A direct torque control system and method for a permanent magnet synchronous motor for an electric vehicle

A permanent magnet synchronous motor, direct torque control technology, applied in the direction of single motor speed/torque control, torque ripple control, etc., can solve the problems of direct torque control flux linkage and torque ripple, poor low-speed performance, etc. Achieve the effect of rapid torque response, fast response speed, and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

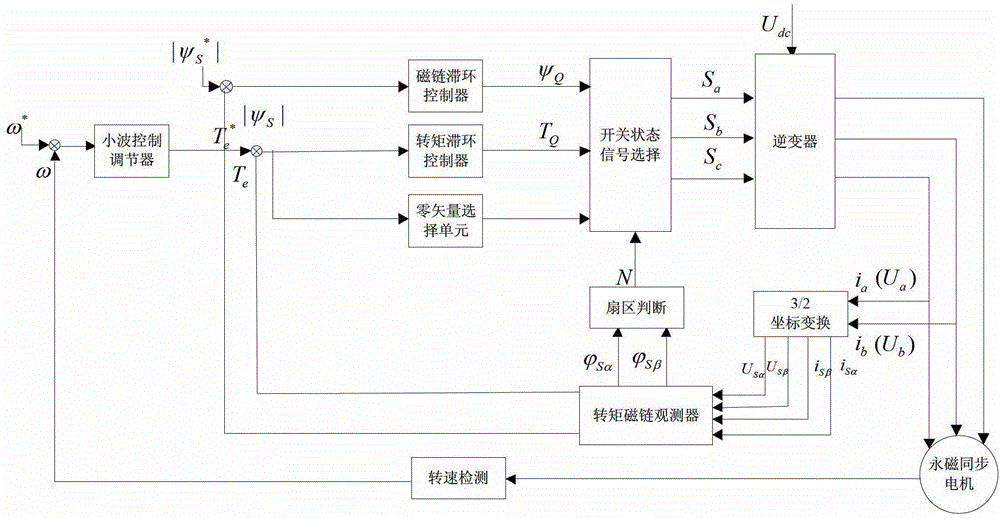

[0024] Such as figure 1 Shown: the permanent magnet synchronous motor direct torque control system for electric vehicles of the present invention includes a torque flux observer, a sector judgment unit, a switch state signal selection unit, a rotational speed detection unit, a composite control regulator, and a flux linkage hysteresis loop A controller, a torque hysteresis controller, a zero vector selection unit, an inverter, and first, second and third computing units. Wherein, the torque flux observer is connected to the output terminal of the permanent magnet synchronous motor through a coordinate conversion unit to detect the current and voltage of the permanent magnet synchronous motor, and the speed detection unit is connected to the output terminal of the permanent magnet synchronous motor end, to detect the speed of the permanent magnet synchronous motor, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com