Continuously variable transmission

a transmission and variable technology, applied in fluid gearings, transportation and packaging, gearings, etc., can solve the problems of high manufacturing cost, complicated system, transmission capacity, etc., and achieve the effect of wide torque change rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

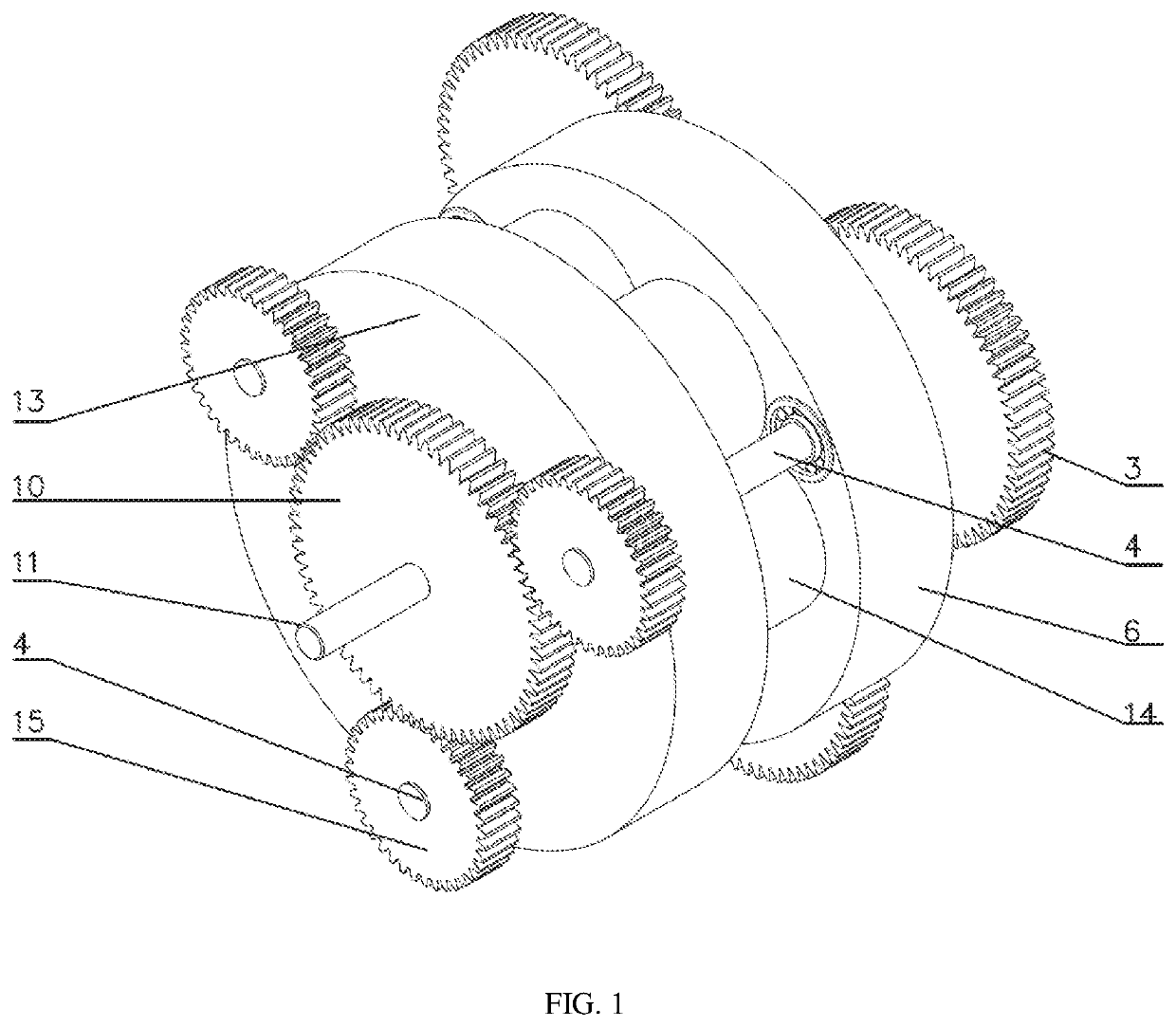

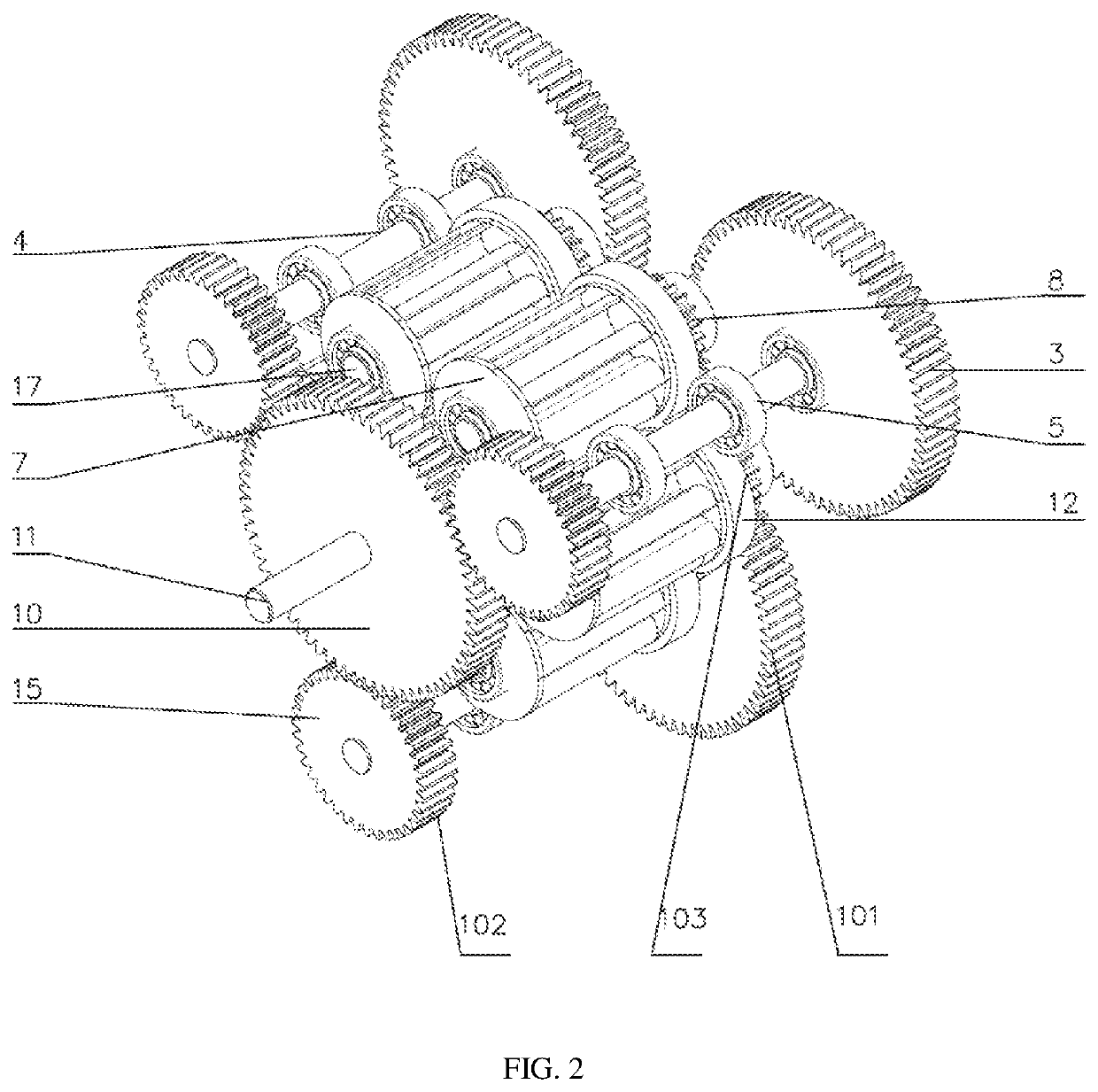

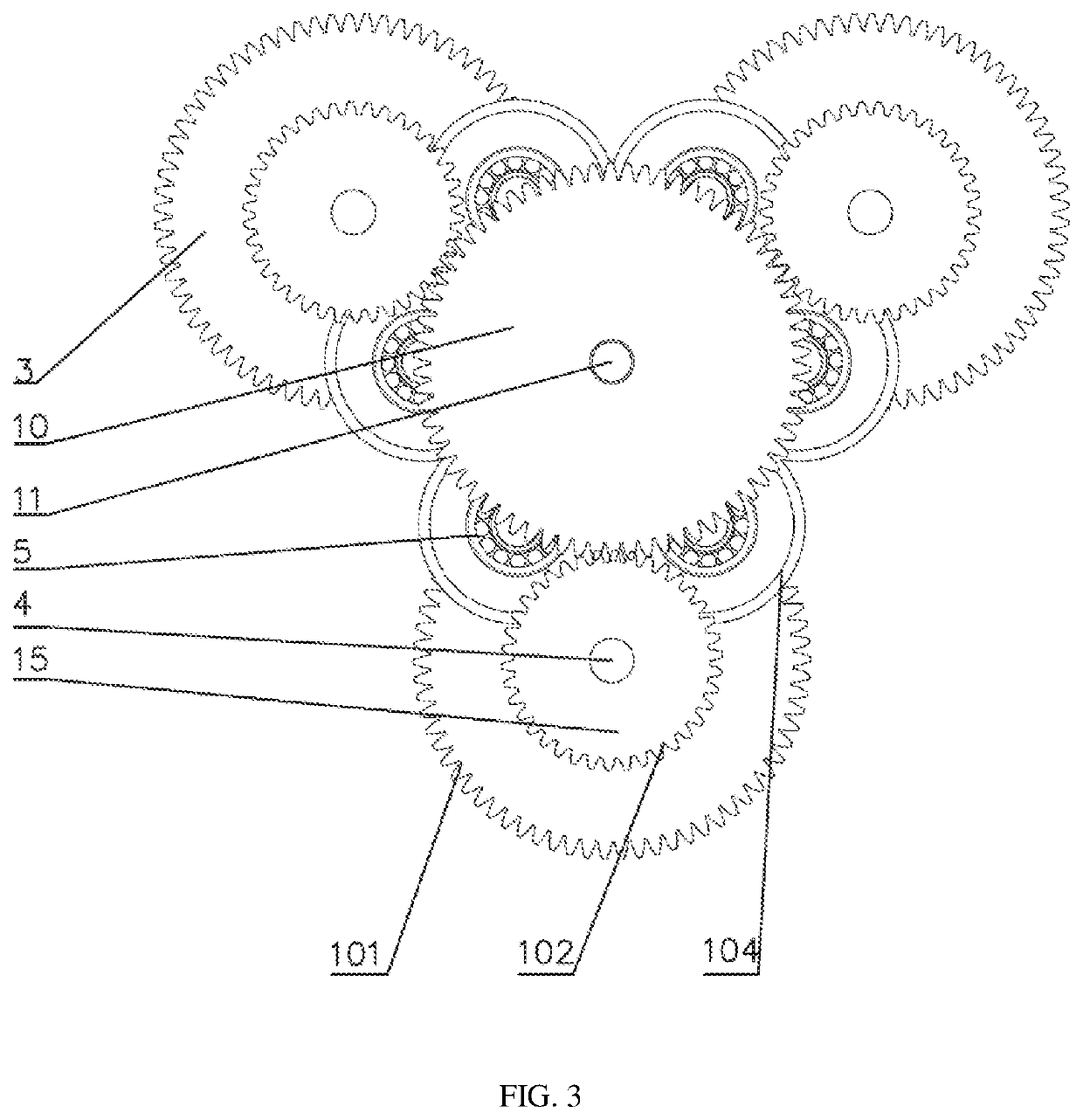

[0037]FIG. 1 to FIG. 5 show a continuously variable transmission of an embodiment of the present invention, which is provided with an input end planetary gear set 101 and an output end planetary gear set 102. A cavity planetary gear carrier 104 is disposed between the input end planetary gear set 101 and the output end planetary gear set 102. The cavity planetary gear carrier 104 includes a cavity input end cover 6 and a cavity output end cover 13. A bucket wheel cavity housing 14 is fixedly disposed between the cavity input end cover 6 and the cavity output end cover 13. An inward side of the input end planetary gear set 101 is connected to the cavity input end cover 6. An inward side of the output end planetary gear set 102 is connected to the cavity output end cover 13. One side of inside of the bucket wheel cavity housing 14 close to the cavity input end cover 6 is provided with a bucket wheel planetary gear set 103. The input end planetary gear set 101 includes one input end su...

embodiment 2

[0045]FIG. 6 to FIG. 9 show a continuously variable transmission of Embodiment 2 of the present invention, which is provided with a bucket wheel planetary gear set 103 and an output end planetary gear set 102. A cavity planetary gear carrier 104 is disposed on an inward side of the bucket wheel planetary gear set 103. The cavity planetary gear carrier 104 includes a cavity input end cover 6 and a cavity output end cover 13. A bucket wheel cavity housing 14 is fixedly disposed between the cavity input end cover 6 and the cavity output end cover 13. An input end planetary gear set 101 is disposed between the cavity input end cover 6 and the bucket wheel cavity housing 14. The bucket wheel planetary gear set 103 includes one bucket wheel sun gear 9 and nine bucket wheel planetary gears 8. The bucket wheel sun gear 9 is engaged with the bucket wheel planetary gears 8. An input shaft 1 is disposed in middle of the bucket wheel sun gear 9. The input shaft 1 passes through the cavity input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com