Device and method for measuring radial deformation of flexible gear teeth of harmonic reducer

A harmonic reducer, radial deformation technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of low accuracy, long measurement time, and inability to measure the radial direction of the flexwheel tooth of the harmonic reducer Deformation and other issues to achieve the effect of improving accuracy and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

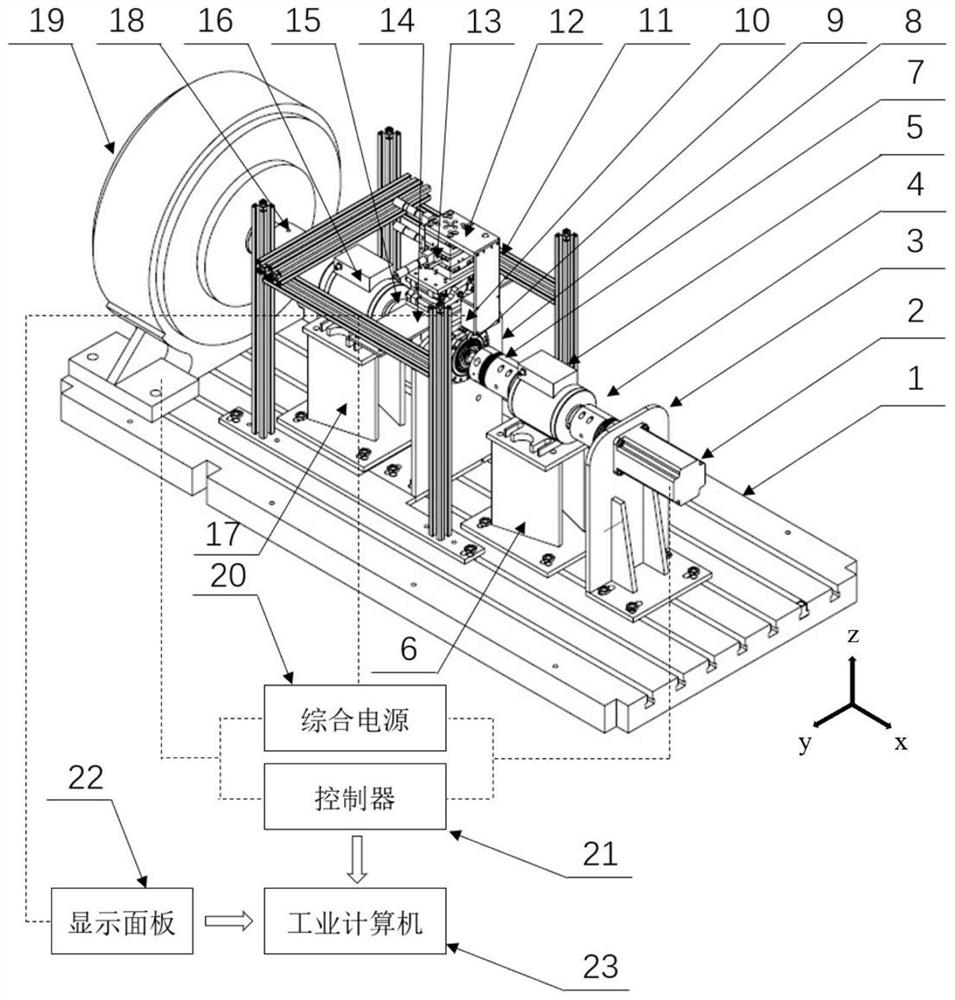

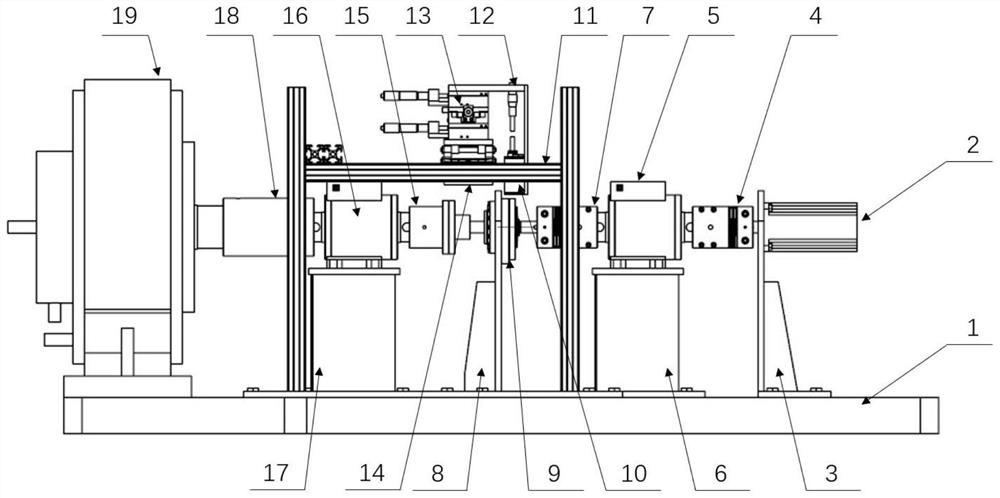

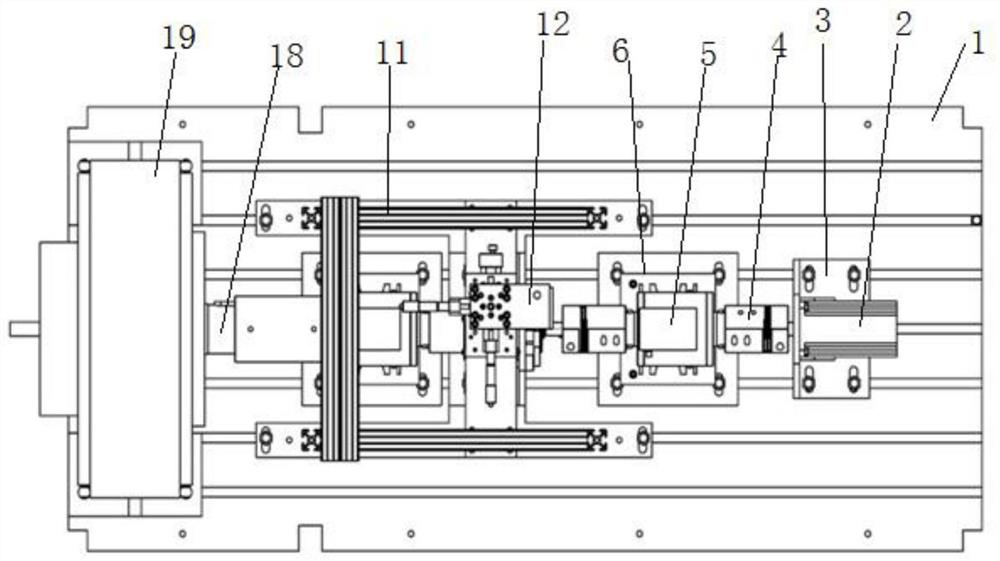

[0042] Such as Figure 1 to Figure 8As shown in Fig. 1, a measuring device for the radial deformation of the flexspline tooth of a harmonic reducer includes a moving device body part and a parameter measuring part fixedly installed on a fixed base; each part will be described in detail below.

[0043] The body part of the motion device: the AC servo motor 2 is fixedly installed on the motor fixed base 3 fixed on the fixed base 1, and the torque speed sensor 15 is driven to rotate through the cross slider coupling 4, and the torque speed sensor 1 5 passes through the cross slide The block coupling 27 drives the harmonic reducer 9 for specific secondary processing to rotate, and the harmonic reducer 9 for specific secondary processing drives the torque speed sensor 2 16 to rotate through the flange coupling, and the torque speed sensor 2 16 passes through the cross The slider coupling 3 18 drives the magnetic powder brake 19 to rotate; the motor fixed base 3 is located in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com