Iron core loss-based direct torque control method for ultra-high-speed permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and direct torque control, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of angular velocity error growth, pulse width modulation distortion, iron loss, etc. Small angle error, good dynamic performance, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It is easy to understand that, according to the technical solution of the present invention, without changing the essence of the present invention, those skilled in the art can imagine the direct torque control method of the ultra-high-speed permanent magnet synchronous motor in the present invention based on iron core loss. Various implementations. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

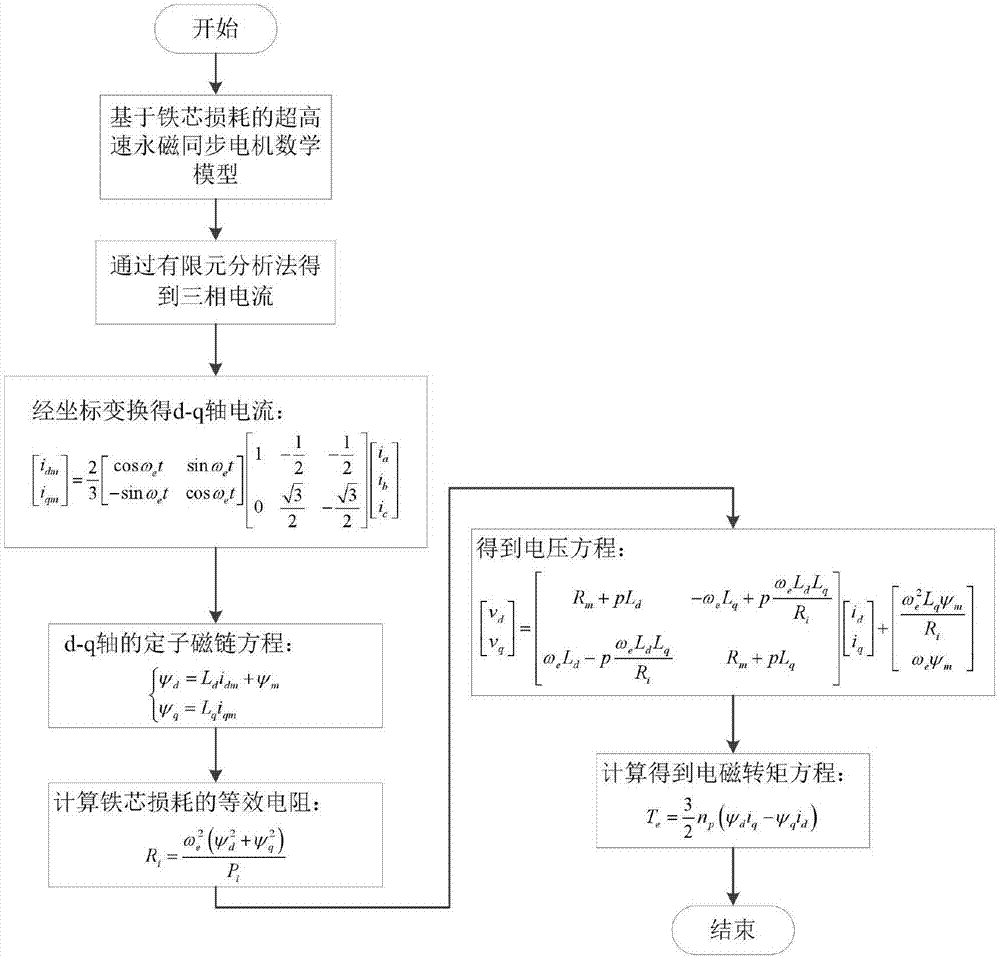

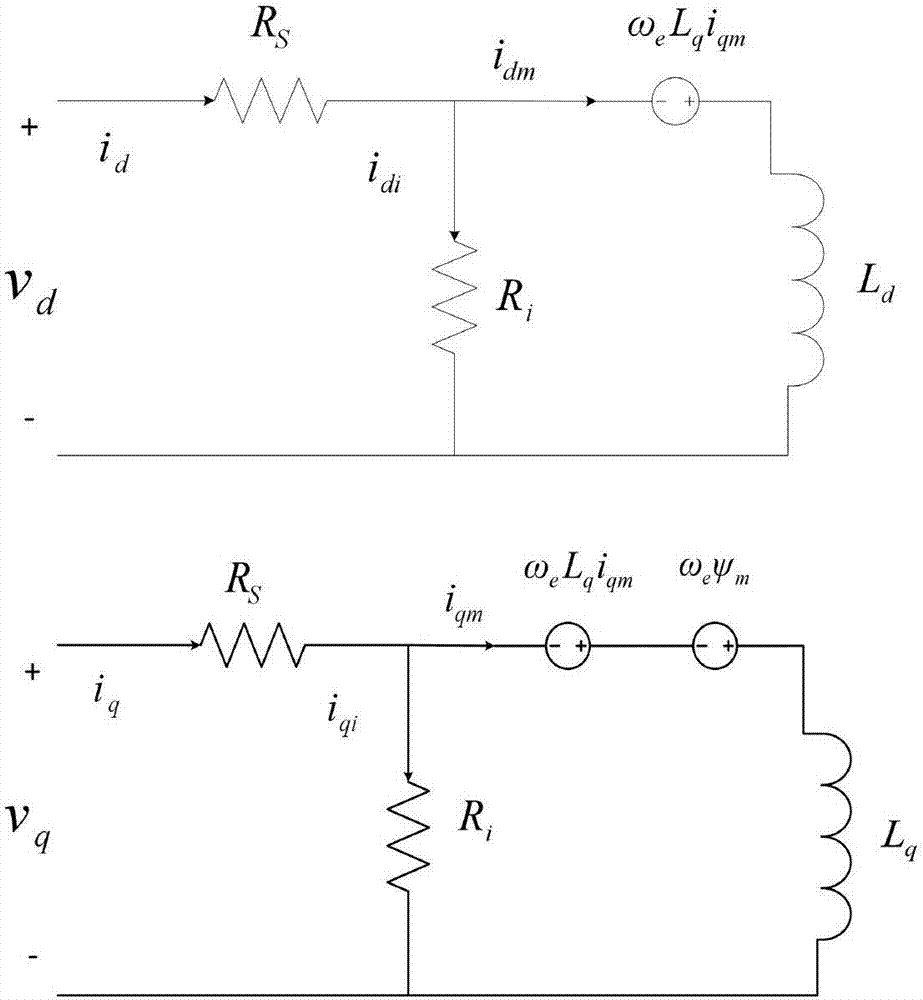

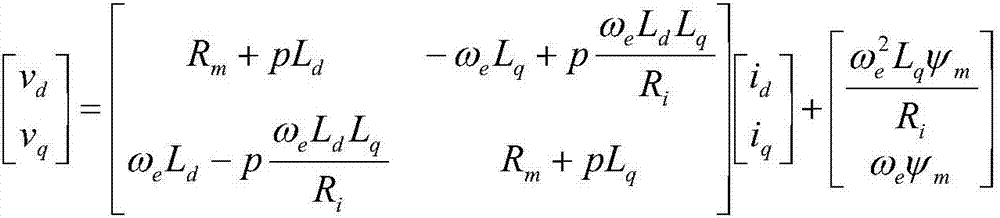

[0029] In the direct torque control of ultra-high-speed permanent magnet synchronous motor, it is necessary to use the mathematical modeling of ultra-high-speed permanent magnet synchronous motor, including voltage equation, flux equation and torque equation. The invention proposes a voltage equation considering iron loss for direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com