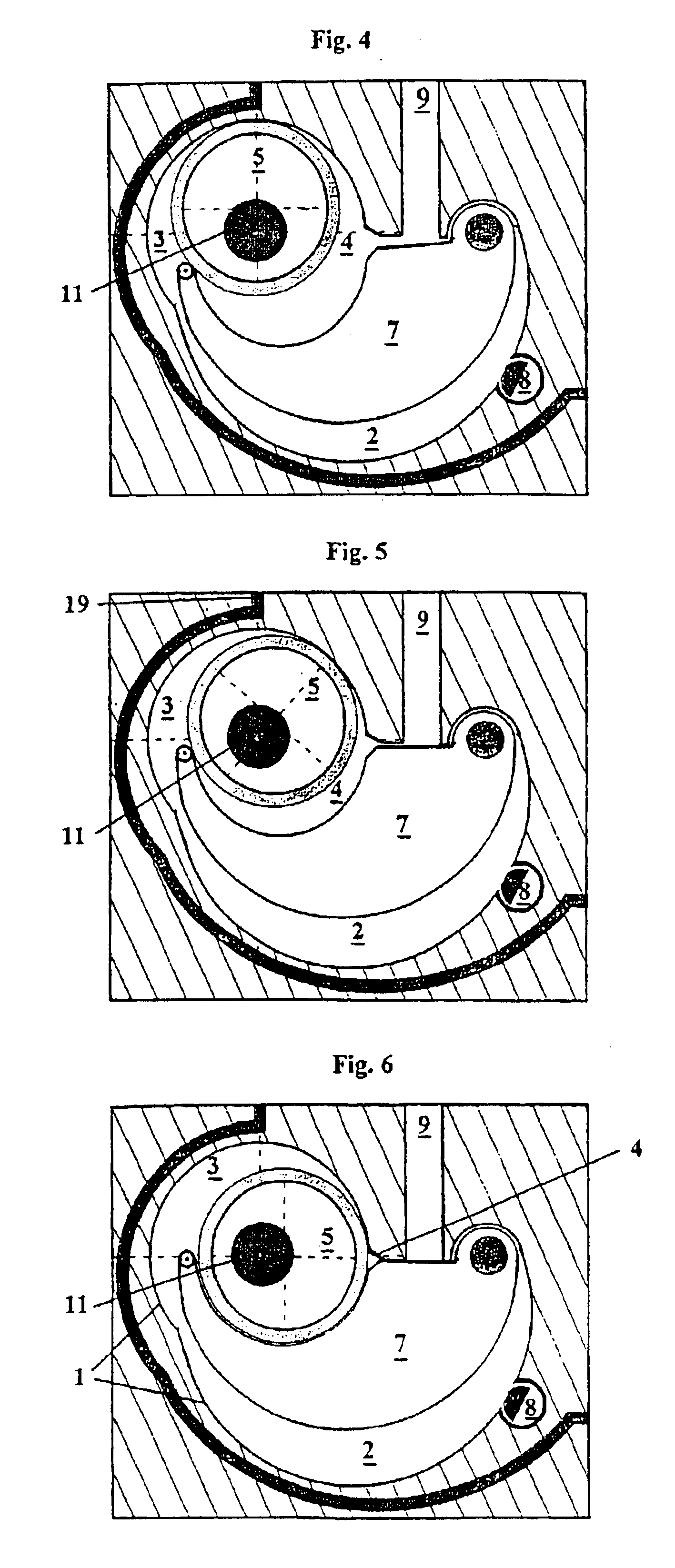

InactiveUS20050087156A1Improve efficiencySmall pollution loadRotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesPistonRing type

A machine, such as an engine, which includes a cylinder (1), an essentially cylindrical piston (5) set on bearings and equipped with an eccentrically-set shaft (11), an inlet port or valve (8), an outlet port or valve (9), and a lever device (7), which is attached by bearings to a shaft (6) and which is intended to be in essentially tight contact with the piston (5). The cylinder (1) forms an essentially cylindrical chamber for the rotary piston (5) and a partially cylindrical chamber for the lever device (7) that moves backwards and forwards. The piston (5) is equipped, in the interior of the working chamber, with sliding-ring-type bearings (13, 14).

Owner:RANTALA VEIKKO KALEVI

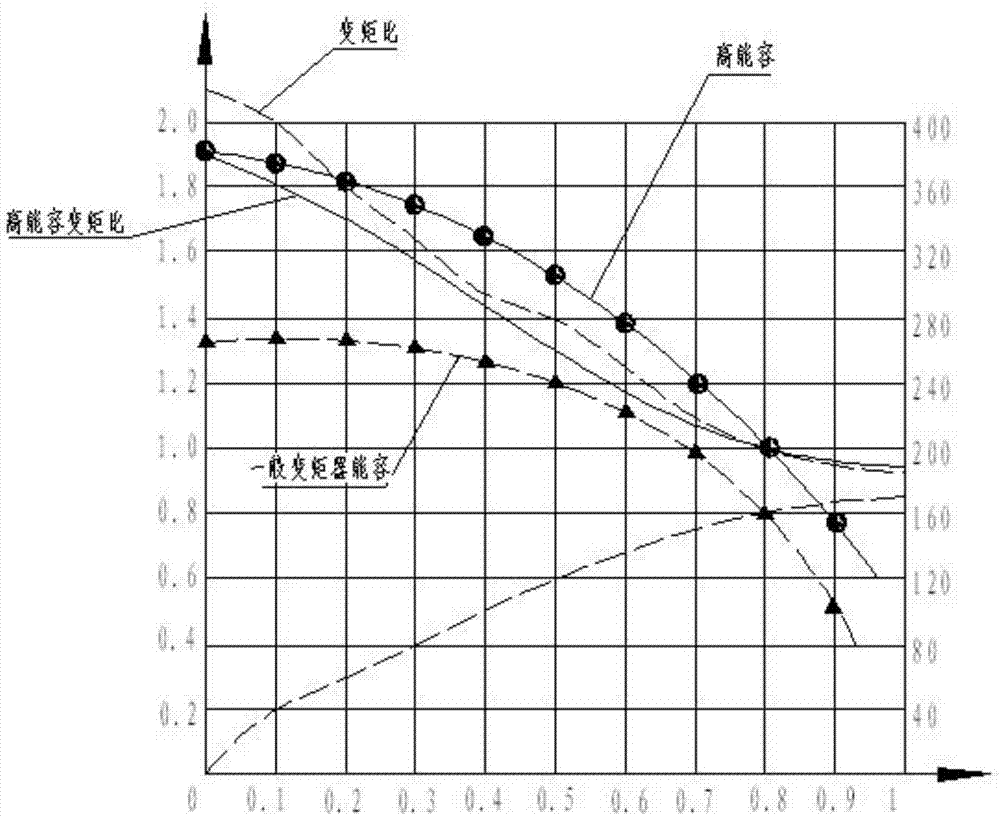

High-capacity locked type hydraulic torque converter

The invention relates to a hydraulic torque converter mainly suitable for a port wharf traction vehicle. The hydraulic torque converter comprises a cover wheel assembly, a turbine assembly, a pump wheel assembly and a guide wheel assembly, wherein the cover wheel assembly and the turbine assembly form a locking working condition; a pump wheel, a turbine and a guide wheel form a torque conversion working condition; and the performances in the high-capacity locked type hydraulic torque converter realize the performances of the hydraulic torque converter by adjusting the angles of pump wheel blades and parameters of guide wheel blades. The hydraulic torque converter adopts a matched engine torque range from 1200-1800 Nm, is wider in range, can realize low speed and high torque, and achieves high-speed locking function.

Owner:SHAANXI AEROSPACE POWER HIGH TECH

Lever-mechanism motor or pump

InactiveUS6887059B2Lower carbon dioxide levelsLight weightRotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesEngineeringMechanical engineering

A machine, such as an engine, which includes a cylinder (1), an essentially cylindrical piston (5) set on bearings and equipped with an eccentrically-set shaft (11), an inlet port or valve (8), an outlet port or valve (9), and a lever device (7), which is attached by bearings to a shaft (6) and which is intended to be in essentially tight contact with the piston (5). The cylinder (1) forms an essentially cylindrical chamber for the rotary piston (5) and a partially cylindrical chamber for the lever device (7) that moves backwards and forwards. The piston (5) is equipped, in the interior of the working chamber, with sliding-ring-type bearings (13, 14).

Owner:RANTALA VEIKKO KALEVI

Continuously variable transmission

Provided is a continuously variable transmission capable of solving a technical problem in which upon activation of a continuously variable transmission, speed increase in vaned-wheel power density is low and unable to meet the requirement for rapidly increasing output torque. The present continuously variable transmission comprises a planetary gear set (101) at an input end and a planetary gear set (102) at an output end. A planetary carrier (104) having a cavity is provided between the planetary gear set (101) at the input end and the planetary gear set (102) at the output end. The planetary carrier (104) comprises an input end cover (6) and an output end cover (13). A vaned-wheel housing (14) having a cavity is fixed between the input end cover (6) and the output end cover (13). An inner side of the planetary gear set (101) at the input end is connected to the input end cover (6). An inner side of the planetary gear set (102) at the output end is connected to the output end cover (13). A vaned-wheel-based planetary gear set (103) is provided at one internal side of the vaned-wheel housing (14).

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

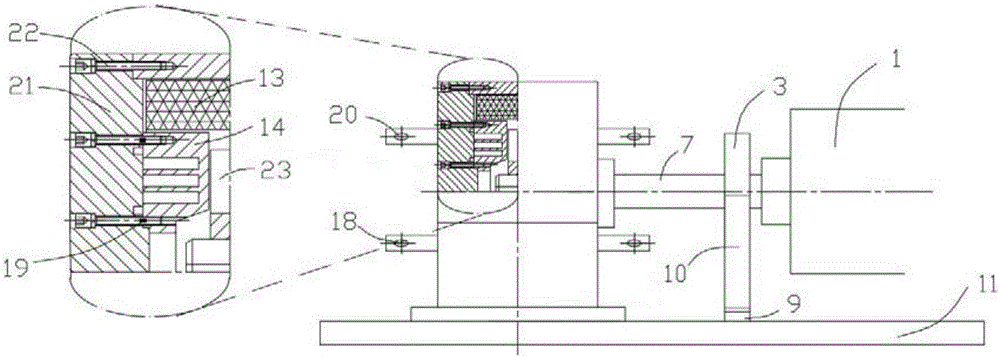

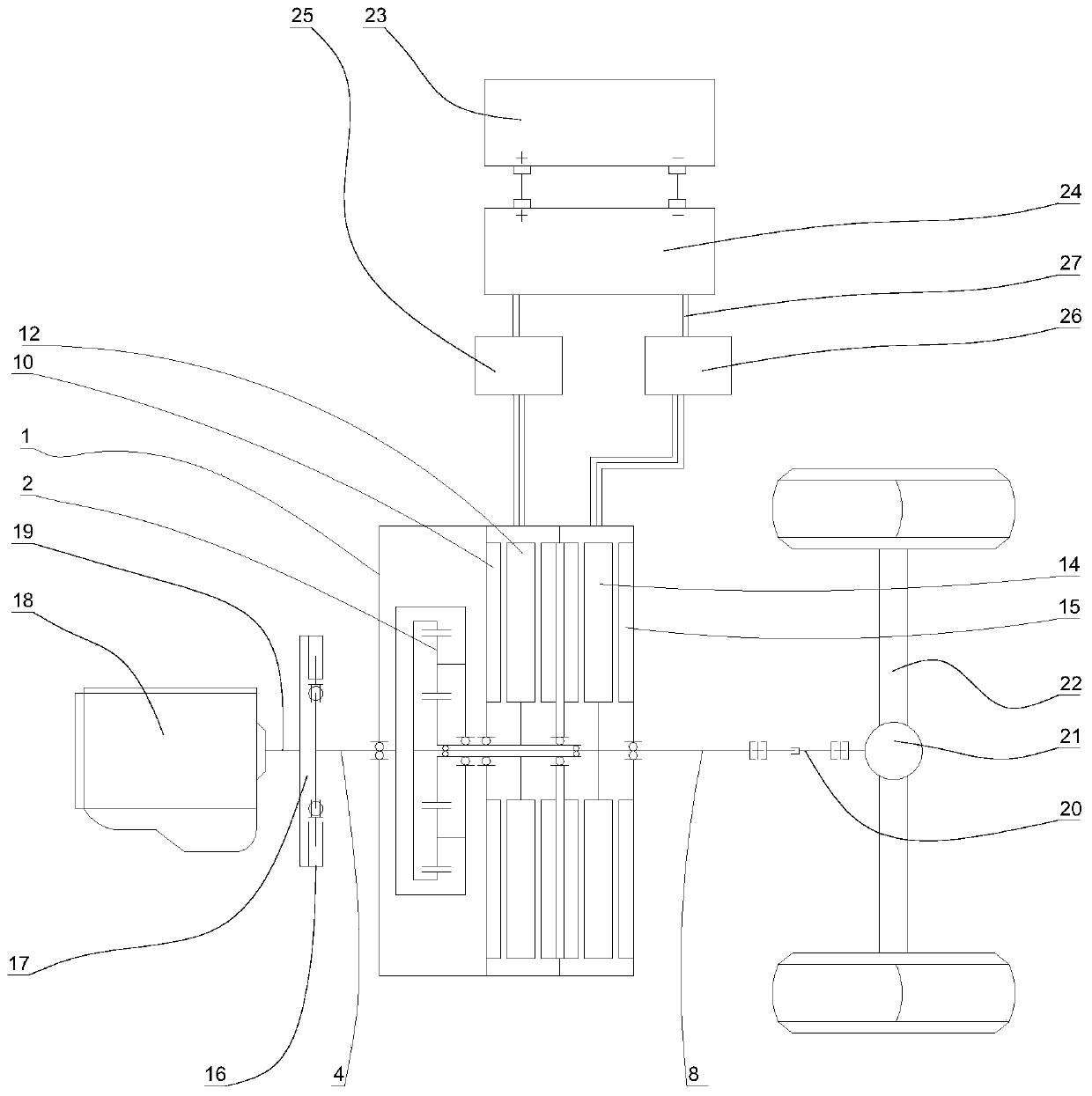

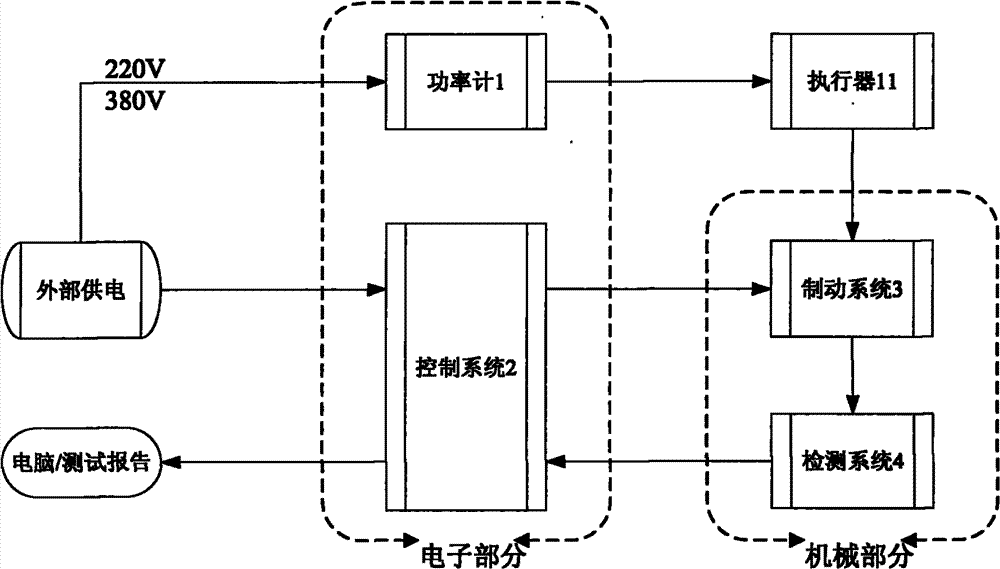

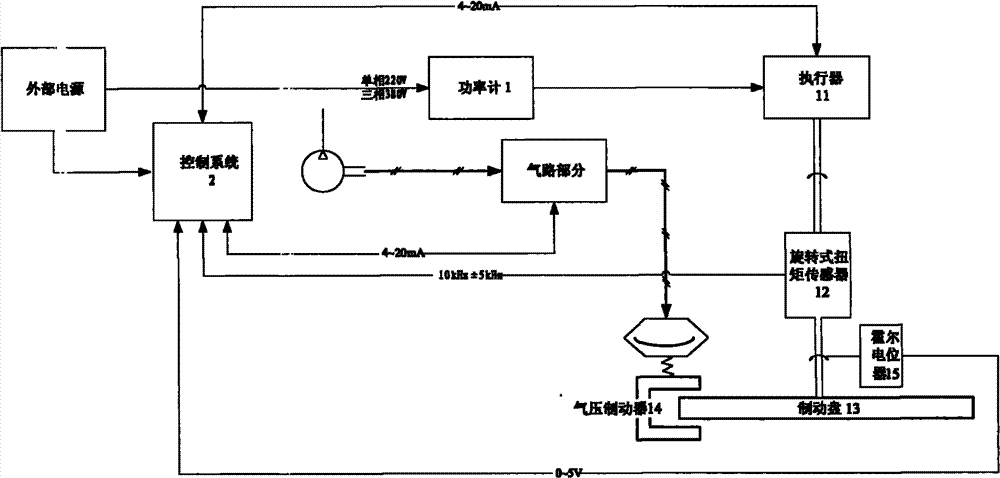

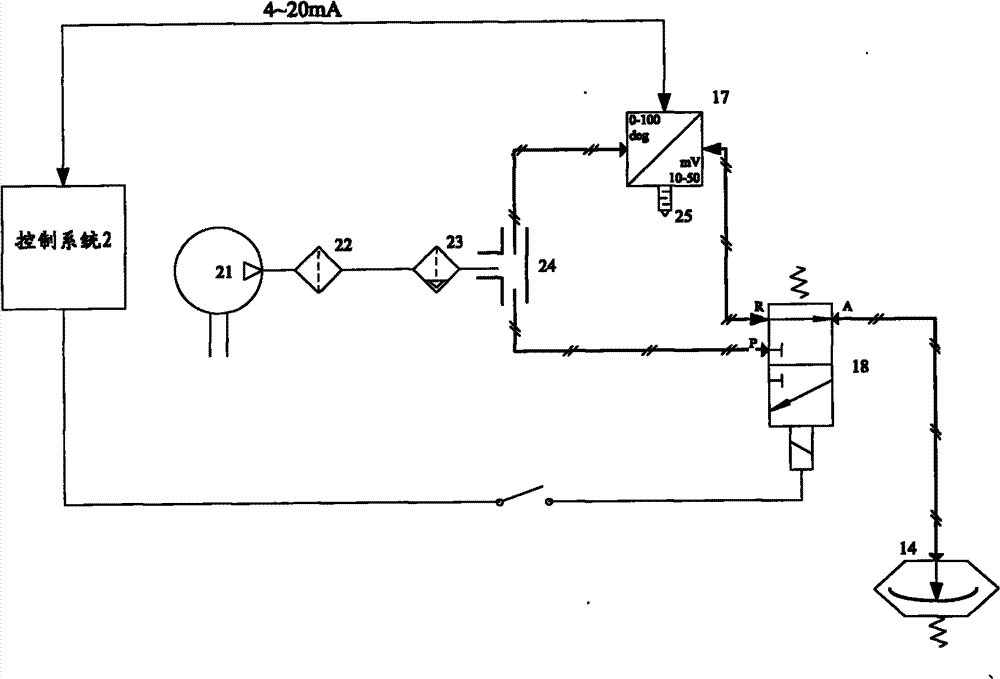

Pneumatic experimental table for loading electrical actuator

InactiveCN101750174BWide torque rangeImprove moisture resistanceCurrent/voltage measurementWork measurementElectricityMultiple modes

The present invention discloses a pneumatic experimental table for loading an electrical actuator. A brake system for loading an electrical actuator comprises an electrical / pneumatic converter for regulating loading air pressure, a change valve for switching loading air circuits, a brake disk and a pneumatic brake. The brake disk is driven by the output shaft of the electrical actuator to rotate. Friction is loaded on the brake disk by the pneumatic brake under the action of compressed air. The following modes can be selected by the change valve: the pressure of the compressed air acts on the pneumatic brake after the adjustment of the electrical / pneumatic converter to exert adjustable friction on the brake disk, and the slow loading mode of the electrical actuator is realized; the compressed air directly acts on the pneumatic brake to exert maximum friction on the brake disk, and the quick loading mode of the electrical actuator is realized; the air pressure acting on the pneumatic brake is controlled by the electrical / pneumatic converter, and the variable speed unloading mode of the electrical actuator is realized. The present invention has the advantages that quick loading, slow loading, variable speed unloading and multiple modes of load control, which are required in the test process, can all be realized.

Owner:SHENZHEN MAXONIC AUTOMATION CONTROL CO LTD

Continuously variable transmission

A continuously variable transmission is provided, solving the technical problems in which a balancing force between a torque-changing bucket wheel and a fluid of a hydraulic two-speed synchronizer is limited, discharging all of the fluid to increase torque results in the loss of flexible transmission, and the structures of control and braking apparatuses are complex. The continuously variable transmission comprises an input end planetary gear set (101) and an output end planetary gear set (102). A cavity planetary gear carrier (104) is disposed between the input end planetary gear set (101) and the output end planetary gear set (102). The cavity planetary gear carrier (104) comprises a cavity input end cover (6) and a cavity output end cover (13). A bucket wheel cavity housing (14) is fixedly disposed between the cavity input end cover (6) and the cavity output end cover (13). An inner side of the input end planetary gear set (101) is connected to the cavity input end cover (6). An inner side of the output end planetary gear set (102) is connected to the cavity output end cover (13). One side inside the bucket wheel cavity housing (14) is provided with a bucket wheel planetary gear set (103). The continuously variable transmission of the invention is widely applicable in the field of transmissions.

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

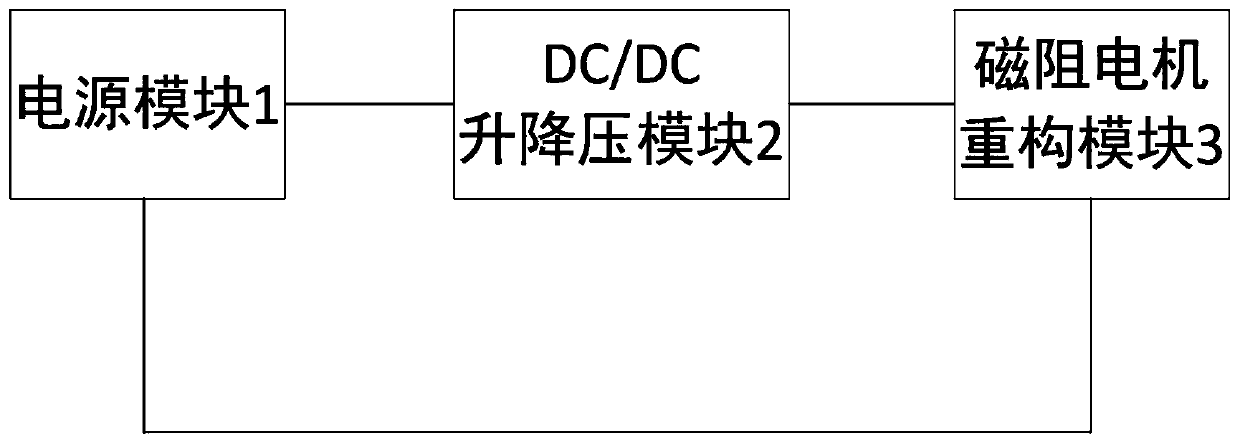

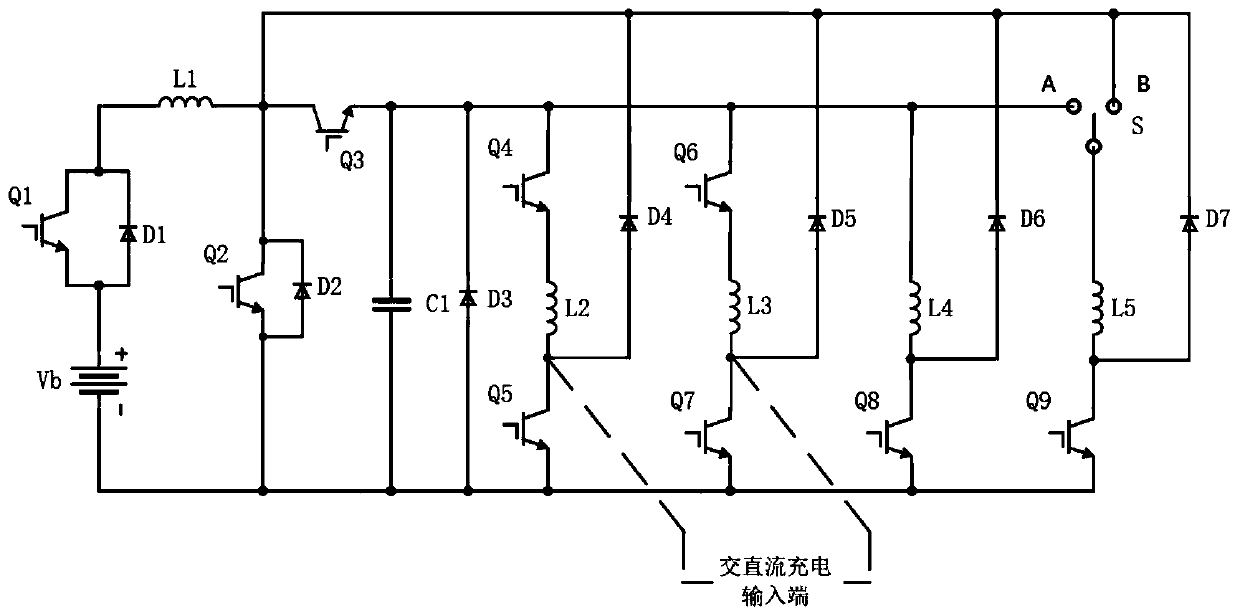

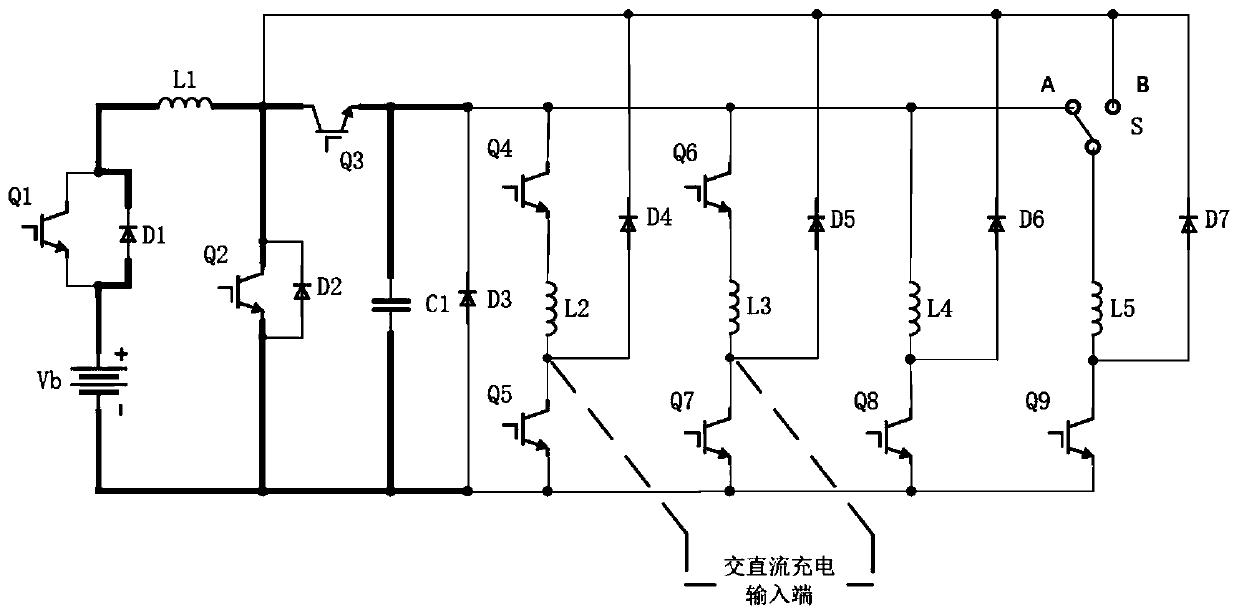

Vehicle-mounted AC/DC charging and driving circuit topology based on winding reconfiguration of reluctance motor

ActiveCN108173430BSave internal spaceHigh-speed smooth starting torqueCharging stationsDc-dc conversionElectrical batteryPower factor

The invention discloses reluctance motor winding reconfiguration-based vehicle-mounted alternating current-direct current charging and driving circuit topology. The circuit topology comprises a powersupply module, a DC / DC voltage boost-buck module and a reluctance motor reconfiguration module which are connected mutually. Through the reconfiguration reluctance motor, the circuit can work in a charging mode or a charging mode, and the manufacturing cost and the internal space of an electric vehicle can be effectively lowered and reduced; in addition, by reducing the number of switching tubes,the circuit reliability is improved; on the aspect of driving, the circuit topology can obtain high-speed and stable starting torque and wider torque range, and electric energy can be fed back in automobile deceleration or downhill, so that battery duration can be prolonged; on the aspect of charging, the circuit topology can lower limitation on the types of external charging piles, and the voltage can be lowered when the charging voltage is too high, so that charging safety can be ensured; and power factor regulation in the alternating current charging mode can be realized, so that the charging efficiency can be improved.

Owner:ANHUI UNIV OF SCI & TECH

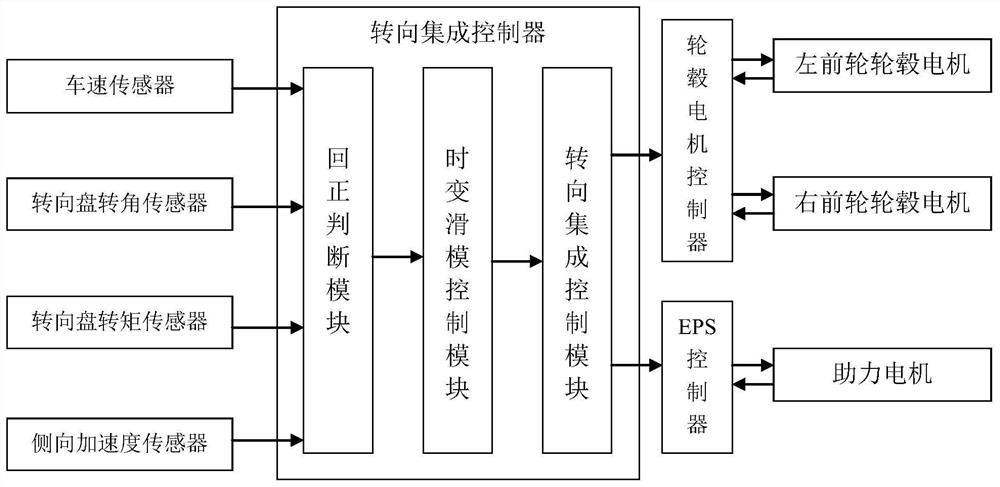

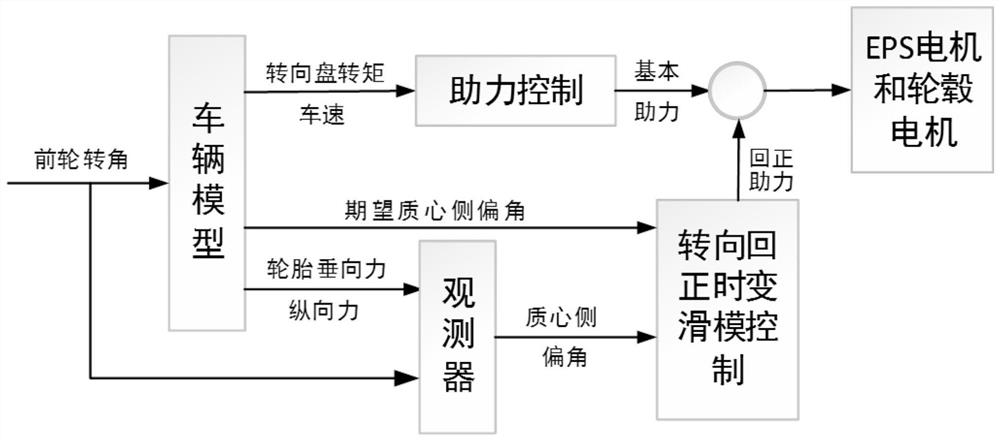

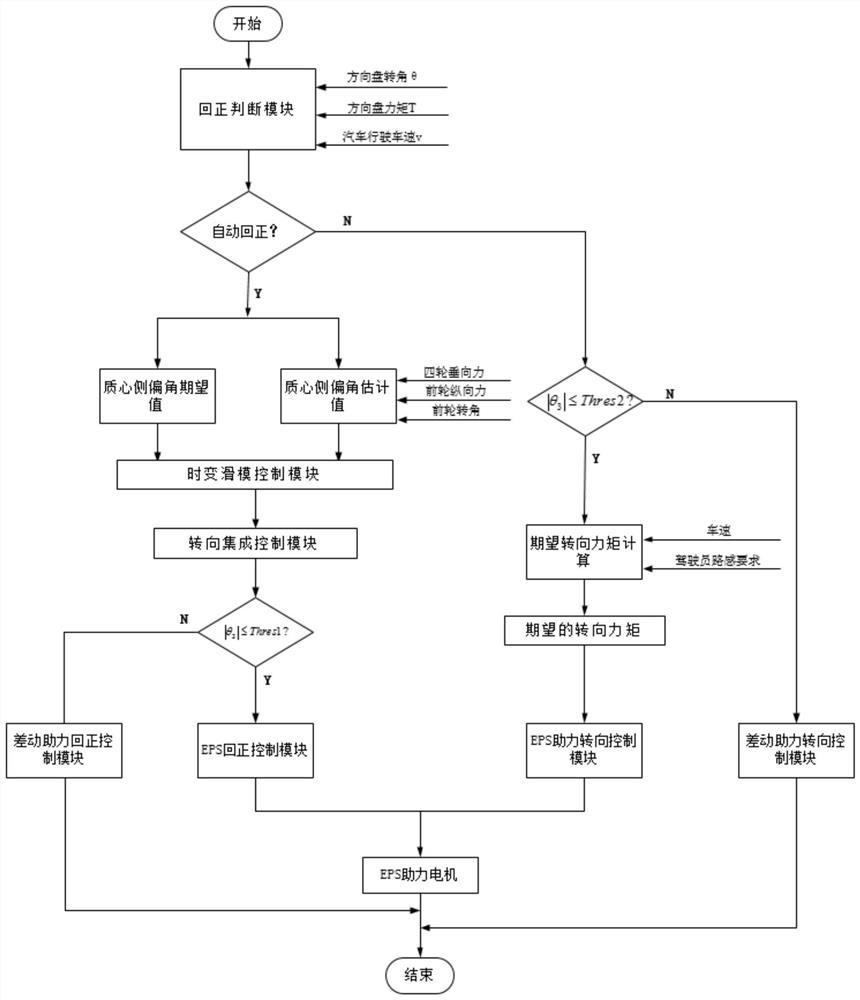

A steering return and intermediate position control system and control method thereof

ActiveCN110723200BHigh control precisionFast torque responseElectrical steeringSteering wheelSteering angle

Owner:JIANGSU UNIV

Power transmission unit

Disclosed is a power transmission unit. The power transmission unit comprises a pump impeller and a turbine, wherein the pump impeller and the turbine are correspondingly arranged, the stage of the turbine is set to be more than two stages, and a fluid loop is formed by the pump impeller and the turbine to transmit the power. The power transmission unit is simple in structure, wide in variable torque range and high in efficiency.

Owner:SHANGLING HLDG CO LTD

Power distribution device between an electric starter and an electric machine towards a shaft of a turbomachine

ActiveUS11415061B2Wide torque rangeIncrease torqueEngine fuctionsGas pressure propulsion mountingElectric machineReduction drive

A power distribution device between an electric starter of a turbomachine and an electric machine toward a shaft of the turbomachine, including the electric starter, the electric machine, and a controller for controlling the electric machine. An epicyclic train reducer includes a first element intended to be coupled to the shaft, a second element coupled to the electric starter, and a third element intended to be rotated by the electric machine. The controller is configured to rotate the third of the three elements so as to obtain two bearings of reduction ratios of the speeds between the first of said three elements and the second of the three elements. The controller is configured to drive the torque of the third of the three elements in accordance with a determined output torque.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Frequency conversion feeding variable speed enhancing torque device for milling machine

PendingCN108247396AMeet heavy cutting needsFlexible and strongGearingDriving apparatusLow speedConstant power

The invention discloses a frequency conversion feeding variable speed enhancing torque device for a milling machine. The device comprises a speed changing frame, a first positioning shaft capable of rotating in the axial direction and a second positioning shaft capable of rotating in the axial direction and moving in the radial direction are arranged on the speed changing frame, a first dual synchronous toothed-shaped belt pulley coaxial with the first positioning shaft is arranged on the first positioning shaft, and a second dual synchronous toothed-shaped belt pulley coaxial with the secondpositioning shaft is arranged on the second positioning shaft. By means of the device, the problems that during the frequency conversion feeding process of an existing lifting platform milling machineand in a low frequency and low speed section which is the section in which the rotation rate does not reach a constant power, the torque cannot reach a rated value resulting in smaller torque, so that loading demands of feeding cutting cannot be borne, cutting is weak, and the performance demands of heavy cutting of the milling machine cannot be met are effectively solved.

Owner:安徽新诺精工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com