PMSM (permanent magnet synchronous motor) load simulation system and control method therefor

A permanent magnet synchronous motor and load simulation technology, applied in the direction of motor generator testing, etc., can solve the problems of prone to flying, not controlling the speed of the permanent magnet synchronous motor load simulation system, unable to test the dynamic performance of the motor load, etc., to avoid flying. phenomenon, easy to popularize and use, and the effect of improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

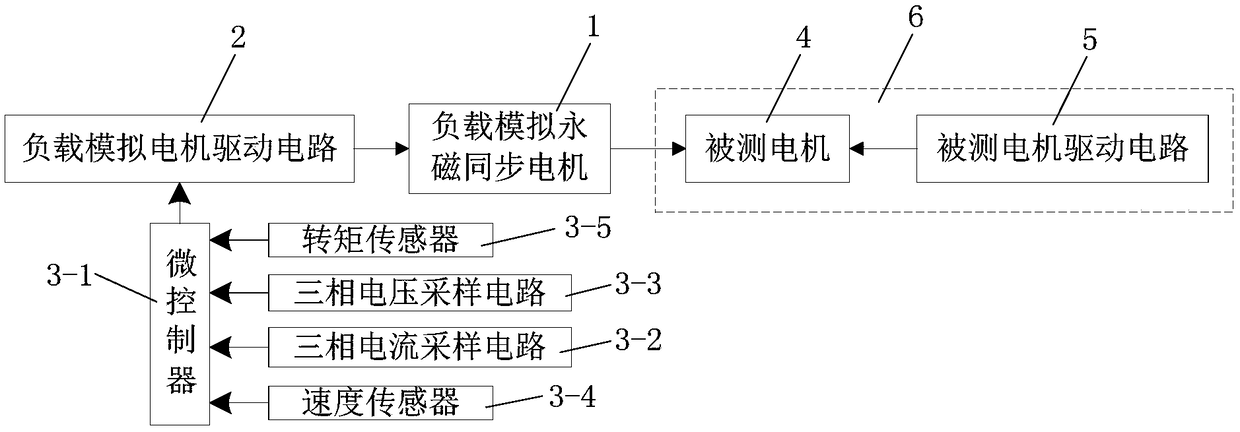

[0055] Such as figure 1 As shown, the permanent magnet synchronous motor load simulation system of the present invention is used to provide a load for the tested motor 4, including a load simulation permanent magnet synchronous motor 1 and a load simulation motor drive circuit 2 for driving the load simulation permanent magnet synchronous motor 1 , and a data acquisition control system; the load simulation permanent magnet synchronous motor 1 is connected to the output end of the load simulation motor drive circuit 2, and the output shaft of the measured motor 4 is connected to the load simulation permanent magnet synchronous motor 1 through a shaft coupling The output shaft is connected; the data acquisition control system includes a microcontroller 3-1, and the input terminal of the microcontroller 3-1 is connected with a three-phase current for sampling the three-phase current of the load simulation permanent magnet synchronous motor 1 Sampling circuit 3-2, a three-phase vo...

Embodiment 2

[0060] The load to be simulated in this embodiment is a potential energy load, and this type of load can drive the motor to reverse. In the process of simulating this type of load, when the output torque of the load simulation permanent magnet synchronous motor 1 is greater than the output torque of the tested motor 4, the tested motor 4 can no longer drive the load simulation permanent magnet synchronous motor 1 to rotate, and the load simulates the permanent magnet synchronous The speed of motor 1 gradually decreases until it is 0. At this time, the load simulated permanent magnet synchronous motor 1 starts to drive the motor 4 under test to reverse.

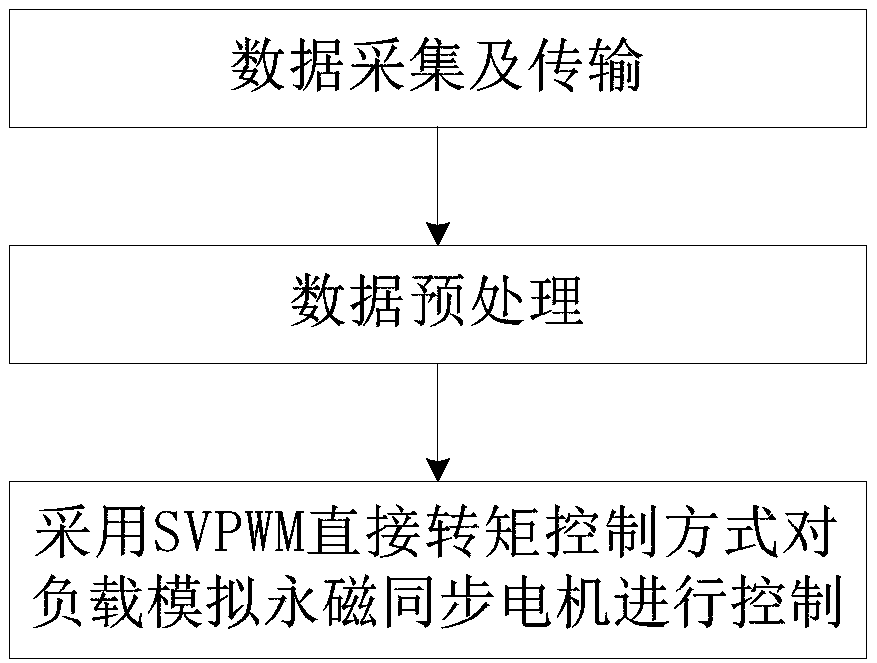

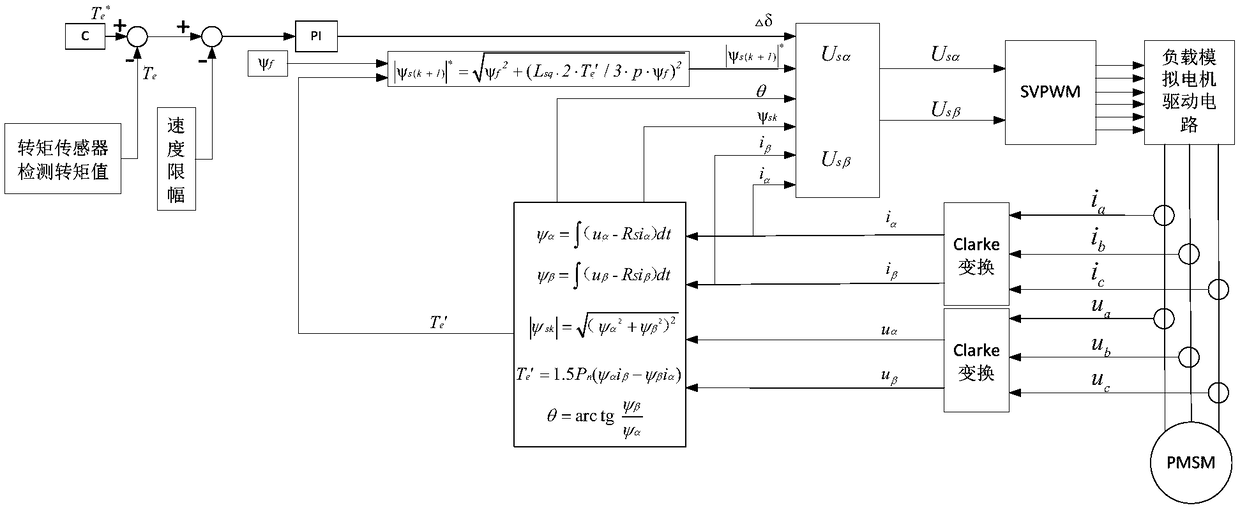

[0061] Such as figure 2 with image 3 As shown, the control method of the permanent magnet synchronous motor load simulation system of the present invention comprises the following steps:

[0062] Step 1, data collection and transmission: the three-phase current sampling circuit 3-2 collects the A-phase current, B-phase cur...

Embodiment 3

[0082] The load to be simulated in this embodiment is a resistive load, and this type of load cannot drive the motor to reverse. In the process of simulating this type of load, when the output torque of the load simulation permanent magnet synchronous motor 1 is greater than the measured motor 4, the load simulation permanent magnet synchronous motor 1 cannot drive the measured motor 4 to reverse. When the load simulates the direction of the rotational speed of the permanent magnet synchronous motor 1 and the torque given value T e * When the directions are the same, the output torque of the load simulated permanent magnet synchronous motor 1 is greater than the output torque of the measured motor 4. It is necessary to adjust the torque to control the load simulated permanent magnet synchronous motor 1 not to drive the measured motor 4 to reverse. Thereby simulating a resistive load.

[0083] Such as figure 2 with Figure 4 As shown, the control method of the permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com