Patents

Literature

52results about How to "Fast torque response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for controlling vehicle rollback

InactiveUS20070191181A1Fast torque responseConserve battery powerHybrid vehiclesEngine controllersElectrical energy storageVariator

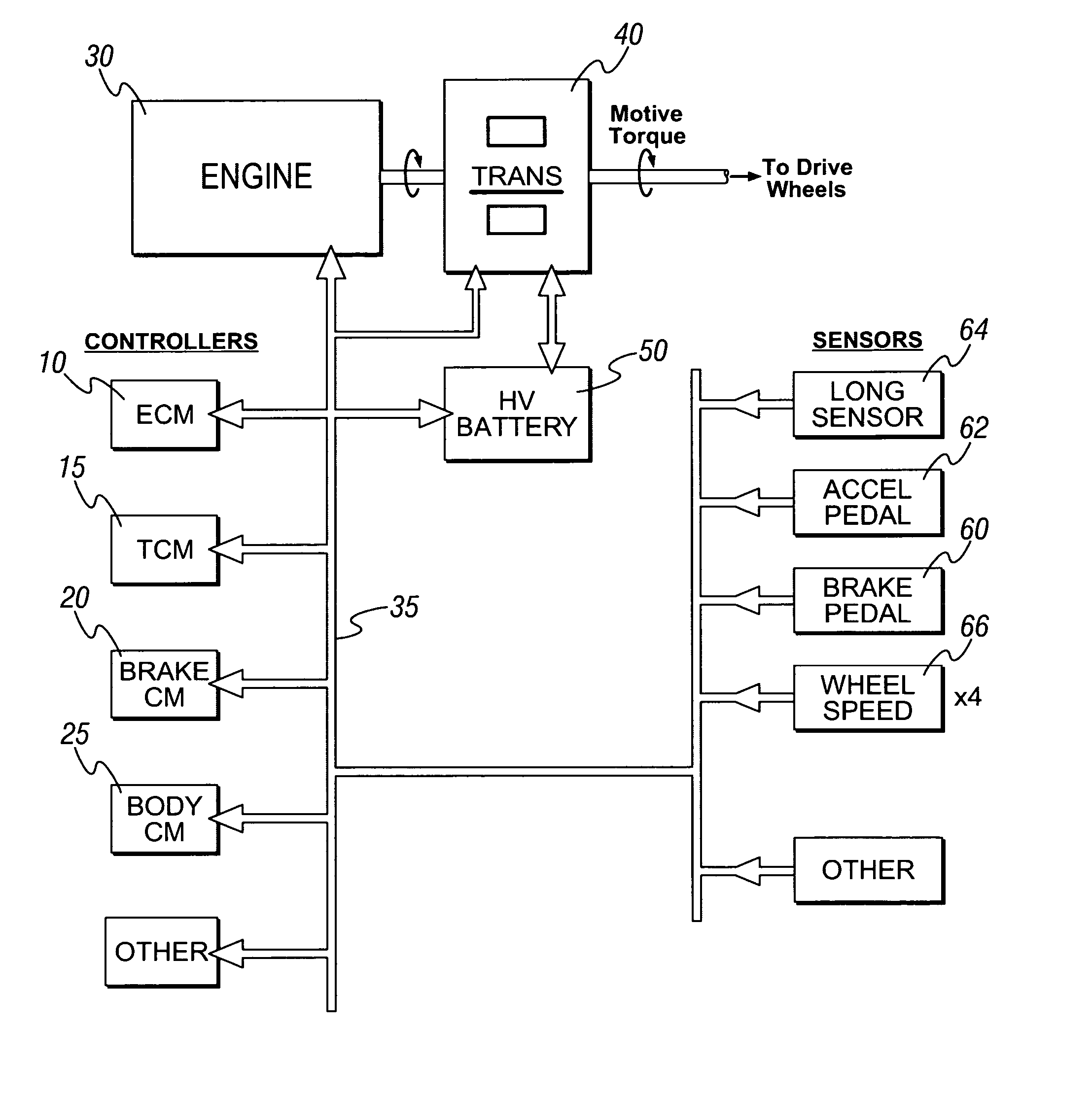

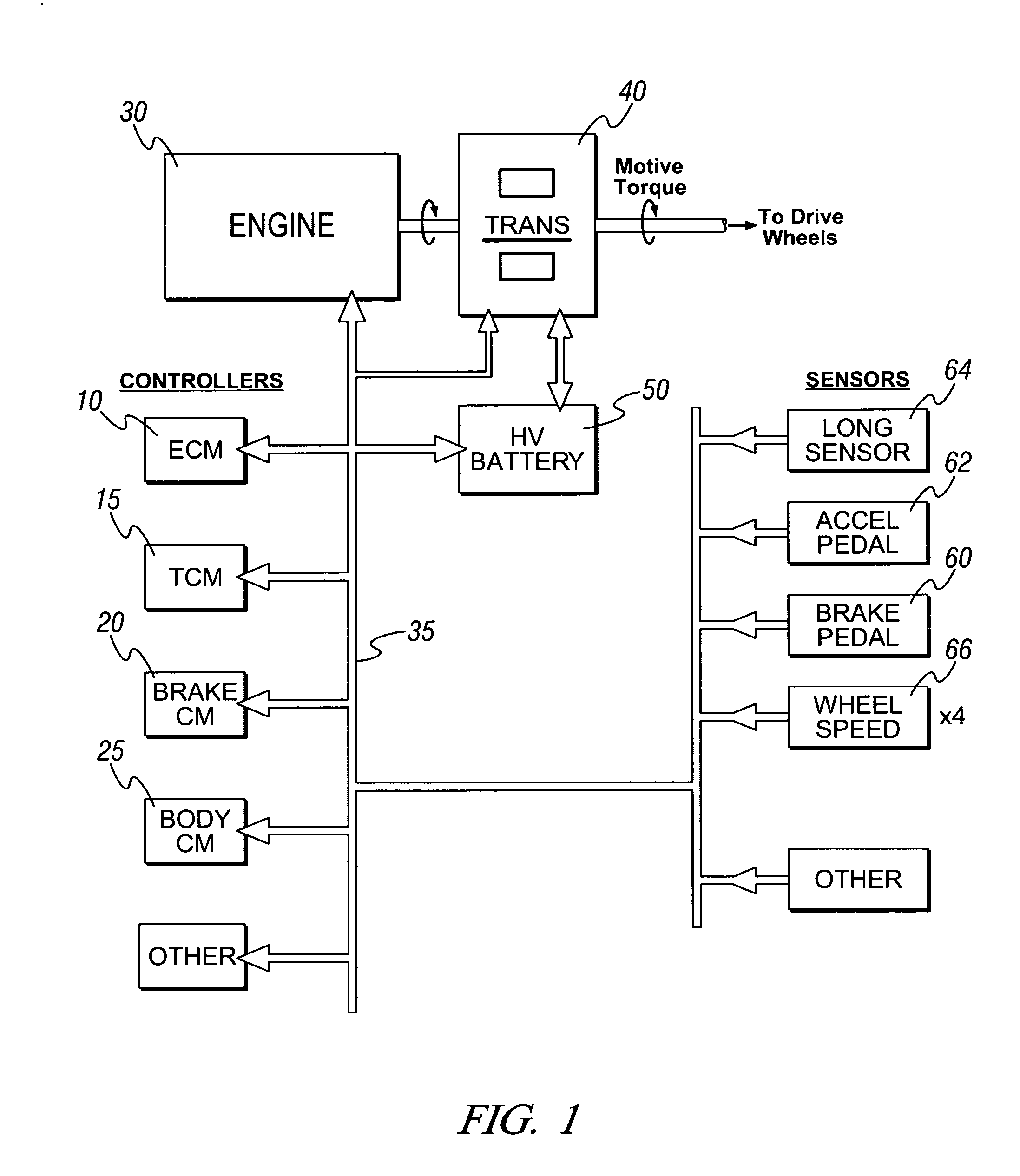

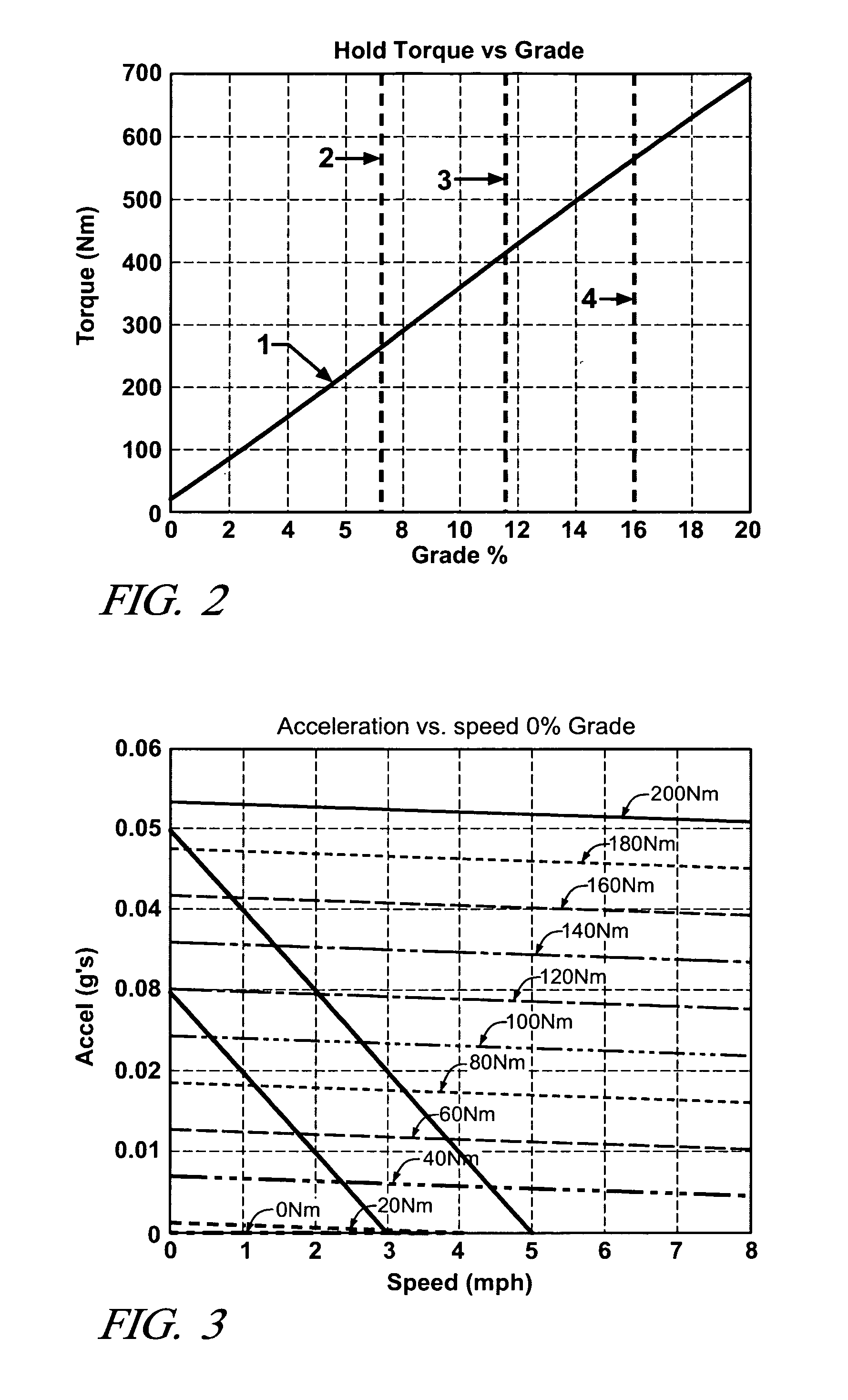

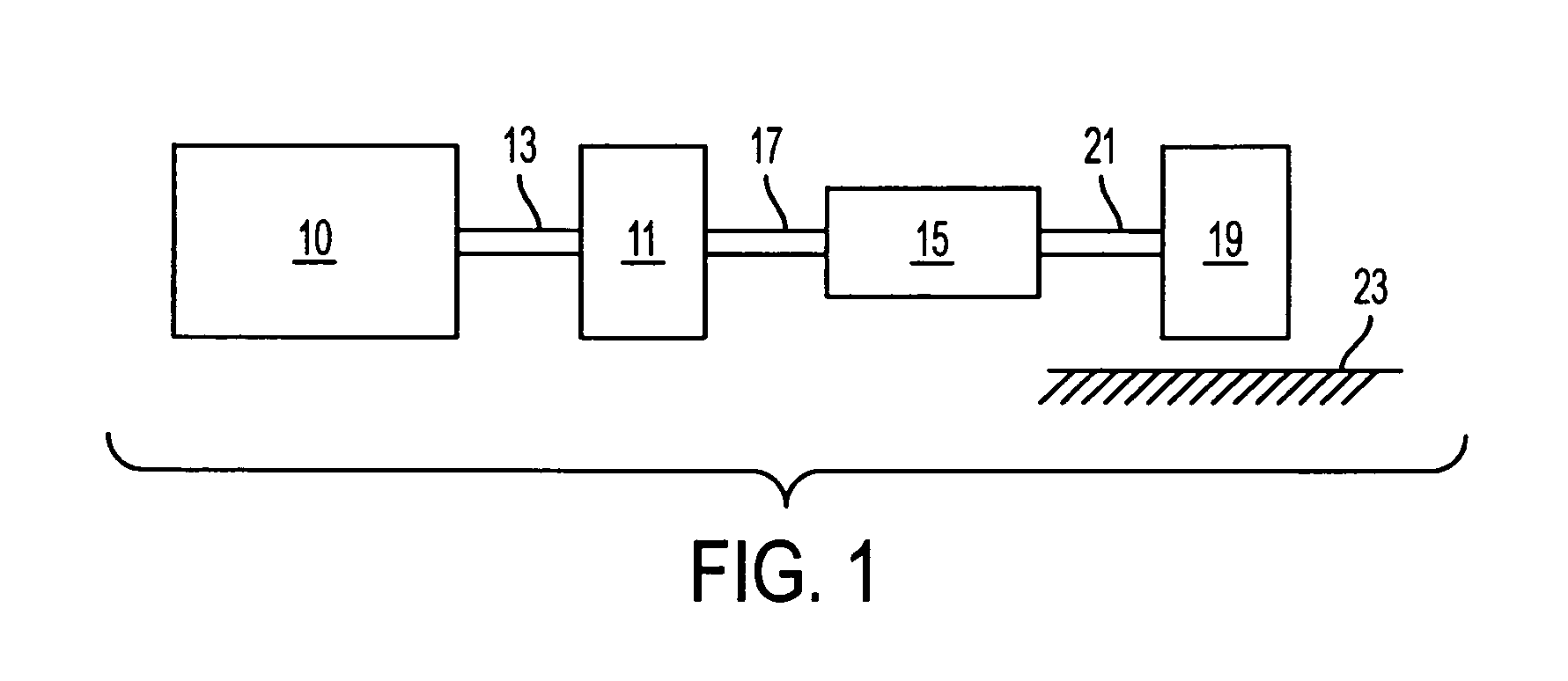

A system and method for maintaining a vehicle at a predetermined velocity on a graded surface is provided, which includes a propulsion system to supply motive torque to a vehicle wheel, a vehicle stability sensor, and a control system adapted to receive signal input from the vehicle stability sensor. The control system controls magnitude of the motive torque supplied to the wheel. The propulsion system may include an electric wheel motor powered by an electrical energy storage system, a hybrid powertrain system, and an internal combustion engine and transmission. The vehicle stability sensor determines orientation of the vehicle relative to a horizontal plane, including a longitudinal acceleration sensor and a virtual longitudinal acceleration sensor. The control system receives inputs from a wheel speed sensor, an accelerator pedal sensor, and a brake pedal sensor to control motive torque. Motive torque is controlled to maintain wheel speed sensor at a null output.

Owner:GM GLOBAL TECH OPERATIONS LLC

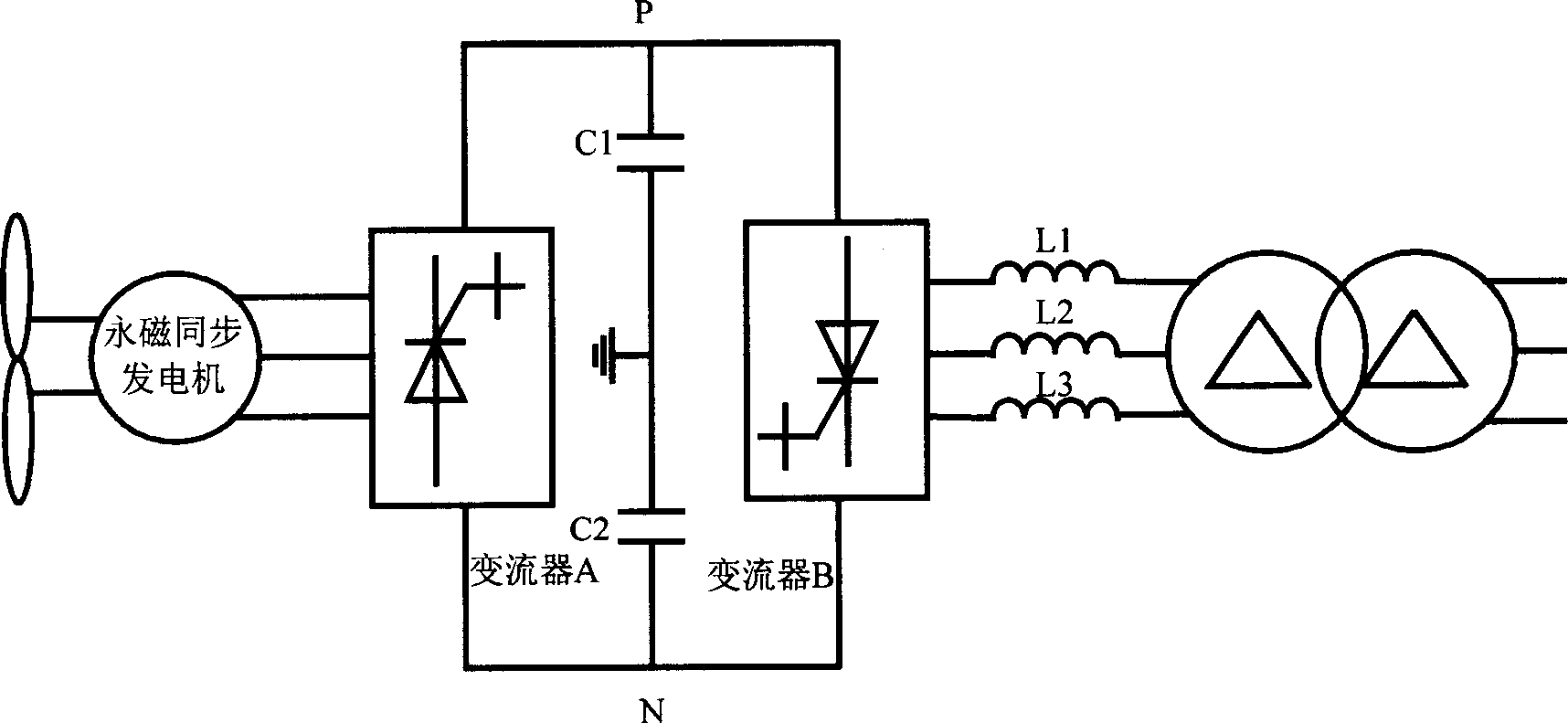

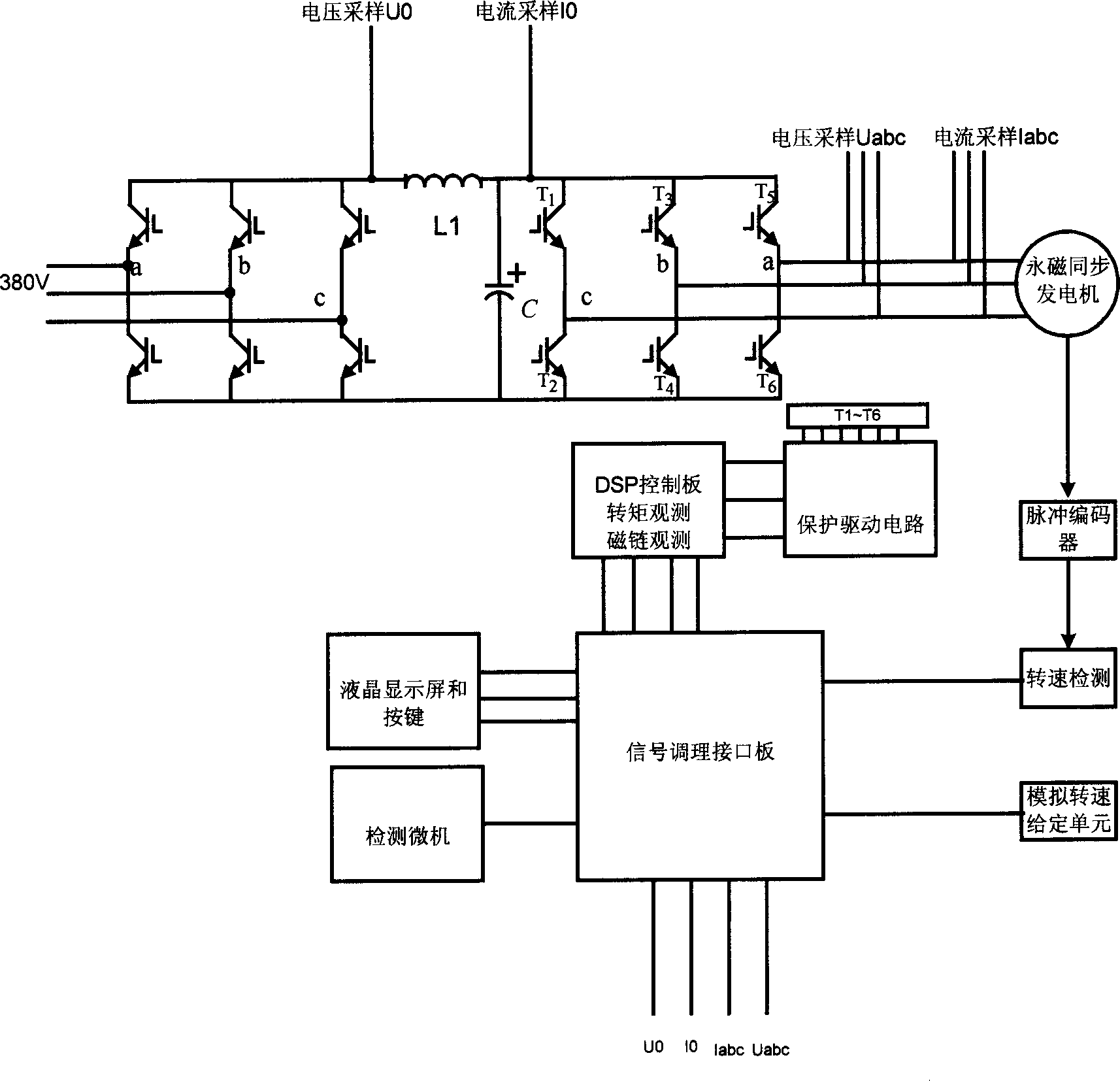

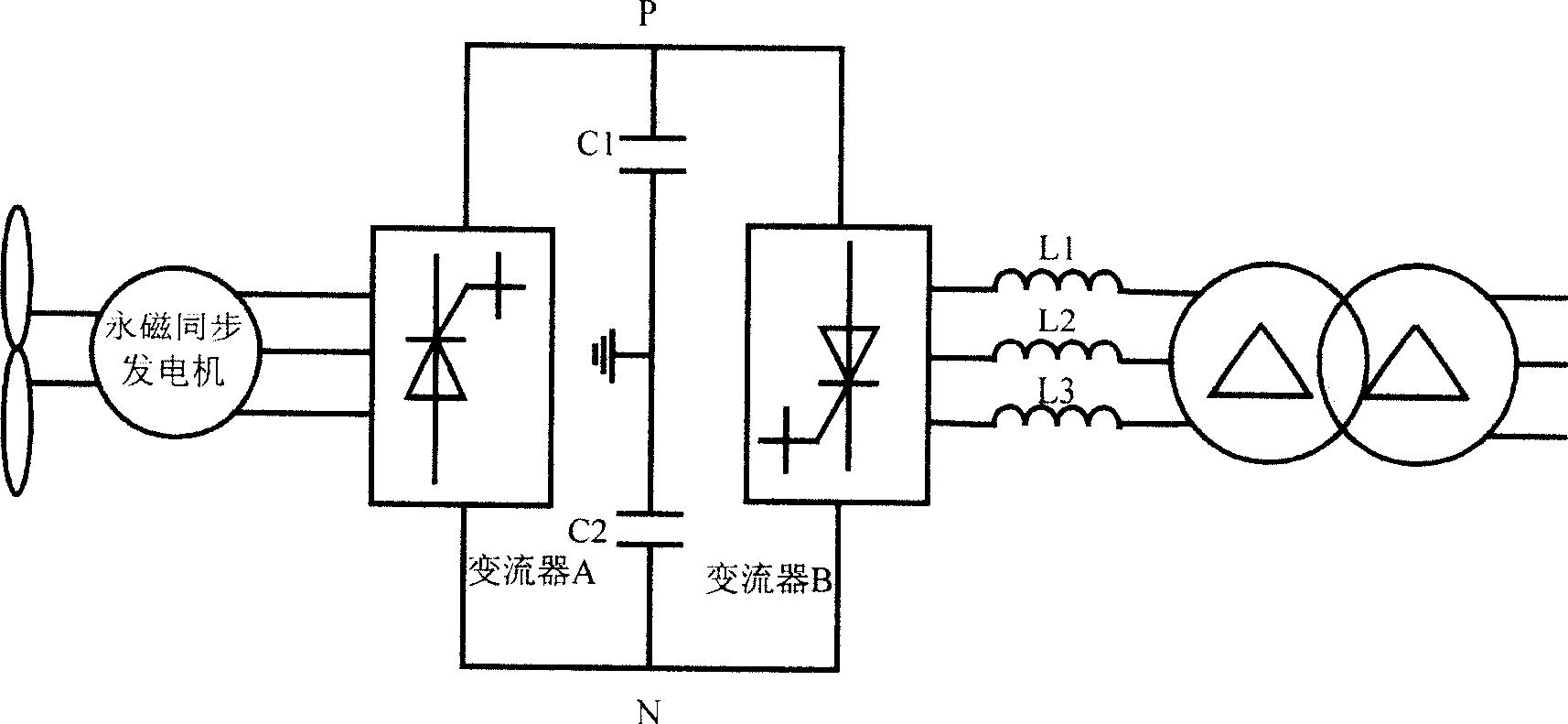

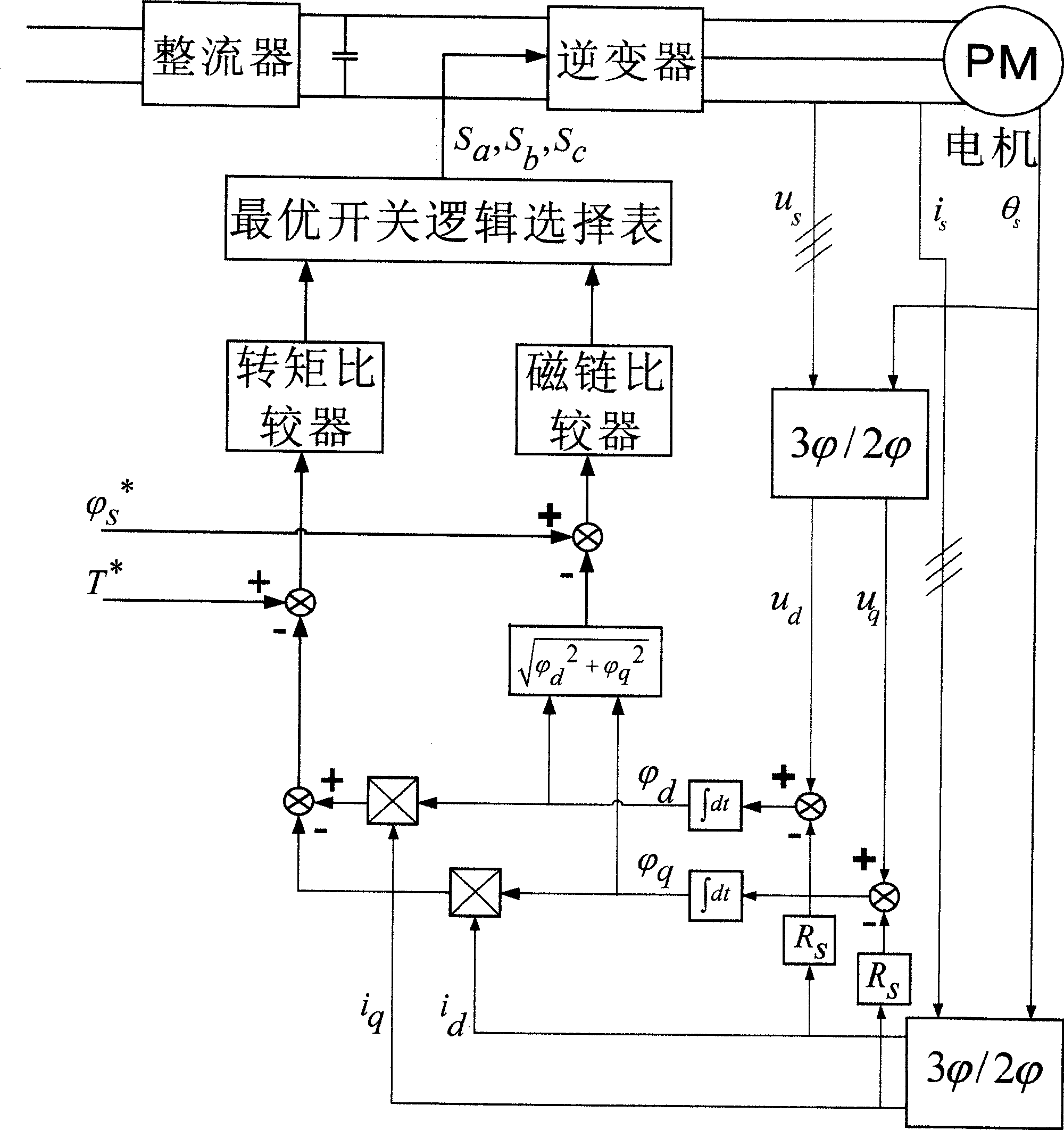

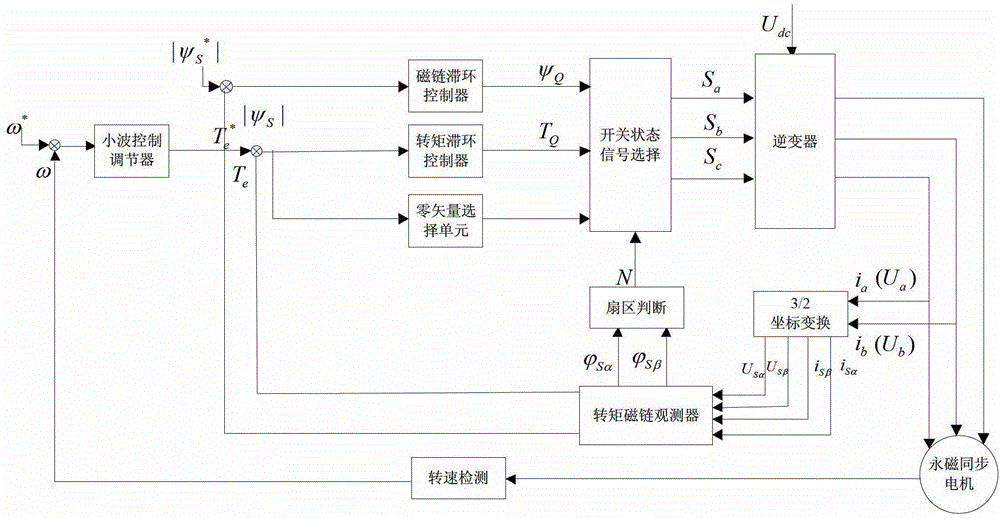

Control structure of full power type AC-DC-AC converter for wind power generation

ActiveCN1881767AReduce switching timesReduce switching lossesElectronic commutation motor controlVector control systemsPower factorDc ac converter

The invention relates to a controller of full-power alternative-direct converter used in wind generation, wherein the alternative-direct converter is formed by network converter and the convert of generator; the used generator is a permanent-magnetic generator; the rotor is in permanent-magnetic structure, without external magnetic activate power supply; two convert loops both uses the PWM converters operating in four quadrants, based on full-control element, which can improve the dynamic response, reduce cost and impact, realize bidirectional transmission of electricity, and realize generating via power factor sine wave current parallel network; and the invention uses improved direct torque technique to control the converter, to confirm the sine wave change of input current at the stator, with quick response, low vibration, torque dynamic control and wide speed adjust range.

Owner:SUNGROW POWER SUPPLY CO LTD

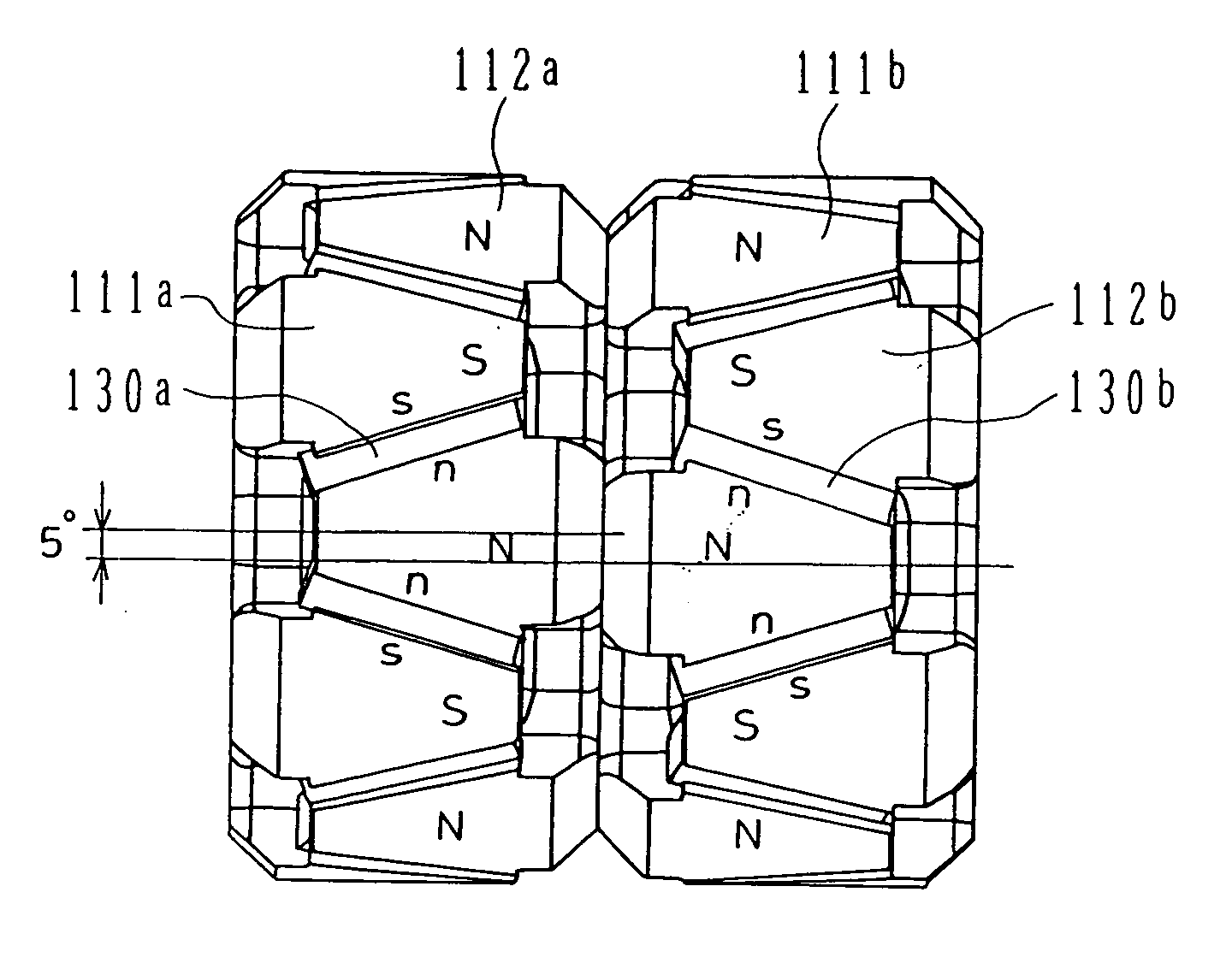

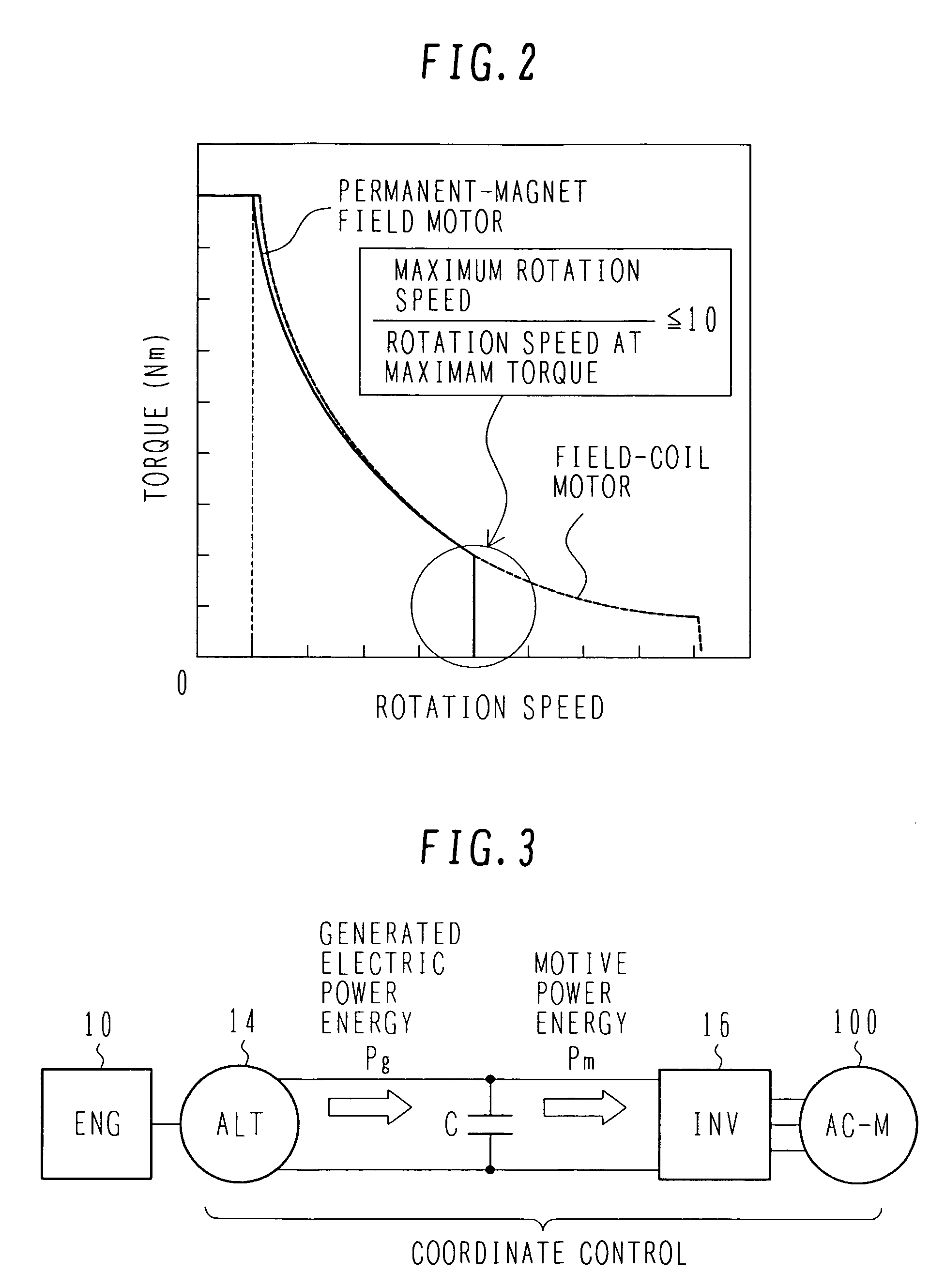

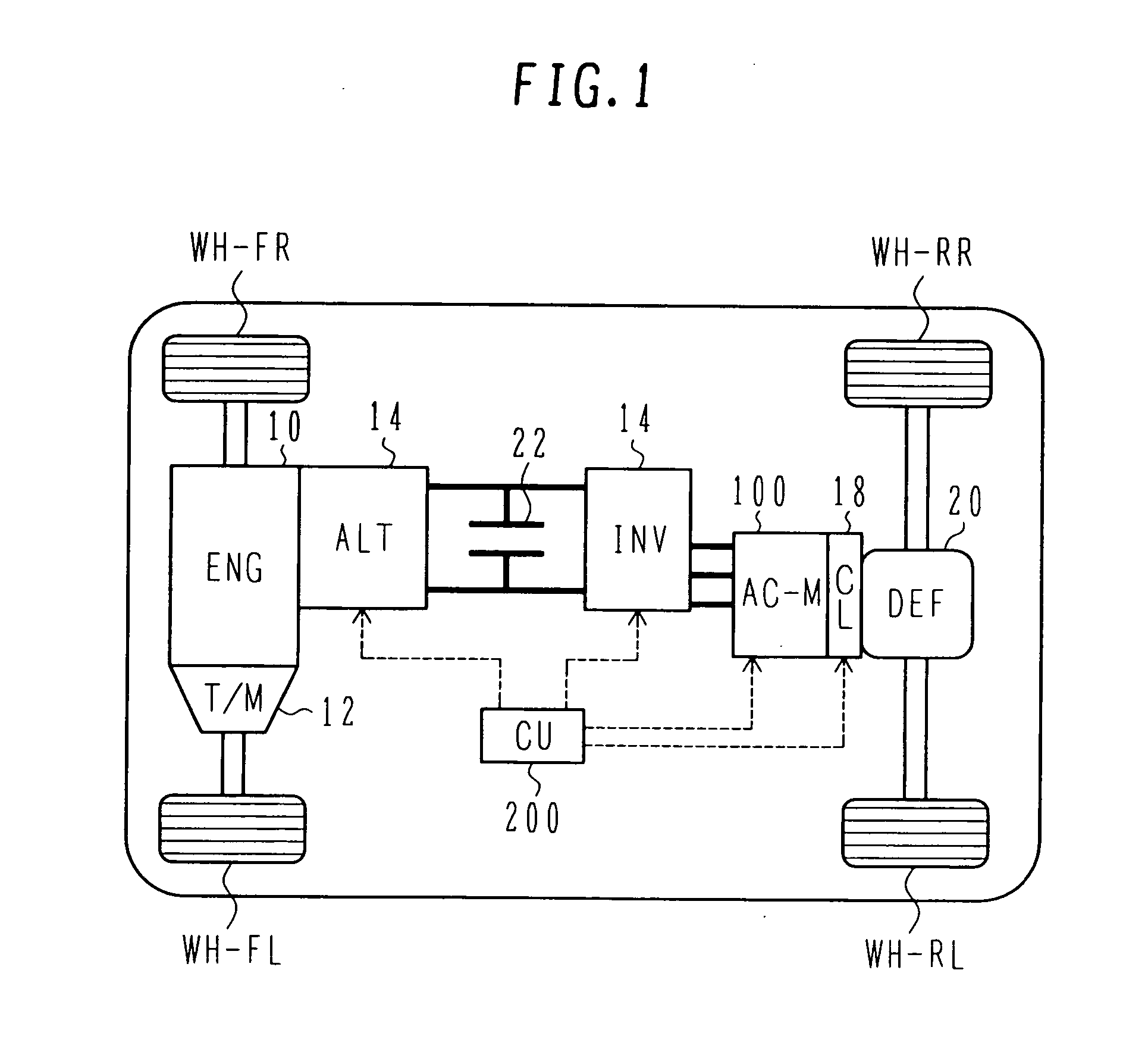

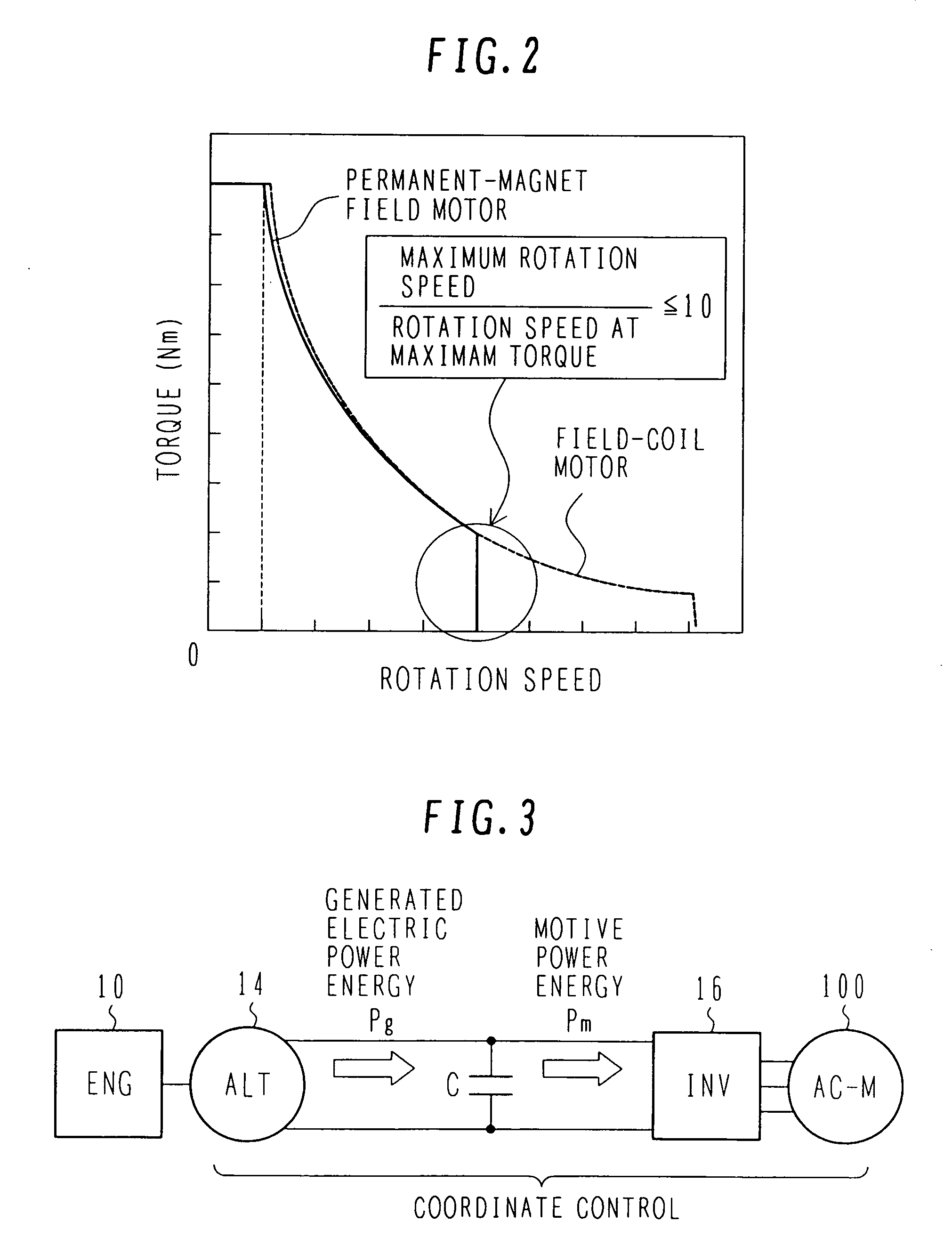

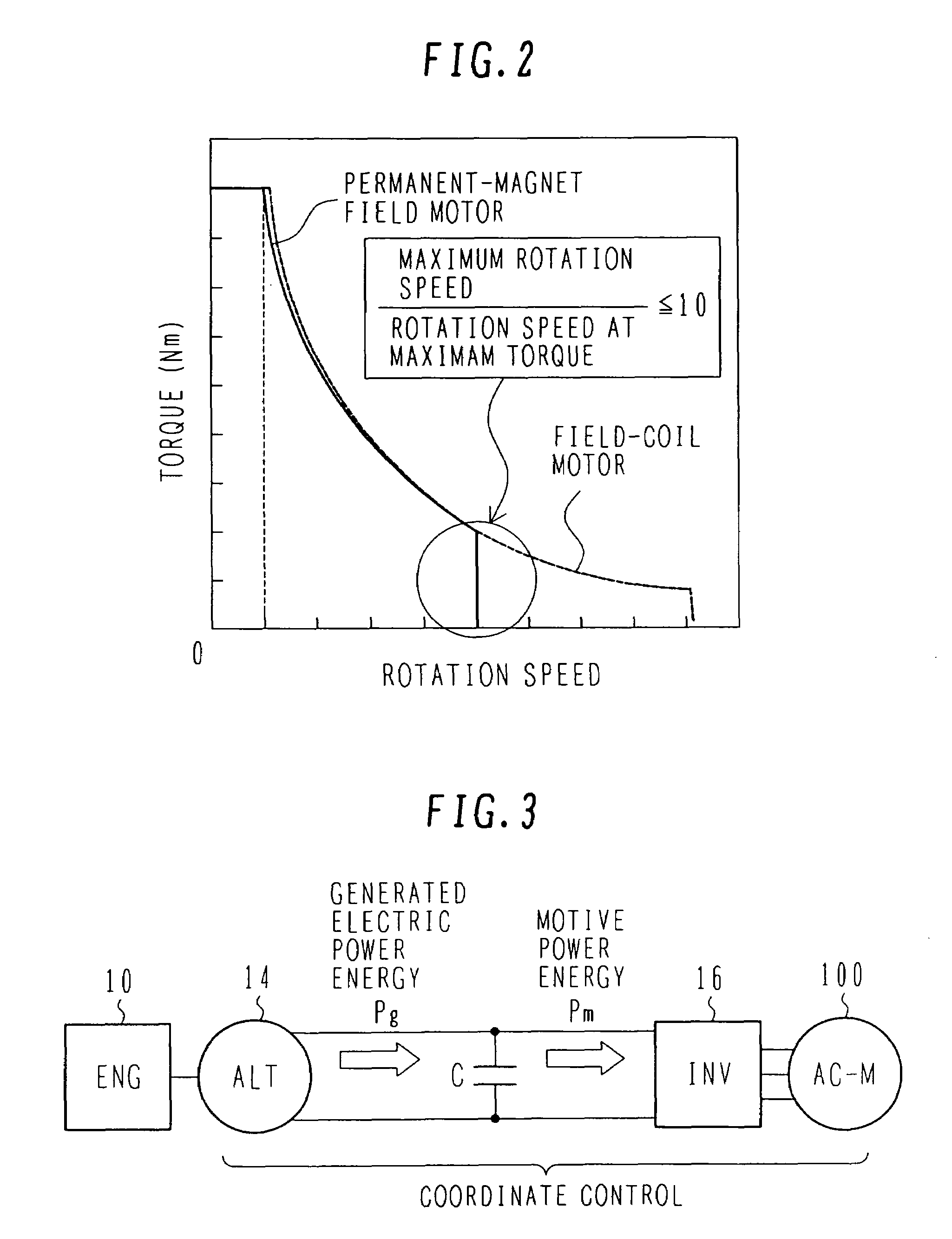

Synchronous motor and electric driving system

InactiveUS20060202582A1Reduce vibrationImprove installabilityMagnetic circuitSingle motor speed/torque controlElectricitySynchronous motor

A synchronous motor with low vibrations and an electric driving system using the motor. A field-coil synchronous motor comprises a stator and a rotor rotatably supported at the inner peripheral side of the stator with a gap left relative to the stator. The stator has a stator coil supplied with electric power while being controlled such that driving torque is reduced as a rotation speed of the rotor increases, and the rotor has a field coil supplied with a field current while being controlled such that the field current is reduced as the rotation speed of the rotor increases. The rotor is a tandem claw-pole rotor comprising plural pairs of N- and S-claw poles disposed side by side in an axial direction, and the plural pairs of claw poles of said tandem claw-pole rotor are relatively shifted from each other in a circumferential direction.

Owner:HITACHI LTD

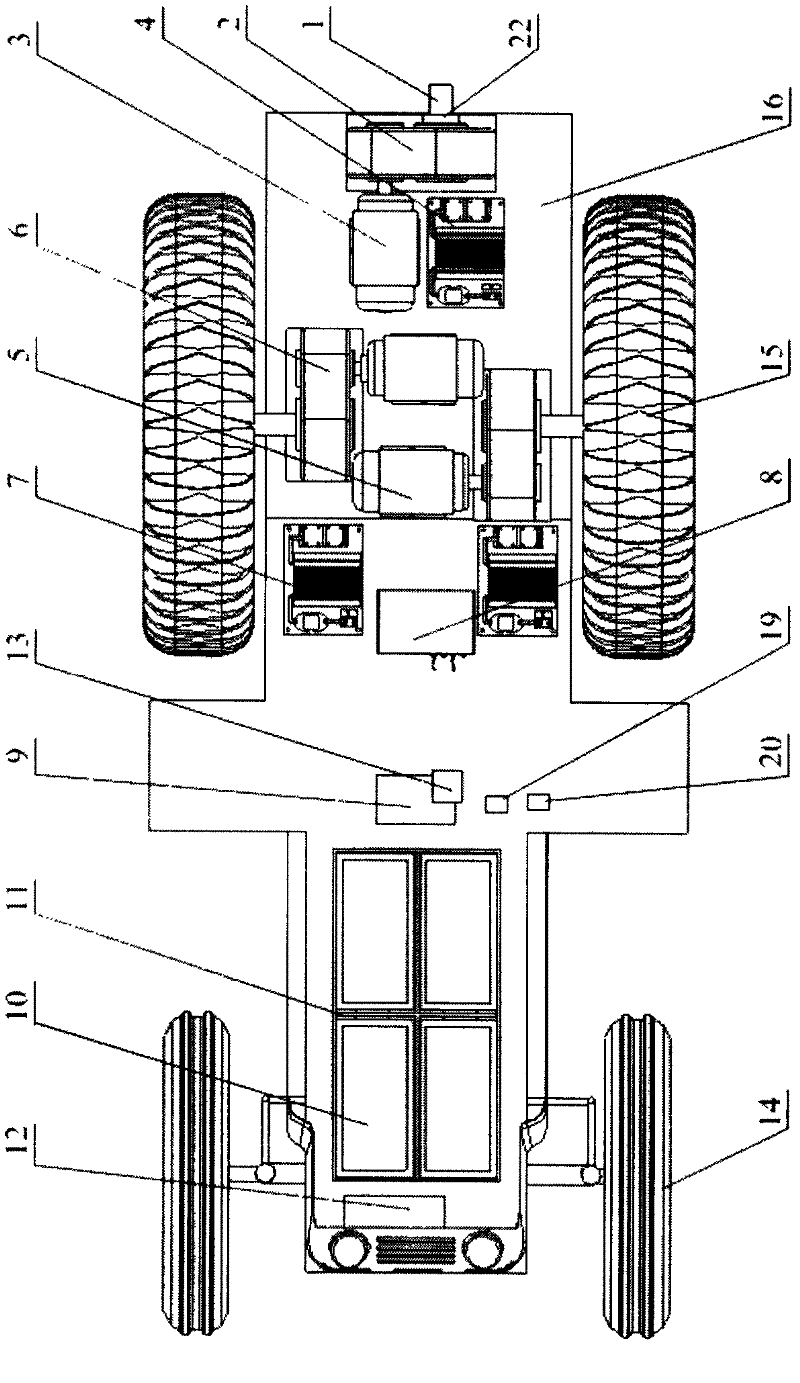

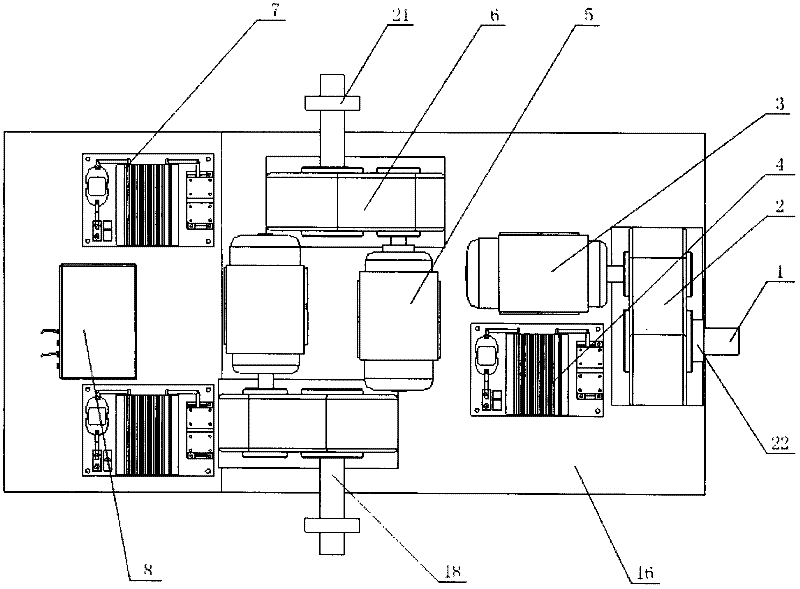

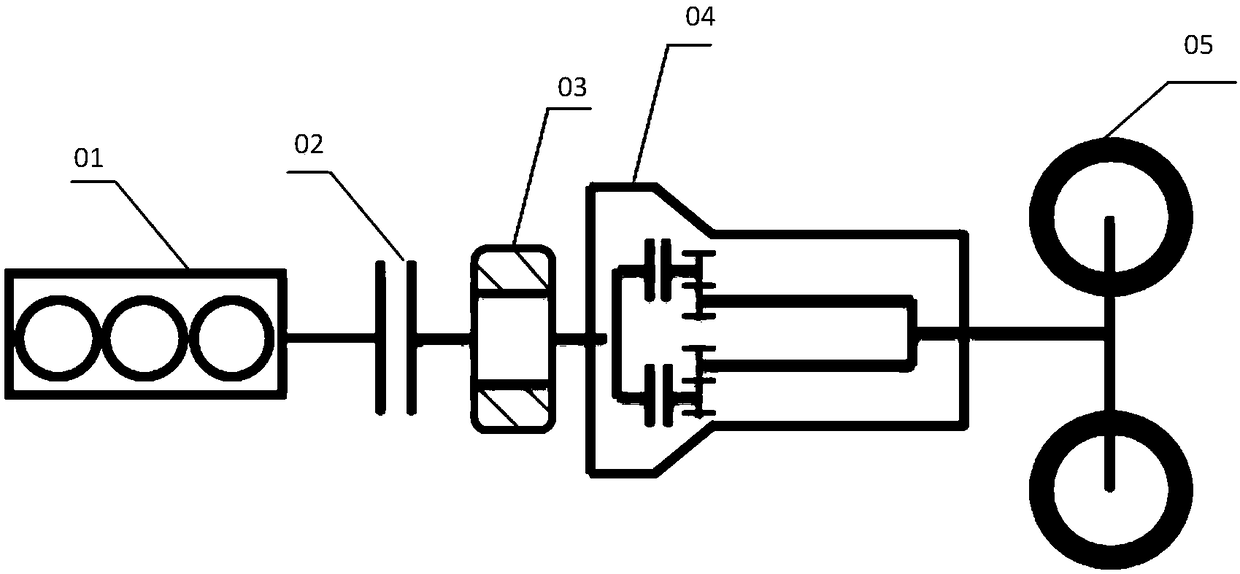

Electric tractor

InactiveCN102649394AAvoid damageFast torque responseElectrodynamic brake systemsElectric propulsion mountingReduction driveHigh energy

The invention provides an electric tractor. The electric tractor comprises a battery pack (10), an energy management system (12), a main controller (8), a motor controller I (4), a motor I (3), a speed reducer I (2), a power output shaft (1), a motor controller II (7), a motor II (5) and a speed reducer II (6). The main controller is used for receiving a motion signal and a working signal of a vehicle and transmitting a control instruction to the motor controller I and the motor controller II so as to carry out corresponding adjustments, like starting, accelerating, braking and the like on the motor I and the motor II; output torques of the motor I and the motor II are respectively used for driving the power output shaft and wheels by the speed reducer I and the speed reducer II so as to achieve multi-motor independent control. According to the invention, steering, downhill and braking energy can be recycled by using electric brake; requirements on different farmland operations, like rotary tillage, ploughing, transportation and the like can be satisfied; and the electric tractor provided by the invention has the advantages of light weight, flexibility, higher energy conversion rate, no waste gas emission and the like.

Owner:NORTHWEST A & F UNIV

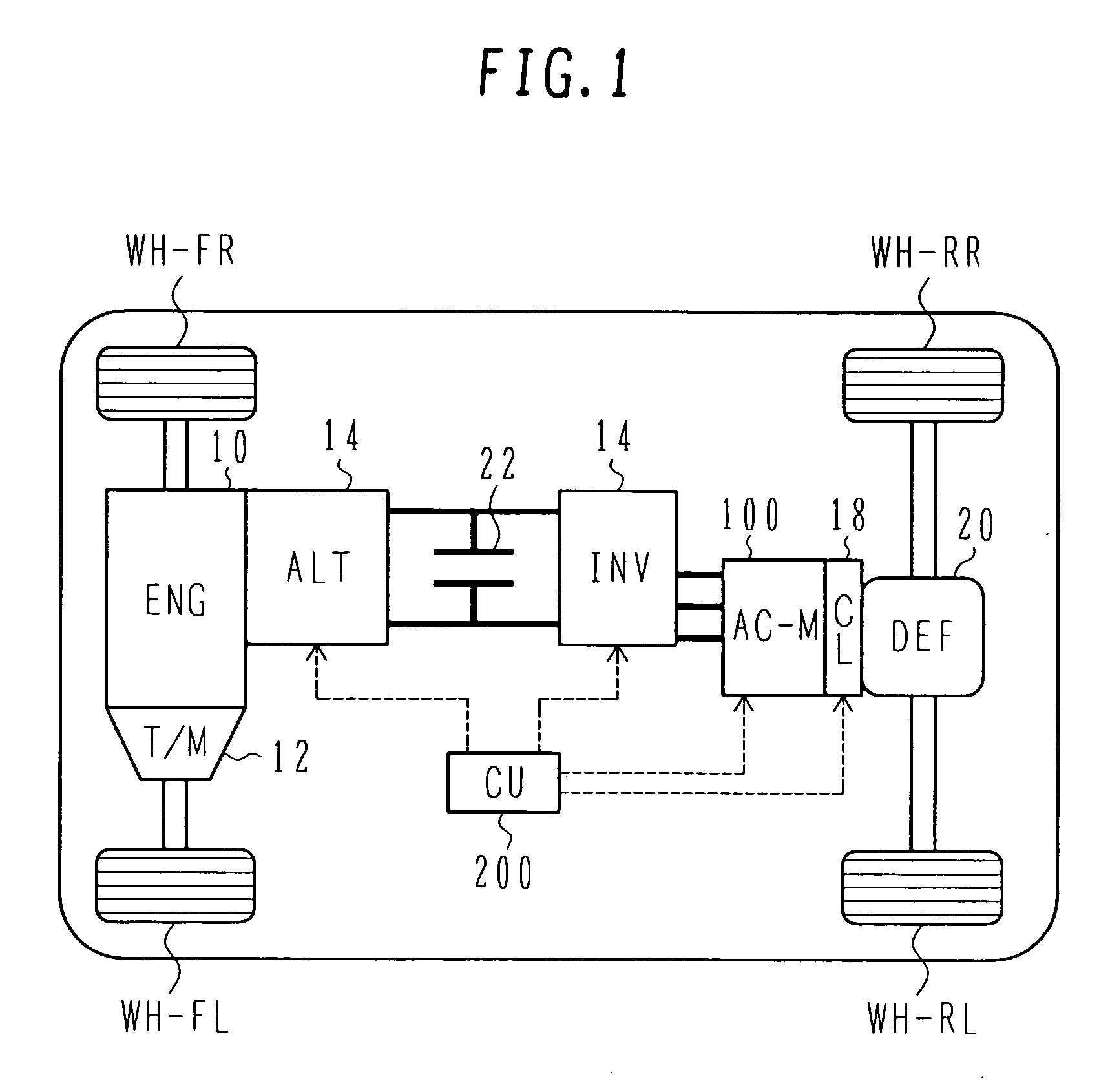

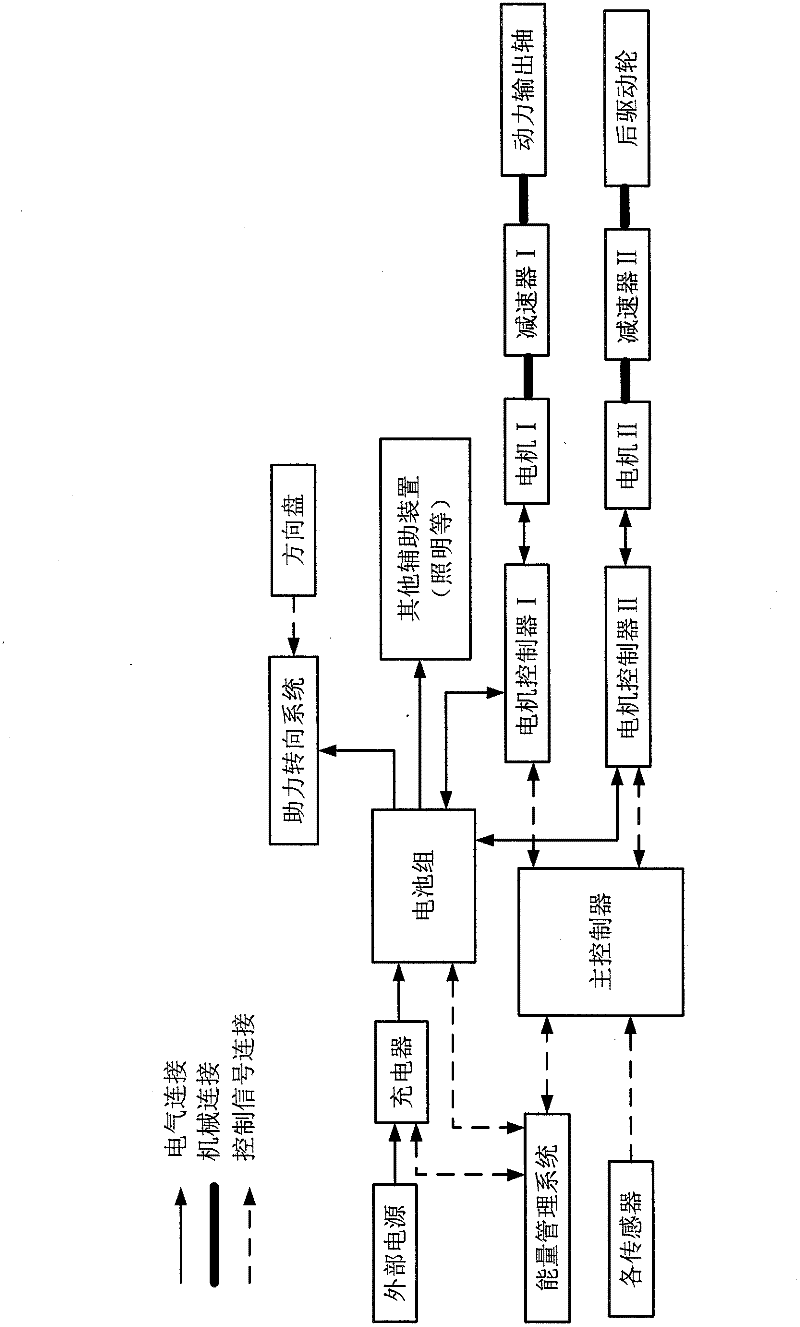

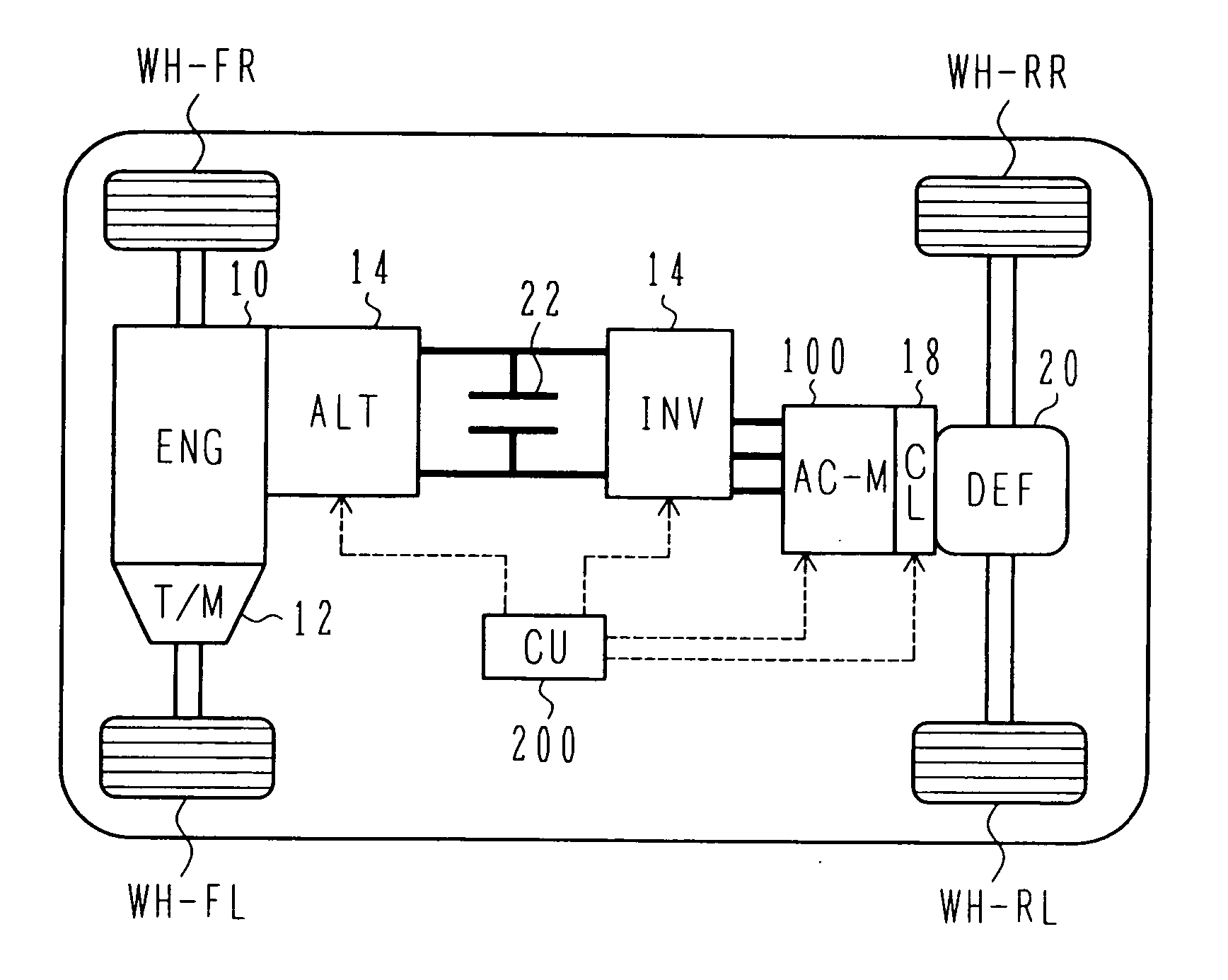

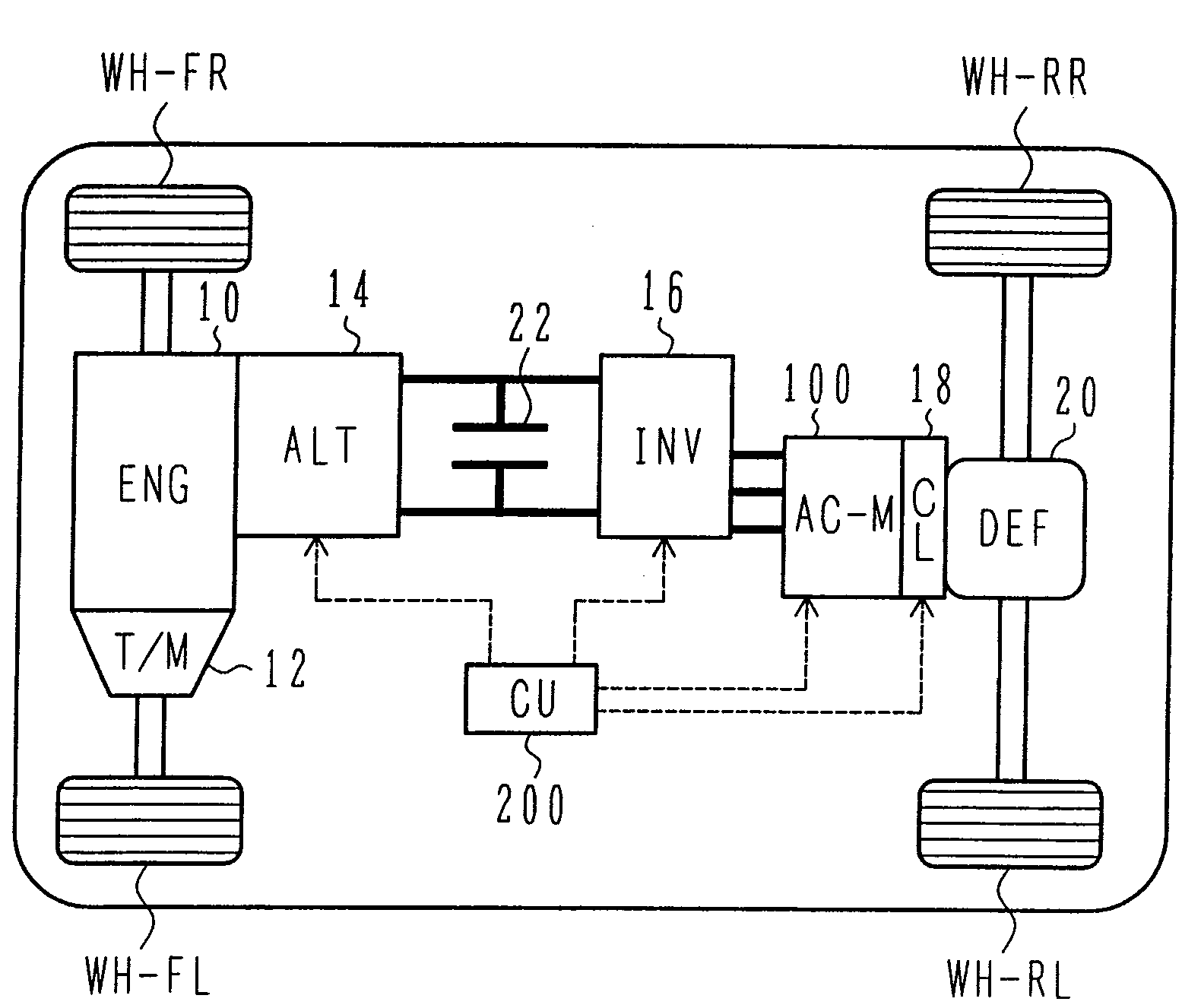

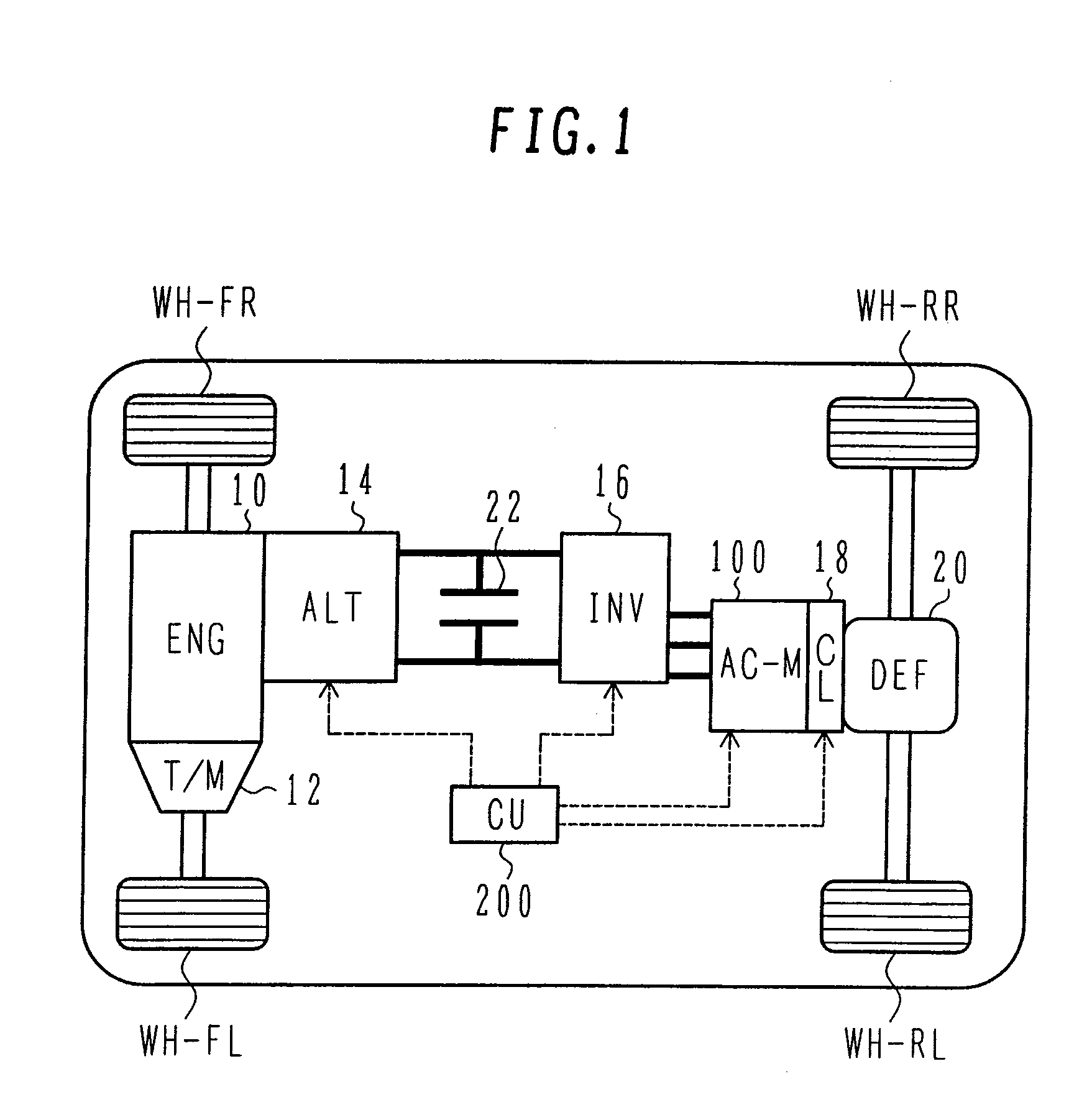

Electric four-wheel drive vehicle and control unit for same

InactiveUS20060201730A1Low costImprove installabilityHybrid vehiclesPlural diverse prime-mover propulsion mountingAC powerAC motor

An electric four-wheel drive vehicle and a control unit for the same, which can be applied to cars of class having larger displacements than the class to which the electric four-wheel drive vehicle equipped with the DC motor is applied, without increasing the cost over that of the known mechanical four-wheel drive vehicle. Front wheels of the vehicle are driven by an engine, and rear wheels are driven by an AC motor. A generator is driven by a rotating force of the engine to output DC power. An inverter converts the DC power outputted from the generator to AC power. A control unit controls the generator such that energy Pm required for driving the AC motor is outputted from the generator.

Owner:HITACHI LTD

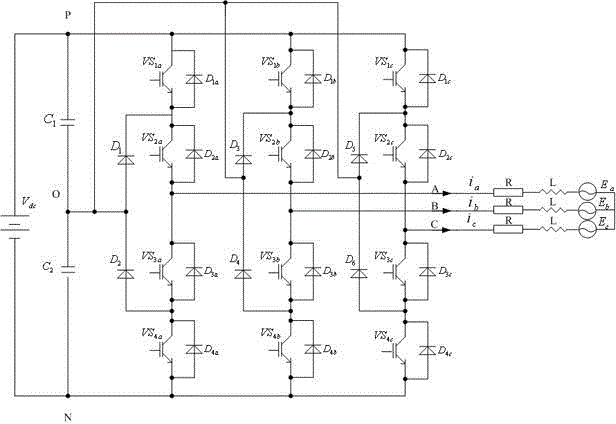

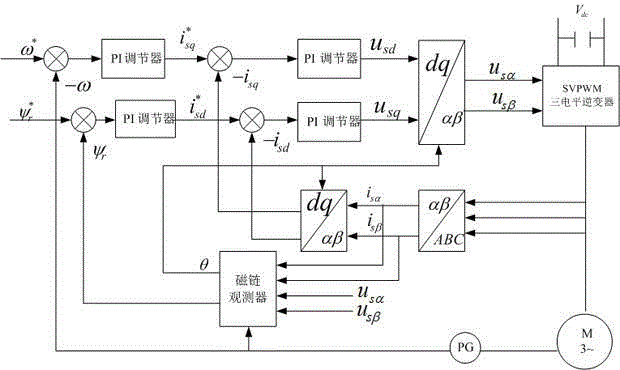

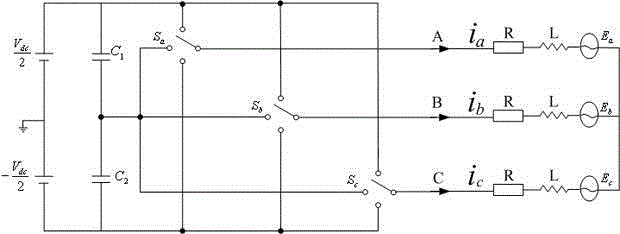

NPC (neutral point clamped) three-level inverter vector control system based on novel flux observer

InactiveCN103338000AReduce complexityImprove dynamic performanceElectronic commutation motor controlAC motor controlThree levelVoltage vector

An NPC (neutral point clamped) three-level inverter vector control system based on a novel flux observer provides a simplified SVPWM (space vector pulse width modulation) algorithm. A three-level space vector is decomposed into a two-level space vector; a reference voltage vector is translated; a two-level SVPWM algorithm is used to obtain action time of each basic vector and to choose a right switching status; and the three-level inverter vector control calculation is reduced. Meanwhile, in the invention, the novel flux observer is employed to calculate the rotor flux, so that a current model and a voltage model are used respectively at a low speed and at a high speed; and when a rotation speed is between the low speed and the high speed, an invented hybrid flux observer is used to calculate the rotor flux.

Owner:HENAN UNIV OF SCI & TECH

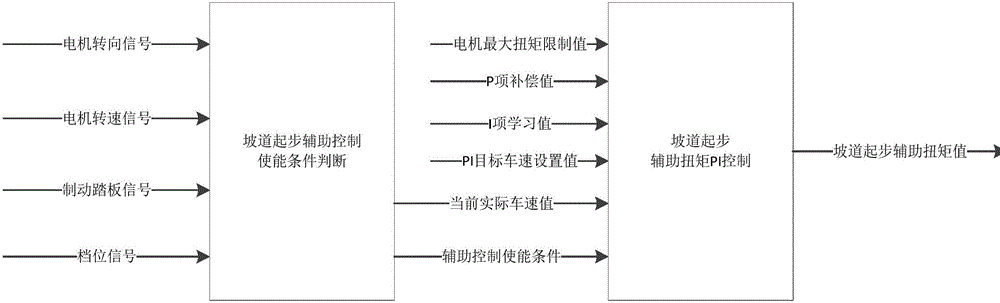

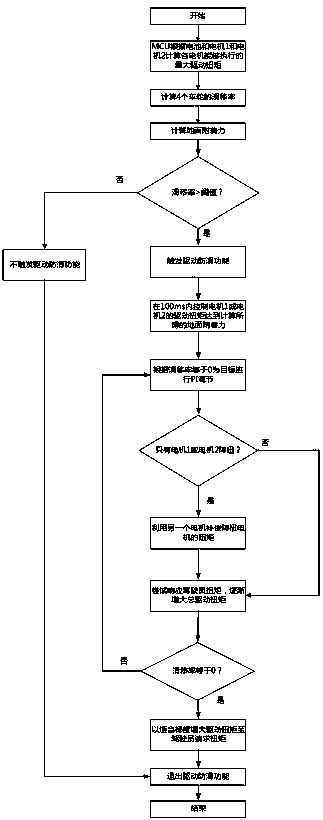

Hill starting auxiliary control method for vehicle directly driven by motor

InactiveCN106218630APrevent slippery slopeImprove securitySpeed controllerOperating modesEngineeringControl theory

The invention discloses a hill starting auxiliary control method for a vehicle directly driven by a motor. Serious hill slipping of the vehicle is avoided by superposition of an anti-slope torque without extra mechanical structures or sensors, hill starting auxiliary control of the vehicle can be realized according to an integral vehicle control strategy, and easiness in implementation is achieved. In addition, PI torque control is well adaptive to different gradients, quickness in torque response and high adaptability are realized, hill slipping risks are effectively reduced, and safety in hill starting is greatly improved.

Owner:澳特卡新能源科技(上海)有限公司 +1

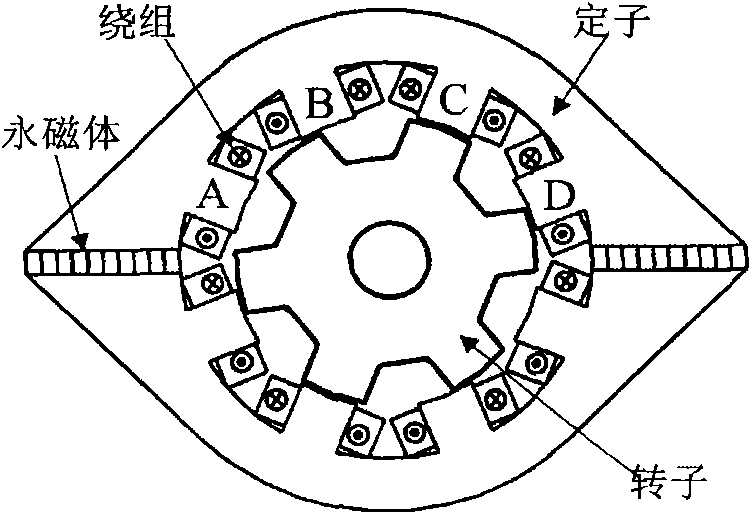

Device and method for controlling doubly salient permanent magnet motor

InactiveCN101789738AReduce torque rippleReduce vibration and noiseTorque ripple controlIntegrated controllerTorque observer

The invention provides a device and a method for controlling a doubly salient permanent magnet motor. The device comprises a doubly salient permanent magnet motor, a rotational speed measuring unit, a rotational speed regulator, a torque observer, a torque regulator, a position sensor, a reference current generator, a current sensor, a current hysteretic loop tracking controller and an inverter. According to the method, proportional integrated controllers are adopted by both the rotational speed regulator and the torque regulator and amplitude limiting is performed on the output of the rotational speed regulator and the torque regulator. The device and the method for controlling the doubly salient permanent magnet motor have simple control, can effectively restrict motor torque pulse, reduce noises, and improve dynamic response and speed adjusting performance of the motor.

Owner:SOUTHEAST UNIV

Electric four-wheel drive vehicle and control unit for same

InactiveUS7455133B2Improve installabilityFast torque responseHybrid vehiclesPlural diverse prime-mover propulsion mountingAC powerAC motor

An electric four-wheel drive vehicle and a control unit for the same, which can be applied to cars of class having larger displacements than the class to which the electric four-wheel drive vehicle equipped with the DC motor is applied, without increasing the cost over that of the known mechanical four-wheel drive vehicle. Front wheels of the vehicle are driven by an engine, and rear wheels are driven by an AC motor. A generator is driven by a rotating force of the engine to output DC power. An inverter converts the DC power outputted from the generator to AC power. A control unit controls the generator such that energy Pm required for driving the AC motor is outputted from the generator.

Owner:HITACHI LTD

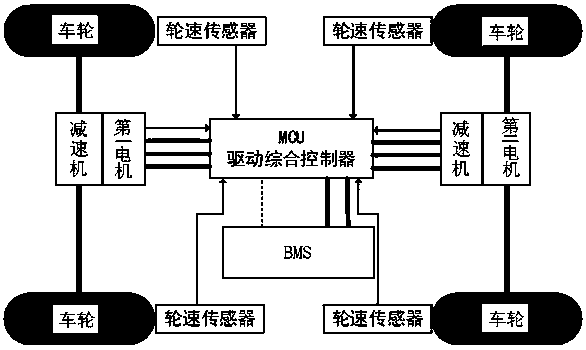

Pure electric vehicle drive antiskid system and control method

ActiveCN109795339AReduce control moduleImprove reliabilitySpeed controllerElectric energy managementElectric machineTraction control system

The invention relates to a pure electric vehicle drive antiskid system and control method. The system comprises an MCU (micro-control unit) integrated drive controller, a drive motor and a wheel speeddetection device, wherein the wheel speed detection device is arranged on a wheel and in communication connection with the MCU integrated drive controller, the drive motor is in communication connection with the MCU integrated drive controller and used for driving the wheel, the wheel speed detection device is used for detecting the wheel speed and / or accelerated speed of the wheel and transmitting the speed to the MCU integrated drive controller, the MCU integrated drive controller receives the wheel speed and / or accelerated speed, calculates slip rate and triggers an drive antiskid functionwhen the slip rate or accelerated speed exceeds a threshold, and the torque of the drive motor is adjusted to ensure the overall dynamic property of a vehicle. control modules are fewer, reliabilityis high, a TCS (traction control system) function can be achieved without an ESP (electronic stability program) module, development period is short, and hardware and software cost is greatly reduced.

Owner:奇瑞新能源汽车股份有限公司

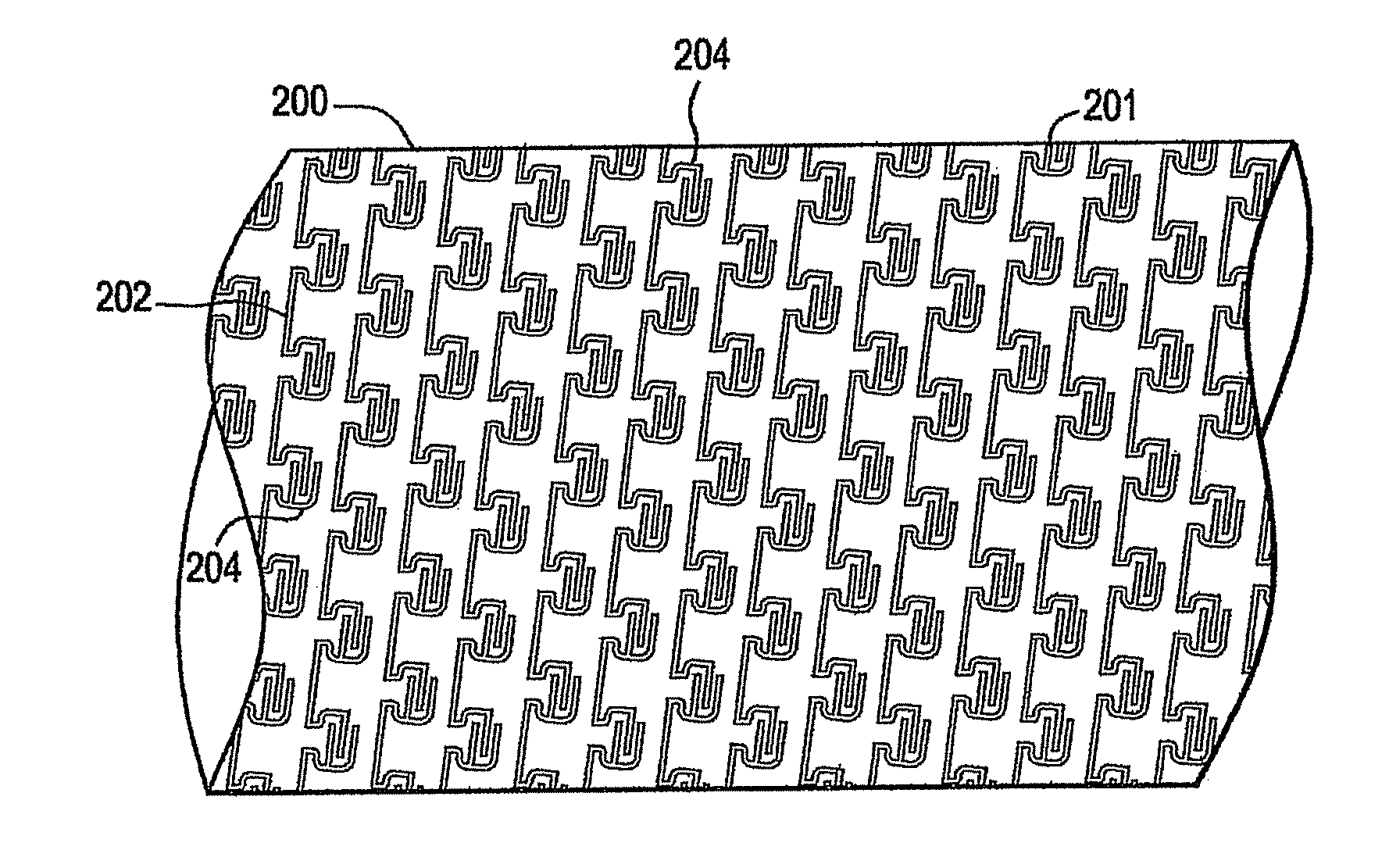

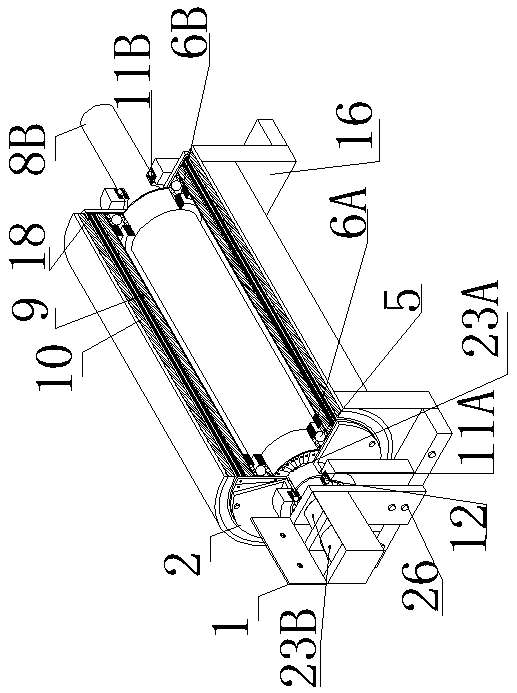

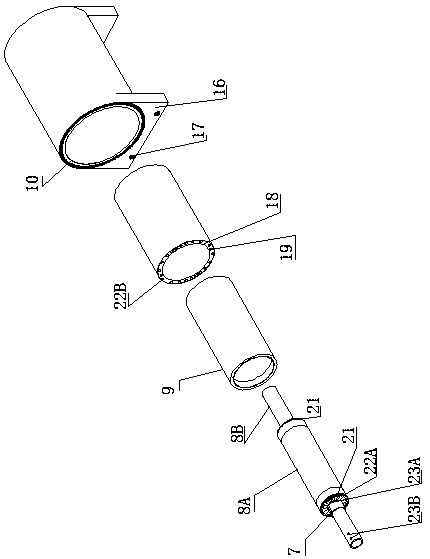

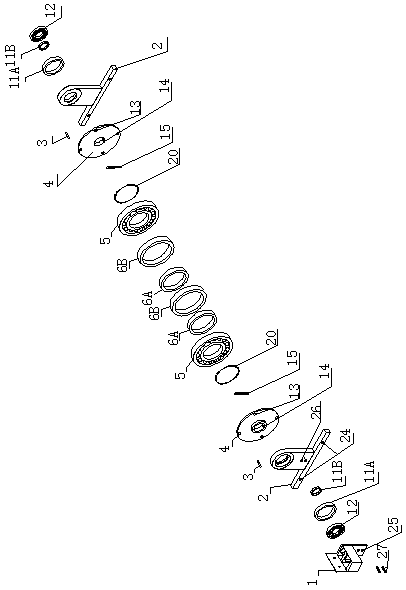

Highly flexible tubular device for medical use

ActiveUS8454535B2Fast torque responseIncrease flexibilityCatheterDiagnostic recording/measuringEngineeringMedical treatment

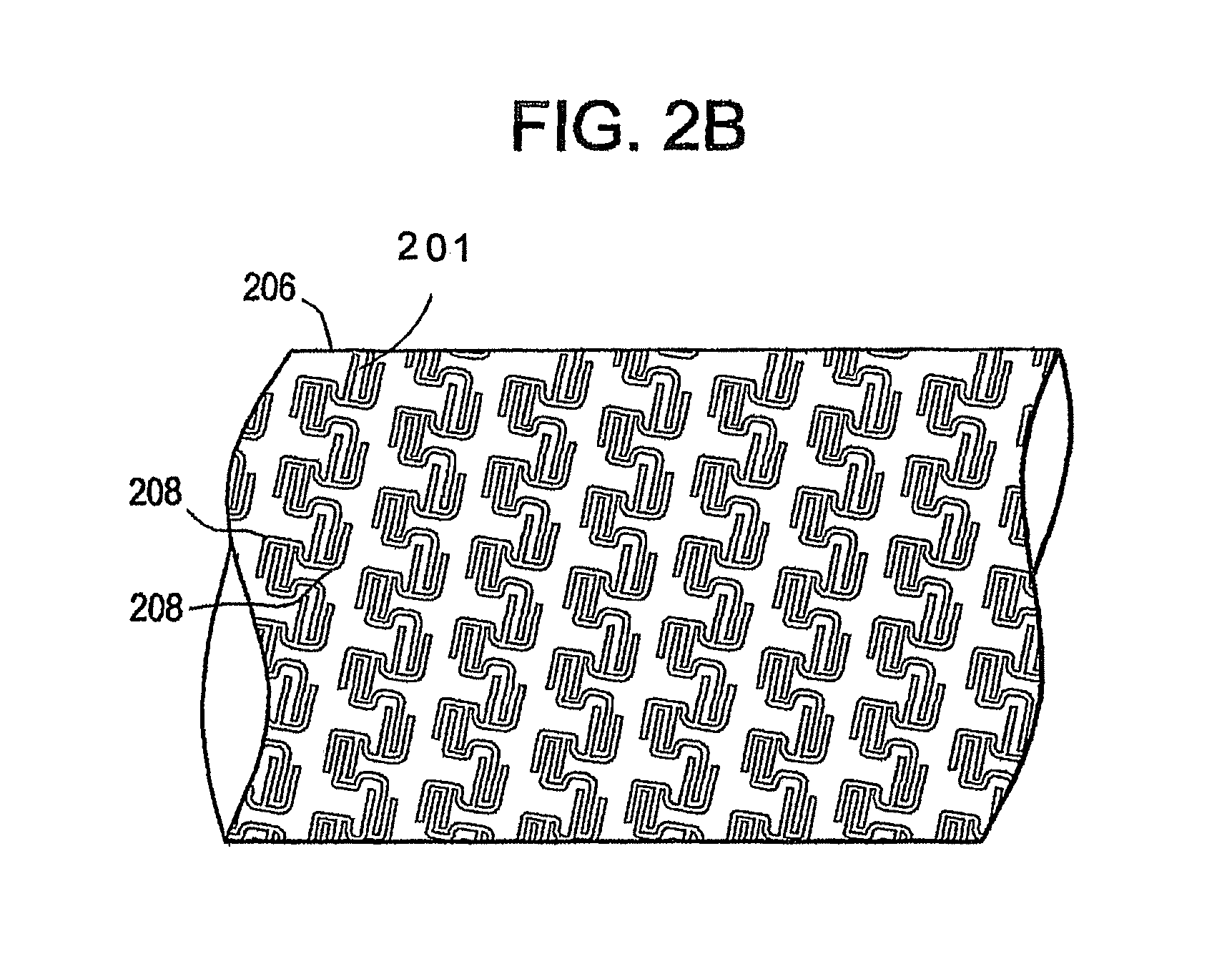

The invention relates to an elongated torque tube for use in medical applications. The torque tube comprises an elongated tubular structure having a cylindrical cross section and defining a longitudinal axis and a circumferential axis, the elongated tubular structure including a helical cut having a finite thickness and extending along the length of the elongated tubular structure, the helical cut being oriented along the circumferential axis and including a plurality of flexural units defined by discontinuous cuts aligned with the circumferential axis.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

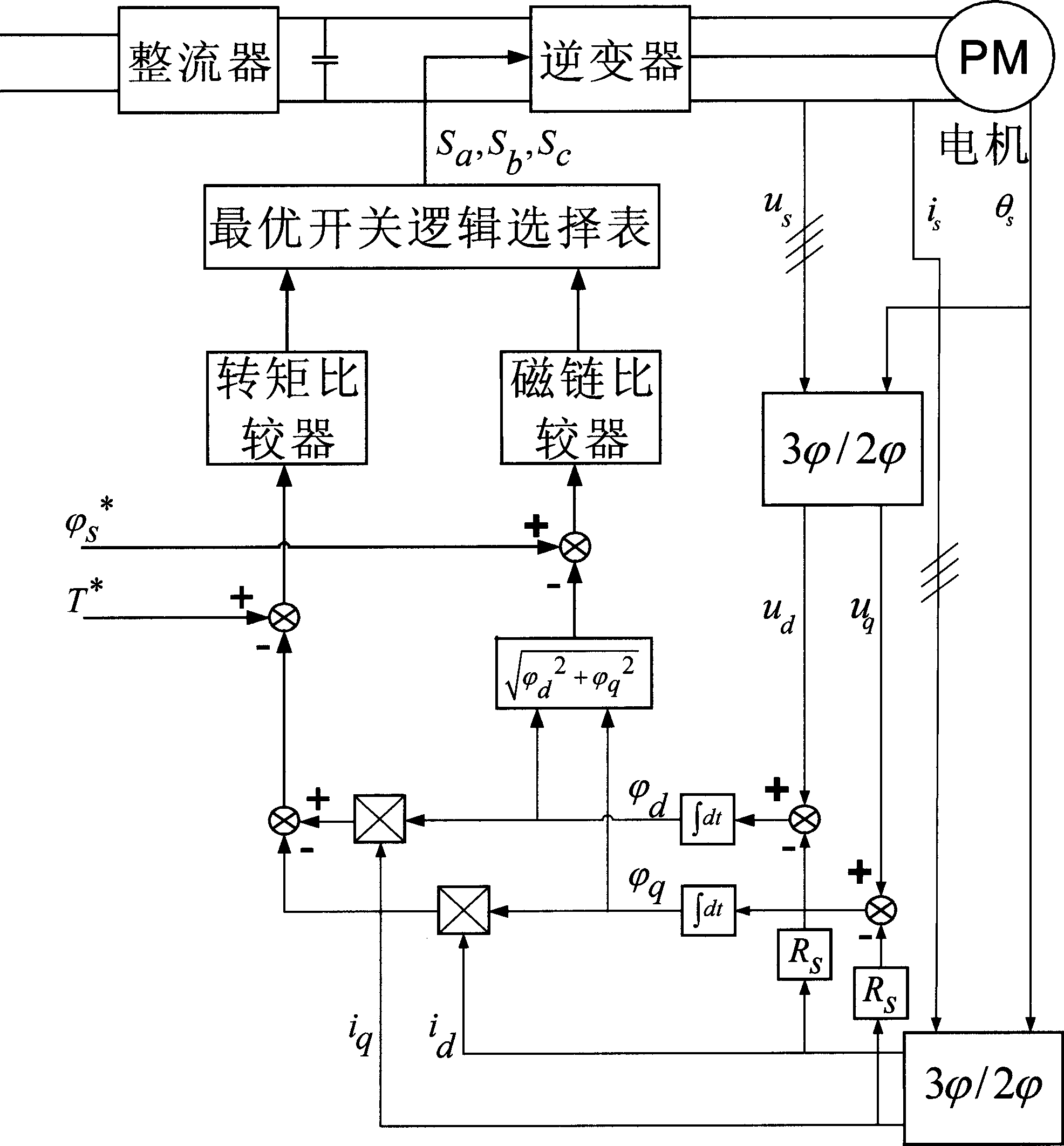

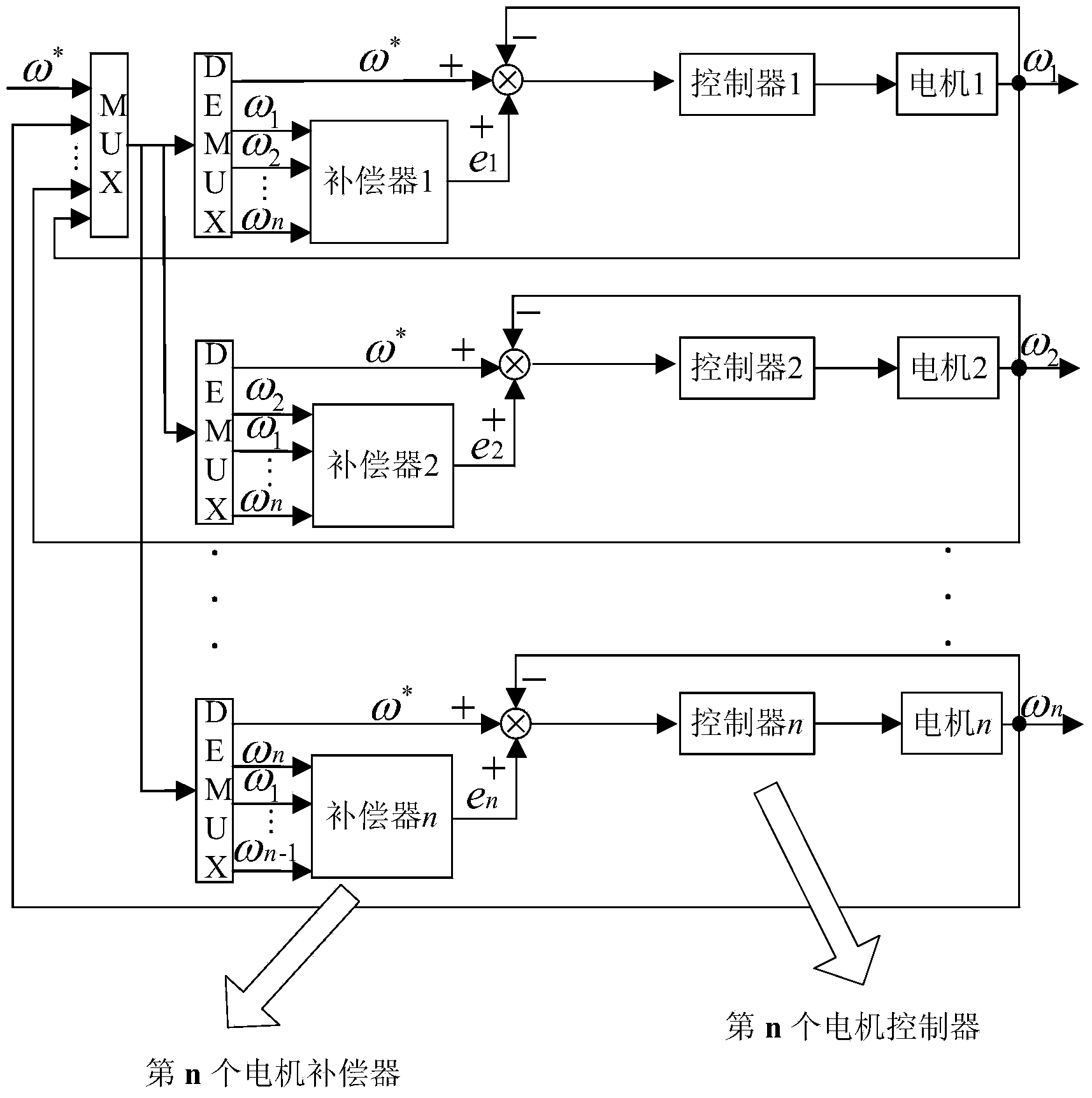

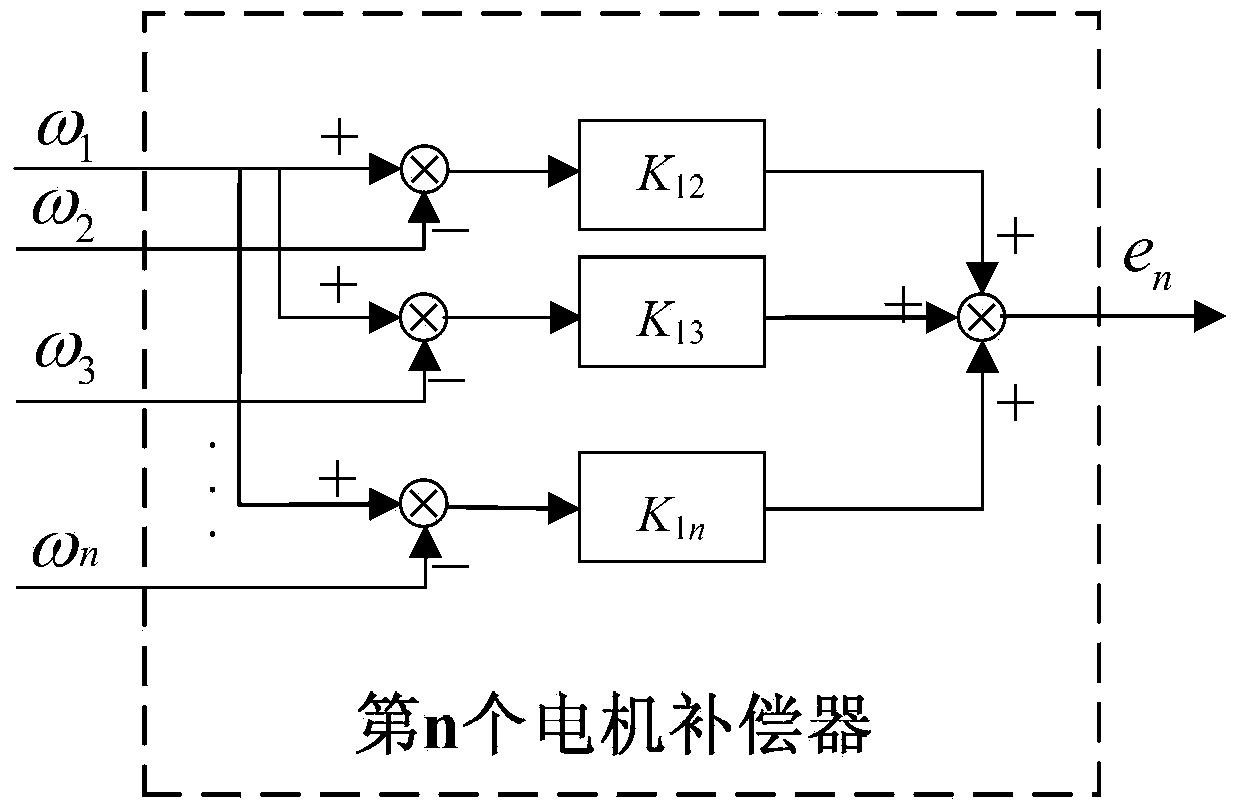

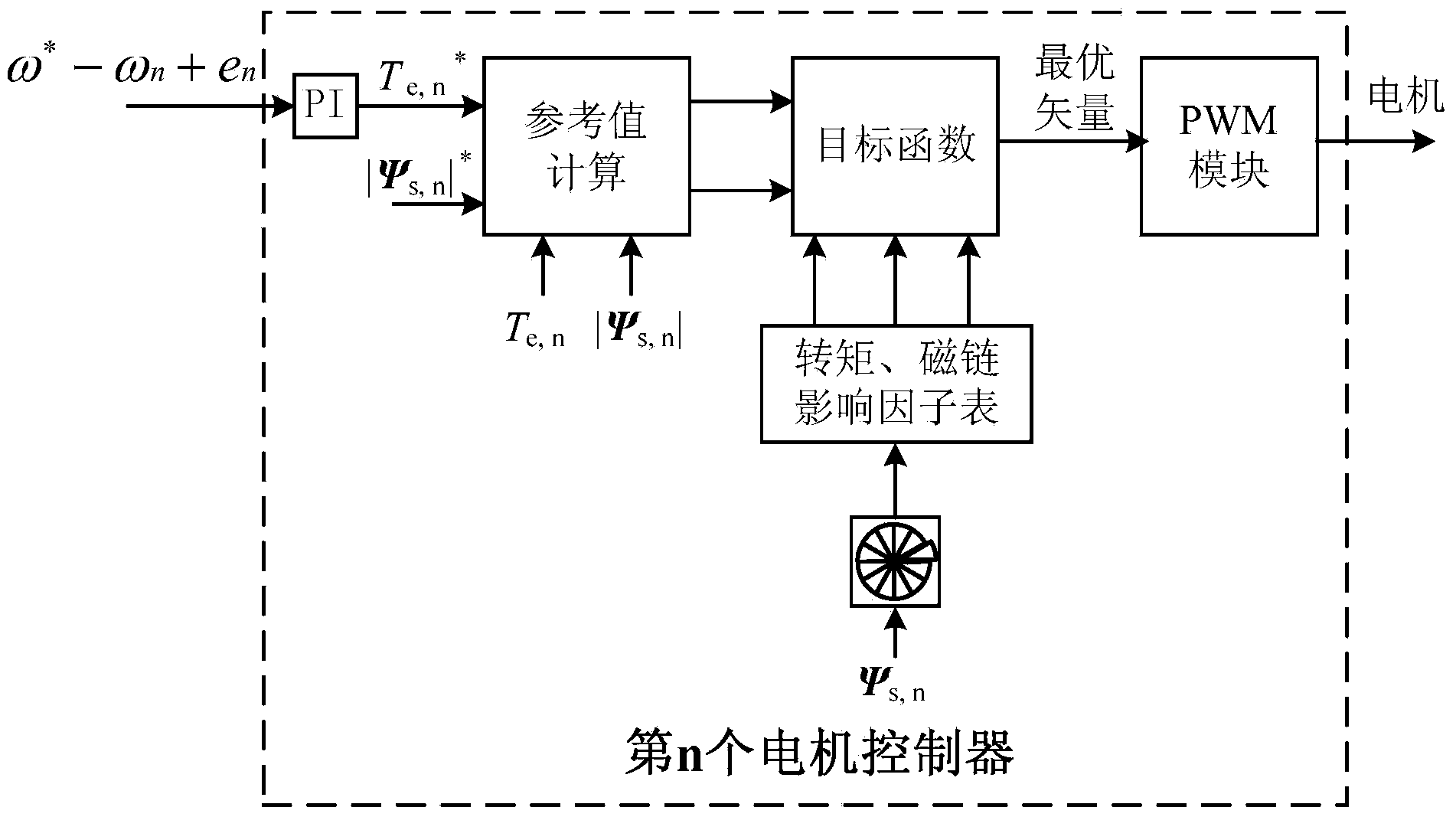

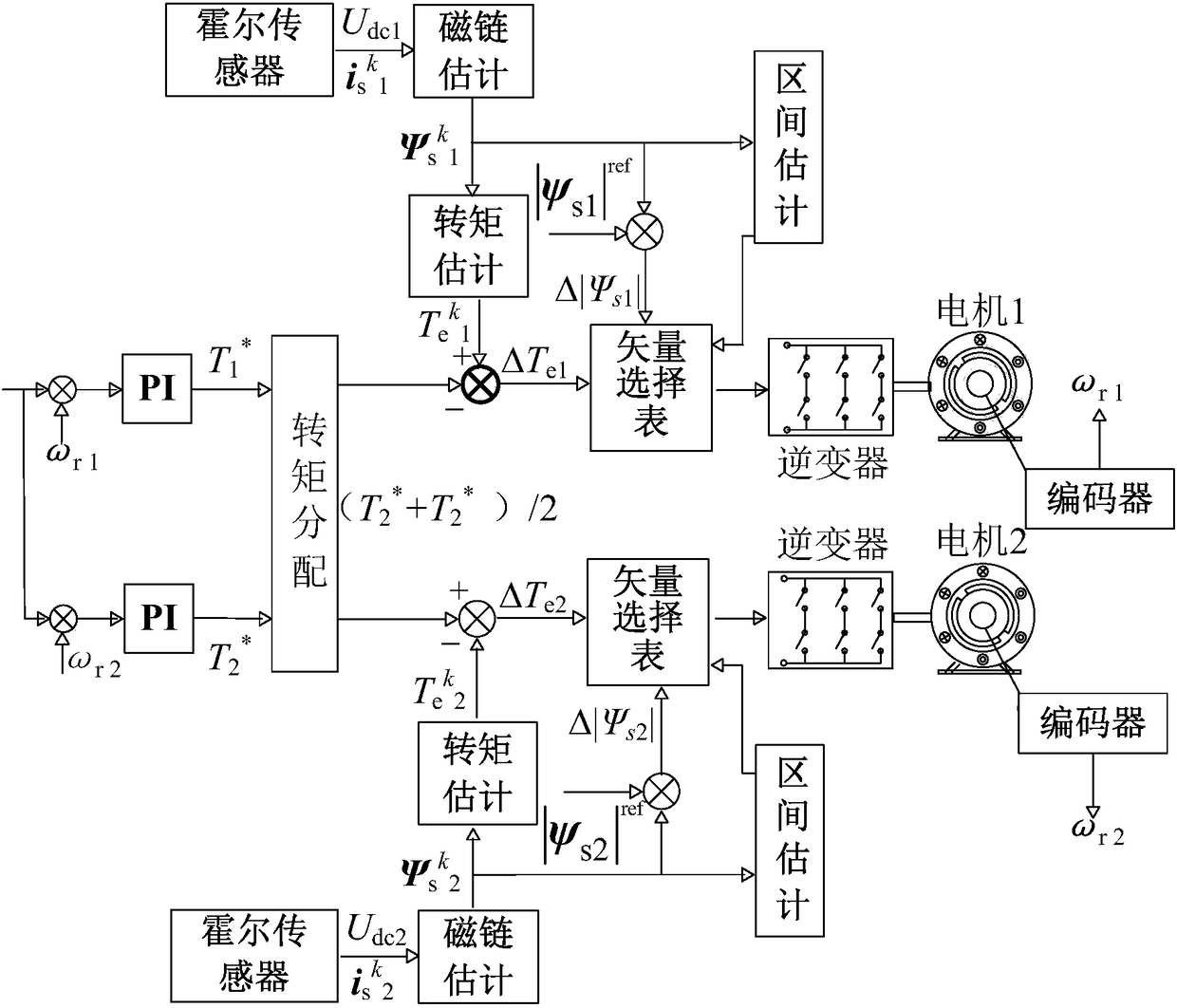

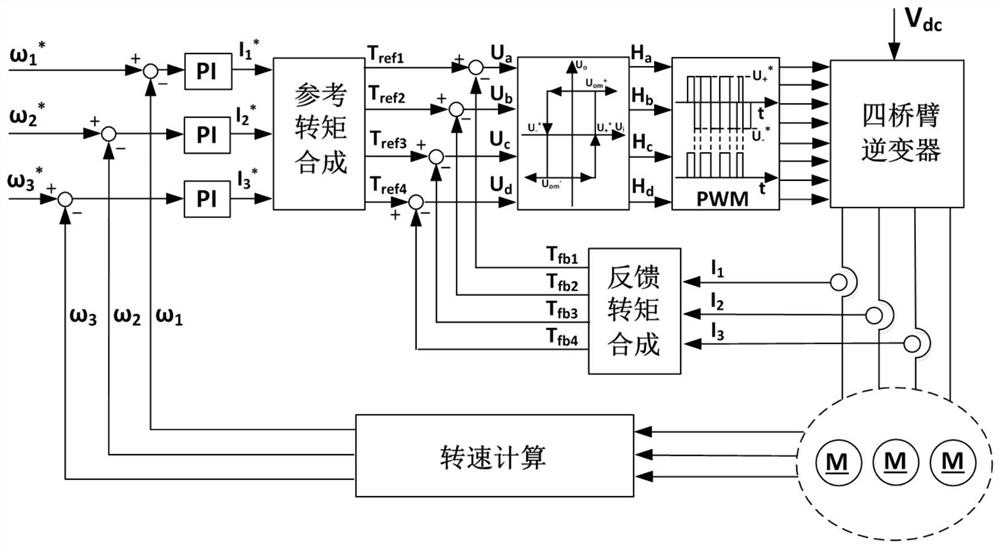

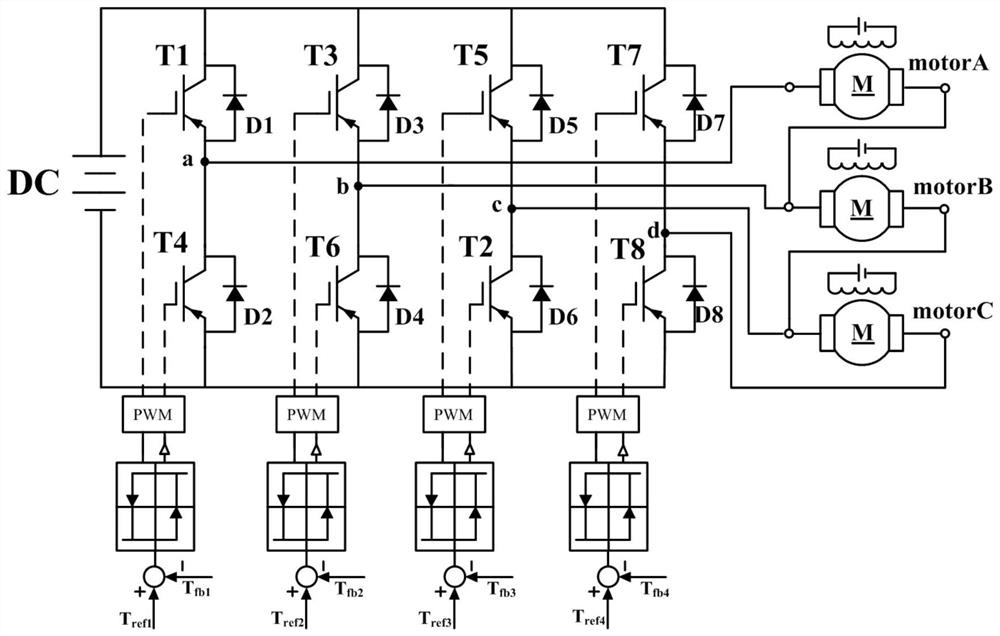

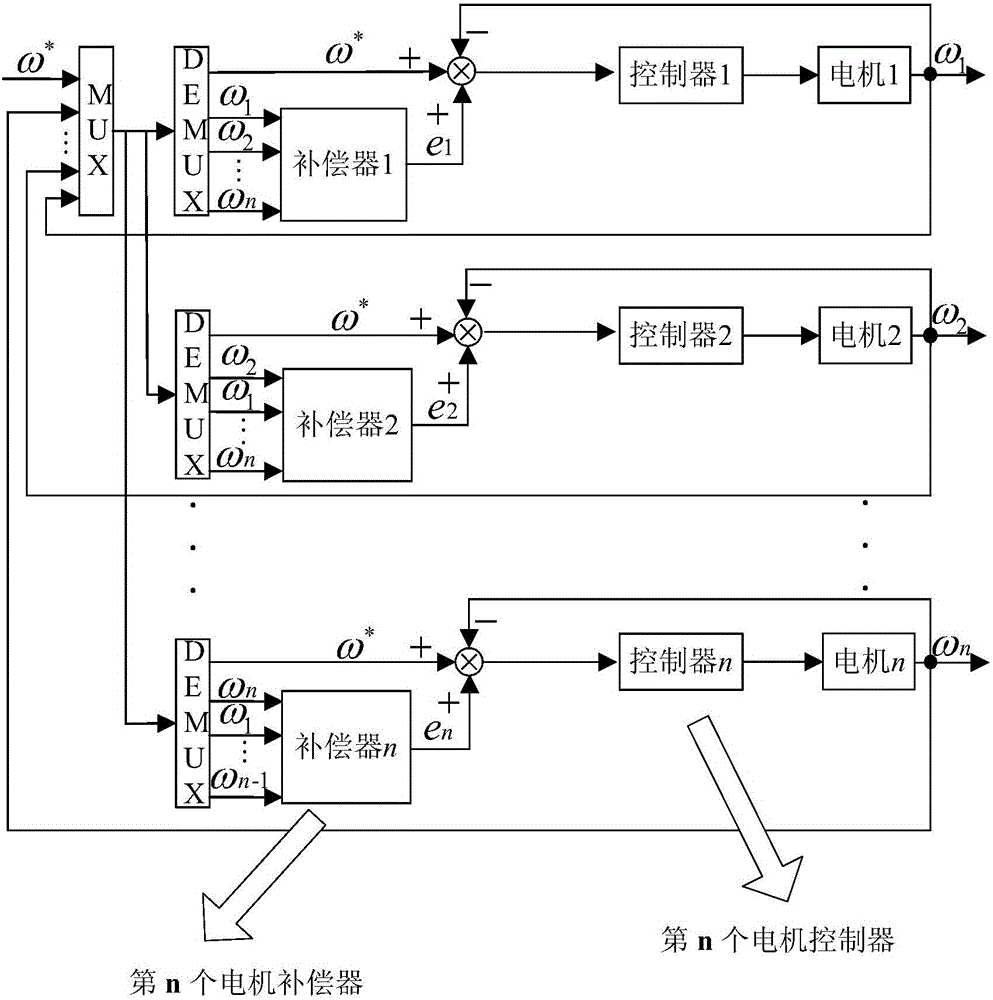

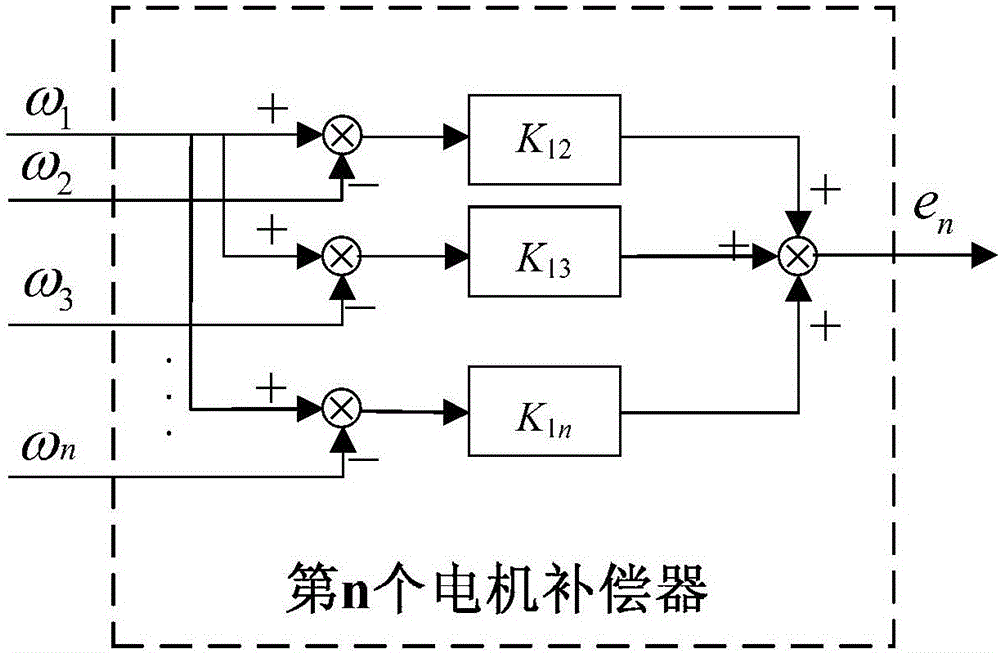

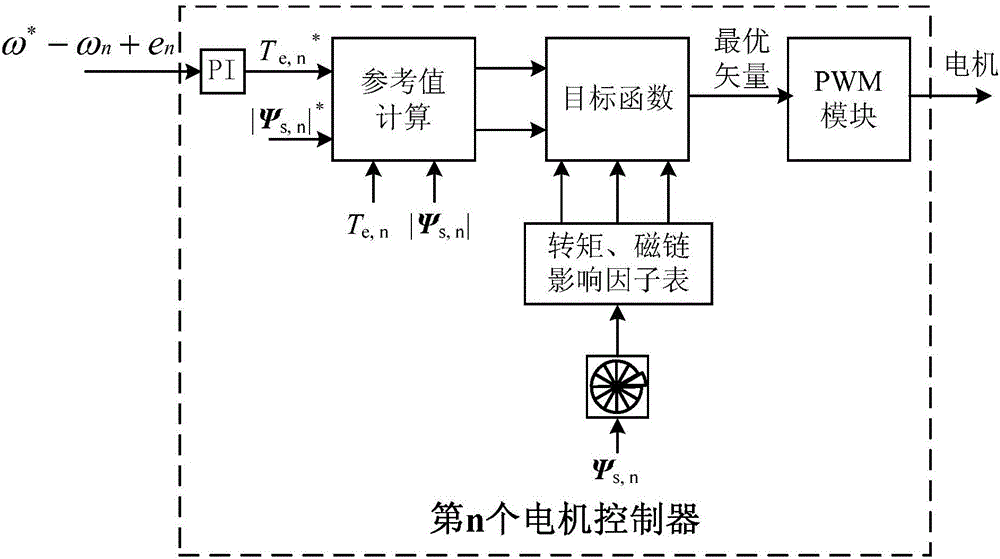

Direct torque control method suitable for multi-motor system

ActiveCN103944459AFast torque responseReduce torque fluctuationElectronic commutation motor controlVector control systemsVoltage vectorEqualization

The invention discloses a direct torque control method suitable for a multi-motor system. Firstly, a torque and flux linkage evaluating function of the multi-motor system is established; a torque and flux linkage impact factor table is obtained through the discretization and equalization processing on the evaluating function; then, the torque reference value of a single motor is generated through a deviation coupling controller of the multi-motor system; lastly, a torque impact factor reference value p Tau* and a flux linkage impact factor reference value p Lambada* are calculated, an objective function is established, and an inverter voltage vector enabling the value of the objective function to be minimum is selected according to the torque and flux linkage impact factor table and is used for controlling the multi-motor system. According to the direct torque control method, fast torque responses of the multi-motor system can be achieved, and torque ripples in steady-state operation can be lowered; the impact degrees of different inverter voltage vectors on the electromagnetic torque and the motor stator flux linkage amplitude of the multi-motor system under the action of different duty ratios can be comprehensively, directly and finely reflected through the established torque and flux linkage impact factor table.

Owner:TIANJIN UNIV

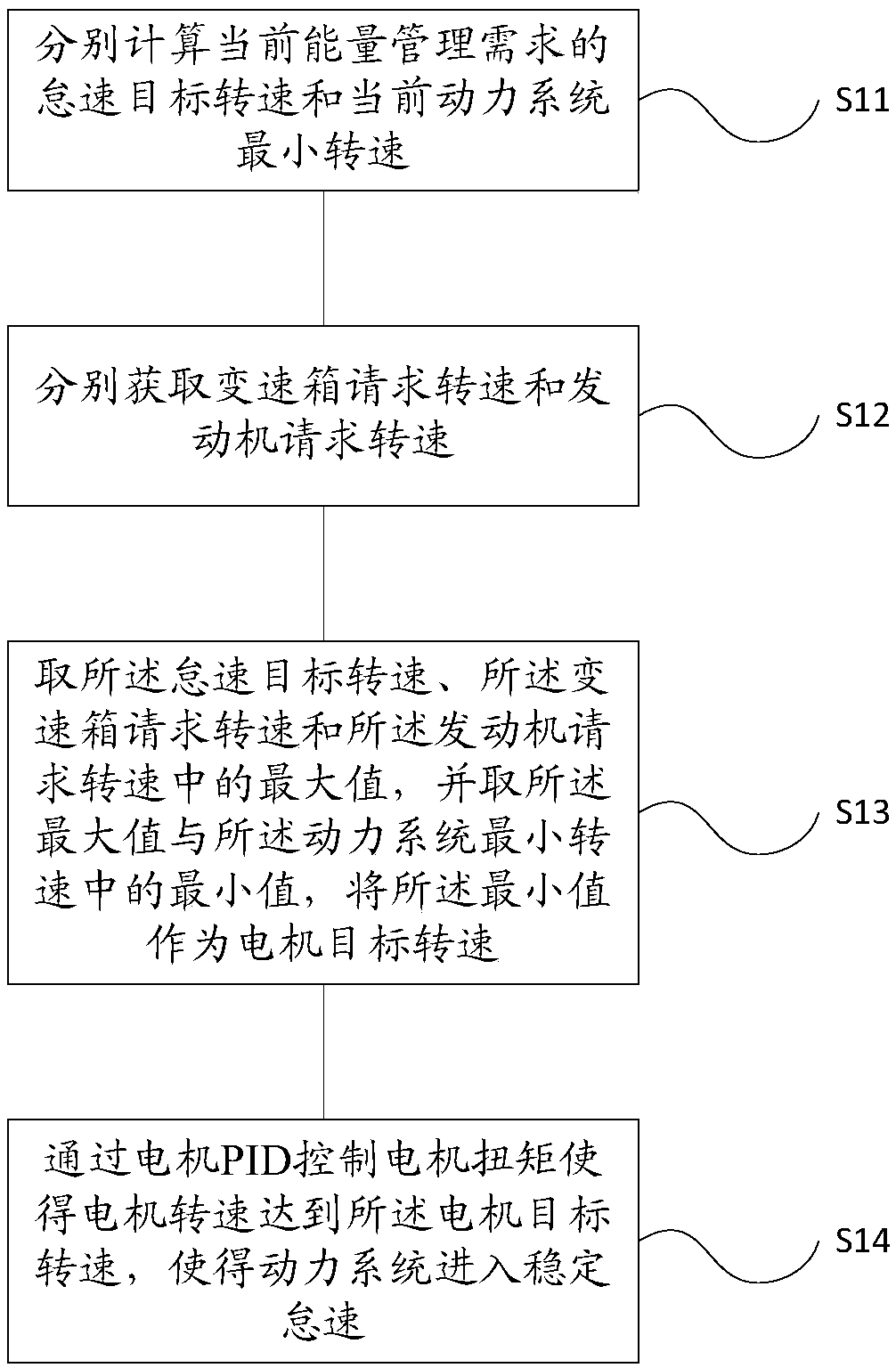

An idle speed control method of a hybrid electric vehicle

The invention discloses an idle speed control method of a hybrid electric vehicle. The idle speed control method comprises the following steps: respectively calculating an idle target speed required by current energy management and a minimum speed of current power system; obtaining a transmission request speed and an engine request speed respectively; taking the maximum of idle speed, transmissionrequest speed and engine request speed, and taking the minimum of the maximum and the minimum of the powertrain speed as the motor target speed; controlling the motor torque by the motor PID controller so that the motor speed reaches the motor target speed and the power system enters the stable idle speed. the method is applied, the idle speed control of the engine with different rotational speeds is realized by the rotational speed control of the electric motor, The motor has fast torque response and stable idle speed, and adopts PID control mode, which limits the upper and lower limits of torque and the speed of change in the speed control process of the motor, ensures the smoothness of the vehicle when entering or exiting the idle speed working condition, and improves the fuel consumption level and NVH level in the idle speed process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

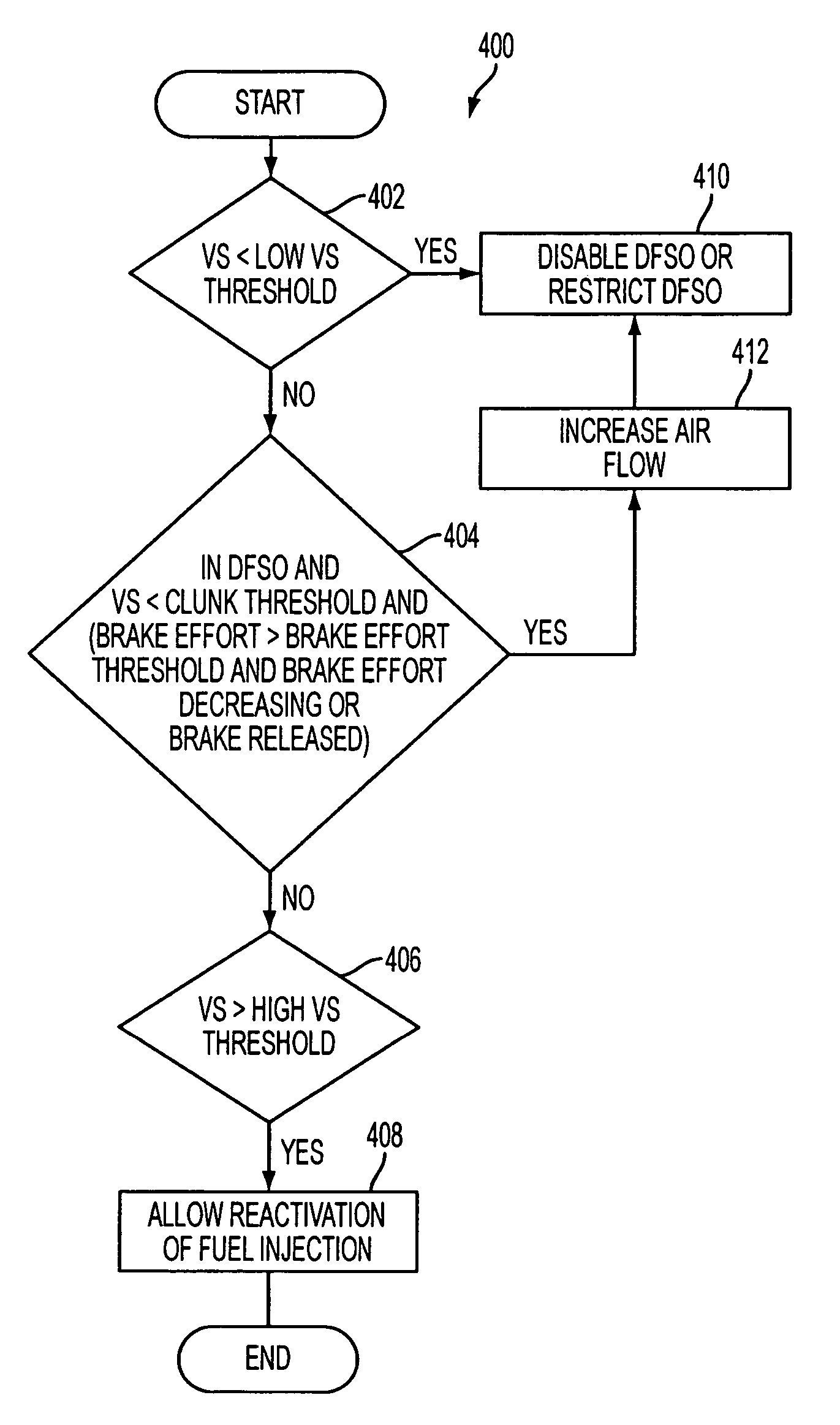

System and method to control fuel injector reactivation during deceleration fuel shut off

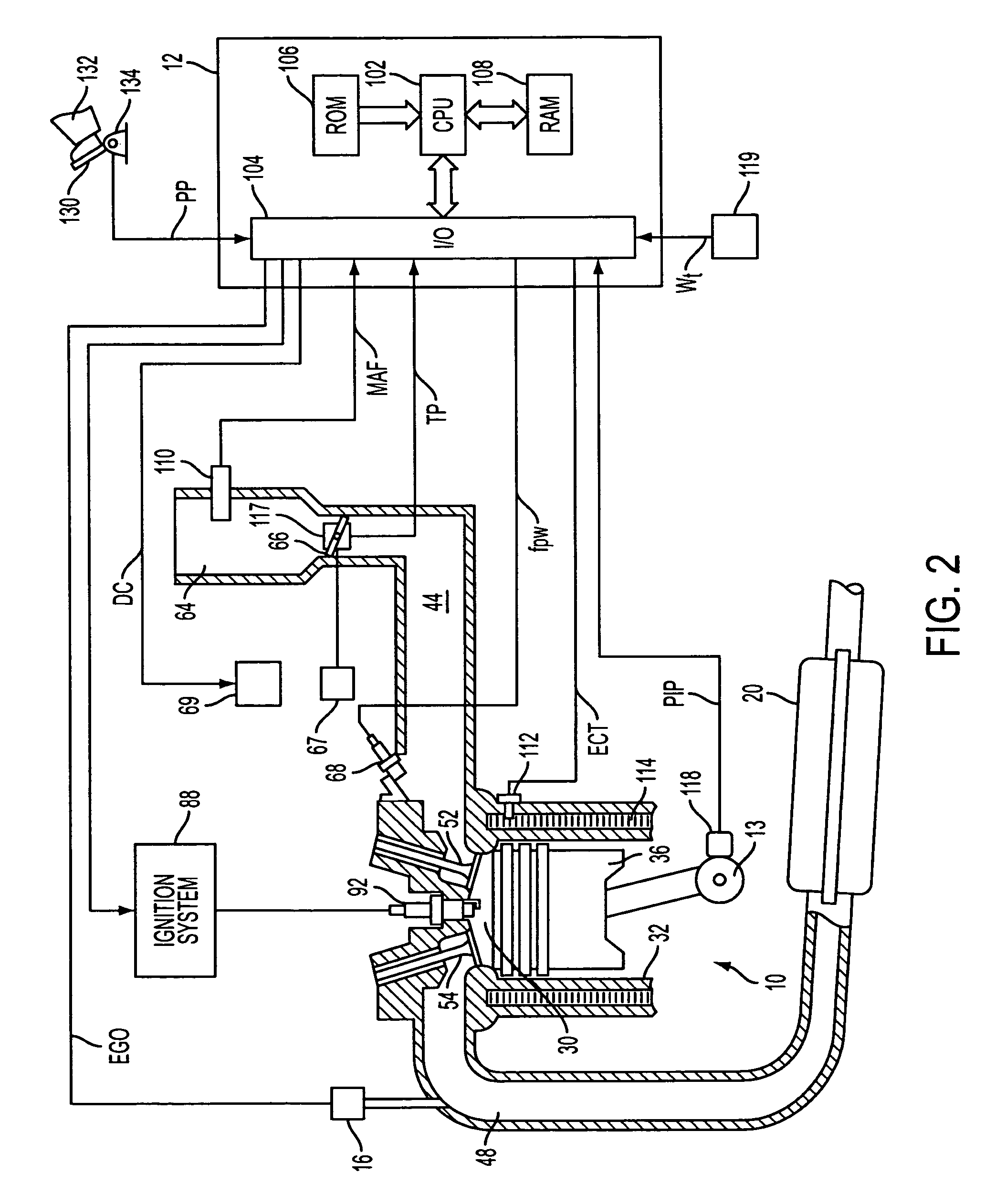

ActiveUS7497805B2Improve fuel economyImprove noiseElectrical controlOutput powerFuel injectionTraffic volume

A method of controlling fuel injection in an engine of a vehicle comprises reactivating fuel injectors based on release or decrease of driver braking during deceleration fuel shut off operation. According to another aspect, a method of controlling fuel injection in an engine of a vehicle comprises reactivating fuel injectors based on release or decrease of driver braking during deceleration fuel shut off; and increasing air flow to a cylinder before reactivation of fuel injectors in response to said release or decrease of driver braking to enhance torque response. The methods allow an engine to exit DFSO earlier by making use the brake input and effort, which provides time to reactivate the fuel injection and stabilize torque control prior to tip-in.

Owner:FORD GLOBAL TECH LLC

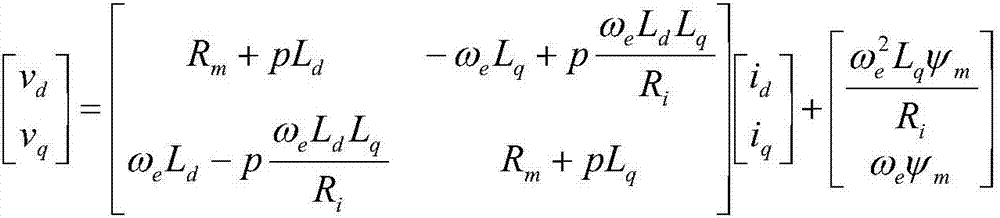

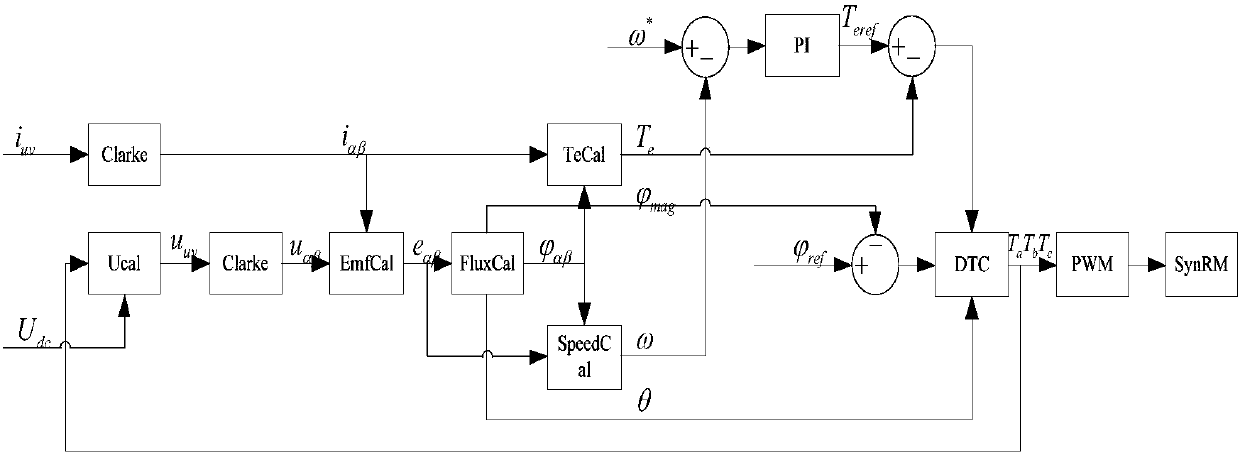

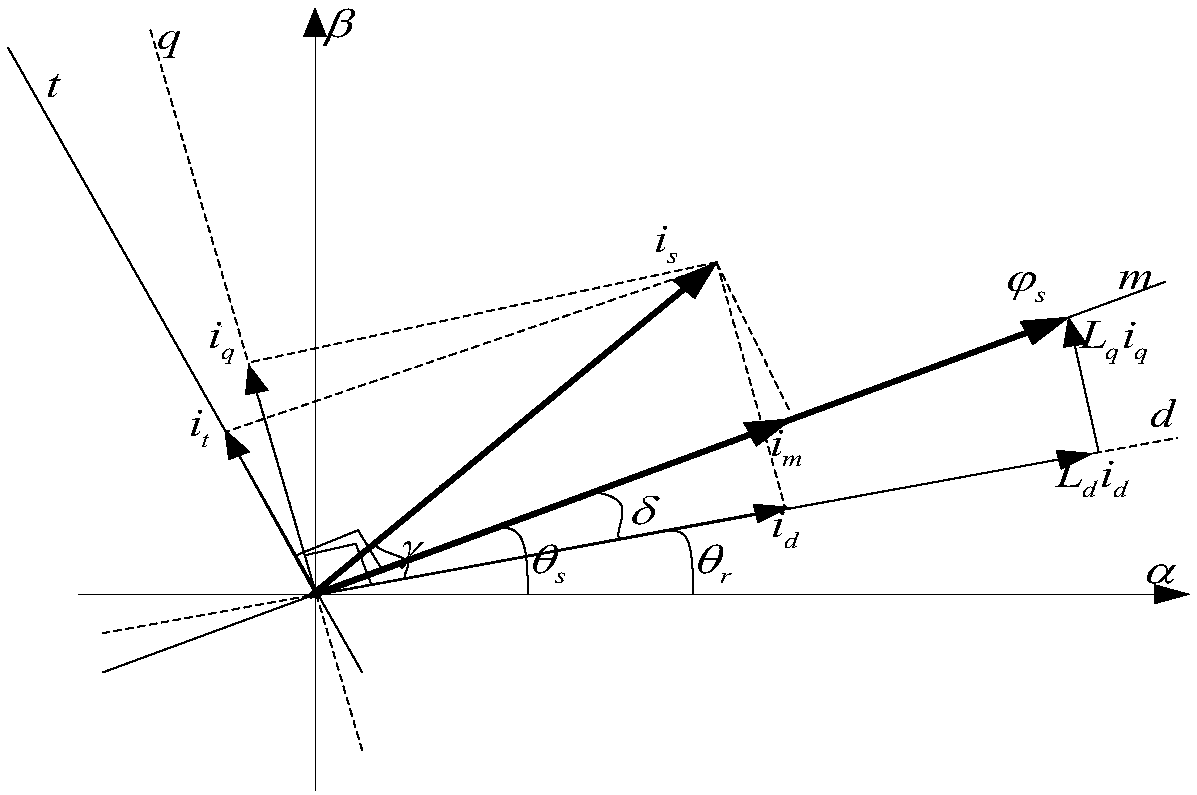

Iron core loss-based direct torque control method for ultra-high-speed permanent magnet synchronous motor

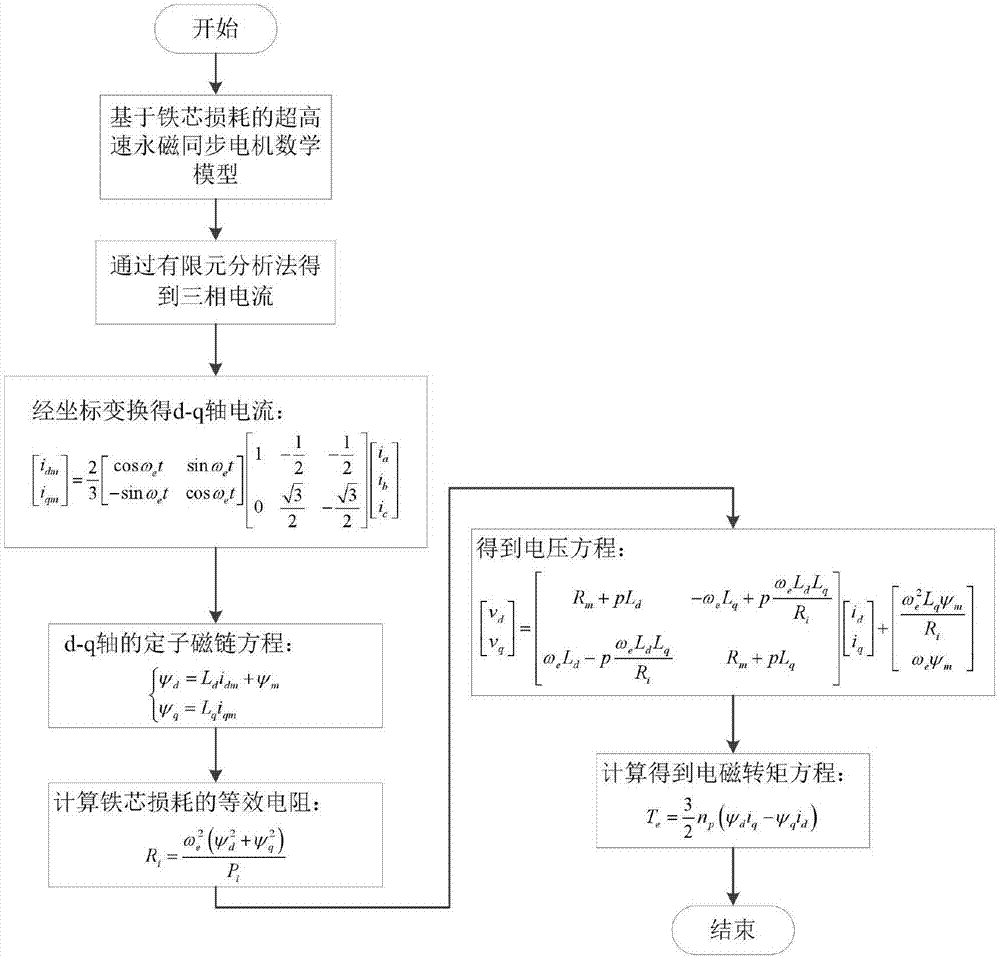

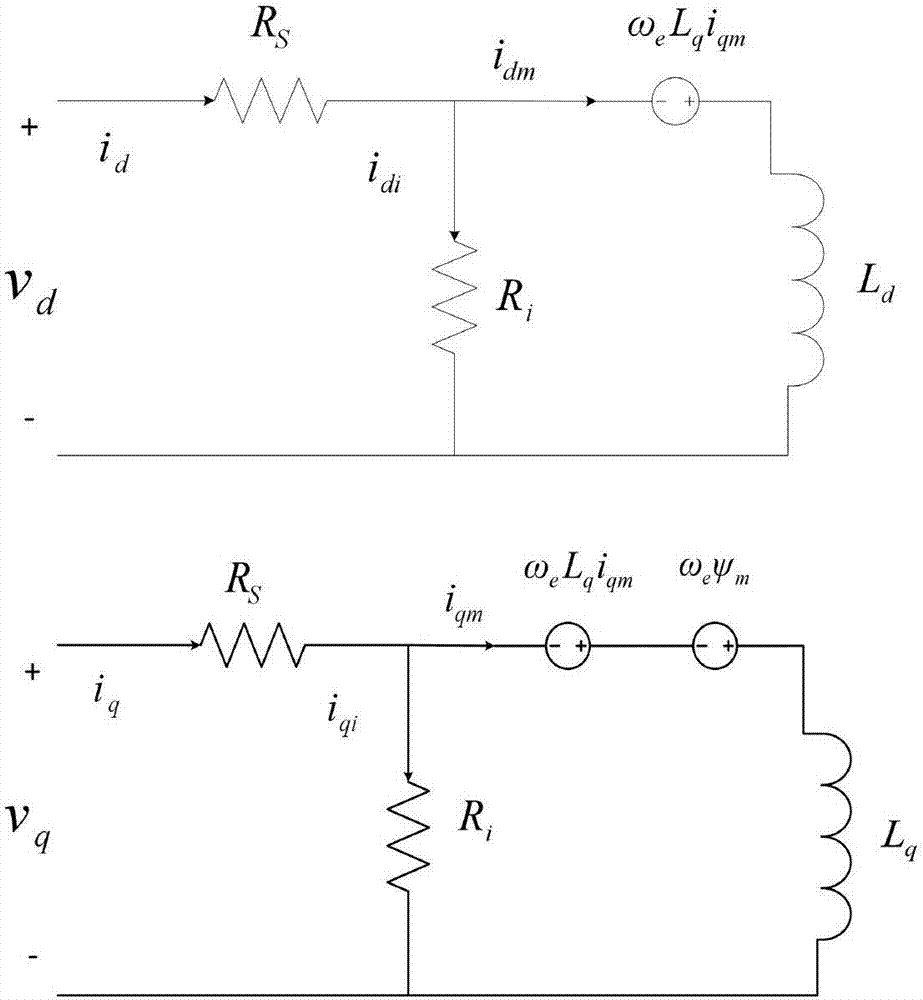

ActiveCN107493051AFast torque responseImprove robustnessElectronic commutation motor controlVector control systemsUltra high speedElement analysis

The invention provides an iron core loss-based direct torque control method for an ultra-high-speed permanent magnet synchronous motor. The invention discloses an iron core loss-based mathematical modeling method for the ultra-high-speed permanent magnet synchronous motor; a voltage equation, a flux linkage equation and a torque equation are adopted in motor rotary speed control by adopting the direct torque control method, wherein the flux linkage value is obtained by three-phase current calculation through a finite element analysis method; and iron core loss is taken into consideration in the voltage equation, and the iron core loss is converted into equivalent resistance. The method disclosed in the invention can be applied to the ultra-high-speed permanent magnet synchronous motor control system based on sensor-less rotary speed estimation; and angular error caused by iron core loss in the sensor-less rotary speed estimation can be effectively lowered.

Owner:NANJING UNIV OF SCI & TECH

Full speed range control method and control device of double-feedback electric motor

ActiveCN101272126ARealize decoupling controlFast torque responseElectronic commutation motor controlAC motor controlFrequency changerPower factor

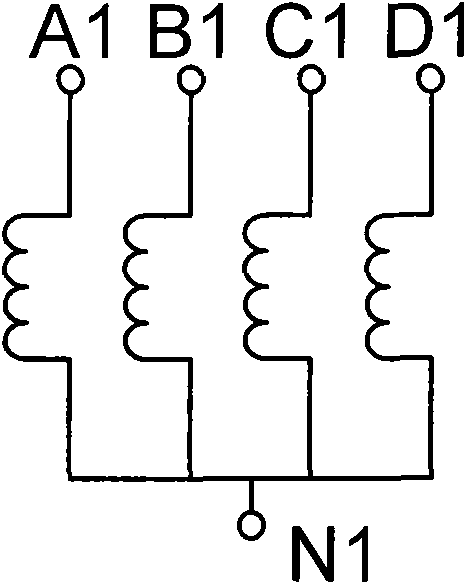

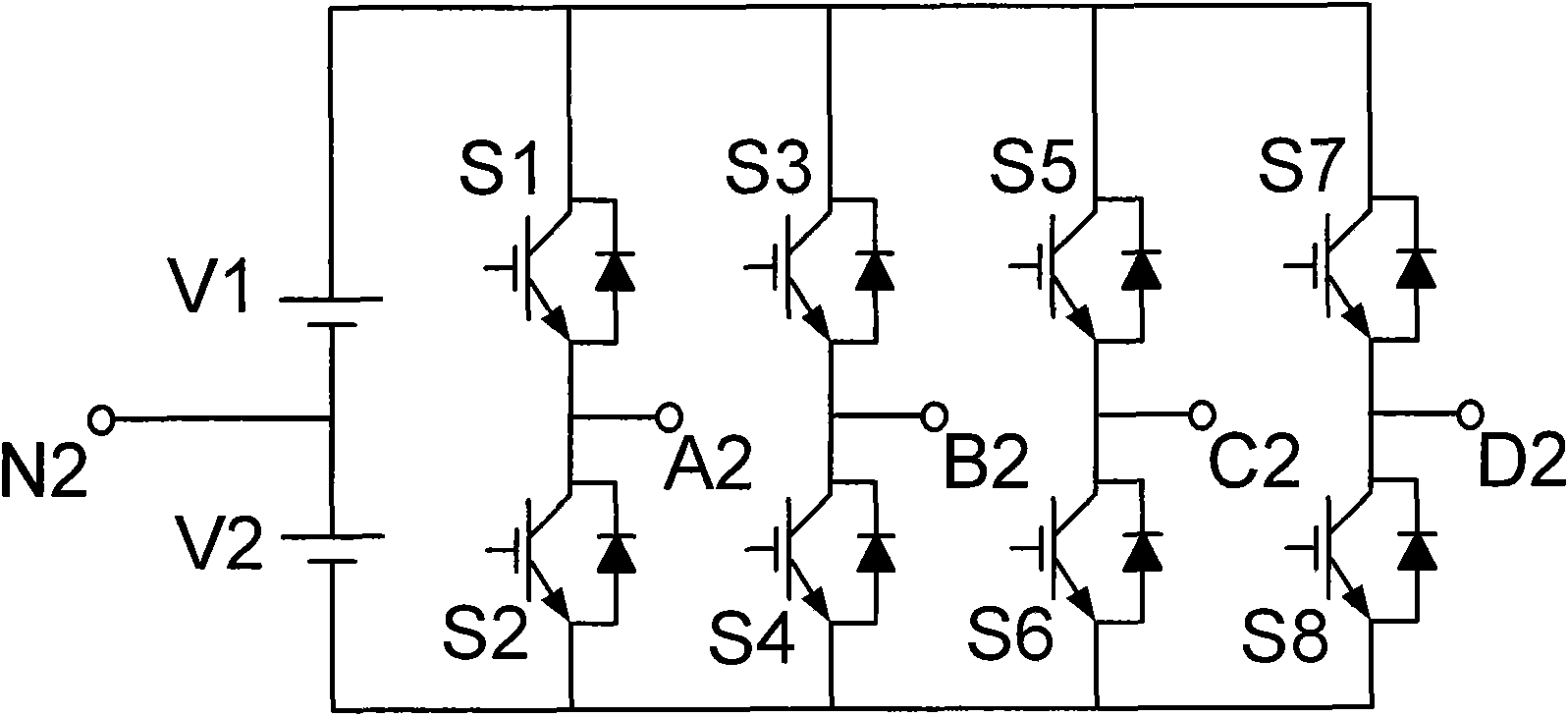

The invention relates to a full speed range control method and control device for a double-feed motor; the invention adopts a rotor side frequency conversion vector control method and carries out adjustment by a given rotating speed and an actual rotating speed, so as to realize the decoupling control of a torque current and a field current; besides, the invention also adopts a diode-clamp back-to-back double tri-level transducer which can lead a rotating difference power to be capable of flowing in double direction by the transducer within the full speed range, thus greatly improving the energy saving efficiency. The method can lead the effects of the device to an electric network to minimize and simultaneously obtain a fast motor torque response; in the whole control process, the voltage and the current aberration rates of the device of the electric network access point are low; the unit power factor operation of the stator side of the motor reduces the reactive impact of the electric network; the switching frequency of the transducer is low, thus reducing the heating of a system and improving the efficiency of the transducer. The method is simple; the device has the advantages of compact structure, being easy to assemble and being convenient to operate; which has board practicability in the technical field.

Owner:CHAJNA MAJNING DRAJVS EHND AUTOMEHJSHN KO +1

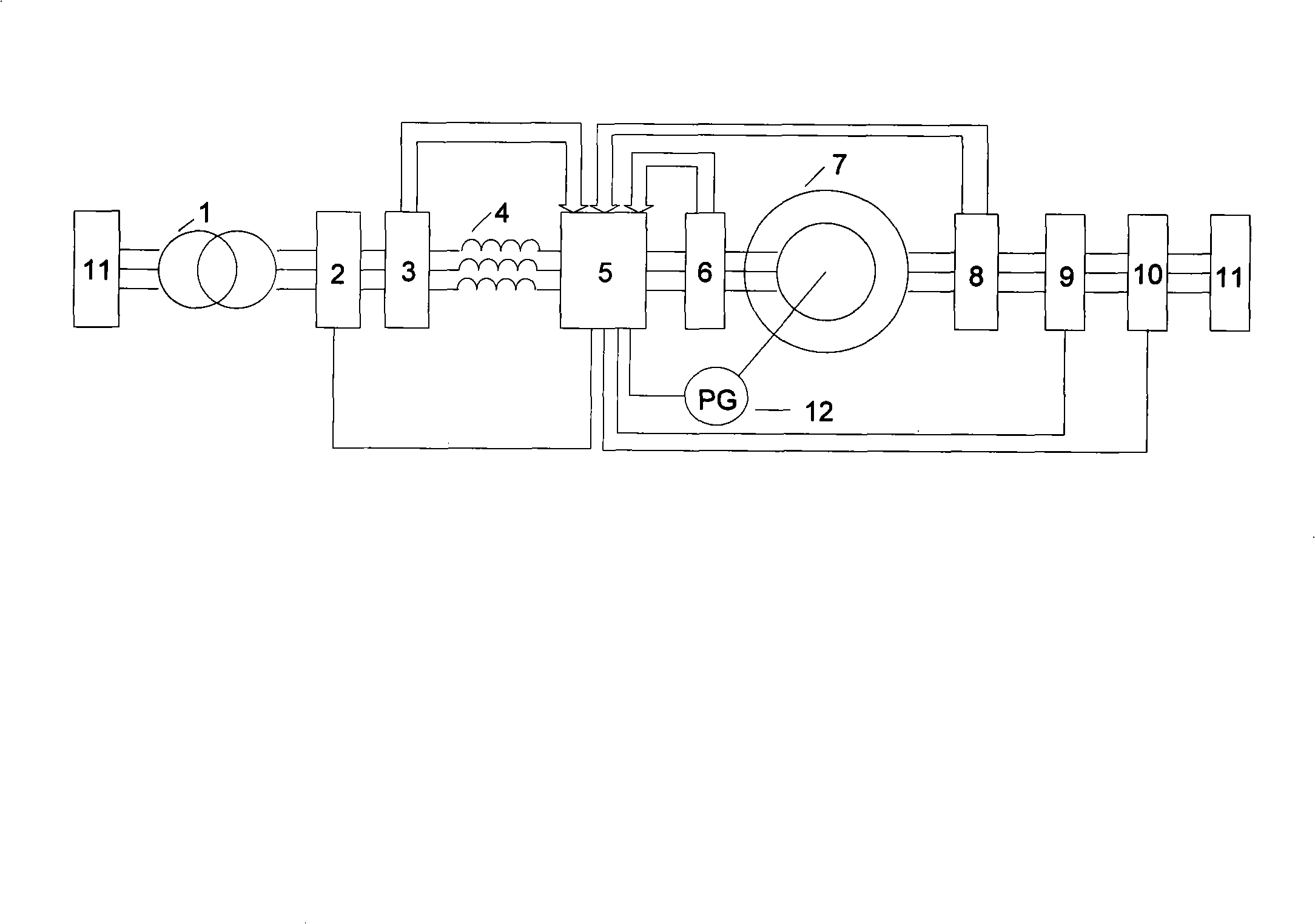

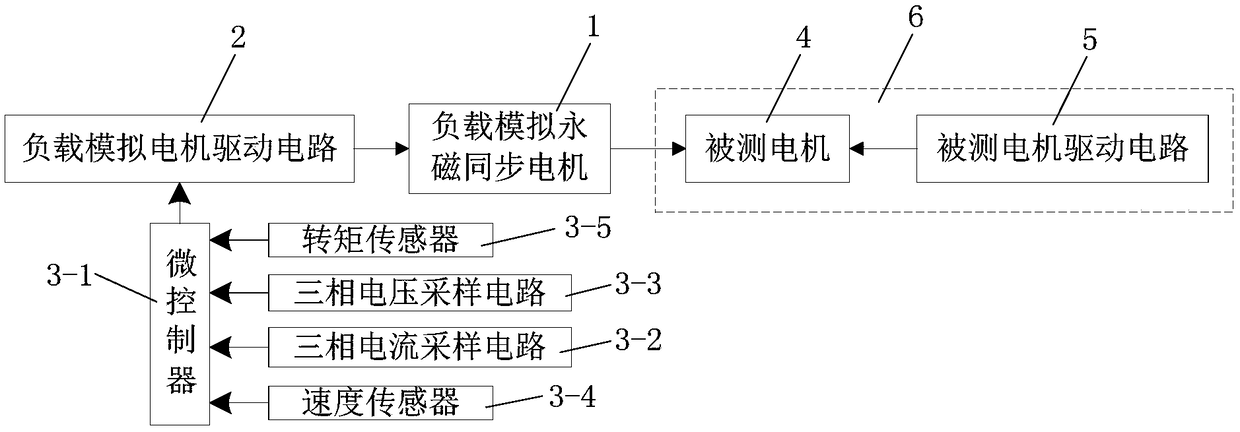

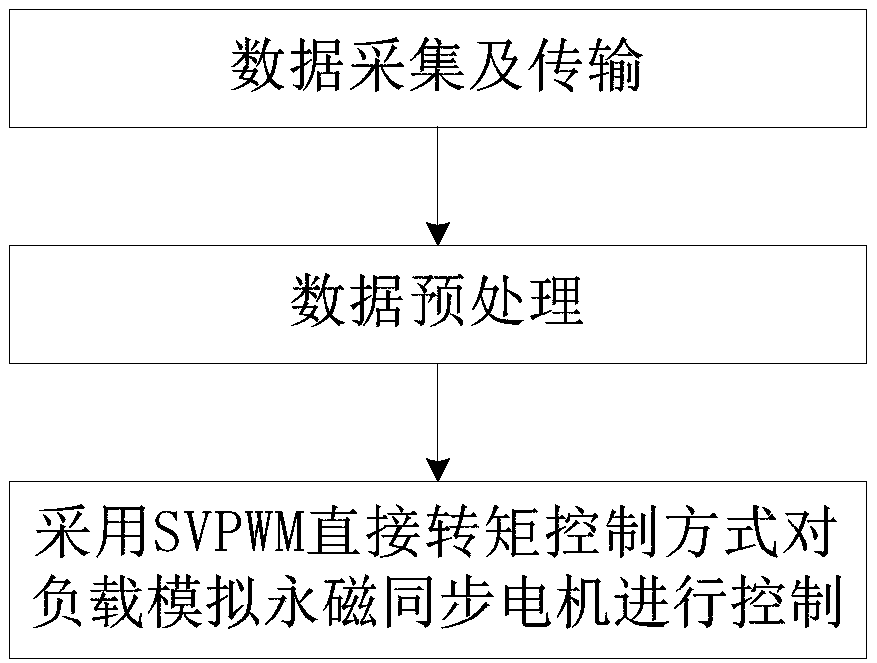

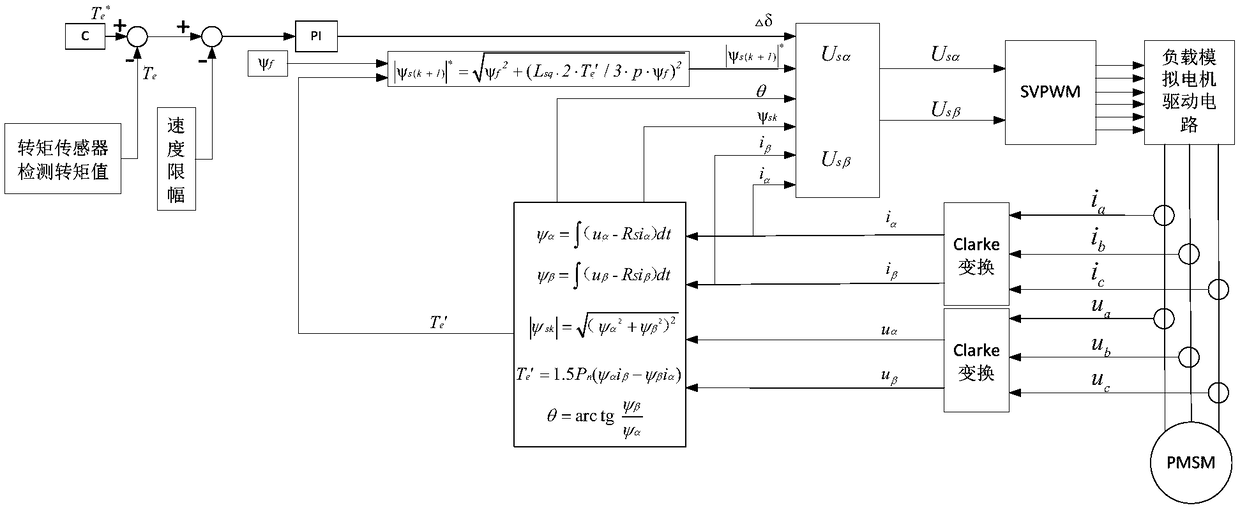

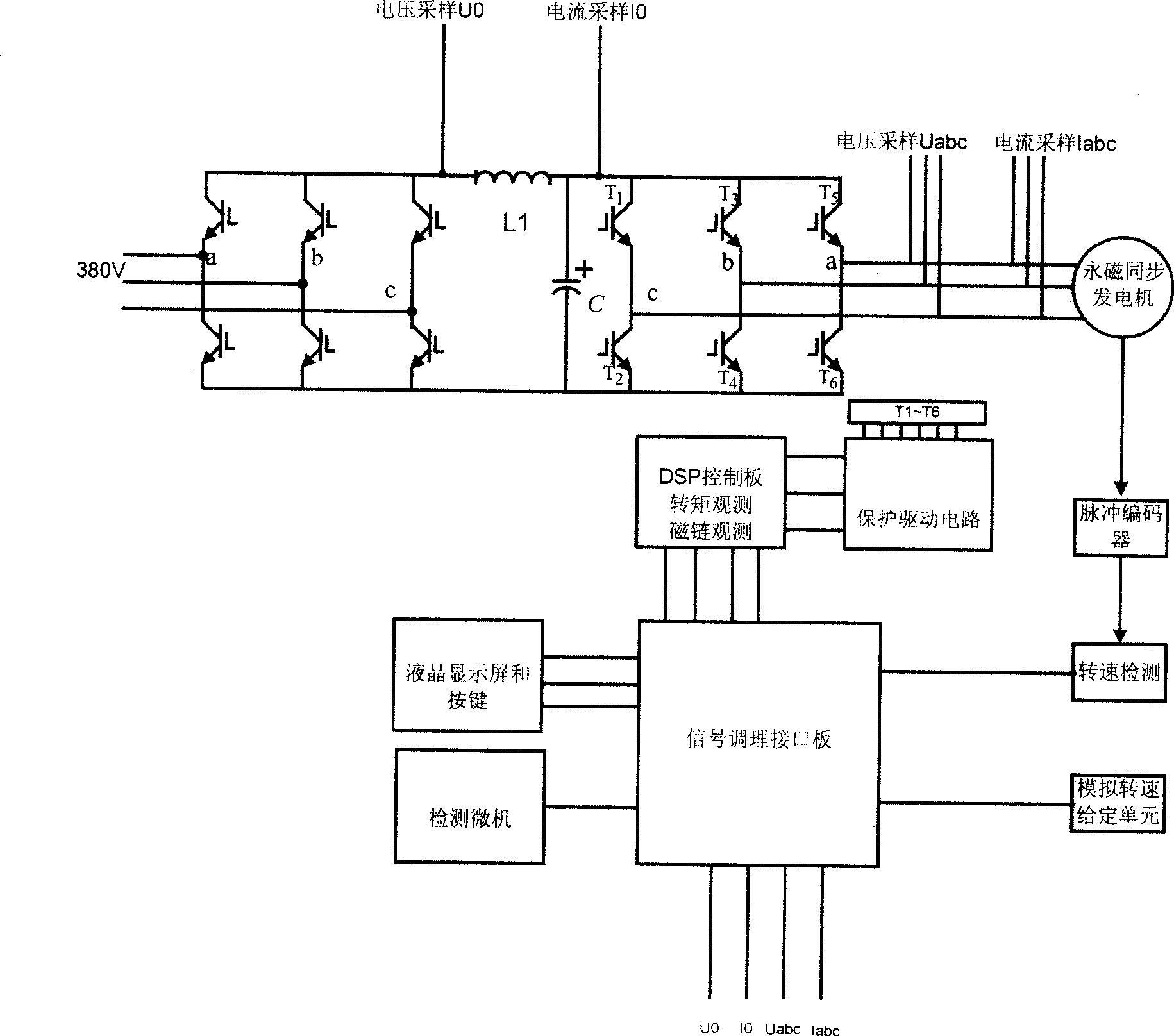

PMSM (permanent magnet synchronous motor) load simulation system and control method therefor

ActiveCN108983099AThe method steps are simpleEasy to implementDynamo-electric machine testingMicrocontrollerControl manner

The invention discloses a PMSM (permanent magnet synchronous motor) load simulation system and a control method therefor, and the system comprises a load simulation PMSM, a load simulation motor drivecircuit, and a data collection control system. The load simulation PMSM is connected with the output end of the load simulation motor drive circuit, and the output shaft of a tested motor is connected with the output shaft of the load simulation PMSM through the shaft coupler. The data collection control system includes a microcontroller, and the input end of the microcontroller is connected witha three-phase current sampling circuit, a three-phase voltage sampling circuit, a speed sensor and a torque sensor. The load simulation motor drive circuit is connected with the output end of the microcontroller. The control method includes the steps: 1, data collection and transmission; 2, data preprocessing 3, the control of the load simulation PMSM in an SVPWM direct torque control mode. The system can accurately simulate a load under different working conditions, has simple method steps, is convenient to implement, and is convenient for popularization and use.

Owner:XIAN UNIV OF SCI & TECH

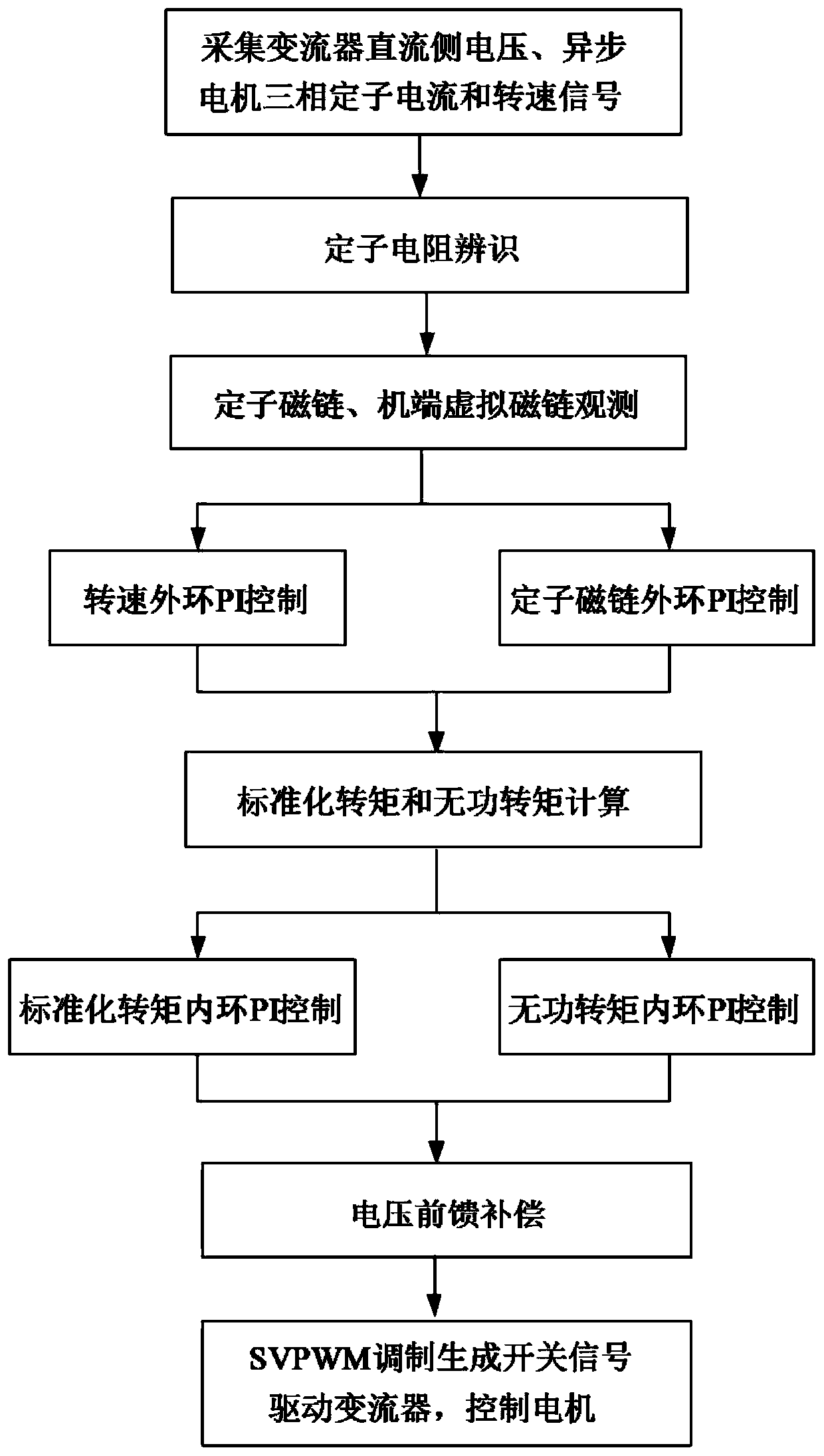

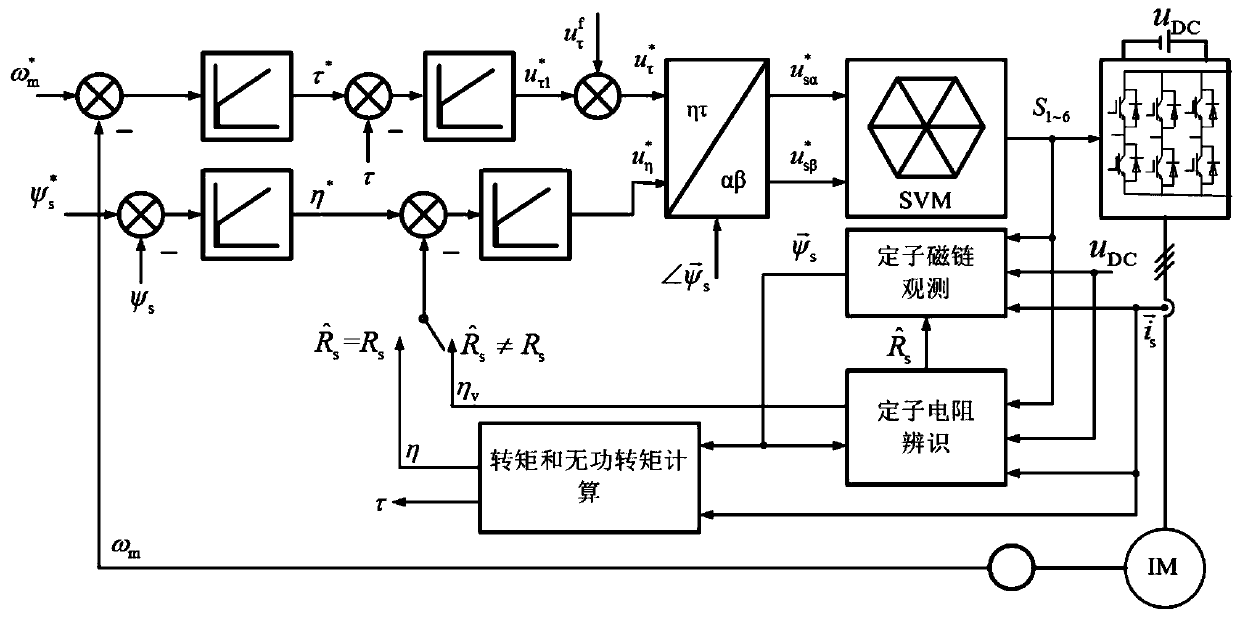

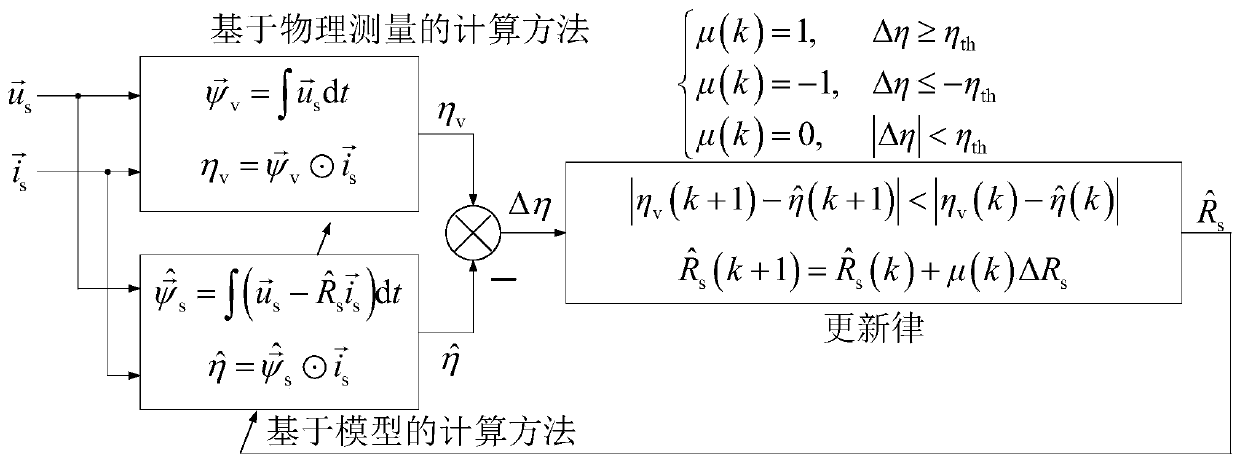

Asynchronous motor stator flux linkage and torque multi-time scale double-level voltage control method

ActiveCN111082722AImplement layered controlEasy to controlElectronic commutation motor controlAC motor controlLoop controlMathematical model

The invention discloses an asynchronous motor stator flux linkage and torque multi-time scale double-level voltage control method. The method comprises signal acquisition, stator resistance identification, flux linkage observation, standardized torque and reactive torque calculation, rotating speed and stator flux linkage outer loop control, standardized torque and reactive torque inner loop control, voltage feedforward compensation and SVPWM modulation. According to the invention, the reactive torque is provided, the reactive torque is corresponding to the reactive action component of the electromagnetic torque along the magnetic flux direction and the reactive power, a fast-changing reactive torque regulator and a torque regulator are arranged in an inner ring, a slow-changing rotating speed and flux linkage regulator is arranged in an outer ring, and the multi-time-scale hierarchical control of the system is realized; according to the independence of reactive power and resistance, the reactive torque eta is introduced into a stator resistance identification process by combining physical measurement based on a machine end and a calculation method of a mathematical model, so thatcontrol is more accurate; feedforward compensation is carried out on output utau1 * of an inner loop controller by adopting feedback linearization of torque and reactive torque, so that torque ripplesare reduced.

Owner:GUANGXI UNIV

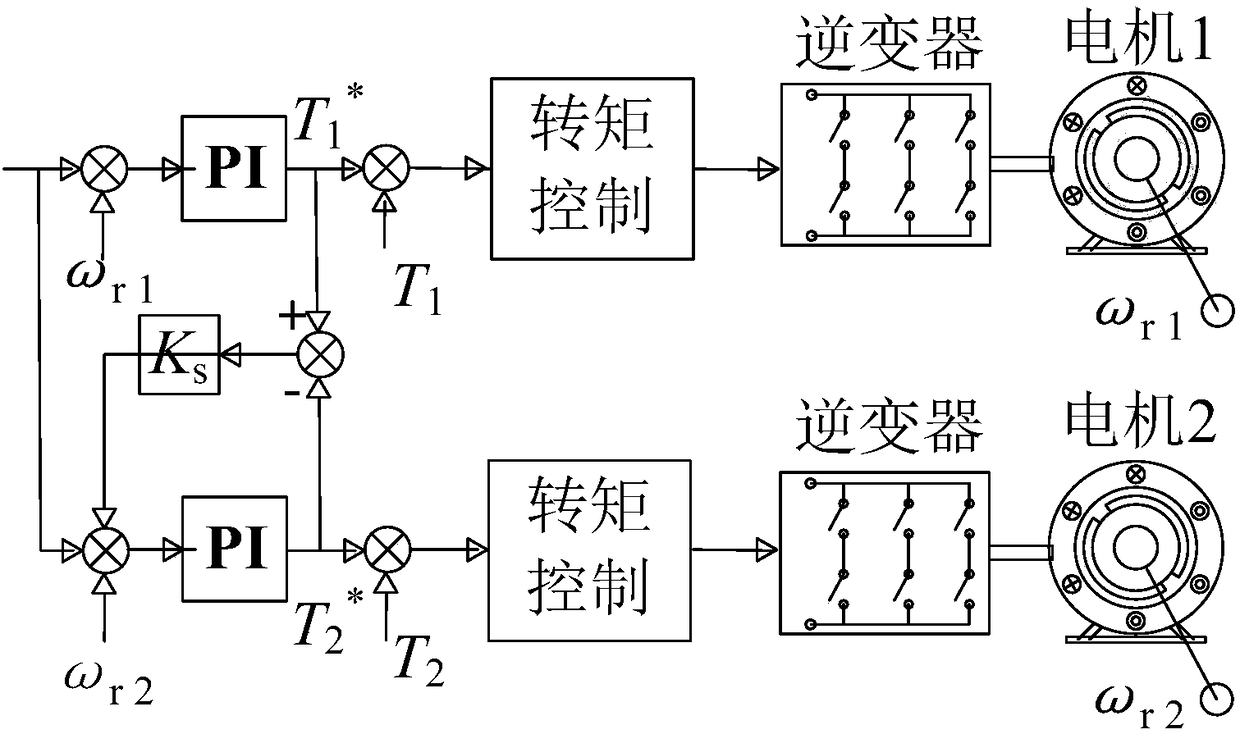

Two-motor torque balance control method

ActiveCN108173462ASolve the speed problemImprove unbalanced response speedElectronic commutation motor controlVector control systemsEngineeringHigh torque

The invention discloses a two-motor torque balance control method. By adoption of the method, a feedforward link is not needed, and the advantages of high torque response speed and almost no overshootquantity of direct torque control are integrated, so that torque imbalance response speed is improved, an adjustment operation of a feedforward coefficient is avoided, a control framework is greatlysimplified, and application simplicity and convenience is improved. According to the method, multi-motor torque is allocated and fused into a direct torque control algorithm, so that a direct torque control method applied to a single motor is modified and then applied to two motors to perform torque balance control; and therefore, the problems of low response speed, troublesome coefficient settingand the like in the conventional method are solved, the motor torque imbalance response speed is improved, the control structure is simplified, and application can be performed conveniently.

Owner:TIANJIN JINHANG COMP TECH RES INST

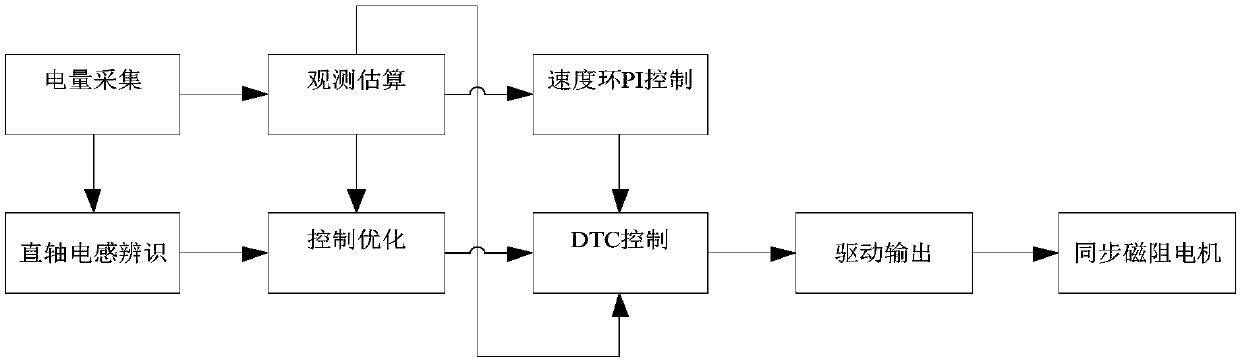

Sensorless DTC control method and control system of synchronous reluctance motor

PendingCN107592046AGuaranteed uptimeLarge starting torqueElectronic commutation motor controlAC motor controlSynchronous reluctance motorControl signal

The invention provides a sensorless DTC control method and control system of a synchronous reluctance motor, and relates to the field of motors. The speed control of the synchronous reluctance motor requires a speed sensor, a position pulse encoder or a magnetic flux transducer etc. to feedback information, the requirement of the installation structure is high, and the cost is high. The method includes following steps: 1) electric quantity acquisition; 2) observation estimation; 3) speed loop PI control; 4) direct-axis inductance identification; 5) control optimization; 6) DTC control; and 7)driving output: converting a control signal output by step 6) to an electric signal required by driving of the synchronous reluctance motor to realize the control of the synchronous reluctance motor.According to the technical scheme, the corresponding speed sensor or the position pulse encoder or the magnetic flux transducer does not needs to be installed, the installation is convenient, the structural requirement is reduced, the production cost is effectively reduced, the production efficiency is improved, stable and reliable operation of the synchronous reluctance motor can be effectively controlled, the starting torque is high, the dynamic performance is good, the steady-state operation efficiency is high, and the flux-weakening and speed-increasing capabilities are great.

Owner:WOLONG ELECTRIC GRP CO LTD

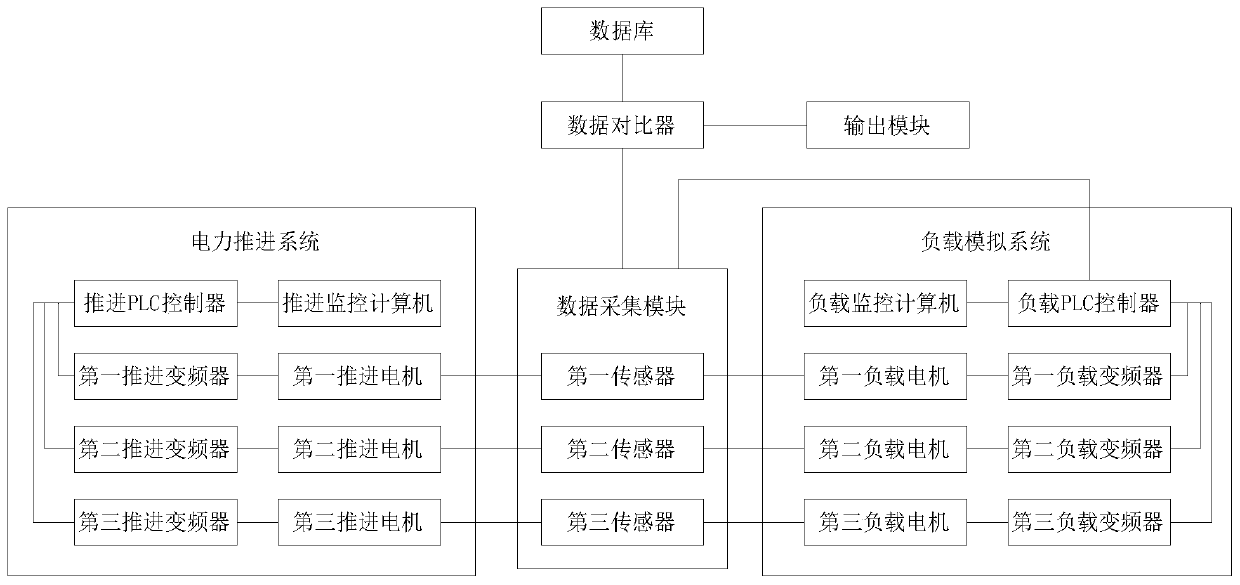

Ship electric propulsion system propeller load simulation system

InactiveCN110155246ACo-function correctStable jobVessel designingProgramme control in sequence/logic controllersPropellerData acquisition module

The invention discloses a ship electric propulsion system propeller load simulation system. The system involves an electric propulsion system, a load simulation system and a data acquisition module, wherein the data acquisition module is used for acquiring data of the electric propulsion system and the load simulation system, the data acquired by the data acquisition module are sent to a data comparator, the data comparator compares the data of the data acquisition module with the data of a database. According to the system, a load frequency converter is used for controlling the operation of aload motor, so that torque which is the same as an actual shaft load torque of a propulsion motor is generated, multiple sets of load simulation are carried out at the same time, the common functionof the load simulation system is correct, the work is stable, the data acquisition period can reach 50 ms, torque control precision is 0.4% or within, control structure is simple, simulation parameters are convenient to set, system torque response is fast, control precision is high, and the problem of low control precision of data such as the rotating speed and the torque of an existing propellerload simulation system is solved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Control structure of full power type AC-DC-AC converter for wind power generation

ActiveCN100486093CReduce switching timesReduce switching lossesElectronic commutation motor controlVector control systemsPower factorDc ac converter

The invention relates to a controller of full-power alternative-direct converter used in wind generation, wherein the alternative-direct converter is formed by network converter and the convert of generator; the used generator is a permanent-magnetic generator; the rotor is in permanent-magnetic structure, without external magnetic activate power supply; two convert loops both uses the PWM converters operating in four quadrants, based on full-control element, which can improve the dynamic response, reduce cost and impact, realize bidirectional transmission of electricity, and realize generating via power factor sine wave current parallel network; and the invention uses improved direct torque technique to control the converter, to confirm the sine wave change of input current at the stator, with quick response, low vibration, torque dynamic control and wide speed adjust range.

Owner:SUNGROW POWER SUPPLY CO LTD

Variable-current variable-speed non-commutated permanent magnet direct current motor

PendingCN108322001ASmall frictional resistanceExtended service lifeMagnetic circuit rotating partsElectric machinesElectric vehicleDynamo

The invention discloses a variable-current variable-speed non-commutated permanent magnet direct current motor, belongs to the field of direct current motors, and solves the problem that the existingdirect current motor consumes a lot of electric energy so as to overcome a magnetic pull of a permanent magnet stator to a rotor. The variable-current variable-speed non-commutated permanent magnet direct current motor comprises a pedestal, a coil inner rotor, a permanent magnet inner stator, a coil outer rotor and a permanent magnet outer stator, and further comprises a rotor shaft, rotor shaft supports, a rotor shaft magnetic levitation inner sleeve, a rotor shaft magnetic levitation outer sleeve, a support magnetic levitation inner sleeve and a support magnetic levitation outer sleeve, wherein the two ends of the rotor shaft are arranged inside support bearings of the two rotor shaft supports; the rotor shaft is tightly sleeved inside the inner cavity of the coil inner rotor; the rotorshaft magnetic levitation inner sleeve is sleeved inside external-diameter openings of the two ends of the coil inner rotor; the rotor shaft magnetic levitation outer sleeve is tightly sleeved insideinternal-diameter openings of the two ends of the permanent magnet inner stator. A high-power ultrahigh-speed permanent magnet direct current motor or generator can be manufactured as required; the variable-current variable-speed non-commutated permanent magnet direct current motor is applicable to the field, which needs power or power generation, of electric vehicles, industrial and mining enterprises and the like.

Owner:甘肃永动电子科技发展有限公司

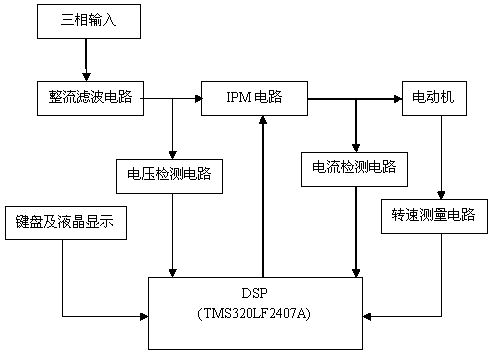

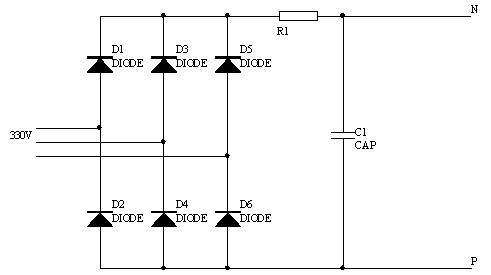

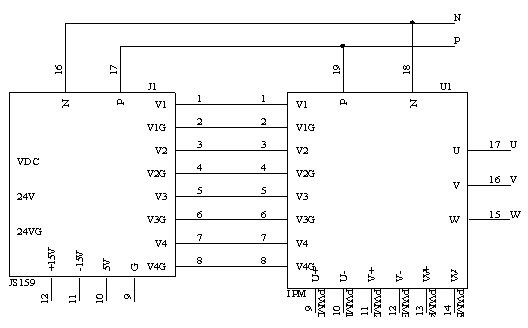

PWM variable frequency speed control system based on control of DSP

InactiveCN103368489ARealize frequency conversion speed regulationSimple structureElectronic commutation motor controlAC motor controlVoltage vectorControl signal

The invention relates to a PWM variable frequency speed control system based on the control of a DSP, and belongs to the technical field of intelligent electrical engineering and electric apparatuses. A motor and an inverter are seen as a whole. A space voltage vector analytical method is adopted for conducting flux linkage and torque calculation on a stator coordinate system, and the torque is directly controlled through a selection of different on-off states of the inverter. Direct torque control is adopted in a control method, and is another novel efficient variable frequency speed control technology after the vector control technology. The direct torque control technology is adopted in the stator coordinate system for calculating the flux linkage and the torque of the motor. Firstly, a dibit controller is adopted, two control signals are directly utilized in the PWM inverter to generate output voltage, and rotation transformation and current control are eliminated, so that the structure of the controller is simplified. Secondly, the stator flux linkage is selected as a controlled variable, so that the model calculating the flux linkage cannot be affected by rotor change, and robustness of the system is improved. Moreover, due to the fact that direct torque control is adopted, rapid torque response can be acquired in the speed-up, speed-down and load change dynamic processes, and variable frequency speed control can be simply and effectively conducted.

Owner:朱金荣

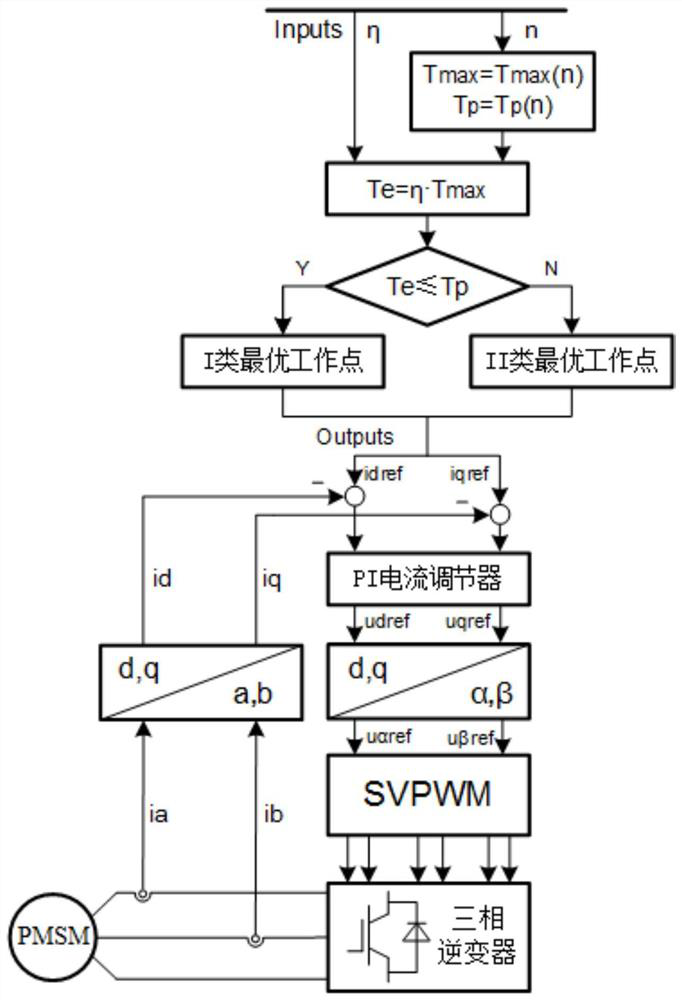

Field Weakening Control Method for Full Speed Range of Permanent Magnet Synchronous Motor

ActiveCN108258957BSimplified Calibration ControlReduce copper lossElectronic commutation motor controlAC motor controlMaximum torqueElectric machine

The invention relates to a full-rotation-speed-range weak magnetic control method of a PMSM. A maximal torque-rotating speed characteristic curve 3D table of the motor is obtained by calibration; a work point in an MTPA (Maximum Torque per Ampere) curve is obtained by calibration, and a switching torque-rotating speed characteristic curve 3D table is obtained by calibration; the maximal torque andswitching torque that can be output in the present rotating speed are obtained; a target output torque in the state is obtained; and an obtained rotating speed-torque-current is looked up to obtain the optimal weak-magnetic work current in the present state. Via the control method, a control strategy for realizing high-efficiency weak-magnetic control for the PMSM in the full rotation speed rangeis obtained, the strategy can be used to simplify calibration control of the PMSM, the optimal work state of the motor is determined in the full rotation speed range, copper loss of the motor is reduced greatly, the control precision is high, response to the torque is rapid, the control efficiency is high, realization is simple and the versatility is high.

Owner:BIT HUACHUANG ELECTRIC VEHICLE TECH

A three-DC motor series system and torque control method

ActiveCN111464080BSimple structureLow costDC motor speed/torque controlElectric motor speed/torque regulationSquare waveformClassical mechanics

The invention discloses a series system of three direct current motors and a torque control method. The rotational speed deviation is generated through a PI regulator to generate three current reference signals; the armature currents of three direct current motors are obtained through current sampling and calculation; the three current reference signals are The signal uses the reference torque synthesis algorithm to synthesize four-way reference torque; the armature current of the three DC motors uses the feedback torque synthesis algorithm to become four-way synthetic feedback torque; the four-way torque reference signal and the four-way torque feedback signal The deviations of the four torque hysteresis controllers are respectively input to the reverse input terminals of the four-way torque hysteresis controller, and output a square wave signal whose amplitude upper limit and lower limit are inverse numbers; the torque hysteresis controller is converted to The adjusted signal is generated by PWM to generate four pairs of two-two complementary level signals, which are input to the four-leg eight-switch inverter to realize the independent four-quadrant operation of three DC motors connected in series. The invention simplifies the system and improves the stability and response speed of the system.

Owner:CHANGAN UNIV

A Direct Torque Control Method Applicable to Multi-motor System

ActiveCN103944459BFast torque responseReduce torque fluctuationElectronic commutation motor controlVector control systemsVoltage vectorElectric machine

The invention discloses a direct torque control method suitable for a multi-motor system. Firstly, a torque and flux linkage evaluating function of the multi-motor system is established; a torque and flux linkage impact factor table is obtained through the discretization and equalization processing on the evaluating function; then, the torque reference value of a single motor is generated through a deviation coupling controller of the multi-motor system; lastly, a torque impact factor reference value p Tau* and a flux linkage impact factor reference value p Lambada* are calculated, an objective function is established, and an inverter voltage vector enabling the value of the objective function to be minimum is selected according to the torque and flux linkage impact factor table and is used for controlling the multi-motor system. According to the direct torque control method, fast torque responses of the multi-motor system can be achieved, and torque ripples in steady-state operation can be lowered; the impact degrees of different inverter voltage vectors on the electromagnetic torque and the motor stator flux linkage amplitude of the multi-motor system under the action of different duty ratios can be comprehensively, directly and finely reflected through the established torque and flux linkage impact factor table.

Owner:TIANJIN UNIV

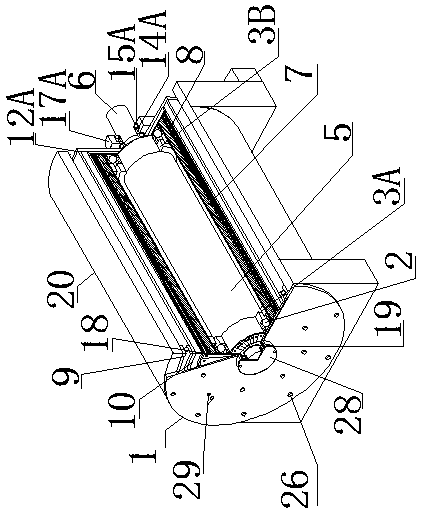

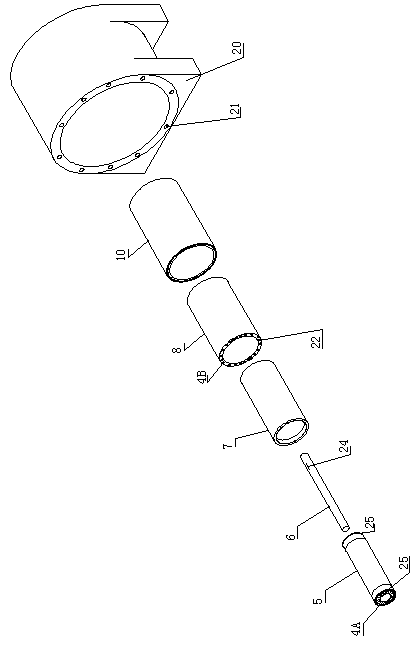

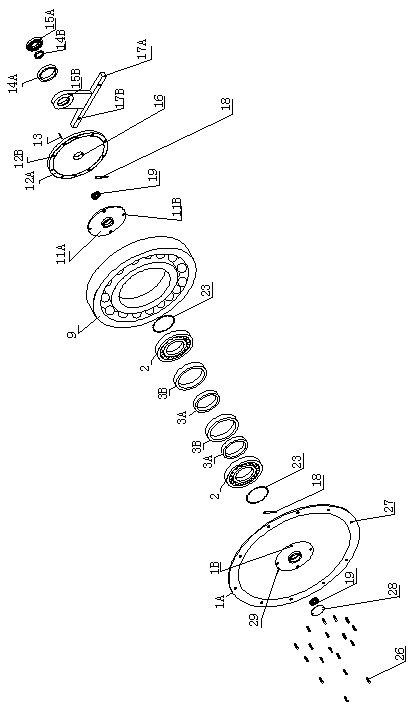

Variable-flow speed-change brushless non-reversing permanent magnet direct-current motor

PendingCN108288898AFast torque responseHigh utilization rate of permanent magnet energyMagnetic circuit rotating partsSupports/enclosures/casingsStator coilElectrical polarity

The invention discloses a variable-flow speed-change brushless non-reversing permanent magnet direct-current motor, and belongs to the field of direct current motors, aiming to solve the problems thatan existing motor is poor in speed regulation characteristic, large in power consumption and high in manufacturing cost. The variable-flow speed-change brushless non-reversing permanent magnet direct-current motor comprises a machine base, a permanent magnet inner rotor, a permanent magnet outer rotor, a coil inner stator and a coil outer stator, wherein a rotor shaft is arranged in the coil inner stator, a rotor shaft support bearing, and a permanent magnet magnetic suspension inner sleeve and a permanent magnet magnetic suspension outer sleeve that are in the same polarity are arranged at the right end of the rotor shaft, and the permanent magnet magnetic suspension inner sleeve is arranged in the permanent magnet magnetic suspension outer sleeve in a sleeved mode, a coil inner stator permanent magnet magnetic suspension inner sleeve is fastened in the outer diameter of the two ends of the coil inner stator in a sleeved mode, and the openings of the inner diameter of the two ends ofthe permanent magnet inner rotor are tightly sleeved with a coil inner stator permanent magnet magnetic suspension outer sleeve with the same polarity. The stator coil has the advantages of no iron core, no iron loss and high torque response, the utilization rate of the permanent magnetic energy is high, the power consumption is low, the variable speed is achieved through the variable flow, and the super-high speed operation can be achieved.

Owner:甘肃永动电子科技发展有限公司

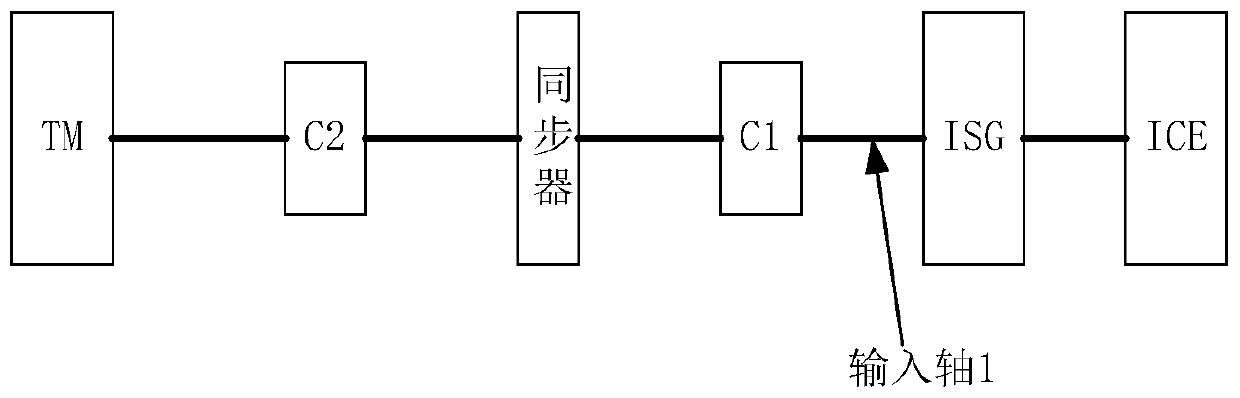

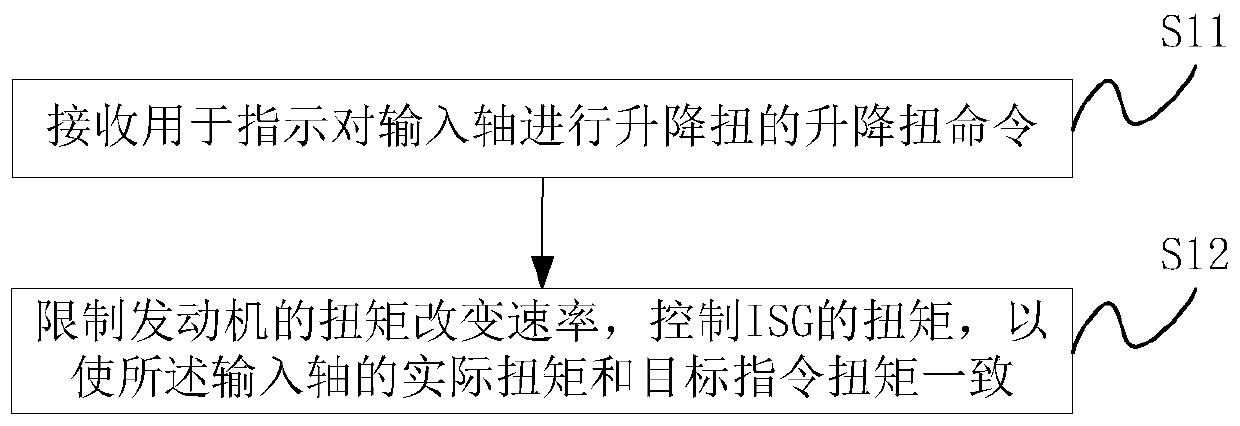

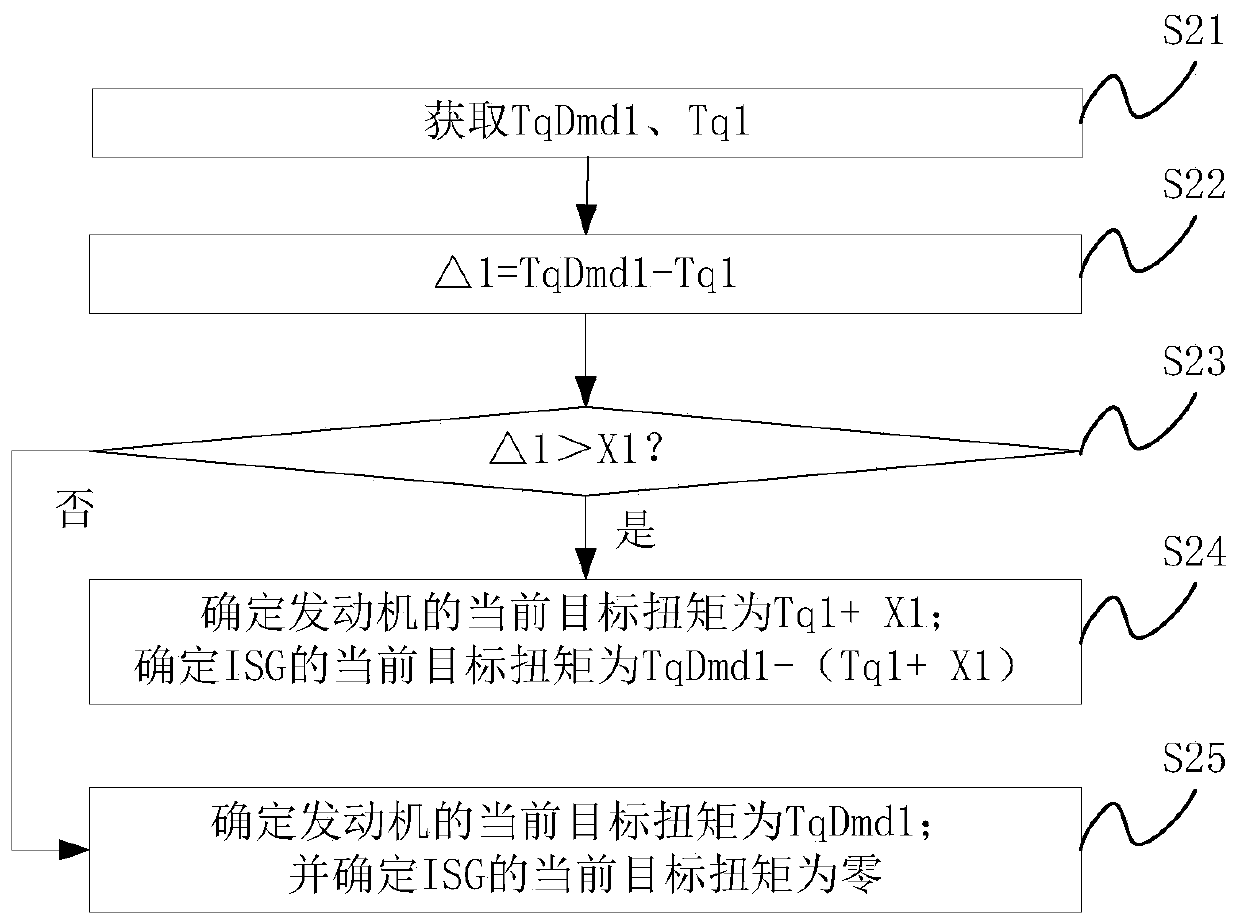

A power source torque distribution method and device for a plug-in hybrid electric vehicle

ActiveCN109693660BFast torque responseImprove driving comfortHybrid vehiclesControl devicesDriver/operatorHybrid electrical vehicle

The invention discloses a power source torque distribution method and device for a plug-in hybrid electric vehicle. The method comprises the steps: receiving a lifting torque command for an input shaft, limiting the torque change rate of an engine, and controlling the torque of an ISG, so that the actual torque of the input shaft is consistent with a target instruction torque. The torque change rate of the engine is limited and the residual torque demand of the input shaft is provided by the ISG; the torque response of the ISG is fast, so that the problems that the torque change is slow and the power interruption time is too long due to the slow torque response of the engine can be avoided, the driving smoothness of a vehicle is improved, and then the driving experience of a driver is improved.

Owner:SAIC MOTOR

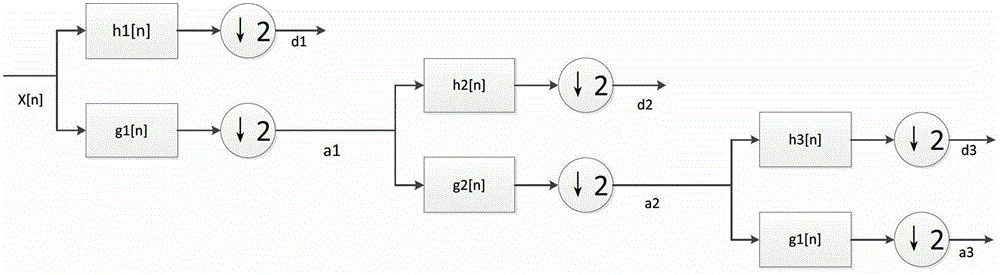

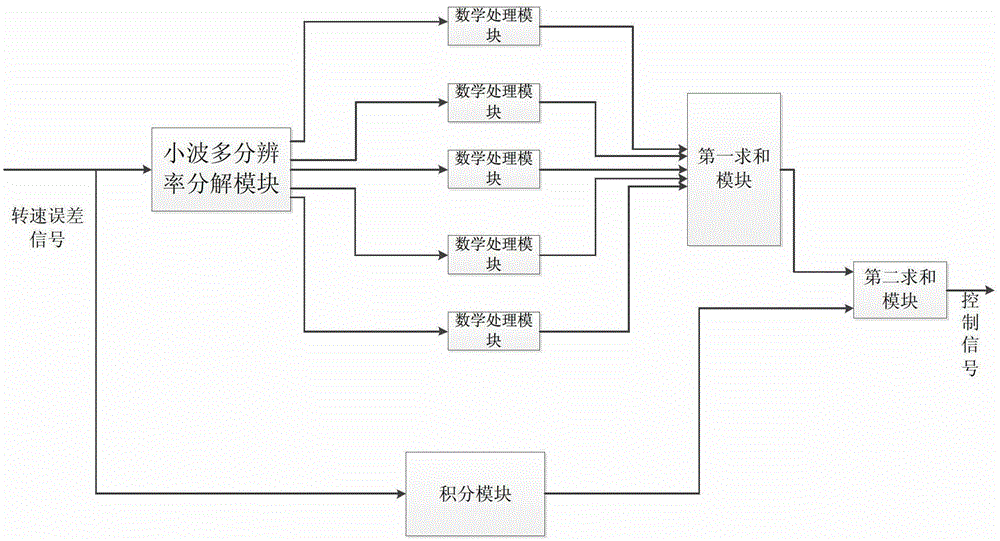

A direct torque control system and method for a permanent magnet synchronous motor for an electric vehicle

ActiveCN103346710BNovel thinkingSimple structureTorque ripple controlSingle motor speed/torque controlVoltage vectorPermanent magnet synchronous motor

The invention discloses a system and method for controlling direct torque of a permanent magnet synchronous motor for an electric automobile. According to the method, a three-phase current, a voltage and an inverter direct-current bus voltage output by an inverter are firstly detected, electromagnetic torque, a stator flux linkage and the section area theta where the stator flux linkage is located under a current state are obtained through a torque, magnetic linkage and theta calculating unit, small-wave multi-resolution MRPID control and integral structure composite control are adopted in a speed ring, the calculated magnetic linkage and the calculated torque are compared with the given magnetic linkage and the given torque signal output by a composite control adjustor respectively, the current error state of the magnetic linkage and the torque is output and decides a selected voltage vector together with the section area where the magnetic linkage is located, and therefore the on-off state of the inverter is further decided, and the operation of the permanent magnet synchronous motor is controlled. The system and method for controlling the direct torque of the permanent magnet synchronous motor for the electric automobile has the advantages of being simple in structure, novel in concept, fast in response and the like, the small-wave multi-resolution MRPID control and the integral structure composite control are adopted in the speed ring, and the control has the advantages of being wide in control range, high in precision, fast in response and the like.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com