A bolt simulator structure

A simulator and bolt technology, applied in the field of measuring equipment testing, can solve problems such as misjudgment of torque wrench error indicators, affecting product quality, and large number of configurations, achieving stable and reliable performance, reducing the number of configurations, and improving stability and repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

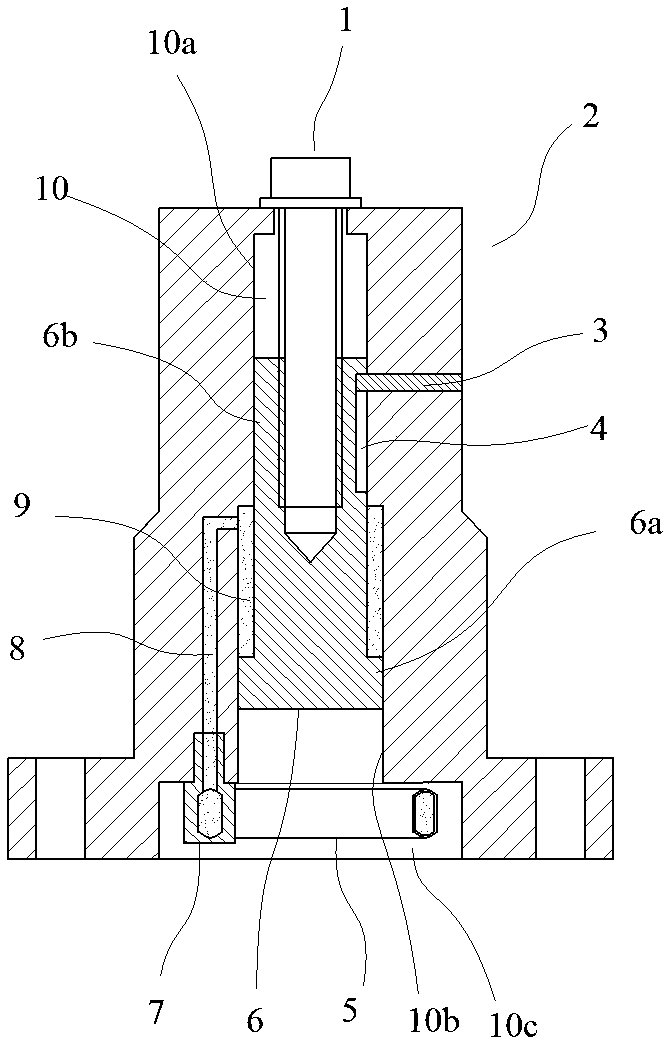

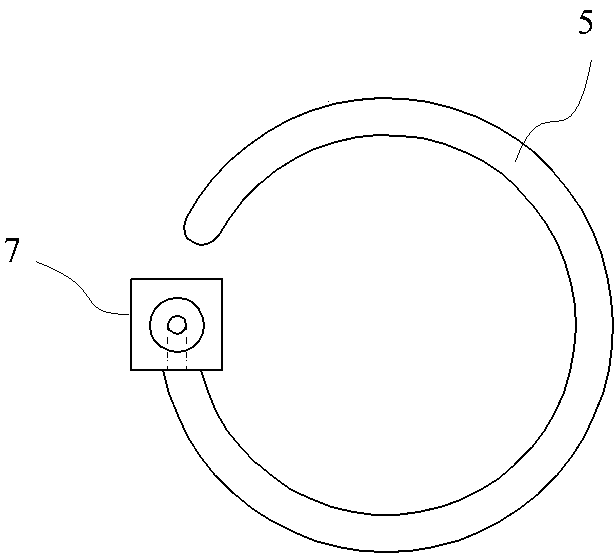

[0020] Such as figure 1 In the shown embodiment, a bolt simulator structure includes a base 2 and a transmission bolt 1, a vertical inner hole 10 is arranged in the base, a relatively slidable piston 6 is arranged in the inner hole, and the threaded end of the transmission bolt It is threadedly connected with the upper end of the piston, and the head of the transmission bolt abuts against the upper surface of the base. A guide groove 4 arranged axially is arranged on the piston, and a guide pin 4 slidingly matched with the guide groove is arranged in the base. When the transmission bolt is turned, the threaded end of the transmission bolt and the upper end of the piston are gradually screwed tightly, thereby driving the piston to move upward.

[0021] The inner hole in the base is a stepped hole, including a connected upper hole 10a and a lower hole 10b. The diameter of the upper hole is smaller than the diameter of the lower hole. The piston is provided with an upper hole se...

Embodiment 2

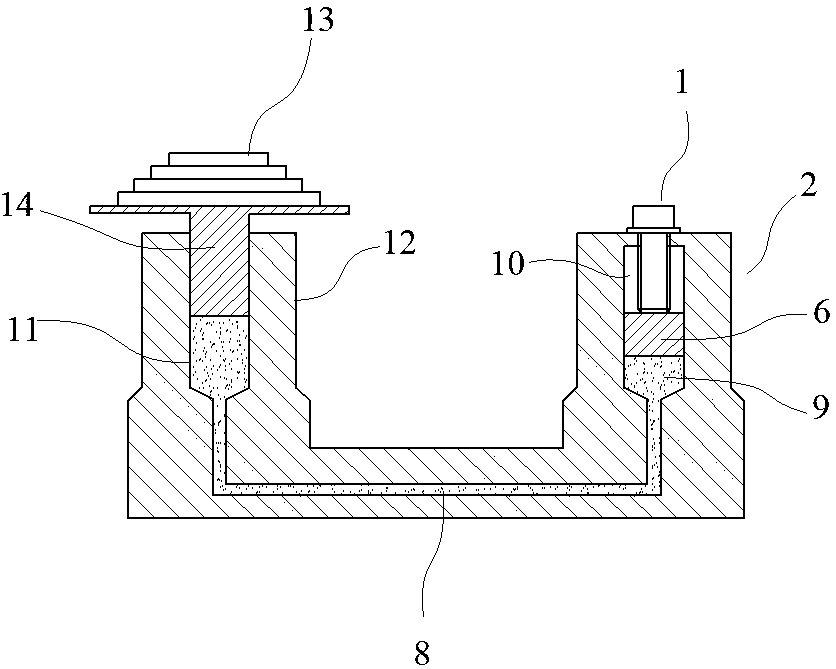

[0024] Such as image 3 As shown, a bolt simulator structure includes a base and a transmission bolt. The base is provided with a vertical inner hole, and a relatively slidable piston is arranged in the inner hole. The transmission bolt is against the surface of the piston. The positioning part that is threaded with the transmission bolt forms an oil pressure chamber between the piston and the inner hole. When the transmission bolt rotates, the piston is pushed down to compress the oil pressure chamber. The base is provided with an oil passage connected with the oil pressure chamber, and the oil passage is connected with a counter force device, which includes a tray 14 and a weight group 13 placed on the tray, and a tray support seat 12 is provided on the base, and the tray supports An oil outlet passage 11 communicating with the oil passage is arranged in the seat, and the oil outlet passage is vertically arranged, and a pallet piston slidingly matched with the oil outlet pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com