Electric tractor

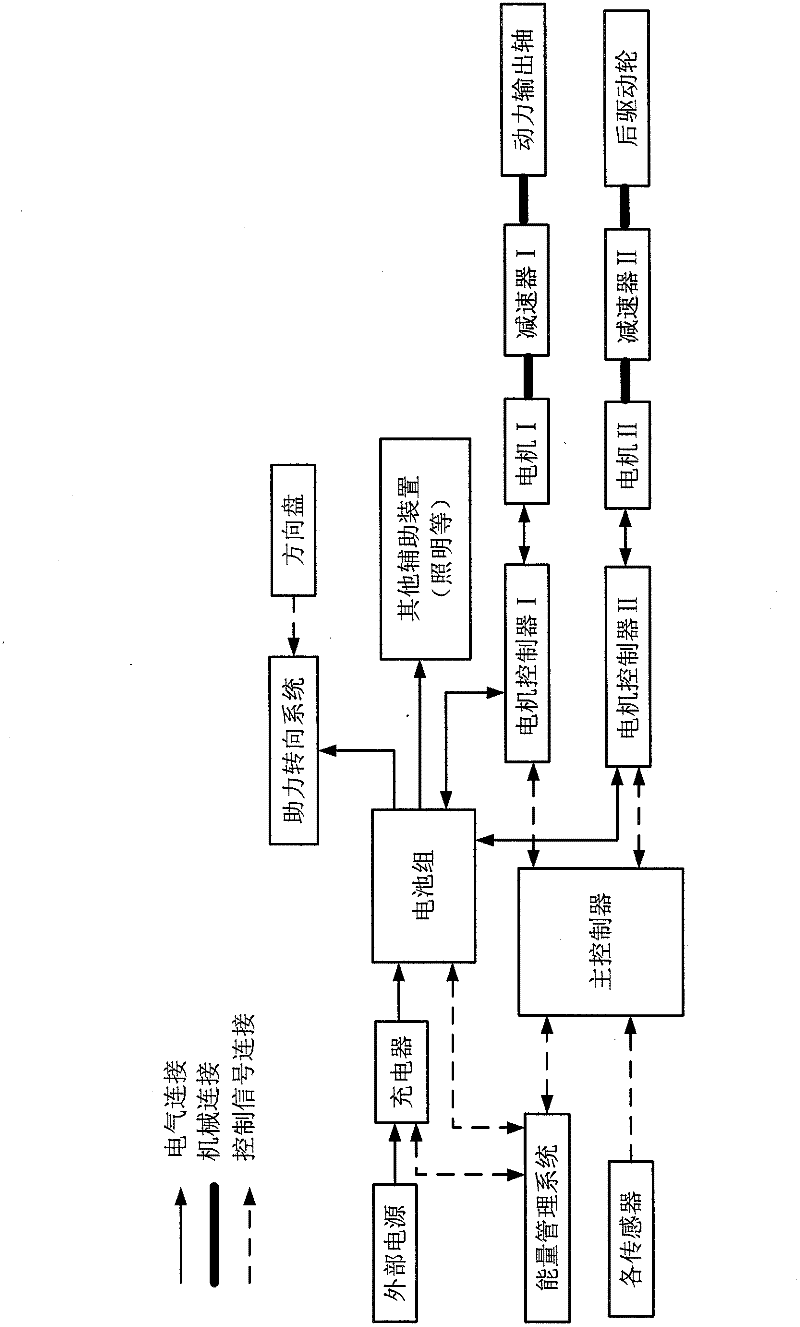

A tractor, electric technology, applied in electric vehicles, electric power devices, electric braking systems, etc., can solve the problems of low system efficiency, low energy conversion efficiency, high noise, etc., achieve ultra-low pollution emissions, improve utilization, The effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

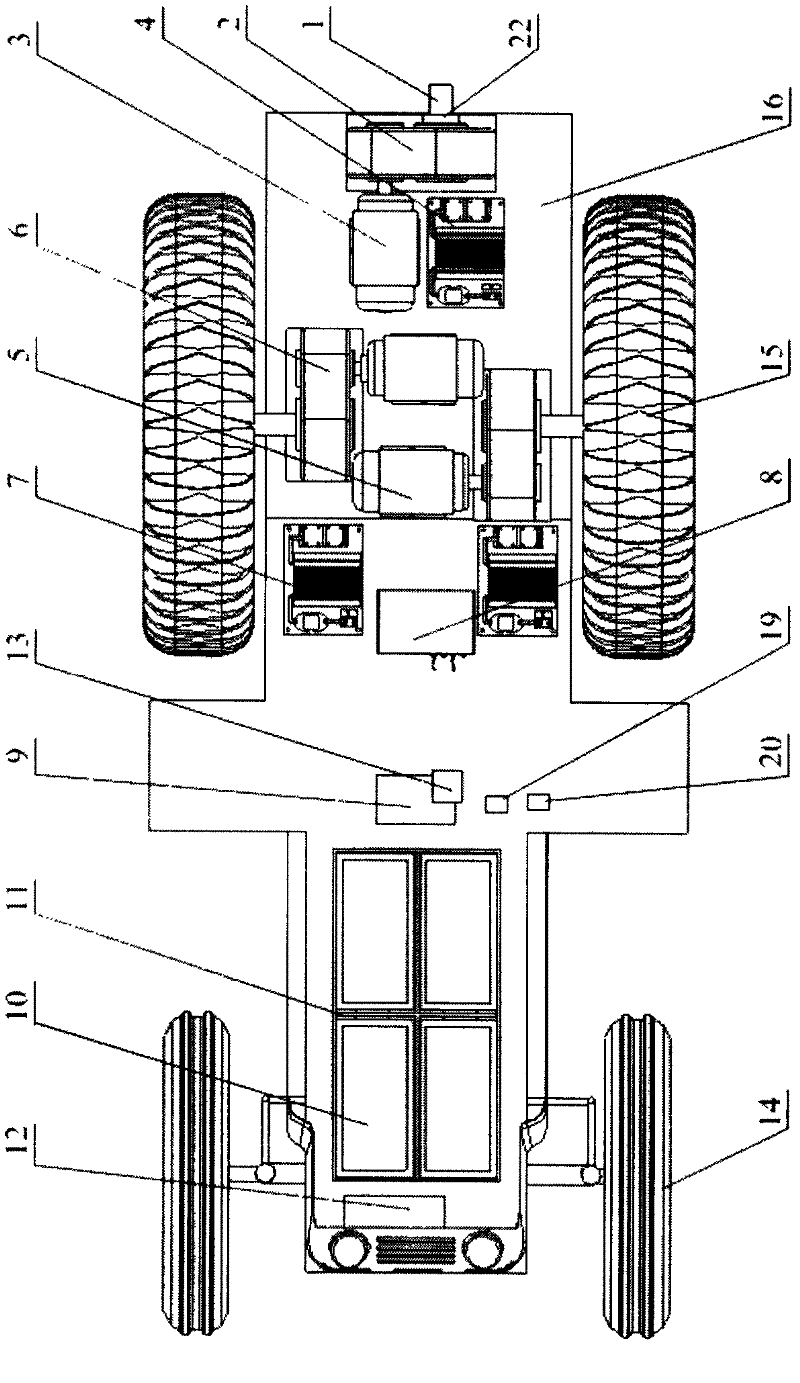

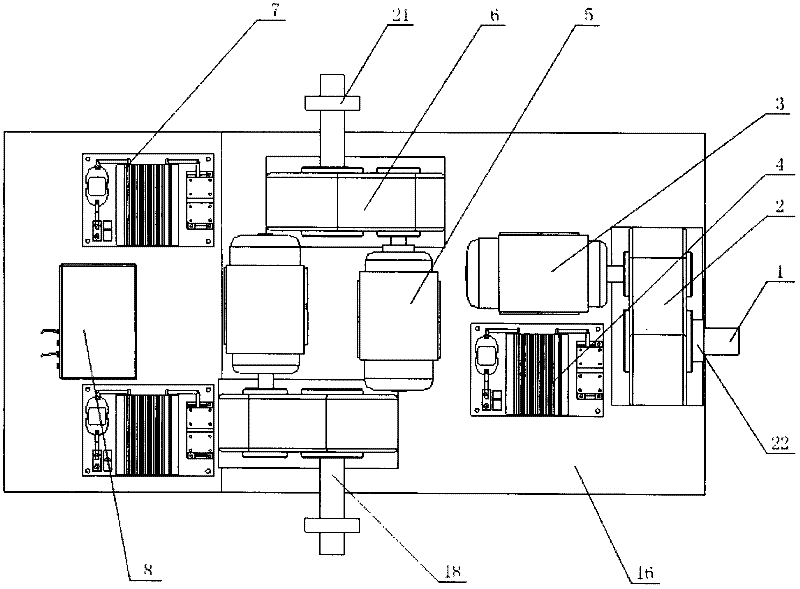

[0032] Embodiment: when the electric tractor drives straight ahead and needs to be accelerated, the driver depresses the accelerator pedal, and the accelerator pedal sensor (19) transmits this acceleration signal to the main controller (8), and the main controller (8) according to the acceleration signal After the size is determined, the drive wheel (15) needs to accelerate the size of the electric power. At the same time, the main controller (8) cooperates with the energy management system (12) to control the discharge of the battery pack (10), and the electric energy of the battery pack (10) passes through the motor controller. II(7) is transmitted to the motor II(5), the motor controller II(7) adjusts the torque or speed of the motor II(5), and the motor II(5) realizes electric energy conversion, and converts the transmitted electric energy into the motor II( 5) output the mechanical energy of the shaft, and then transmit the mechanical energy to the reducer II (6), the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com