Pneumatic experimental table for loading electrical actuator

A technology of electric actuators and test benches, which is applied in the direction of electric power measurement through current/voltage, instruments, and electric devices, etc., which can solve the problems of long maintenance cycle of pneumatic brakes, narrow applicable torque range, and increased magnetic force of magnetic powder. Achieve fast loading, fast response, easy maintenance, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

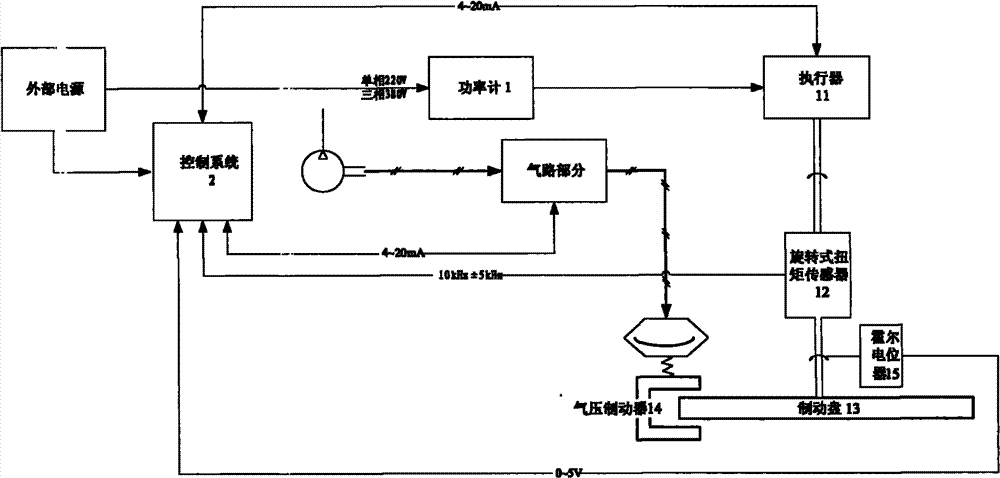

[0029] The electric actuator test bench of the present invention adopts a pneumatic loading method, that is, the pneumatic brake is used as the load of the actuator. The test bench has a compact structure, can reach the maximum load in a very short time (<0.1s), has good low-speed and high-speed torque controllability, does not need water cooling and forced air cooling, and has high temperature resistance.

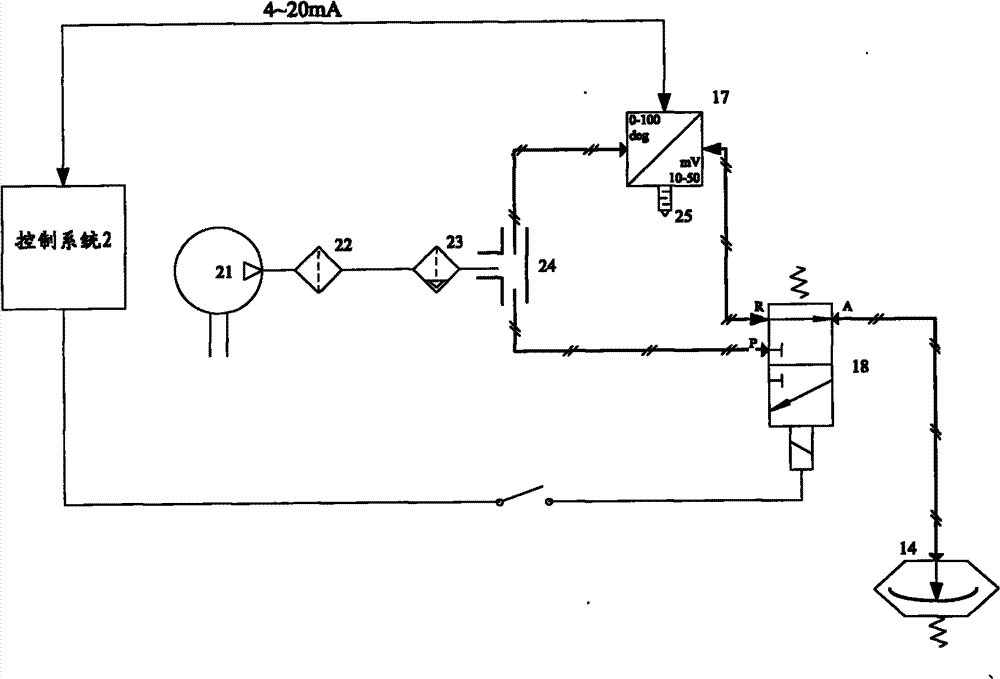

[0030] The test bench uses 0-8Bar compressed air commonly used in factories and laboratories as the power source, and realizes slow loading and fast loading by switching the air circuit and adjusting the given air pressure, and at the same time realizes variable speed release of the load.

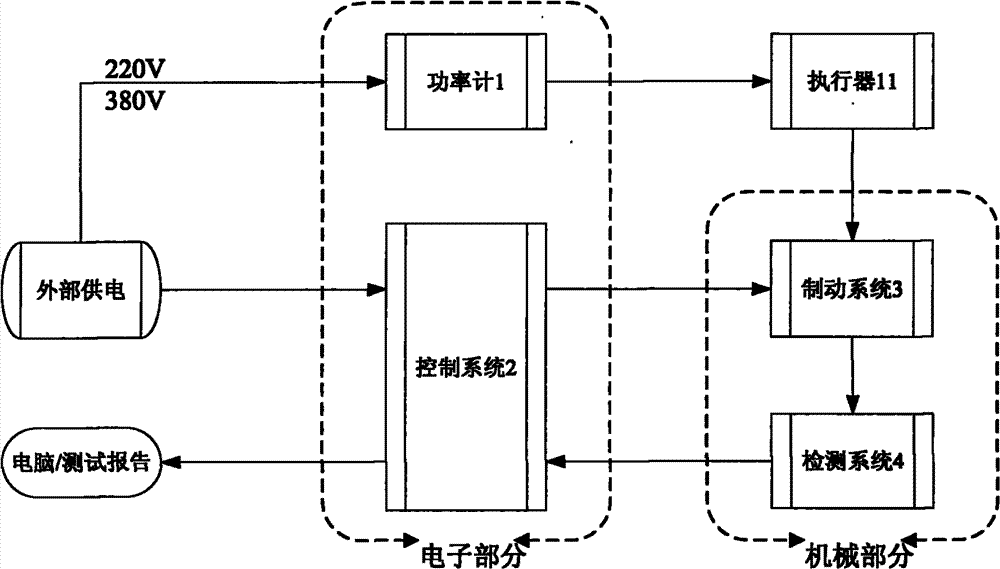

[0031] Such as figure 1 As shown in the system block diagram, the main components of the test bench include:

[0032] The brake system 3 includes a brake disc 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com